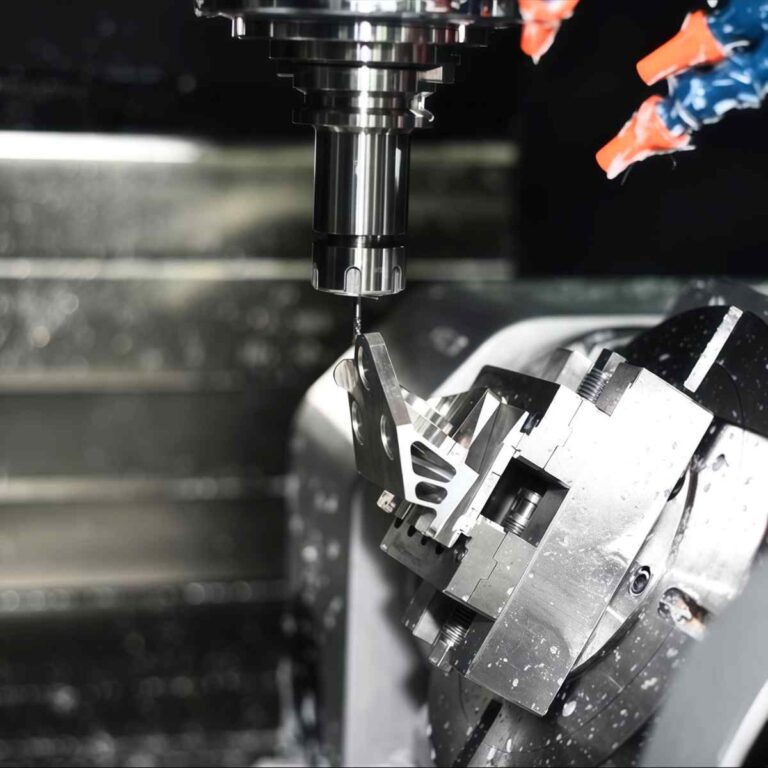

Steel CNC Machining combines precision engineering with the incredible strength of steel to produce high-performance components across industries. With advanced computer-controlled tools, it transforms raw steel into durable, dimensionally accurate

Washers may be small, yet they are vital in fastening systems. They distribute pressure, protect surfaces, and prevent loosening or corrosion. From aerospace to household use, washers are indispensable. This

In today’s manufacturing industry, CNC machining technology plays a vital role, and the selection of metal materials often determines the success of a project. When it comes to hard metal

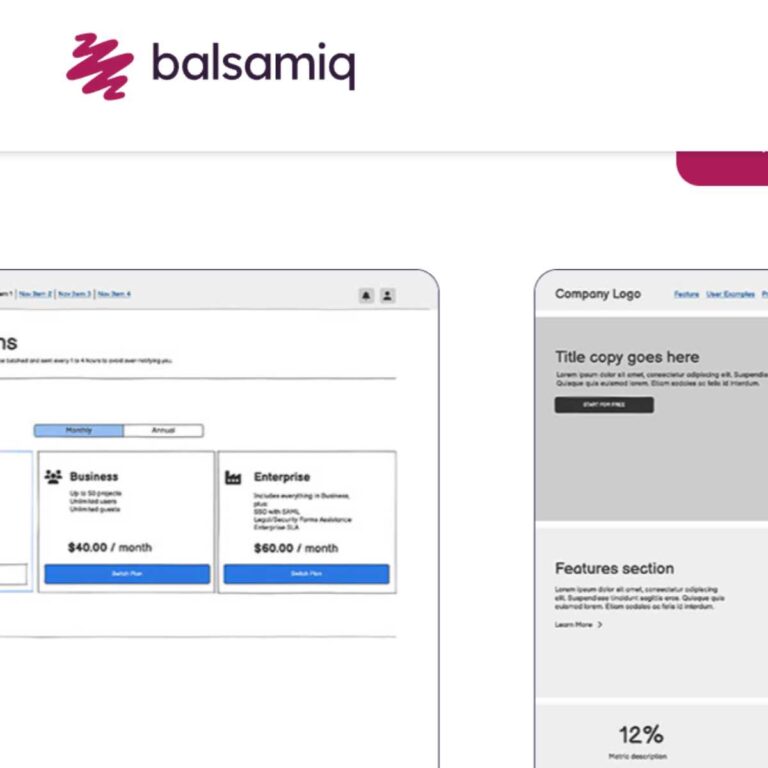

What is prototype in software engineering? It is an early model created to test design and feasibility before full development. A prototype helps visualize ideas, gather user feedback, and reduce

Every great product starts with a prototype — the bridge between imagination and creation. From simple paper sketches to working models, prototypes allow designers to experiment, validate, and refine ideas.

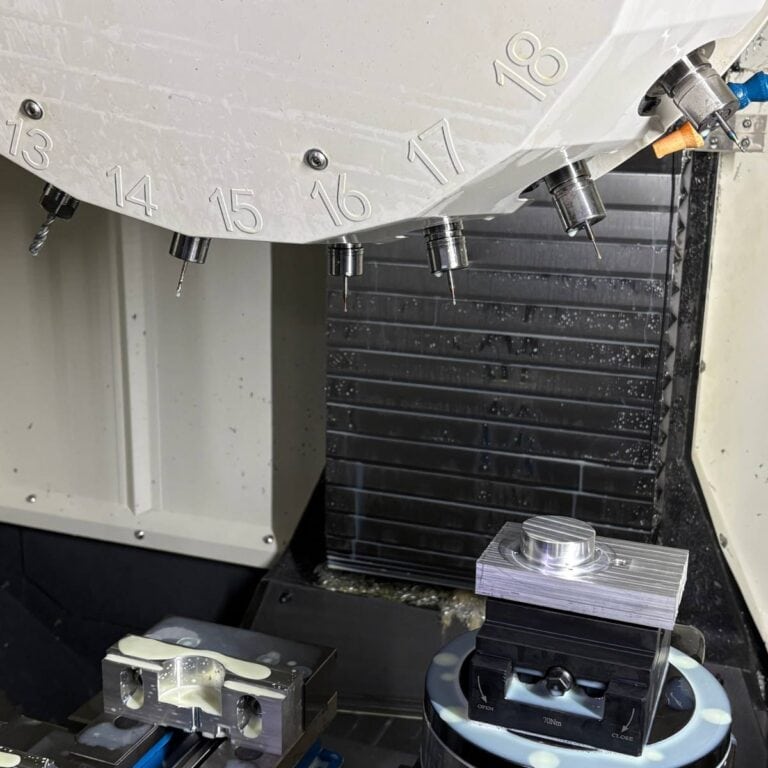

Are you developing a new product or part but unsure where to start production? A CNC machine shop is the bridge between design and manufacturing—where raw materials are transformed into

In modern manufacturing, precision drives success. CNC precision machining plays a vital role in producing aerospace and medical components. Using computer-controlled tools, it achieves micron-level accuracy and consistency, turning complex

Before turning ideas into parts, I assess machinability—using standard tools, proper tolerances, and minimal setups.This Designing for CNC Machining guide offers practical rules and DFM tips from concept to delivery,

Aluminum is valued for its strength, light weight, and corrosion resistance. Yet, its surface often requires additional finishing to meet specific functional and aesthetic needs. From anodizing to powder coating,

The global robotics industry continues to grow rapidly, with leading manufacturers driving breakthroughs in automation, artificial intelligence, and precision engineering. In this article, we present the Top 10 Best Robot

In manufacturing, prototypes bridge imagination and production. Different types of prototyping help verify designs, test performance, and improve usability before mass production. By applying the right methods, companies can cut

In engineering practice, carbon steel vs stainless steel selection plays a crucial role in determining a product’s lifespan, cost, and overall appearance. In this article, I’ll explore both materials in