Trusted CNC Manufacturing Partner for Global Engineering Teams

- Fast quotes

- Tight tolerances

- From prototype to production

What Our Customers Say

Among the Best Chinese CNC Machining Manufacturers Trusted by Global Engineers

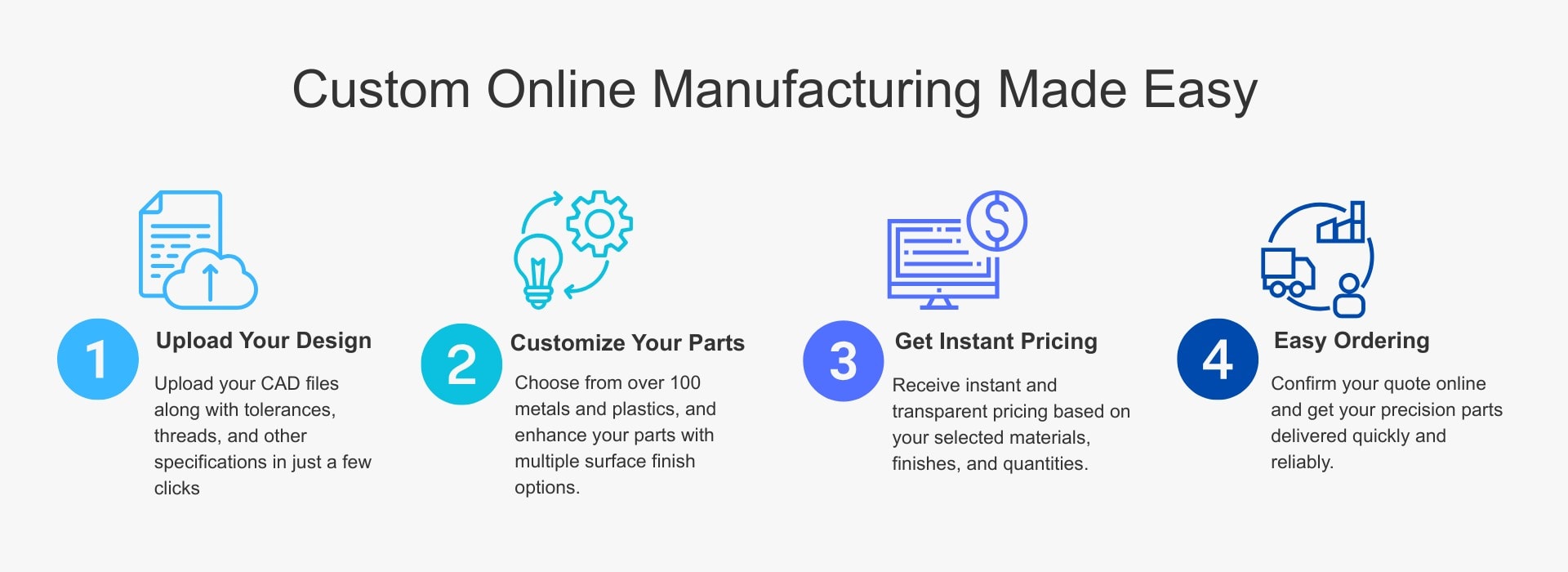

Seamless Manufacturing, Simplified

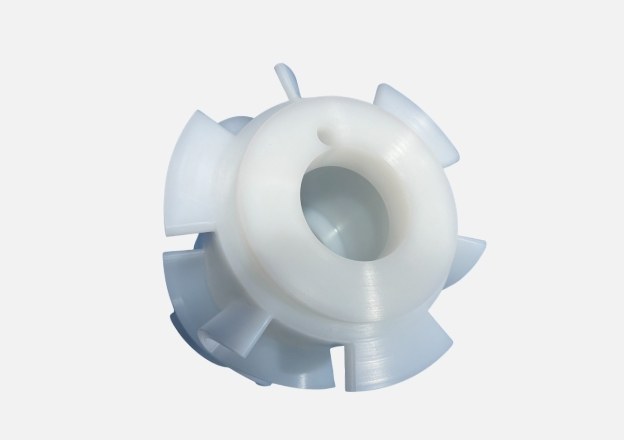

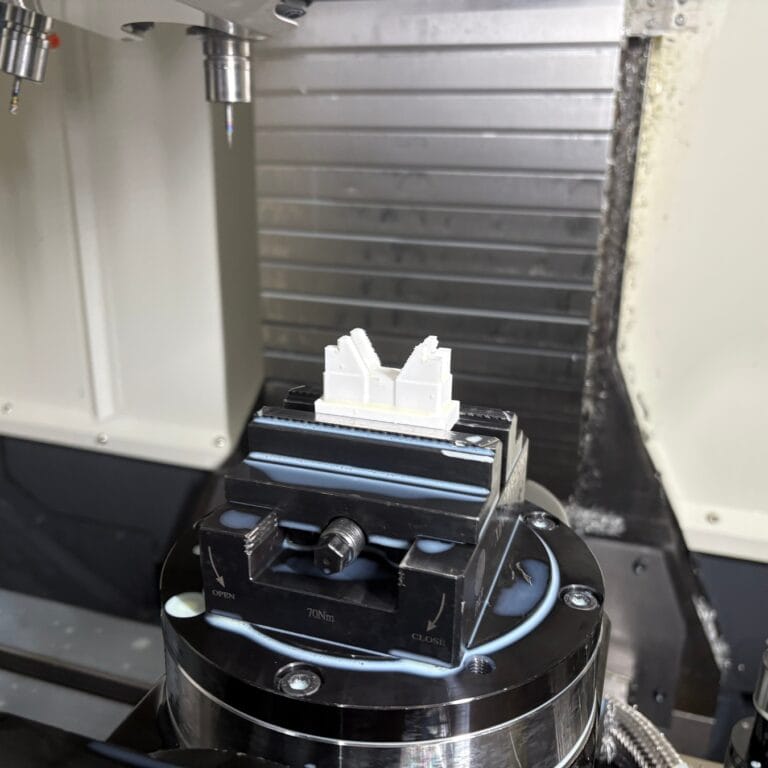

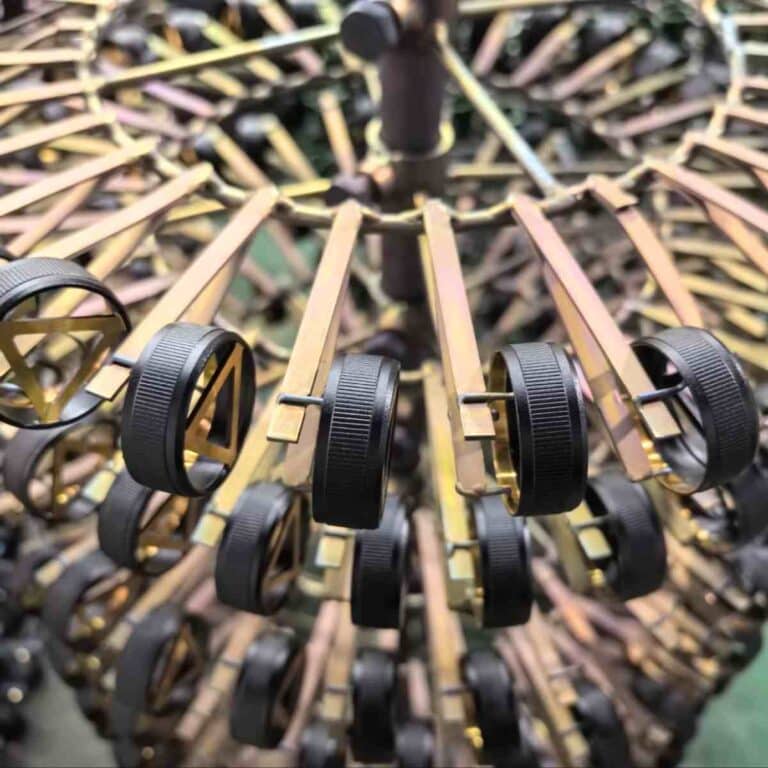

TiRapid makes CNC machining fast and easy. Our CNC Machining, sheet metal, 3D printing cover all your prototyping and production needs. Choose from over 100 materials and 60 surface finishes, and get parts delivered in days — precision, speed, and reliability all in one place.

Real-Time Quotes & Rapid Results

Upload your 3D CAD files (stp,step) and receive competitive pricing, lead times, and design-for-manufacturing (DFM) insights in no time. Our streamlined process ensures fast lead time in as little as 1-7 days, helping you meet tight project deadlines.

Value-Added Services

Our value-added services cover every step of the process, including prototype design, 3D scanning, CAD file support, assembly, outsourcing and supply chain procurement, and packaging design. Combined with our advanced machining, finishing, and CMM inspection capabilities, we deliver end-to-end solutions that enhance efficiency and bring your ideas to life faster.

Get Your Quote Today?

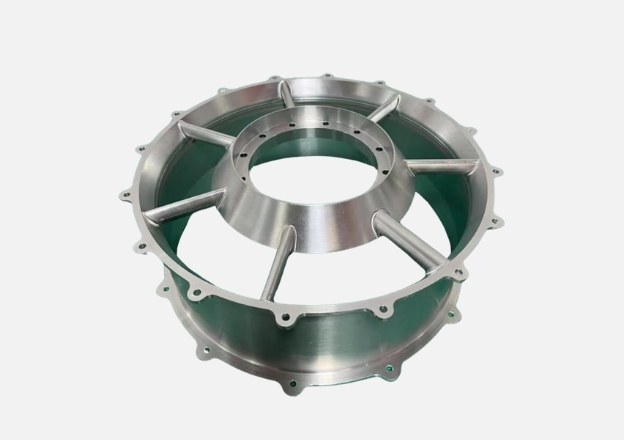

Metal CNC Machined Parts

Plastic CNC Machined Parts