Aluminum prototype manufacturing occupies an important position in modern industry. It is widely used in aerospace, automobile manufacturing, heavy machinery and medical equipment. Aluminum has become one of the preferred materials for prototype manufacturing due to its advantages such as light weight and high strength, excellent thermal and electrical conductivity, good corrosion resistance and easy processing. This article will introduce six common processing methods for aluminum prototype manufacturing to help readers better understand how to choose the most suitable processing technology according to specific needs.

6 Common Processing Methods for Aluminum Prototype Manufacturing

-

Processing method overview

1.CNC Machining

CNC (Computer Numerical Control) machining is a process whereby computer-controlled cutting tools are used to remove excess material from aluminum billets to create the desired shape. This method includes CNC milling and CNC turning.

2. Sheet Forming

Sheet metal forming is the process of creating prototypes by cutting, bending and assembling aluminum sheets. This method is suitable for making functional prototypes such as housings and industrial parts.

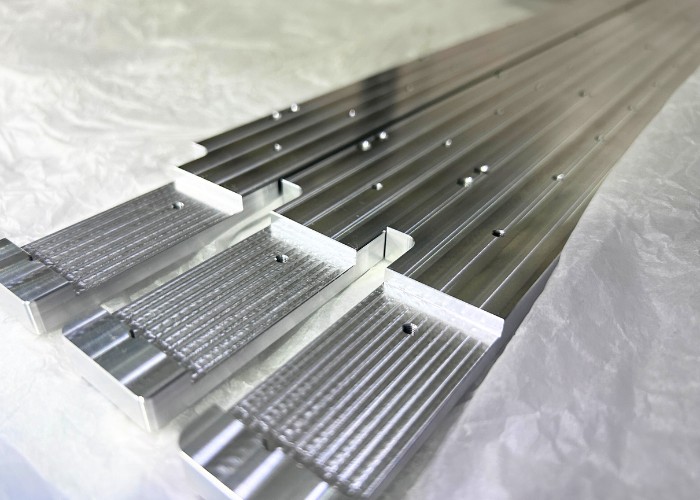

3.Aluminum Extrusion

Aluminum extrusion is a process in which aluminum alloys are forced through a die to form long parts, suitable for manufacturing metal rods, brackets and joints, etc.

4.3D Printing

3D printing is an additive manufacturing technology that forms the desired prototype by adding material layer by layer. Common methods include direct metal laser sintering (DMLS).

5.CNC Engraving

CNC Engraving is a precision machining method based on computer numerical control technology. It controls the movement of the engraving machine through a computer program to accurately engrave the design pattern, text or graphics on the surface of the material.

6.EDM

It is a non-traditional processing method widely used in the processing of hard materials and complex geometric shapes. The high temperature generated by the discharge is used to melt and vaporize the material, thereby achieving material removal.

-

Advantages and disadvantages comparison

| Processing Method | Advantage | Shortcoming |

| CNC machining | High precision and repeatability , suitable for complex designs , compatible with a variety of aluminum alloys , quick design changes | The cost is high , not suitable for large-scale production , and there is a lot of material waste |

| Sheet metal forming | Suitable for large-size and thin-walled parts , can realize the simultaneous production of multiple identical prototypes , and the production speed is fast | High cost , limited design complexity , certain restrictions on thickness and size |

| Aluminum Extrusion | Efficient production of long strip parts , high material utilization , suitable for mass production | High initial tooling cost , limited applicable aluminum alloys , mainly suitable for parts with constant cross-section |

| 3D Printing | Suitable for complex geometries , reducing material waste , and rapid prototyping | The cost is high , the surface quality needs post-processing , and the physical and chemical properties are limited |

| CNC engraving | High precision and repeatability , suitable for complex patterns and details , applicable to a variety of materials | High initial equipment cost , complex operation requires professional skills , not suitable for large size and thick materials |

| EDM | High precision, suitable for complex shapes, no mechanical stress, hard material processing | Slow speed, high surface roughness, large electrode consumption, high cost |

Advantages of Aluminum as a Prototyping Material

- Excellent mechanical properties

Aluminum has excellent mechanical properties, including high strength, light weight and good ductility. This makes aluminum prototypes excellent in applications that need to withstand high loads or complex deformations. - Excellent corrosion resistance

Aluminum and its alloys have excellent corrosion resistance, especially when exposed to moisture and chemical environments. By forming a natural oxide film on the surface, aluminum can effectively resist atmospheric corrosion and chemical attack, thus extending the service life of the prototype. - High thermal and electrical conductivity

Aluminum’s high thermal and electrical conductivity make it an ideal material for applications that require good heat dissipation and electrical conductivity. For example, in applications such as electronics and heat sinks, aluminum prototypes can effectively manage heat and ensure stable operation of the device. - Easy to process and shape

Aluminum has good machinability and can be processed by a variety of methods . These processing methods can meet different design needs and production requirements, making the aluminum prototype manufacturing process efficient and flexible.

Selection Guide: How to Choose Between Different Methods?

Choosing the most appropriate aluminum prototype manufacturing method requires a combination of factors, including design complexity, functional requirements, production quantity, cost, delivery time, etc. Here are some key considerations and guidelines:

1. Design complexity and details

Complex geometries and details: 3D printing, CNC machining and EDM (Electrical Discharge Machining) are suitable.

Simple designs or parts with uniform cross-section: Extrusion and die casting are more efficient.

2.Prototype function

Simulate the mechanical properties of the final product: Forging or CNC machining provides the required strength and durability.

Appearance models or non-functional prototypes: 3D printing or laser cutting may be sufficient.

3.Material properties

Suitability of certain aluminum alloys: Sand casting is suitable for a wide range of aluminum alloys, while die casting is more picky.

The desired properties of the final product : such as strength, weight or thermal conductivity, will influence the choice.

4.Production quantity

Small batch production or single parts : CNC machining and 3D printing are cost-effective.

High volume production: Die casting or extrusion at lower cost per piece.

5.Tolerance and precision

High Precision Parts : CNC machining or EDM provides close tolerances.

Lower precision parts: Sand casting or extrusion is acceptable.

Conclusion

Conclusion

Aluminum prototyping not only plays a key role in several industrial fields, but also meets the needs of different applications through its excellent material properties and diverse processing methods. Improve product quality and efficiency by understanding and selecting the most suitable processing methods. It is hoped that the detailed information provided in this article will help readers make informed decisions in the aluminum prototype manufacturing process and achieve the best production results.

FAQs

1.How Much Does Aluminum Prototyping Cost?

Costs depend on the complexity of the chosen machining method, the amount of material used, and machining time. CNC machining is generally more expensive but provides high precision and quality parts.

2. How to Choose the Best Aluminum Prototype Manufacturing Method?

The method selected depends on several factors, including design complexity, production quantity, functional requirements, cost, delivery time, etc.

3. Which aluminum alloy is best for prototyping?

Common aluminum alloys include 3003, 5052, 6061, 7075 and 6063. Different aluminum alloys have different properties, such as corrosion resistance, strength, machinability, etc. Choosing the right aluminum alloy depends on the specific application requirements.