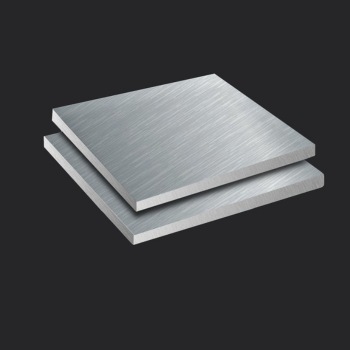

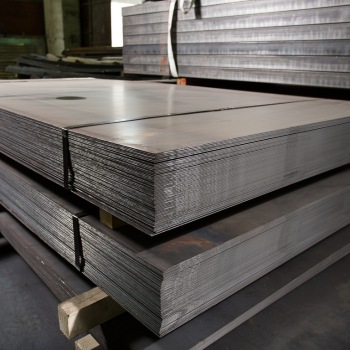

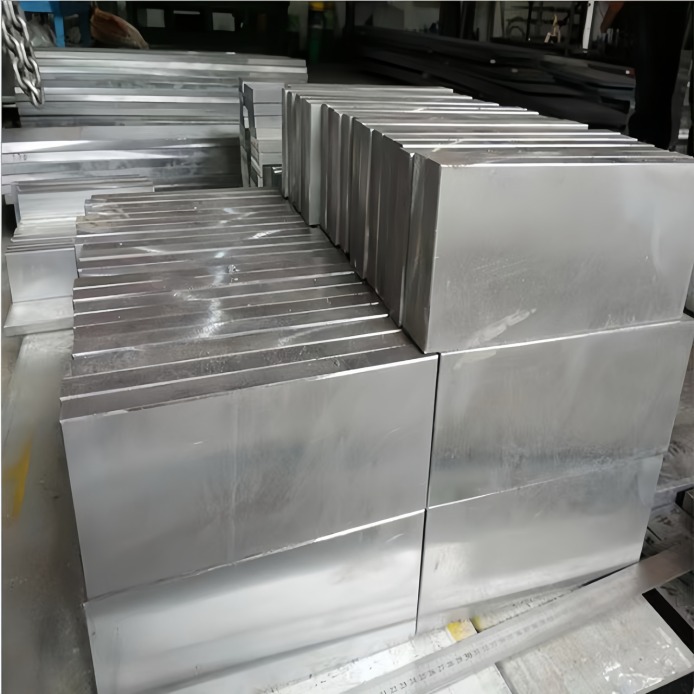

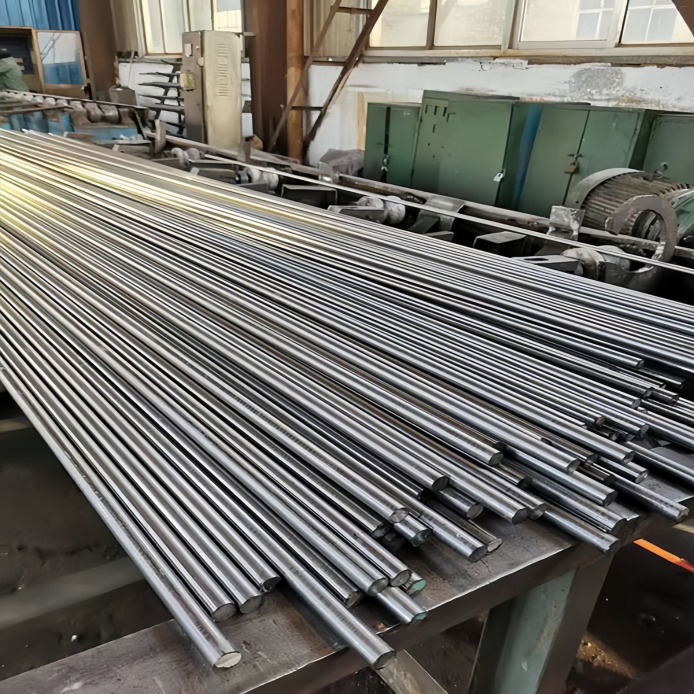

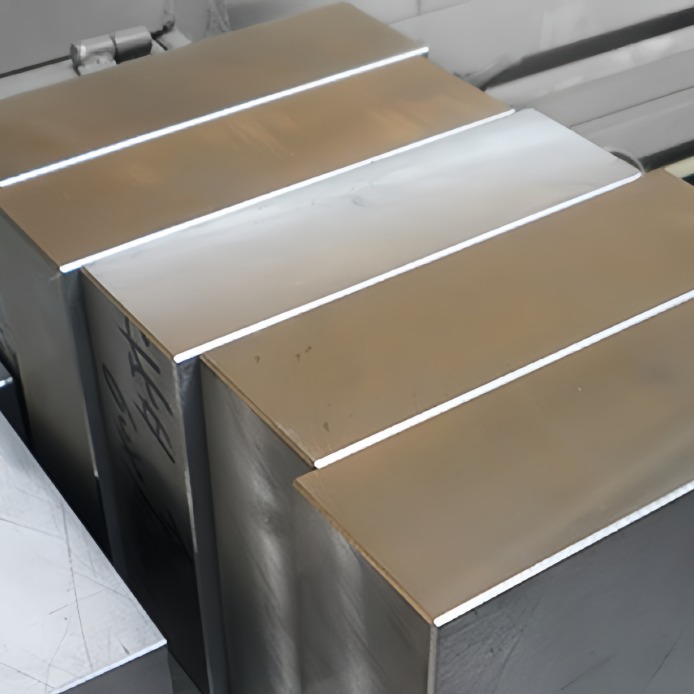

Tool steel, celebrated for its high mechanical strength and ability to resist wear, serves as a crucial material in manufacturing assorted tools, gauges, and molds. Often requiring heat treatment after machining, tool steel maintains shape and dimensional stability, making it more suitable for the manufacture of tools and molds that require high precision.

Machining parts made of tool steel is not an easy task. Special processes and techniques are required. By understanding the various tool steel materials and machining methods, you can obtain high quality machined parts.

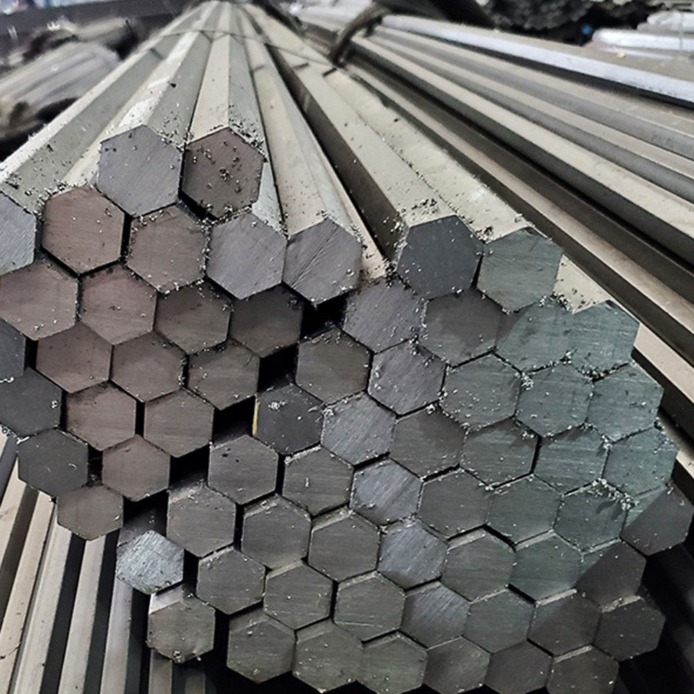

Types of Tool Steel

W-grade tool steel, also referred to as water-hardening steel, undergoes hardening by water quenching. This process imparts a desirable mix of wear resistance and toughness to the steel when correctly tempered.

High-speed tool steel (H-grade) is well-suited for cutting tools that operate at very high speeds, as it can maintain high hardness and heat resistance. Typical applications include drill bits, power-saw blades, and milling cutters.

Employed in high-temperature environments, H-grade tool steels are optimal for applications like forging and aluminum die-casting.Maintains strength and hardness even at temperatures approaching 540°C.

Tool Steel Processing Advantages

- High Hardness and Strength

Tool steels have excellent hardness and strength, making them suitable for the manufacture of tools and parts that require high strength and wear resistance. - Wear Resistance

The excellent wear resistance of tool steels ensures a long service life of machined parts. - Thermal Stability

Tool steels have good thermal stability and maintain their hardness and strength at high temperatures. - Cutting Performance

Compared with other steels, tool steel has better cutting performance, which makes it easier to carry out precision machining.

Tool Steel Processing Technology

- CNC Milling

The milling of tool steel is carried out using a milling machine, where the surface of the workpiece is continuously cut by a rotating tool to achieve the desired shape and size. - CNC Turning

Turning tool steel using lathes, where the surface of the workpiece is gradually cut to the desired shape by rotating the workpiece and the tool. - Laser Cutting

Laser cutting of tool steel using a laser cutter, which cuts or engraves the workpiece by means of a high-energy laser beam.

Appropriate Surface Finishing

- Polishing

The surface of the workpiece is polished using abrasives and polishing machinery. Polishing improves surface finish and flatness, making the surface of the workpiece more decorative and smooth. - Sandblasting

Sand particles are blasted onto the surface of the workpiece through a high-pressure air stream to remove oxidized layers, burrs, and rough surfaces. Sandblasting increases surface roughness and improves coating adhesion. - Electroplating

Improves the properties of a workpiece by depositing a metal or alloy layer on its surface. Typical plating techniques include applying layers of nickel, chromium, and zinc to surfaces, enhancing their hardness, resistance to abrasion, and ability to withstand corrosion. - Nitriding

Nitriding improves surface hardness, wear resistance and corrosion resistance by nitriding the surface of the workpiece to form a nitride layer. Nitriding also improves the lubricating properties of the workpiece surface.

Tool Steel Performance Parameters

| Performance Indicators | Numerical Value |

| Intensity | 7.7-7.8 g/cm³ |

| Melting point | 1538°C |

| Durometer | 60-65 |

| Heat distortion temperature | – |

| Water absorption | >0.003 |

| Tensile strength | – |

| Yield strength | 1200-2500 MPa |

| Elongation (at break) | 5-25% |