Tolerance is used to ensure that the size of our parts meets the functional requirements. It allows for a certain degree of error in the manufacturing process while ensuring the normal use of the product. When designing, a reasonable choice of tolerance can balance cost, efficiency and product quality . In order to make you no longer unfamiliar with it, I will introduce you to the definition, characteristics, application scenarios of unilateral tolerance and bilateral tolerance, and how to choose the appropriate tolerance according to different needs.

What Is Tolerance?

The concept of tolerance was first introduced by the Geometric Dimensioning and Tolerance (GD&T) system and has gradually become a standardized tool in actual manufacturing. Proper tolerance setting can effectively ensure part fit, assembly accuracy, and functional performance of parts.

The setting of tolerance not only takes into account the matching requirements of parts, but also balances the relationship between cost and efficiency. Especially in our mass production projects , choosing a reasonable tolerance can reduce material waste and production delays.

Generally, tolerance is divided into two categories: unilateral tolerance and bilateral tolerance . Each of these two tolerances has its own applicable scenarios, and designers will choose the most appropriate type based on specific needs.

What Is Unilateral Tolerance?

Unilateral tolerance means that the dimension is allowed to change in only one direction. It can maximize the control of certain key dimensions to ensure that the parts will not be too small during the production process. This is crucial for some parts with strict matching requirements.

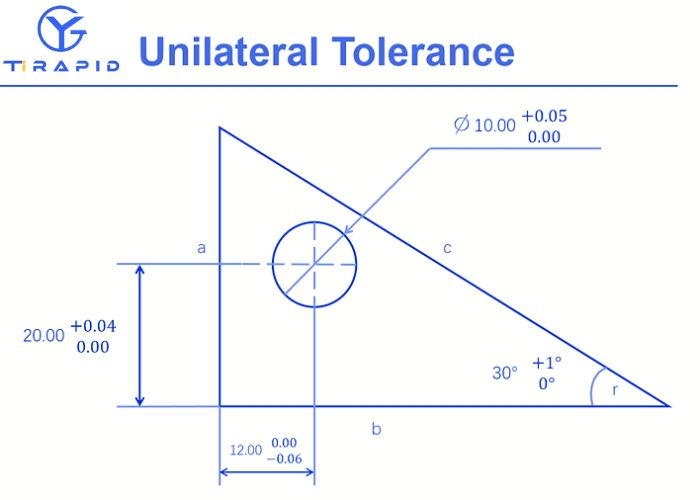

For example , the one-way tolerance specifies the acceptable range of variation in a single direction from the nominal size. For the right triangle in our figure:

The distance from the center of the hole to the edge should be 12 mm, but it can be as small as 11.94 mm, which reflects a negative one-way tolerance (that is, the size can only change in the direction smaller than the nominal size, and the minimum can be 11.94 mm).

The distance to edge b is set at 20 mm, but it can be slightly increased to 20.04 mm, which indicates a positive unidirectional tolerance (that is, the dimension can exceed the nominal dimension by up to an additional 0.04 mm).

The smallest angle r is ideally 30°, but can be as large as 31°, which is another case of positive unidirectional tolerance.

The target size of the hole diameter is 10.00 mm, and it can be increased by a maximum of 0.05 mm, which is also the positive unidirectional tolerance.

This clearly shows that while some dimensional measurements can be increased within the tolerance range specified in our schematic, the distance to a certain edge can only be decreased, not increased.

Applicable Scenarios Of Unilateral Tolerance

Single-side tolerance is suitable for parts that require an increase in size and do not allow a decrease in size. As I recall, common applications include:

- Bearings And Seals : For example, the outer and inner diameters of bearings are often toleranced on one side to ensure they are not too small and thus do not fit properly during installation.

- Mechanical Mating Parts : such as gears, connecting pins, etc. These parts have high requirements on mating accuracy. The use of unilateral tolerance can avoid problems such as looseness or leakage during assembly.

- Hydraulic And Pneumatic Systems : In the design of components such as seals and joints, unilateral tolerance ensures that the equipment does not leak oil or gas during operation.

Practical Example Of Unilateral Tolerance

Suppose we are designing a hydraulic system and the outer diameter of the hydraulic joint is required to be 20mm and the tolerance is U+0.2mm . Then the outer diameter of the part can vary between 20mm and 20.2mm, but cannot be less than 20mm. This design can ensure that the joint can fit tightly during installation, thus avoiding leakage in our hydraulic system.

Another practical application is the transmission gears in precision instruments . The outer diameter and aperture of the gears often use a single-sided tolerance to ensure their matching accuracy. Assuming the target size of the gear is 50mm, the tolerance is set to U+0.1mm , which can ensure that the gears always have a suitable fit during installation, thereby improving the stability of the machine.

What Is Bilateral Tolerance?

Bilateral tolerance allows part dimensions to deviate in two directions. In other words, the dimensions of the part can vary in both directions above and below the target dimension. Bilateral tolerance is suitable for applications with relatively loose precision requirements. It can provide greater production flexibility and reduce production costs.

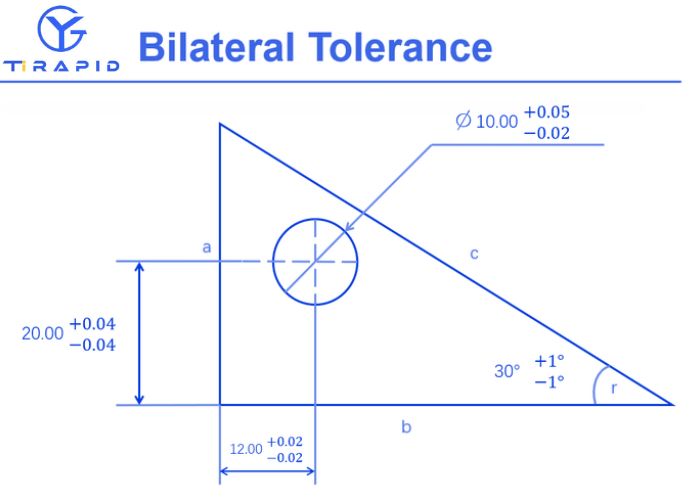

For example, the bilateral tolerance in the diagram defines the acceptable range of variation in both positive and negative directions from the nominal size. For the right triangle in the diagram:

For side a, the center of the hole can be 12 mm ± 0.02 mm, so its size can be between 11.98 mm and 12.02 mm.

With respect to side b, the permissible distance range is from 19.96 mm to 20.04 mm, allowing for the same degree of variation.

The tolerance of angle r is ±1°, and the acceptable range is between 29° and 31°.

The target hole diameter is 10.00 mm, the maximum allowed is 10.05 mm and the minimum allowed is 9.98 mm. This is an asymmetric bidirectional tolerance, so the allowed variation in the positive direction is greater than the negative direction – since the tolerance range is not symmetrical around the nominal value, this is a case of unequal bidirectional tolerance.

Asymmetric bidirectional tolerances (unequal bidirectional tolerances) have different allowable variations above and below the nominal dimension, while symmetric bidirectional tolerances have equal allowable variations on both sides, ensuring consistent variation limits around a particular dimension.

Applicable Scenarios Of Bilateral Tolerance

Bilateral tolerance is suitable for occasions with lower dimensional accuracy requirements and higher production efficiency requirements. I remember common applications include:

- Standardized Mechanical Parts : For example, conventional nuts, bolts, washers, etc., usually adopt bilateral tolerances to ensure efficiency in mass production.

- Structural Parts : such as frames, brackets, etc. The dimensions of these parts can allow a certain deviation to avoid being too tight or too loose during assembly.

- Pipes And Fittings : Equipment such as pipe fittings and valves usually adopt bilateral tolerance to improve production flexibility, especially in large-scale production.

Practical Example Of Bilateral Tolerance

In the automotive industry , engine parts such as brackets, wheel bearings, etc. often use bilateral tolerances. For example, the size of the bracket is 100mm, and the tolerance is **±0.2mm**, which means that the actual size of the bracket can vary between 99.8mm and 100.2mm. This design ensures that the parts can adapt to different tolerances during assembly, while also improving production efficiency.

Another example is standard pipe fittings , where I usually use bilateral tolerances during production to ensure that the installation of the pipe system can be flexible to accommodate different fittings and size changes. This design helps us reduce production cycle time and reduce manufacturing costs.

The Difference Between Unilateral Tolerance And Bilateral Tolerance

Unilateral tolerance and bilateral tolerance is the direction of the size change. Unilateral tolerance only allows the size to increase, while bilateral tolerance allows the size to change in both directions.

I made a table comparing unilateral tolerance and bilateral tolerance, hoping to help you understand the difference between the two more intuitively:

| Characteristic | Unilateral Tolerance | Bilateral Tolerance |

| Size Variation Range | Only allow for oversizing, limit undersizing | Allow size to fluctuate in both directions (increase and decrease) |

| Application Scenario | Applicable to situations where it is necessary to prevent parts from being too small and ensure matching accuracy | Suitable for parts that do not require high matching accuracy and allow a certain error range |

| Tolerance Type | Single side tolerance (e.g. +0.05mm, 0) | Bilateral tolerance (e.g. +0.05mm/-0.05mm) |

| Accuracy Requirements | Used for parts with high precision requirements, such as shafts, gears, mating parts, etc. | Used for parts with low precision requirements, such as housings, brackets, general mechanical parts, etc. |

| Manufacturing Flexibility | Lower, the size can only be increased, not too small | Higher, the size can fluctuate in both positive and negative directions, and the manufacturing flexibility is large |

| Common Applications | Precision parts, transmission systems, bearings, etc. | Shell parts, structural parts, plastic parts, etc. |

| Production Efficiency | Relatively low, because the scope for size reduction is limited | Relatively high, because the size is allowed to fluctuate within a wider range |

| Cost Impact | May increase production costs because more precise dimensional control is required | Can reduce production costs because dimensional variations are more tolerated |

| Practical Examples | In the shaft-hole fit, the shaft size cannot be smaller than the target size | In the design of some asymmetric parts, the dimensions are allowed to vary. |

How To Choose The Right Tolerance

When choosing tolerance, we need to consider the functional requirements of the parts and the production environment. If the parts have high matching accuracy requirements, such as parts used in hydraulic systems and transmission systems, unilateral tolerance is usually selected. For standard parts produced in large quantities, bilateral tolerance can be selected to improve production efficiency and reduce costs.

Product Requirements

If we consider the functional requirements of parts , for example, some parts that require precise fit, such as seals, bearings, gears, etc., usually choose unilateral tolerance to avoid poor fit caused by undersized parts. For parts with low size requirements, bilateral tolerance can provide higher production flexibility.

Manufacturing Costs And Efficiency

The choice of tolerance also affects the cost and efficiency of production . Single-sided tolerance usually leads to higher production costs because it requires stricter dimensional control and requires us to have more sophisticated manufacturing processes and testing methods. Bilateral tolerance provides a larger tolerance range, which can speed up our production process and is suitable for standardized parts in mass production.

The Practical Impact Of Tolerance In Manufacturing

In manufacturing, the setting of tolerance is not only related to the size of the parts, but also directly affects the processing accuracy, product quality and the subsequent assembly process. In my many years of manufacturing experience, I have deeply realized that whether the tolerance is set properly often determines whether the entire production process is smooth or not.

Processing Accuracy

The setting of tolerance has an almost decisive influence on the processing accuracy. Processing accuracy not only depends on the high precision of the equipment and the skills of the operator, but more often depends on the reasonable setting of tolerance.

When the tolerance we set is too strict, although the parts produced are accurate in size, any slight error will result in failure and even increase the scrap rate. This means higher production costs and longer processing time. On the contrary, if the tolerance is set too wide, although it can improve production efficiency, it may cause poor fit of parts, affect assembly accuracy, and further affect the function and performance of the final product.

For example, when we produced precision bearings, we found that the processing cost increased significantly and the wear of equipment and tools became more serious when the tolerance was too tight. In the end, after re-adjusting the tolerance standard, we not only improved the processing efficiency, but also successfully reduced the scrap rate and ensured the perfect fit of the bearings.

Product Quality

The impact of tolerance on product quality is more intuitive and critical. In the manufacturing process with high precision requirements, accurate tolerance control can ensure the good fit of parts, thereby ensuring the overall quality of the final product.

Is automobile engine parts. During the production process, every small error may affect the performance of the engine and even cause equipment failure. Therefore, strict tolerance standards combined with high-precision processing can effectively prevent these problems from happening.

On the other hand, if our tolerance is not set properly and the parts do not meet the requirements, it may lead to poor assembly results, which in turn affects the function of the entire product. For example, when manufacturing aircraft parts, if the tolerance control is not strict, it may cause deviations in the installation of the parts, affecting the stability and safety of the aircraft, which is unacceptable for the aviation industry. Therefore, whether in aviation, automobiles or other high-precision fields, strict control of tolerance is the key to ensuring product quality and function.

Application Of Tolerance In Different Industries

In my work, I have a deep understanding of the impact of tolerance on manufacturing quality in various industries. Especially in industries with high precision and high safety requirements, such as automobiles, aerospace, electronics, medical equipment, heavy industry, energy, precision instruments, etc., tolerance not only affects the function and performance of the product, but also affects the end-user’s experience and life safety.

Automotive Industry

Precise tolerance control ensures the safety and operating stability of the vehicle, especially in parts with high matching accuracy requirements.

Aerospace Industry

Is the key to ensuring aircraft safety and reliability. Components such as engines and airframe structures require strict dimensional tolerances to withstand high temperature and high pressure environments.

Electronics Industry

Tolerance directly affects the performance and stability of the circuit. A small error may cause the circuit to not work properly.

Medical Device Industry

In the manufacture of medical devices and equipment, precise tolerances are an important factor in ensuring device accuracy and functionality, especially in the production of surgical instruments and implants.

Precision Instrument Industry

In the manufacturing process of precision instruments such as microscopes and measuring instruments, strict control of tolerance determines the measurement accuracy and repeatability of the instrument.

Energy Industry

In the manufacture of equipment such as nuclear power and oil drilling, tolerance control is crucial to ensure the long-term stability and durability of the equipment.

Packaging Industry

Reasonable tolerance settings can ensure the sealing of the packaging and the smoothness of operation, thereby improving production efficiency.

FAQs

Which Is Better, Bilateral Tolerance Or Unilateral Tolerance?

There is no absolute advantage or disadvantage, it depends on our specific application requirements. Single-sided tolerance is suitable for parts with precise matching requirements, while double-sided tolerance is suitable for parts with high production efficiency requirements.

What Are The Basic Dimensions Of Unilateral Tolerance?

The basic size of the unilateral tolerance refers to the upper and lower limits of the target size and tolerance. For example, if our target size is 10mm and the tolerance is U+0.5mm, the actual size can vary between 10mm and 10.5mm.

What Is Tolerance In Engineering?

I remember that tolerance in engineering refers to the allowable error range of part size in design. Reasonable setting of tolerance is the key to ensuring product function and quality.

What Is Tolerance In Mechanics?

Mechanical tolerance refers to the allowable error range of the size of the parts during our mechanical manufacturing process. It helps to ensure the fit, assembly and long-term use of the parts.

What Are The Tolerances Of A Pre-Grinder?

The tolerance of the pre-grinding machine refers to the dimensional error range of the part when we use the grinder for pre-machining. It is usually loose to allow for subsequent precision machining.

Conclusion

Through the analysis in this article, we can clearly see that unilateral tolerance and bilateral tolerance each have their own applicable scenarios and characteristics. When choosing the appropriate tolerance, we must not only consider the functional requirements of the parts, but also comprehensively consider factors such as production cost, efficiency, and processing accuracy. By choosing a reasonable tolerance, we can improve the efficiency and sustainability of the entire production system.