Acetal (Delrin®) is a high-performance engineering thermoplastic widely used in the manufacture of high-precision mechanical parts such as gears and bearings. Not only does it have excellent mechanical properties, but it also has excellent dimensional stability.

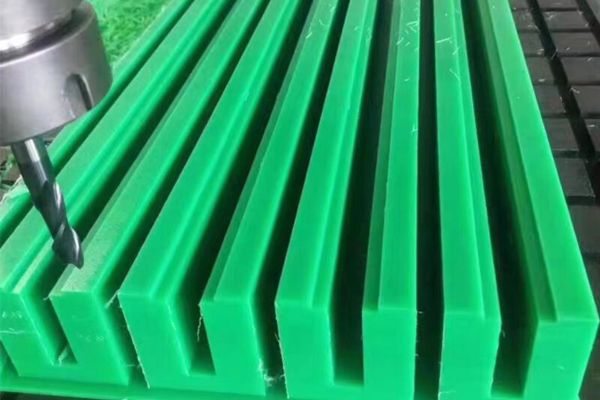

The Machining of Delrin® often involves complex CNC machining techniques, which makes it irreplaceable in a variety of industries such as consumer electronics, automotive, and industrial equipment.

Acetal Advantages

- Mechanical Excellence

Acetal has excellent mechanical properties, including high impact resistance and low friction characteristics. - Dimensional Stability

Acetal demonstrates superior dimensional stability during CNC machining and is suitable for high precision products. - Temperature Resistance

Acetal is able to maintain performance over a temperature range of -40°C to 120°C for a wide range of environmental conditions. - High Processing Efficiency

Acetal is easy to cut and machine, reducing machine wear and shortening production cycles.

Acetal Machining Technology

- CNC Machining

Includes CNC turning, CNC milling and drilling. - Injection Molding

Suitable for mass production, such as quick couplings and fasteners. - Extrusion

For the production of Acetal rods, tubes and profiles. - Laser Cutting

Can be used to accurately cut thin sheet materials. - Other technology

Including bonding, mechanical fastening and thermal welding.

Surface Finishing

- As-Machining

Acetal’s CNC machined parts are machined to an excellent surface finish, and with the right cutting tools and parameters, a Ra3.2 finish can be achieved directly. - Spray Painting

Acetal spray painting requires a number of surface treatments to improve the adhesion of the coating for different colors. - Mechanical Grinding

Sanding removes the gloss from the surface, making the surface more suitable for painting or other coating treatments.

Design Recommendations

- Designed to the Standard Dimensions of the Material

Acetal is normally supplied in standard thicknesses in sheet or solid bar. Standard sizes should be used in design wherever possible to minimize material waste and processing costs. - Avoid Pursuing Minimum Wall Thicknesses

Minimum wall thickness designs may be difficult to fix and reproduce and may result in material bending, distortion or vibration. Best practices in machined designs should be used to improve reliability and economy of production. - Simplified Design

Complex designs often mean higher machining costs. Simplifying the design of a part and minimizing unnecessarily complex features can significantly reduce the cost of machining time.

Technical Parameters of Acetal

- Delrin®150

- Delrin®100 (AF)

| Property Name | Numerical Range |

| Tensile Strength, Yield Strength (MPa) | 73-76 |

| Elongation at break (%) | 25-45 |

| Hardness (Rockwell M) | 94 |

| Heat Deflection Temperature at 0.46 MPa (°C) | 160-169 |

| Melting point (°C) | 175-178 |

| Property Name | Numerical Range |

| Tensile Strength, Yield Strength (MPa) | 53-56 |

| Elongation at break (%) | 10-19 |

| Hardness (Rockwell M) | 77 |

| Heat Deflection Temperature at 0.46 MPa (°C) | 160-169 |

| Melting point (°C) | 175-178 |