Polyoxymethylene (POM) is more than just an engineering plastic—it’s a pivotal resource in high-performance manufacturing. Known for its stellar mechanical properties and adaptability, POM is the go-to material for precision parts in demanding industries. Here’s why and how to leverage its full potential through CNC machining.

Read More

Why Choose POM for CNC Machining?

- Exceptional Machinability

POM stands out with its ease of machining, which includes CNC operations, injection molding, and extrusion. This quality makes it possible to achieve high precision and complex geometries effortlessly. - Superior Mechanical Properties

With outstanding tensile strength and impact resistance, POM can handle high-load applications making it ideal for manufacturing robust mechanical components. - Low Friction Coefficient

The low friction coefficient of POM allows for operation under unlubricated conditions, minimizing wear and extending the lifespan of components. - Excellent Chemical Resistance

POM’s resistance to various chemicals, fuels, and lubricants enhances its durability and suitability across multiple environments without the risk of corrosion.

Advanced POM Machining Techniques

- Milling and Turning

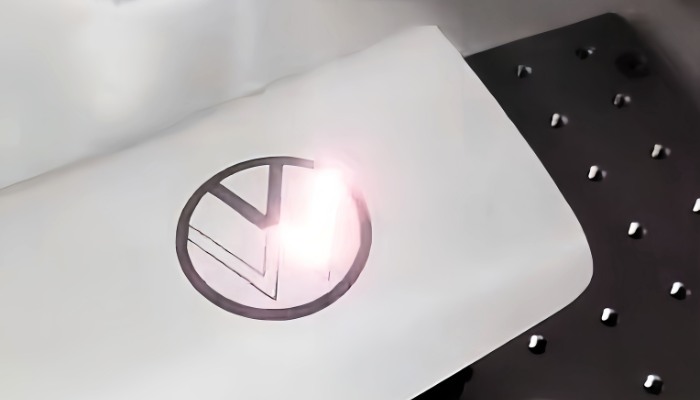

Remove excess material with precision using advanced milling and turning processes, perfect for crafting intricate parts and prototypes. - Laser Cutting

For complex patterns and fine details, laser cutting offers a high-precision method that ensures smooth, clean edges. - Injection Molding

Ideal for mass production, this technique involves melting and injecting POM pellets into molds to quickly and efficiently create large volumes of complex parts.

Key Performance Metrics for POM

| Property | Numerical value |

| Density | 1.41-1.43 g/cm³ |

| Melting Point | 165-175°C |

| Hardness (Shore D) | M80-M90 |

| Water Absorption | M80-M90 |

| Heat Distortion Temperature | 110-120°C |

| Tensile Strength | 70Mpa |

| Yield Strength | 50-60 MPa |

| Elongation | 20-50% |