The selection and design of thread types is critical.They not only affect the efficiency of component assembly, but also directly relate to the quality and performance of the final product. This article details the various types of threads to reduce design and manufacturing risks through an in-depth understanding of threads.

What are Threads?

Threads are a shape of continuous helical thread projections present on the inside or outside of bolts, screws, nuts and corresponding fittings. They are mainly used to assemble two or more objects together by converting rotational movements into linear movements for fastening and joining.

Classification of Threads

1. Classification by Structure

- Whorl of fingerprint

- External thread

2. Classification by Tooth Shape

- Triangle thread

- Trapezoidal thread

- Rectangular thread

- Serrated thread

3. Classification by Number of Wires

- Single-ended threads

- Multiple threads

4. Classification by Screw in Direction

- Left-hand thread, labeled LH, e.g. M24×1.5LH

- Right-hand thread, not labeled

5. Classification by Use

- Metric Plain Thread

- Pipe threads sealed with threads

- Pipe threads for non-threaded seals

- 60°conical pipe thread

- Metric Taper Thread

The Most Common Thread Types

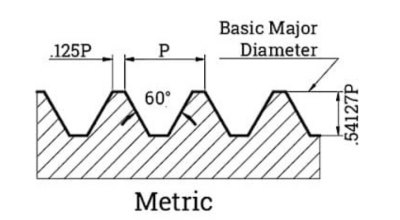

1. ISO Thread(Metric)

Metric threads follow the International Organization for Standardization (ISO) and are one of the most widely used thread types worldwide. This thread system is measured in millimeters (mm).

Specificities

- Shape: Metric threads are usually 60 degree equilateral triangular threads.

- Standardization: ISO standards provide detailed specifications for dimensions, pitches and tolerances, ensuring international compatibility and consistency.

- Versatility: Due to their high degree of standardization, metric threads are widely used in mechanical, automotive, electronic and industrial equipment worldwide.

- Ease of use: Because the decimal system is used, metric threads are relatively simple to calculate and understand.

- Versatility: A wide range of precision levels and strength grades are available to suit different mechanical and environmental requirements.

Typology

- M Series (General Purpose Threads)

1) M Standard Thread: Used for most mechanical connections with standardized pitches and diameters.

2) MJ Series: Has an increased root radius to provide better fatigue strength and is commonly used in aerospace.

Coarse vs. fine threads:

- Coarse threads: have a relatively large pitch for faster installation and better resistance to loosening for most standard applications.

- Fine threads: have a smaller pitch and higher tensile strength for applications carrying heavy loads or for joining thin-walled materials.

- Left-hand threads: Specially designed for applications where the standard right-hand threads may loosen during use due to the direction of rotation.

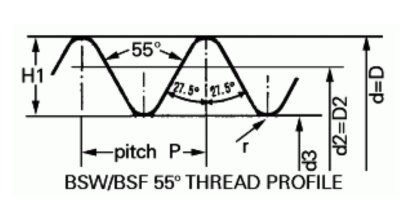

2. British Standard Thread(BST)

The British Standard Thread is used primarily in the United Kingdom and its former colonies and spheres of influence, including some historical and traditional applications.

Specificities

- Shape: British threads usually have a V-shaped thread with a 55-degree angle, unlike the American standard of 60 degrees.

- Units: Use inches as the basic unit of measurement.

- Versatility: Includes many different thread forms for a wide range of mechanical and engineering needs.

- Standardized: with strict size and pitch standards to ensure compatibility between components.

- Applications: Widely used in heavy industry, automobile, aviation and marine engineering.

Typology

- BSW (British coarse thread): the most traditional type, used for general engineering and construction applications.

- BSF (British Fine Thread): has a finer pitch than coarse threads and is suitable for applications with higher load carrying capacity requirements.

- BSP (British Pipe Thread):

1) BSP/T (BSP Taper, Tapered Pipe Thread): Threads used to make sealed joints, often used for pipe connections.

2) BSP/P (BSP Parallel, Parallel Pipe Thread): For joints that require the use of seals in conjunction.

- BA (British miniature thread): Used in small electronics and instrumentation.

- BSPT (British tapered pipe thread): For pipe connections to ensure a tight seal at the connection.

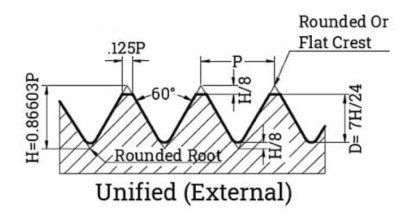

3. Unified Thread Standard(UTS)

American Standard Threads are a common thread standard used in the United States and Canada.

Specificities

- Shape: U.S. threads are usually V-shaped threads with a 60-degree angle.

- Standardized: Thread sizes and pitches (number of threads per inch) are strictly standardized.

- Compatibility: Designed to ensure that parts made by different manufacturers will work with each other.

- Unit of measure: Use inches as the basic unit of size.

- Accuracy and roughness: with different tolerances and accuracy levels to meet a variety of engineering needs.

Typology

- UNC (coarse thread): Regular use, provides good resistance to stripping and is suitable for most environments.

- UNF (fine thread): better vibration resistance and load distribution compared to coarse threads for applications requiring higher accuracy.

- UNEF (Ultra Fine Thread): for special applications such as connectors requiring extreme precision and strength.

- UNS (Special Threads): Specially designed threads for non-standard pitches or diameters.

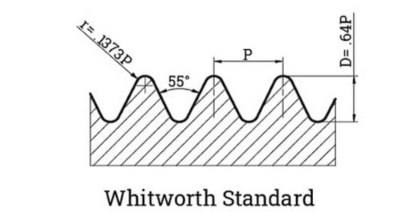

4. Whitworth Thread(BSPP/BSPT)

The Whitworth thread is a form of thread invented by British engineer Joseph Whitworth in 1841, and it was the world’s first standardized threading system. Whitworth threads are widely used in many industrial applications, especially in the mechanical and engineering fields.

Specificities

- Angle: Whitworth threads have a tooth angle of 55 degrees, which is different from the U.S. standard threads (which have an angle of 60 degrees).

- Rounded Top and Rounded Bottom: Whitworth threads have teeth with rounded tops and rounded bottoms, which helps reduce stress concentrations and makes them more suitable for variable loads.

- Size standardization: The Wheatstone system offers a range of standard diameters and number of threads per inch specifications for ease of use in engineering and manufacturing.

- High load-bearing capacity: The rounded top and bottom design provides a larger load-bearing area, giving Whitworth threads a better load-bearing capacity than other types of threads, such as spiked threads.

Typology

- BSW, British Standard Whitworth: This is the most common type of Whitworth thread and is suitable for many general applications.

- Fine Whitworth thread (BSF, British Standard Fine): has a finer pitch than the standard Whitworth thread and is suitable for applications where higher tightening forces are required but space is limited.

- Pipe Thread (BSP, British Standard Pipe): Used for pipe connections and designed with the need for sealing in mind.

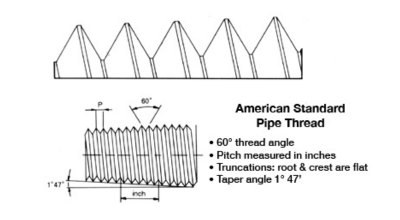

5. Pipe Thread

Pipe threads are a type of thread specifically designed for pipe connections, which are mainly used to achieve a sealed connection between pipes, hoses, valves, etc. Pipe threads ensure the safe and efficient transfer of fluids (e.g. water, oil, gases) through the piping system.

Specificities

- Good sealing performance: Pipe threads are designed taking into account the need to be leak-proof, especially for liquids and gases. As a result, such threads are often self-sealing or require the use of sealing materials (e.g., Teflon tape, liquid sealants) to prevent leakage.

- Versatile connections: Pipe threads can be either straight or tapered. Straight threads usually require additional sealing material, whereas tapered threads achieve a better seal on their own.

- Standardized sizes: A wide range of standardized pipe thread systems are available globally, allowing for international compatibility and exchange of piping components.

Typology

- NPT (National Pipe Thread): American standard pipe thread, a tapered thread, widely used in North America.

- BSP (British Standard Pipe):

1) BSP-T (BSP-Taper): conical thread for direct sealing connections.

2) BSP-P (BSP-Parallel): Straight thread, usually requiring additional sealing.

- DIN Pipe Thread: The German industry standard pipe thread, also widely used in other European countries.

- JIS Pipe Thread: Japanese Industrial Standard Pipe Thread, commonly used for products in Asian markets.

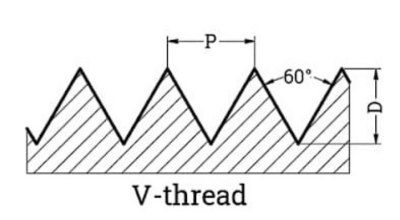

6. V-Thread

V-threads are a common thread form, named for the “V” shape of the thread cross-section, and are widely used in screws, nuts, bolts and other fasteners because they are simple to design and easy to manufacture. Widely used in screws, nuts, bolts and other fasteners because of its simple design and ease of manufacture, the V-thread provides good force transmission and self-locking.

Specificities

- Simple and versatile: V-threads are widely used for their simplicity of construction and are widely used in most industrial and construction applications.

- Cost-effective: V-threads are easier to machine than other more complex thread forms, reducing production costs.

- Self-locking: The V-thread design provides a degree of self-locking capability, especially noticeable with thicker threads.

- Adaptability: Can be used in a variety of materials, including metal, plastic and wood.

Typology

- S. standard threads (UN/UNC/UNF/UNEF):

1) UN (Unified National): Unified standard thread for general purposes.

2) UNC (Unified National Coarse): Coarse pitch, providing good load carrying capacity and corrosion resistance.

3) UNF (Unified National Fine): Fine pitch for applications that carry high loads or require high strength.

4) UNEF (Unified National Extra Fine): Finer pitch for applications requiring precise adjustment or high strength connections.

- Metric threads (ISO/Metric):

These threads follow international standards with clearly defined pitches and angles and are widely used worldwide.

- Other standard threads:

Standards such as BSW (British Standard Whitworth) or other national/regional standards may have different pitch and angle specifications.

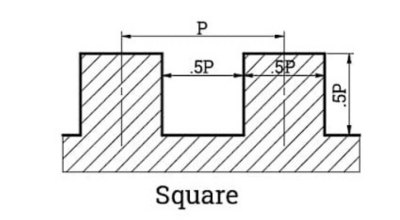

7. Square Thread

A square thread is a form of thread whose main characteristic is that the cross-section of the thread has a square shape. Due to their unique design and construction, square threads are often used in applications subject to heavy loads, such as in lifting machines and compression devices.

Specificities

- Low coefficient of friction: The square threads are designed to be nearly parallel on the contact surface, which helps reduce friction and makes them more efficient when carrying heavy loads.

- Better load carrying capacity: square threads can withstand higher loads and are especially suitable for equipment that needs to be jacked or adjusted for heavy loads.

- Easy reverse motion: Square threads are easier to reverse than other types of threads, such as tapered or round threads, which makes them useful in applications that require frequent position adjustments.

- Easy to manufacture: Square threads are relatively easy to machine, especially in metalworking, and can be manufactured by chipping or rolling.

- Wear resistance: The shape of the square thread provides a larger contact area, which reduces the pressure per unit area and increases wear resistance.

Typology

- Single Thread Square Thread: A simple structure with only one threaded helix, widely used in different mechanical designs.

- Multi-threaded Square Threads: Containing multiple parallel threaded helixes, this design provides faster travel speeds and higher load carrying capacity for applications requiring rapid movement or large torque transfer.

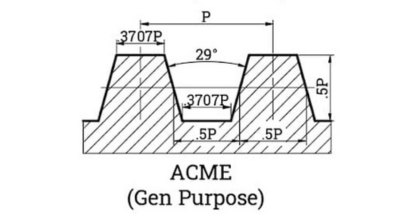

8.Trapezoidal Thread

Trapezoidal threads,also known as Acme threads, are threads with a trapezoidal cross-section that are designed to withstand axial forces while allowing sliding or rotation. This thread shape effectively distributes pressure and is suitable for applications subject to heavy loads, such as elevators, screw drives and valve regulators.

Specificities

- High load carrying capacity: Due to the trapezoidal shape of the threads, trapezoidal threads provide a large contact area and are thus able to withstand large axial and radial loads.

- Self-locking properties: Some types of trapezoidal threads have a good self-locking feature, which means that they can be prevented from turning back on themselves in the absence of an external force, which is important for applications with high safety requirements.

- Resistant to wear and impact: The trapezoidal thread construction is designed to minimize friction and wear, especially in environments with frequent operation.

- Precise adjustment: The trapezoidal thread is suitable for precise adjustment of the load position, which is particularly important in machine tools and measuring equipment.

Typology

- Single Start Trapezoidal Thread: A single helical thread composition, usually used for general lifting or adjustment tasks.

- Multi-start trapezoidal threads: have multiple helixes, which increases the screw’s travel speed and load capacity. Ideal for applications where heavy loads need to be moved quickly.

- Left-handed and right-handed trapezoidal threads: Depending on the direction of rotation of the thread, trapezoidal threads can be left-handed or right-handed to suit different rotational needs and assembly requirements.

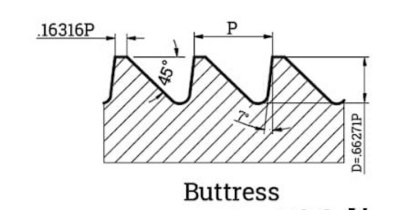

9. Serrated Thread (Buttress Thread)

Buttress threads (serrated or mitered threads) are a form of thread designed for high load and vibration environments. Their unique serrated or helical shape makes them excellent for certain industry-specific applications, especially where vibration resistance and anti-loosening are required.

Specificities

- Anti-loosening ability: The serrated thread design makes it less likely to loosen when subjected to vibration and shock, making it ideal for use in automotive, aerospace and heavy machinery.

- High load-bearing capacity: The structure of serrated threads distributes the pressure on the thread contact surface, thus increasing the load-bearing capacity and the ability to withstand impacts.

- Quick Assembly: Serrated threads often allow for faster assembly and disassembly, which is useful in applications that require frequent maintenance or replacement of parts.

- Self-Locking Feature: Some serrated thread designs are self-locking and do not require an additional locking mechanism to maintain a stable connection.

Typology

- Symmetrical Serrated Threads: This type of thread has a symmetrical serrated shape and is suitable for a wide range of standard applications, especially where even load distribution is required.

- Asymmetric Serrated Threads: Serrated teeth may be angled in one direction, this design enhances its resistance to loosening in a specific direction and is commonly used in high speed rotating applications.

- Fine Pitch Serrated Threads: With a fine pitch, they are suitable for use in precision equipment to provide higher load carrying capacity and better adjustment accuracy.

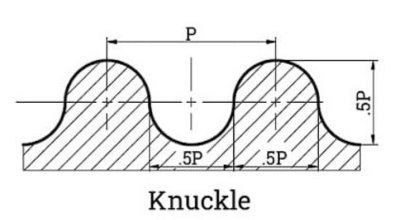

10. Knuckle Threads

Knuckle Thread, also known as Ball Joint Thread or Knuckle Thread, is a specially designed form of thread that is mainly used for connections that require frequent disassembly or adjustment.

Specificities

- Resistant to wear: The rounded cross-section of the joint thread reduces sharp angles, which in turn reduces friction and wear and prolongs the life of the thread.

- Easy to disassemble: the rounded cross-section makes the tightening and loosening process smoother, especially for applications that require frequent disassembly or adjustment.

- Moderate Strength:While joint threads may not have the same load carrying capacity as traditional sharp-edged threads, their design balances adequate strength with good durability for moderate load conditions.

- Vibration resistance: Joint threads have good vibration resistance due to their structural characteristics and can maintain a stable connection in a vibrating environment.

Typology

- Standard joint thread: This is the most common type and is used for connectors in a wide range of general-purpose machinery and equipment.

- Customized Joint Threads: Depending on the needs of a particular industrial application, joint threads can be customized to specific sizes and shapes to suit particular loads or operating conditions.

Summary

Threads are a fundamental element in mechanical design and are mainly used to connect and secure various components. When selecting the appropriate thread type, factors such as its application environment, load requirements, installation conditions and cost must be considered to ensure a reliable and economically efficient connection.

Tirapid team has extensive experience in machining parts for the industrial and consumer product categories and can provide many different types of threading solutions. Contact us for more specialized threading application experience and support.