CNC engraving, as an ancient craft, engraving used to rely heavily on the experience and talent of craftsmen to create perfect masterpieces. Nowadays, engraving technology has embraced programming, allowing computer programs to facilitate batch production, uniformity, and consistent quality. Engraving brings about high efficiency, resulting in time and labor costs.

This article will take you to an in-depth understanding of the application and advantages of CNC engraving technology, and how to use this technology to make our works reach another level.

What is CNC Engraving?

CNC engraving means that the engineer sets the program on the computer, and the tool of the CNC machine tool cuts shallowly from the surface of the workpiece along the set path to remove excess surface materiato to accurately move and position the cutting tool or engraving drill bit to create The process of CNC engraving in fine detail.

How Does CNC Engraving Work

CAD

The designer initially creates a 3D drawing on CAD and completes the final drawing through continuous modification. The mastery of CAD skills is a must for engineers. Only with a firm grasp can complex patterns be created accurately.

CAM

CAM stands for Computer Aided Manufacturing software. Engineers use computer software and hardware to automate and control manufacturing processes. Engineers generate instructions and toolpaths in CAM systems that guide and control the machinery and equipment involved in manufacturing, such as CNC (computer numerical control) machines. These instructions are based on a digital model or design of the desired product, enabling precise and efficient manufacturing operations.

CNC Engraving

In the early stage, the staff only needs to place the workpiece in the correct position, the finished product is disassembled, and finally enters the automatic engraving program until the workpiece is completed.

Types of CNC Machines for Engraving

There are many types of engraving machine tools to choose from. Selecting the correct engraving machine tool according to the specific requirements of the project can make the project go smoothly and save time. The following are some common engraving machine introductions and their advantages:

-

CNC Rotary Engraving

Rotary CNC engraving is a commonly used CNC engraving technique. Its spindle is fixed, and engraving is performed by rotating the engraving tool. CNC rotary cutting tools follow a predetermined toolpath to remove material from the surface of a workpiece. Common shapes for rotary cutting tool sharpness are V-shaped milling cutters and ball nose milling cutters.

The rotation, cutting depth, and speed of the cutting tool are controlled by the CNC machine tool according to the programmed instructions. Typically 19,000 to 20,000 RPM per minute.

The cutting depth of rotary engraving can be varied according to material and design requirements. The CNC engraving machine can achieve cutting depths from 0.5 to 2mm, offering versatility for different applications.

CNC rotary is fast and cheap, and it is one of the most commonly used engraving techniques in daily life.

-

CNC Laser Engraving

CNC lasers use laser beams to engrave text or patterns on various materials. The process involves digitally preparing the design, setting up the material, configuring laser parameters, calibrating the machine, and executing the engraving. CNC laser engraving delivers precise results, versatility, and the capability to create intricate designs. It finds extensive application in personalized items, signs, awards, promotional products, and artistic engravings.

-

Diamond Drag Engraving

Diamond drag engraving known as diamond scribing, is a precision technique that uses a diamond-tipped tool to create precise designs on the surface.

Instead of removing material, the diamond tip scratches the surface to create lines and patterns. The process involves preparing the design, setting up the material, selecting the diamond-tipped tool, and using a machine to scratch the surface with controlled pressure. Diamond drag engraving is known for its accuracy, permanence, and ability to work on various materials. It finds applications in nameplates, plaques, jewelry, signage and decorative, etc.

Types of Engraving Machine Tools

Commonly used carving knives are: V-knives, carving knives, and ball mills, and each type is designed for a specific purpose and material. The following content allows us to learn more about the use and characteristics of engraving tools.

1. V-shaped Knife

Usually used on CNC milling machines, it is a common metal, plastic, and wood carving knife. The V-shaped tip is made of a steel core and can be used to create thin, deep lines and sharp corners. And according to your needs, different line widths and shallowness can be produced by adjusting the cutting depth and angle.

2. Flat Bottom Cutters

Flat bottom cutters have a flat, straight edge and are used for creating wide, flat-bottomed grooves or channels in materials. They are often used for lettering, borders, and backgrounds in engraving projects.

3. Ball Nose Cutters

Ball nose cutters have rounded tips resembling a ball. They are used for creating smooth, curved cuts and contours in materials like metal, wood, and plastic. Ball nose cutters are particularly useful for creating three-dimensional effects and adding texture to engravings.

4. Diamond Point Cutters

Diamond tip, diamond-shaped tip with diamond coating. Diamond knives last longer than ordinary knives. Making it very effective for cutting and engraving a variety of materials. Due to its hardness and sharpness, the diamond tip produces a clean, smooth finish on engraved surfaces. This is especially important for applications that require a polished or high-quality appearance.

5. Parallel Cutters

Parallel cutters have straight sides and are used for creating parallel lines or borders in engravings. They are available in various widths and are often used for decorative purposes or to create consistent spacing between lines.

6. Burnishing Cutters

Burnishing cutters are used for metal engraving and produce a polished, raised effect rather than a cut. They have a rounded or flat profile and are used to push the metal surface to create a raised design.

7. Insert Cutters

Insert cutters are replaceable cutting tools that fit into a holder or machine. They come in various shapes, sizes, and cutting profiles, making them versatile for different engraving applications. Insert cutters are commonly used in engraving machines.

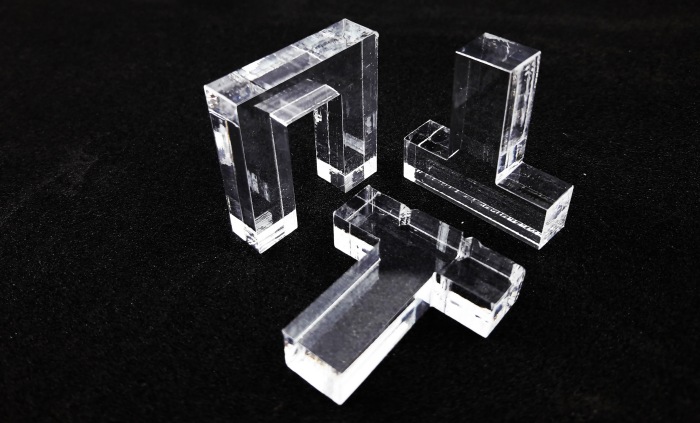

Material Options for Engraving

CNC engraving machines are more inclusive of materials, the following are the materials we can use for engraving.

-

Metal

Metal is a common material for engraving and is often used to create personalized items, signs, labels, nameplates, and decorative elements. Metals that can be used for engraving include:

- Silver

- Aluminum

- Steel

- Stainless steel

- Brass

- Copper

In addition to the above common metals, metals such as gold, silver, and titanium alloys can also be CNC engraved. When CNC engraving, you need to pay attention to the properties of the material. It is very important to choose the right tool. Harder metals require special tools for processing, to avoid the wrong choice that will cause the tool to break and cause economic losses.

-

Plastic

Plastic is a common material for engraving, suitable for diamond drag engraving and laser engraving. Plastic engraving is widely used in signage, electronic and promotional products.

Laser engraving is known for its speed and precision, especially for plastic materials. Rotational engraving can also be applied to hard plastics, which May require addressing challenges with burrs and softening. Overall, plastics offer enormous possibilities for creating custom designs, logos, and labels.

The commonly used plastics for engraving are as follows:

Advantages of CNC Engraving

- Precision

Engraving ensures highly accurate engravings with intricate and detailed designs due to precise movement and positioning controlled by the computer.

- Efficiency

Engraving is time and labor efficient. Once programmed, the machine produces consistent engravings with minimal human intervention, resulting in increased productivity.

- Reproducibility

Engraving allows easy replication of designs, eliminating variations between individual engravings. This is advantageous for mass production and maintaining consistency.

- Complex Designs

CNC engraving effortlessly creates intricate and complex designs that are difficult or impossible to achieve manually, enabling highly detailed and artistic engravings.

- Customization

CNC engraving allows for easy modification and personalization of designs, making it suitable for creating unique and individualized products, such as personalized gifts, awards, and signage.

Applications of CNC Engraving

- Sign Making

Engraving is commonly used in sign-making to create eye-catching signs. It can engrave letters and logos.

- Jewelry Production

CNC engraving is widely used in the jewelry industry. We have seen a lot of exquisite jewelry and jewelry accessories on the market made of engraving. Engraving can easily create detailed patterns, text, and designs on gold, silver, and platinum.

- Artwork

With the advancement of technology, many artists use engraving in their creative process. engraving convenience and efficiency allows them to work with tough materials such as metal, stone, and glass.

- Logo Fabrication

CNC engraving marks serial numbers, identification numbers, and part numbers on metal parts. It is also used to engrave company logos and brands on metal products.

Conclusion

CNC engraving is a versatile technology that turns ordinary objects into captivating works of art. It has evolved from manual craftsmanship to automated precision, offering efficiency and consistent quality. The process involves using CAD to create a design, CAM to generate instructions, and CNC machines for accurate engraving on materials like metal, plastic, stone, ceramics, and wood.

As a leader in the CNC machining industry, Tirapid provides you with professional CNC engraving solutions and technologies. Contact us to get a free online quote for your project!

FAQs

1. What are the differences between CNC engraving and laser engraving?

The main differences between engraving and laser engraving include operation, tooling (contact vs. non-contact), material compatibility, engraving depth and detail capabilities, and speed.

Engraving is working slower and has a deeper engraving depth for complex designs. And laser engraving is faster and more efficient for mass production and high-volume projects.

2. What factors affect the speed of CNC engraving?

Affecting the speed of engraving includes the following factors, such as materials, complexity of design patterns, tools, CNC machine, etc.

- Material type: Different materials have different characteristics, and the engraving speed may vary accordingly. For example, soft materials such as wood or plastic can be engraved at higher speeds than metals.

- Design Complexity: More complex designs with fine details will require slower engraving speeds to ensure precision and accuracy. A simple design can achieve faster engraving speed.

- Tool: The type of sculpting tool used will affect the speed. For example, diamond-tipped tools are typically used for engraving hard materials and may require slower speeds to avoid damage.

- CNC Machine Capability: The speed at which a CNC machine can move the cutting tool is a key factor. High-end machines equipped with advanced motors and control systems can achieve faster engraving speeds.

3. What disadvantages of a CNC engraving machine?

- A CNC router is a major investment with high upfront costs. and the payback period may be longer.

- Installing a CNC router may involve additional costs such as setup, training, and possible modifications to the workspace. Considering these expenses ahead of time is crucial to a well-managed budget.

- CNC machine tools are complex systems. Once a failure occurs, skilled professional maintenance personnel are needed to solve the problem.

- Having a proper maintenance schedule in place and having a reliable service provider on hand can help minimize downtime and repair costs.

- With the transition to automated systems, the need for manual machine operators has decreased. However, a well-trained operator is still required to operate a CNC router effectively. Providing training to existing staff or hiring skilled operators is critical to smooth operations.