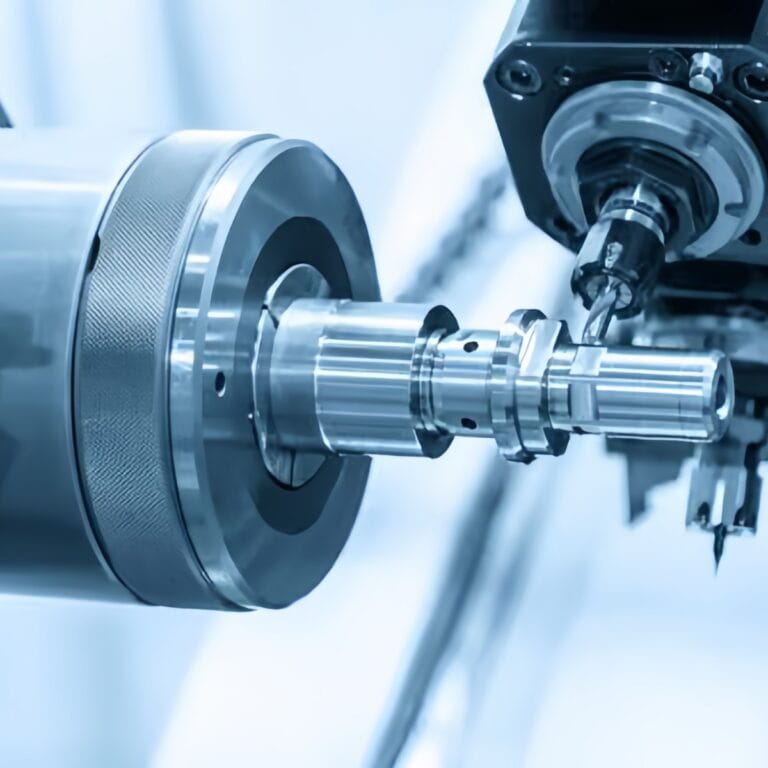

Automotive CNC machining is driving industry upgrades at an unprecedented pace. Its advantages lie not only in speed and precision, but also in its adaptability to a wide range of

Form milling, with its ability to produce complex surfaces and contours in a single pass, has become an indispensable process in industries such as aerospace, automotive, mold and die, and

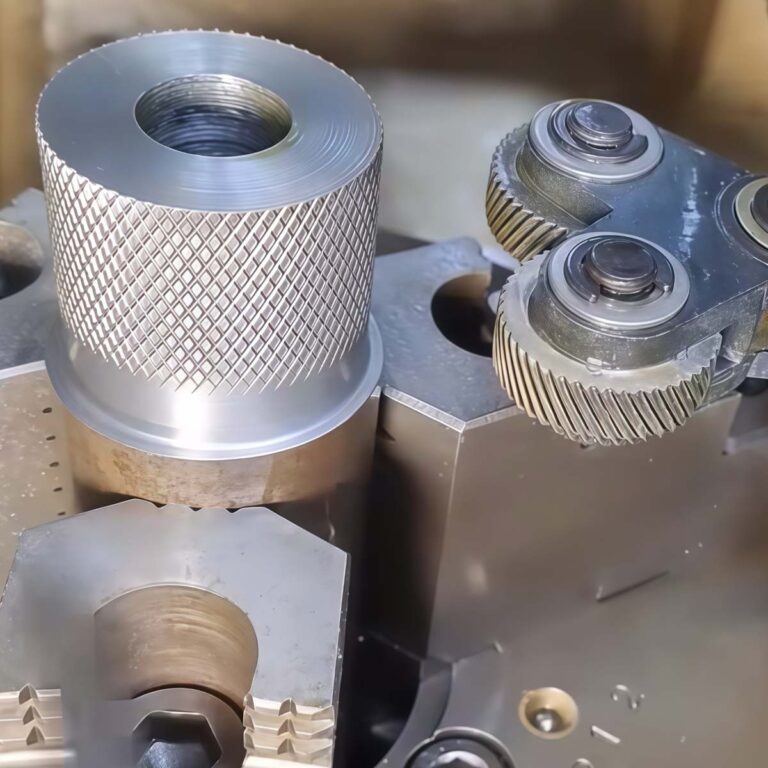

Knurling is a surface finishing process that creates a textured pattern on workpieces, primarily cylindrical parts, for better grip, aesthetics, and functional fit. In this guide, I’ll explain what knurling

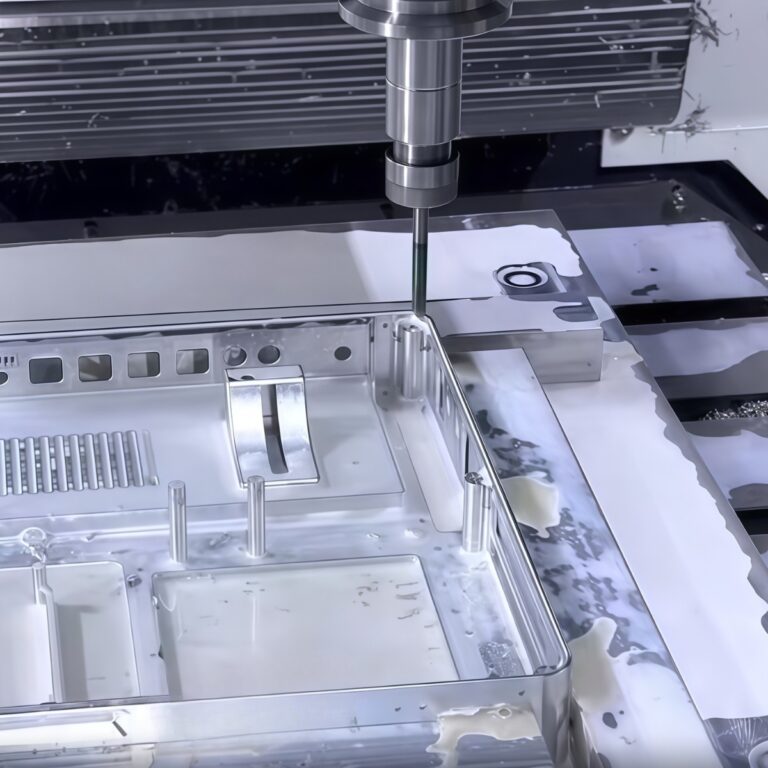

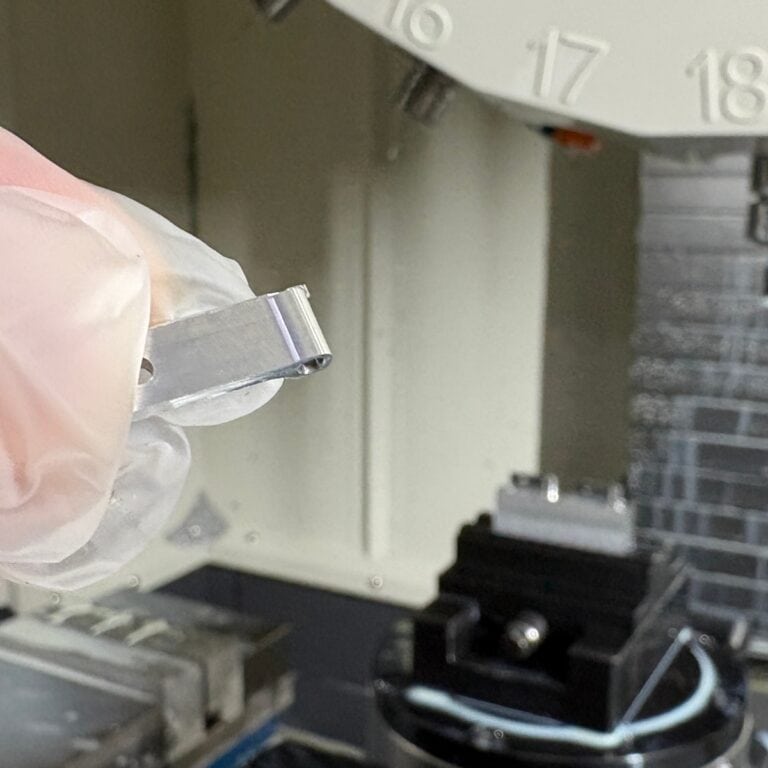

Thin wall machining is one of the most challenging processes in CNC manufacturing. Its core difficulty lies in insufficient part rigidity, which easily leads to vibration, deformation, and precision deviation.

What is Wire EDM?In the manufacturing industry, if you want to cut parts with complex shapes and high precision down to the micron level, Wire EDM is almost an unavoidable

Stainless steel has become an important material in modern manufacturing due to its high strength, corrosion resistance, and good surface quality requirements. However, machining stainless steel is not easy: its

CNC milling technology has been widely used in many industries in modern manufacturing due to its high precision, efficiency and flexibility. In this article, I will lead you to have

Drills are integral to CNC machining production, where accuracy and efficiency are critical. Capable of machining a wide range of materials such as metals and plastics, each type of drill

Face milling cutters play a key role in the machining industry as an important milling tool. They come in a variety of types and configurations that can be applied to

In grooving machining, an operator uses a CNC lathe to cut a long/narrow indentation called a groove into a workpiece. These CNC grooves are functional. However, they can have aesthetic

Part manufacturers that need to switch CAD/CAM manufacturing processes like CNC machining must convert the 3D model file to a supported format. Of the many conversion types available, converting from

Custom sheet metal fabrication is a flexible and precise metal processing method that can produce high-quality sheet metal parts that meet the specific needs of customers through a series of