Polyethylene terephthalate (PET) is a thermoplastic polymer used in applications such as textile fibers, beverage bottles, and food containers.PET materials offer excellent mechanical strength, transparency, and superior chemical resistance, making it the material of choice for the packaging industry and other high standard applications.

With its high melting point and excellent processing properties, PET is suitable for a wide range of molding techniques such as injection molding, blow molding and extrusion. Utilizing advanced CNC machining technology, PET can be processed into a variety of complex shapes and high precision parts to meet the needs of multiple industries.

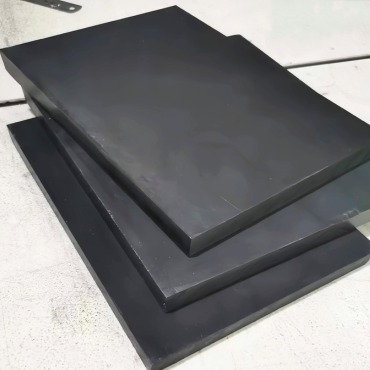

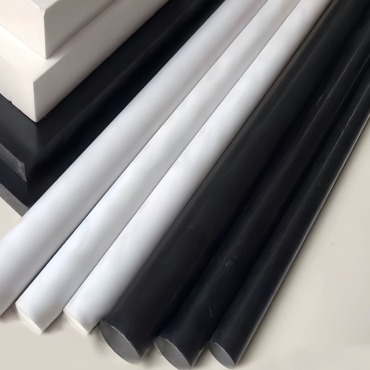

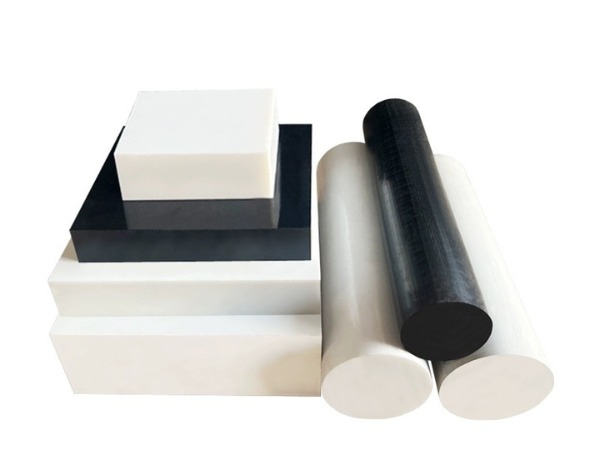

Types of PET Materials

The most common type of PET with good mechanical strength and transparency,used in beverage bottles, food containers and packaging films.

Glycol-modified PET added to standard PET to improve toughness and processability, used in thermoforming, injection molding and blow molding.

Thermoset PET is chemically cross-linked to make it a thermoset plastic with higher heat resistance and dimensional stability.

Higher molecular weight and viscosity for enhanced mechanical strength and chemical resistance. It is used in the production of high-strength fibers, industrial fibers and engineering plastics.

Made from recycled PET material, environmentally friendly and sustainable, used in the manufacture of fibers, packaging materials and non-food contact plastics.

PET modified with copolymer monomers to improve processing properties and toughness for applications requiring high impact strength and good processability.

Low crystallinity PET provides higher transparency and better optical properties.

The addition of glass fibers or other reinforcing materials improves mechanical strength and rigidity.

Treated by a specific crystallization process to provide higher crystallinity and heat resistance.

Advantages of PET

- Excellent Transparency

PET has a high degree of transparency, with a high light transmission rate, similar to glass, and is suitable for packaging and containers that require high transparency and aesthetic appearance. - Good Chemical Resistance

PET has good resistance to a wide range of chemicals and can resist corrosion by acids, alkalis and most organic solvents, making it suitable for chemical packaging and storage. - Low Water Absorption

PET has a low water absorption rate and is able to maintain stable performance in humid environments without significant dimensional changes or performance deterioration due to water absorption. - Excellent Thermal Stability

PET has a high heat distortion temperature and glass transition temperature, can maintain good mechanical properties in a wide temperature range, suitable for high temperature environment.

PET Machining Technology

- CNC Machining

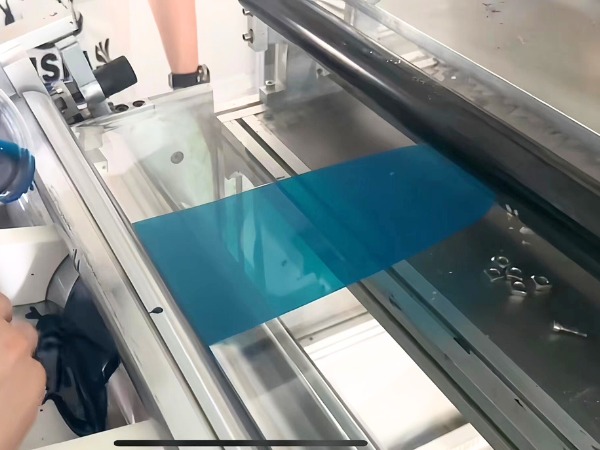

CNC Machining is a manufacturing process that utilizes computer numerical control technology to accurately control machine tools to efficiently process complex shapes and fine parts in an automated manner. - Extrusion

PET pellets are preheated to a molten state, plasticized by an extruder, and then extruded. - Injection Molding

PET is injected into a mold in a molten state and formed into the desired product by pressure and cooling.

PET Surface Finishing

- Spray Coating

By spray coating, PET surfaces can be given a uniform color and gloss, while improving their abrasion resistance, UV resistance and chemical resistance. - Corona Treatment

By means of high voltage discharge, the surface energy of PET material is increased, thus improving its wettability and adhesion. - Surface Coating

Pre-coating a layer of ink-friendly coating on the surface of PET material to improve its wettability to ink and the firmness of ink, this method is considered to be the most stable surface treatment method for PET material.

PET Performance Parameters

| Performance Indicators | Numerical Value |

| Intensity | 1.35-1.45 g/cm³ |

| Melting point | 255-265°C |

| Durometer | R110-R125 |

| Heat distortion temperature | 60-75°C |

| Water absorption | 0.1-0.4% |

| Tensile strength | 50-150Mpa |

| Yield strength | 60-75 MPa |

| Elongation (at break) | 50-150% |