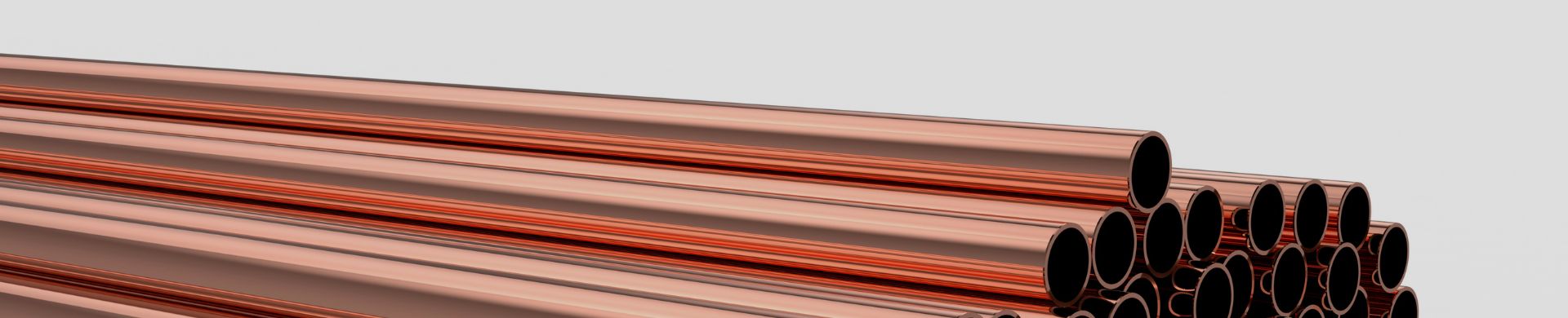

Copper parts are widely used in electrical and heat exchange systems due to its excellent electrical and thermal conductivity. Its high resistance to corrosion makes it suitable for use in a variety of environments, including seawater and chemical treatment sites. Copper’s natural luster and rich color also make it an ideal material for making decorative items and works of art.

When manufacturing copper parts, mechanical engineers select the appropriate manufacturing process based on the complexity and quality needs of the product. This careful selection ensures that copper parts meet the high standards of a given application, both functionally and aesthetically.

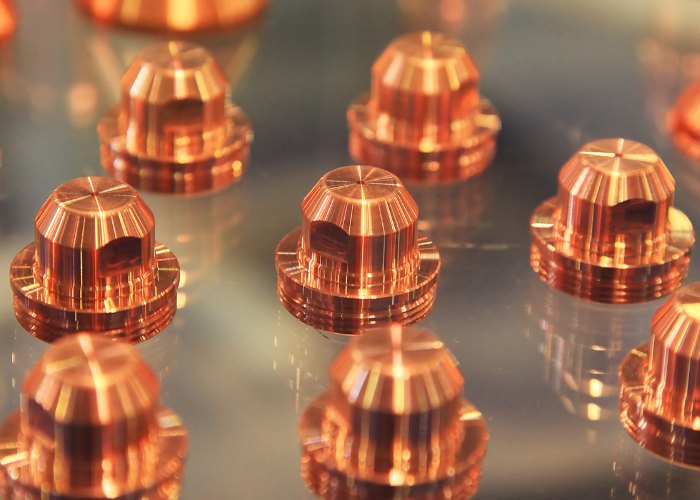

Custom Copper Parts Machining Services

- CNC Machining

- CNC Milling(3axis/4axis/5axis)

- CNC Turning

- Sheet Metal Fabraction

- Laser Cutting

- CNC Bending

Advantages of Custom Copper CNC Machining

At Tirapid, we customize copper parts exactly to your drawings. We will carefully review your drawings before quoting you a price, ensure that the product meets your requirements and recommend the most competitive machining method.

The main advantages of copper parts include:

- Thermal and electrical conductivity

- Better antibacterial properties

- Environmentally friendly materials, recyclable

- Good mechanical properties

- Good processability

- Strong corrosion resistance

- Non-magnetic

Common Surface Finish Options

In order to improve the performance and aesthetics of copper parts, copper can be subjected to a variety of surface treatment, common copper surface finishing methods:

- Electroplating nickel

- Chemical nickel

- Passivation

- Gold plating coating

- Electrolytic polishing

- Chromium plating

A Guide to Getting High Quality Copper Parts

1. Design Considerations

- Design Simplicity: The design should take into account the machining characteristics of copper, avoiding complex geometries and fine features to reduce machining difficulty and cost.

- Tolerance and Fit: Considering the coefficient of thermal expansion of copper, the tolerance range should be adjusted appropriately during design to ensure the accuracy and performance during assembly.

- Structural Strength: Although copper has good ductility and toughness, special attention needs to be paid to the thickness of the material and the supporting structure when designing the load-bearing structure or stressed parts to avoid deformation in use.

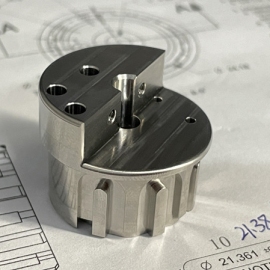

2. Processing Technical Considerations

- Tool Selection: It is critical to select the right tool for the copper material. Due to the soft nature of copper, coated tungsten carbide or high-speed steel tools are recommended, which can reduce adhesion and improve cutting efficiency.

- Cutting Parameter Optimization: Copper machining requires adjusting the appropriate cutting speed and feed rate to prevent overheating and tool wear. Higher cutting speeds help reduce cutting temperatures and minimize workpiece deformation.

- Monitor the concentration of cutting fluid: Keep the concentration of cutting fluid within normal values to ensure that the cutting fluid is clean.

3. Surface Finishing Considerations

- Surface Finishing: After machining of copper parts is completed, rust prevention treatment is carried out in a timely manner. Commonly used methods: sealed preservation, spraying antirust oil,soaking kerosene,plating and coating.

- Precision Machining: In order to obtain high precision surface quality, it may be necessary to realize it through high precision machining methods such as CNC machining or EDM.

- Inspection and Testing: After finishing, detailed dimensional and performance tests should be conducted to ensure that each part meets design specifications. Inspection is carried out using high-precision measuring tools such as CMMs to ensure that parts meet high quality standards.