Aging heat treatment is a technique that changes the physical and chemical properties of metal alloys through heating and cooling processes, thereby enhancing their hardness, strength, wear resistance and dimensional stability. I will give you a detailed introduction to the aging heat treatment process to help you better understand this critical manufacturing process.

What Is The Aging Heat Treatment Process?

Aging heat treatment mainly controls the temperature and time of metal materials to promote the precipitation of alloying elements in the metal, thereby improving the mechanical properties of the material. It was gradually systematically studied and applied with the development of materials science in the early 20th century, and is mainly used for metal materials such as aluminum alloys .

We found that during the heating process , alloy elements form evenly distributed precipitates in the metal matrix . These precipitates effectively hinder dislocation movement, ultimately improving the hardness, strength, and wear resistance of the material .

For example, we know that the main elements of aluminum alloy 2000 series are copper , magnesium, silicon and zinc , so its typical precipitate is Al2Cu (θ phase) , and after aging treatment, its tensile strength can be increased from 320 MPa to 480 MPa.

Main Types Of Aging Heat Treatment

Aging heat treatment can be divided into several different types according to the aging process, the most common of which are artificial aging, natural aging, precipitation hardening, strain hardening and stabilization. The choice of each type depends on the type of alloy, the expected performance requirements and the application field.

The following is a detailed introduction to these main types:

Artificial Aging

Artificial aging heats the metal to a specific temperature (usually 150°C to 250°C), causing the alloy elements dissolved in the matrix to rapidly precipitate and form a strengthening phase (such as a precipitation hardening phase), thereby significantly enhancing the strength of the metal. Hardness and other mechanical properties.

it with natural aging , we can find that artificial aging is more time efficient and can obtain the required enhancement effect in a shorter period of time. For materials that require high strength and fast delivery (such as aluminum alloys, steel, etc. in the aerospace and automotive industries), artificial aging is an efficient and necessary option.

I learned in a project before that the yield strength of aluminum alloy 7075 can be increased to more than 500MPa through artificial aging treatment in the T6 state, which is more than 60% higher than 300MPa in the annealed state.

Natural Aging

Natural aging is different from artificial aging and is mainly carried out at room temperature or slightly higher temperature. This process does not rely on heating, but promotes the formation of precipitation phases through temperature changes in the natural environment. This usually takes a long time, but for some materials, the effect is long-lasting and stable.

Natural aging is commonly used for aluminum alloys, copper alloys, etc. For applications that are not in a hurry to strengthen quickly, it is particularly suitable for parts used in low or normal temperature environments.

Assuming that we allow aluminum alloy 2024 to undergo natural aging treatment , we will find that its strength will increase by 30% to 40%. This process will take several weeks, but this will also make its strengthening effect relatively stable and long-lasting.

Precipitation Hardening

Precipitation hardening is a process that increases the hardness and strength of metals by precipitating second phase particles in solid solution. This process is usually combined with aging treatment to accelerate the precipitation of second phase particles by adjusting temperature and time, thereby significantly improving the properties of the alloy.

Let’s take aluminum alloy 7075 as an example. After precipitation hardening, the strength of this alloy is greatly improved , at least to more than 500MPa, which makes it an ideal choice for aircraft structural parts.

Strain Hardening

Strain hardening relies on external forces to cause plastic deformation of metal materials, resulting in an increase in dislocation density, which will entangle with each other and hinder the slip of the metal lattice. When combined with aging treatment, the refinement of the precipitate phase further enhances the hardness and strength of the metal. It is particularly suitable for parts that need to withstand greater stress during work, such as high-strength parts in the automotive and machinery industries.

Like the steel we are familiar with, after strain hardening treatment, the strength can be increased by 20%30%, which significantly improves its durability under high load conditions.

Stabilization Treatment

Stabilization treatment is often used for metals in high temperature environments, such as nickel-based alloys, titanium alloys and high-temperature steels. These materials will undergo phase changes or precipitate unstable phases when exposed to high temperatures for a long time, but we can use stabilization treatment to control and reduce the instability caused by the aging process . This method is mainly used for materials that work in high temperature environments or are used for a long time.

For example, our common nickel-based alloy 718 can maintain excellent mechanical properties under extremely high temperatures after stabilization treatment, and is widely used in high-temperature fields such as aircraft engines and nuclear reactors.

Which Materials Can Be Subjected To Aging Heat Treatment?

Aging heat treatment is widely used in alloy materials, especially aluminum alloys, copper alloys, nickel alloys, etc. After aging treatment, the mechanical properties of these materials are significantly improved, especially in terms of strength and hardness. At the same time, aging heat treatment can also improve its corrosion resistance, wear resistance and high-temperature performance without affecting the appearance of the material.

The following are the applications of aging heat treatment processes in different materials:

Aluminum Alloy: Aluminum alloy is a typical material whose properties can be significantly improved through aging treatment. Through appropriate aging processes, the strength and hardness of aluminum alloys can be greatly improved, and they are widely used in aerospace, automotive manufacturing, and high-performance structural parts.

Especially aluminum alloys 7075, 2024, etc., through our artificial aging treatment, their strength can be increased to more than 500MPa, which is suitable for engineering environments with high stress.

Copper Alloy: Copper alloys (such as brass, bronze, etc.) can not only enhance their strength but also improve their corrosion resistance through aging heat treatment . They are widely used in electronics, machinery manufacturing and shipbuilding industries.

When we subject brass to an aging heat treatment , we find that its resistance to wear is significantly improved, making it suitable for parts that require durability, such as electrical connectors and drive shafts.

Nickel-Based Alloys: Nickel alloys undergo aging heat treatment , especially in high-temperature environments, to improve their oxidation resistance, corrosion resistance and strength.

Nickel-based alloys (such as Inconel alloys) often require higher strength and high temperature resistance in high temperature environments. Aging heat treatment can ensure their stability and long-term service life in high temperature extreme environments such as aircraft engines and nuclear reactors.

Steel: Certain low-carbon and medium-carbon steels can be effectively improved in hardness and strength through aging heat treatment .

For example, aging treatment of low carbon steel can improve its hardness and wear resistance, making it more suitable for precision machinery and tool manufacturing. We usually use these steels in mechanical parts, automotive components and building structures that require high strength and hardness .

Aging Heat Treatment Process Steps

Aging heat treatment includes three main steps: solution treatment, aging treatment and cooling treatment. Each step plays a vital role and directly affects the mechanical properties of the final metal. By precisely controlling the temperature, time and environmental conditions of each step, the strength, hardness and wear resistance of the metal material can be optimized, making it perform well in different engineering applications.

This is the tabular data I obtained after analyzing the detailed steps of the aging heat treatment process :

| Step | Target | Temperature Range | Time | Processing Principles And Applications |

| Dissolution Treatment | Dissolve alloying elements to lay the foundation for precipitation of strengthening phases | 450°C to 550°C | 1-4 hours | By heating the metal to a suitable temperature, the alloying elements are fully dissolved into the matrix, providing optimal conditions for subsequent aging treatment. For example, the dissolution treatment temperature of aluminum alloy 2024 is controlled at 480°C to 500°C to dissolve elements such as copper and magnesium. |

| Aging Treatment | Promote the precipitation of strengthening phases and improve hardness and strength | 150°C to 250°C | hours to days | Controlling temperature and time promotes the precipitation of alloy elements and improves the hardness and strength of metal. Aluminum alloy 7075 is usually aged at 180°C to 190°C for several hours, which promotes the precipitation of elements such as zinc and magnesium and significantly improves strength. |

| Cooling Treatment | Fixed precipitate phase structure to ensure maximum hardness and strength | Rapid cooling (air cooling, water cooling, oil cooling) | Cool down quickly | Rapidly reduce the temperature of the metal to fix the structure of the precipitated phase and ensure hardness and strength. The cooling rate has an important influence on the stability and particle size of the precipitated phase. Aluminum alloys are often cooled by air, while nickel-based alloys are often cooled by oil or water to fix the strengthening phase structure. |

Why Is Aging Heat Treatment Required?

our aging heat treatment is to improve the hardness, strength, wear resistance and dimensional stability of our materials by optimizing the metal’s microstructure . These performance improvements enable the material to maintain excellent performance and extend its service life under extreme working conditions (such as high temperature, high load and high friction environment).

Improved Hardness

Aging heat treatment is an effective way to improve the hardness of metal materials. By precisely controlling temperature and time, dissolved elements in the metal precipitate in the matrix to form strengthening phases. These strengthening phases significantly hinder the movement of dislocations, thereby increasing the hardness of the metal. Especially for materials such as aluminum alloys and copper alloys, after aging treatment, the hardness can be increased by more than 50%, significantly enhancing the material’s load-bearing capacity.

Let’s take aluminum alloy 2024 as an example. After aging treatment, the hardness of the alloy can be increased from 90 HB before treatment to 160 HB after aging, an increase of 77%. This makes the application of aluminum alloy 2024 in aerospace and automobile manufacturing more reliable.

Enhanced Wear Resistance

Wear resistance refers to the ability of a material to maintain its original shape and properties under conditions of friction or wear. Through aging heat treatment, the microstructure of the metal has changed significantly, forming dense and uniform precipitated phases on its surface. These precipitated phases can effectively enhance the wear resistance of the material and reduce damage caused by friction and wear.

For example, after aging treatment, the wear resistance of aluminum alloy 7075 is increased by about 40%, which means that the service life of the treated material will be greatly extended in high friction environments , especially in bearings and gear components that are subject to high friction. Excellent performance.

Dimensional Stability

From my past experience, in many applications with high precision requirements, dimensional changes will cause parts to be unable to match other components. Aging heat treatment can reduce the dimensional changes of metal materials under high temperature and load, improve the dimensional stability of the material , and ensure that the material’s geometric shape remains unchanged during use.

In some precision mechanical parts, such as aerospace components, the dimensional stability of metal materials that have undergone aging treatment is improved by about 30%, effectively reducing deformation caused by temperature changes or load changes.

Application Areas Of Aging Heat Treatment

Aging heat treatment is widely used in many industries such as aerospace, automotive industry, electronic equipment, and energy fields. By precisely controlling the aging process, the hardness, strength, wear resistance and dimensional stability of metal materials such as aluminum alloys, copper alloys, and nickel alloys can be significantly improved , thereby meeting the stringent requirements for materials in various industries.

Aerospace : Aging treatment enables aluminum alloys to maintain low density while meeting high strength requirements, ensuring the lightweight of aircraft. Aerospace components often bear high-intensity loads, so the strength and durability of these materials can be greatly enhanced through aging heat treatment to ensure flight safety.

Automotive Industry : With the advancement of the trend of lightweight automobiles, the application of aluminum alloys in the automotive industry has gradually increased. Aging treatment can effectively improve the hardness and wear resistance of aluminum alloys, extend the service life of automotive parts (such as engines, transmissions and suspension systems), and reduce maintenance costs. In addition, aging heat treatment can also improve the strength and fatigue life of steel, making it more suitable for high-speed driving and high-load conditions.

Electronic Devices : In the electronics industry, aging treatment can be used to improve the corrosion resistance and strength of materials, especially in the manufacture of lithium battery casings and electronic connectors. Through aging treatment, equipment failures caused by material fatigue or corrosion can be avoided .

Energy Field : Aging heat treatment improves the corrosion resistance and high temperature resistance of metal materials in extreme environments, and is particularly suitable for the manufacture of oil and gas drilling equipment and generator sets. These equipment often work under high temperature and high pressure conditions, so their materials must have excellent mechanical properties and stability.

What Should Be Paid Attention To During Aging Heat Treatment?

Although aging heat treatment is a relatively mature process, it requires precise control of multiple factors during implementation to obtain ideal material properties. We need to strictly control the temperature, time, cooling method, etc. during the operation. Any error in any link may affect the hardness, strength, toughness and other properties of the metal.

The following are some aspects that require special attention when performing aging heat treatment:

Excessive Aging

I found that over-aging can lead to excessive hardness of the material, which in turn affects its toughness and may even cause embrittlement. To avoid this, the time and temperature of the aging treatment must be precisely controlled. Too long an aging time or too high a temperature may lead to excessive growth of the precipitate phase, thereby reducing the overall performance of the material.

Alloy Composition Control

The effect of aging treatment is closely related to the alloy composition. Different alloying elements will affect the formation and distribution of precipitates. Therefore, the chemical composition of the alloy needs to be strictly controlled. Especially in materials such as aluminum alloys and nickel alloys, the type and content of alloying elements and the matrix structure of the alloy will directly affect the effect of aging treatment and the final performance of the material. Therefore, before carrying out aging treatment, we must understand the specific composition of the material and make a reasonable ratio.

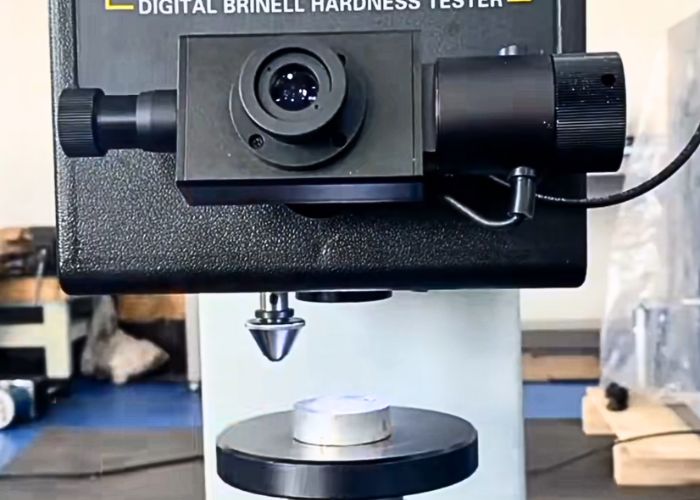

Heat Treatment Equipment And Technology

We should use advanced heat treatment equipment and technology , which can effectively improve the accuracy and efficiency of aging heat treatment. Modern equipment provides more precise temperature control, time control and cooling rate adjustment, which can ensure that each batch of aging treatment meets the technical requirements. At the same time, because of the application of computer simulation optimization technology, we can predict the problems that may occur in the treatment process in advance and reduce the uncertainty in the production process.

FAQs

What Is The Aging Process In Heat Treatment?

The aging process is to promote the precipitation of alloy elements through heating and cooling, and improve the hardness, strength and wear resistance of the metal. It is worth noting that different metals have different aging conditions , and we should understand them thoroughly before processing.

What Are The Stages Of Heat Treatment?

Heat treatment usually includes three main stages: heating, insulation and cooling. Aging, as one of the heat treatment methods, helps to improve the performance of materials.

Can Aging Heat Treatment Be Applied To PbSn Alloys?

PbSn alloys are generally not suitable for aging heat treatment because they are not easy to form favorable precipitation phases during heat treatment. The strengthening of this alloy mainly depends on the alloy composition and cooling rate.

What Is The Purpose Of Heat Treatment?

treatment is to change the structure and properties of metal by controlling temperature and time, and to improve the strength, hardness, toughness and wear resistance of the material.

Conclusion

As a researcher deeply involved in the field of materials, I am well aware of the value of aging heat treatment. It accurately optimizes the microstructure of alloys and improves performance, which is crucial in many fields. Here, I will analyze its principles and applications in depth, hoping to help you understand and master this technology, improve the quality and reliability of your products, and move forward steadily on the professional path.