There are many similarities and differences between brass vs copper vs bronze, and the comparison can show the different advantages between them.

Although for some, their appearance is indistinguishable. For this reason, this blog post still refers to the guide that can quickly distinguish brass vs copper and bronze. Also, this Tirapid blog post shares interesting details about brass vs copper and bronze by presenting their comparative analysis.

You can learn more about the respective brass vs copper vs bronze grades, application areas and their respective advantages in this blog post. And based on the analysis information below, find the most suitable metal material for your project.

Brass vs Copper vs Bronze: What Are They

After understanding the basic situation of brass, copper and bronze. The following shows you the comparison between them, so that you have a deeper impression and understanding of brass vs copper vs bronze.

Brass

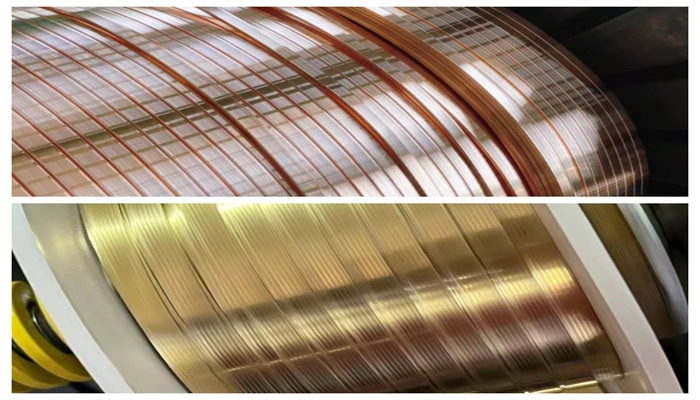

It is a metal alloy based on copper and zinc elements. Reddish brown to golden color or different functions can be obtained by adjusting the content of zinc element.

Functions of Brass

- Extensibility. Brass is a soft metal, and its wire, rod, and tube can meet the elongation requirements of rolling or stretching. Usually it can be used in various musical instruments, wires, and thin foils.

- Aesthetic appearance. The golden-yellow hue of the brass has a unique beauty that beautifies components with unique finish requirements. For example, decorative hardware objects such as handles in furniture, photo frames, and collection coins.

- Machinability. Brass is friendly to machining requirements such as turning, 5-axis milling, drilling, etc., which can reduce problems when manufacturing or machining components.

- Low friction. Brass has a smooth surface, so that the surface of the brass part does not cause excessive friction with other parts. Components such as gears, bushings, and latches use this feature to maintain their wear-resistant benefits.

- Solderability. Brass can cope with deformation, surface cracks and fractures during the welding process. Generally used in hydraulic parts, water pipe joints, valves, etc. that require good connectivity.

Grades of Brass

C260

It is also known as 70/30 brass with approximately 70% copper (Cu) and 30% zinc (Zn). Because of its good ductility, it can handle the shaping and forming requirements of cold working (such as extrusion, drawing and rolling). Usually because of its high strength, it is used to make ammunition shells, radiator cores, hydraulic parts, etc. However, the corrosion resistance of C260 is weak, which is not conducive to long-term use in acidic environments.

C280

Brass 280, referred to as Muntz brass. Because of its good corrosion resistance and high strength, it can be used for a long time in high-salt and high-humidity marine environments. However, its formability and machinability are not as good as other grades of brass. Common applications and parts are propellers, anchors, radar mounts, etc.

C360

Brass 360 is a brass alloy containing lead element (Pb). It has good machinability and produces lead chips to protect the tool and reduce wear during cutting. And through the advantages of high-strength materials, it ensures that the parts can be subjected to tight tolerance finishing operations.

However, the corrosion resistance of C360 is poor and the lead element in it has certain toxicity. It is commonly used in cable glands, terminal blocks, socket connectors, etc.

C464

Brass 464 is also known as Navy Brass. In addition to the copper and zinc elements in general alloys, its content also contains some tin elements (Sn). It is an excellent choice for marine applications due to its excellent corrosion resistance and antimicrobial properties. Specific application parts include hinges, impellers, joints, etc. But in terms of cost, its cost price is higher than other brass grades.

Bronze

It is a metal alloy composed of copper (more than 80%) and tin, which also includes elements such as aluminum (Al), silicon (Si), phosphorus (P) or nickel (Ni). The content of these elements constitutes bronzes of different properties and grades.

Functions of Bronze

- High strength. Bronze is a high-strength metal alloy that is reliable and this feature allows bronze to handle complex machining designs and withstand high-impact or heavy-duty applications. For example, dies, dies and punches used in machining.

- Thermal conductivity. Bronze has the ability to conduct heat for specific applications, helping parts dissipate heat in high-temperature environments. Generally, bronze can exhibit the thermal conductivity of bronze in the application of electronic parts, such as heat sinks, electronic housings, electrical contacts, etc.

- High melting point. The high melting point properties of bronze enable smooth operation in high temperature or high heat environments. For example, bronze is commonly used in aerospace turbine blades, exhaust nozzles and combustion chambers.

- Wear resistance. Elemental components in bronze, such as tin and aluminum, add hardness to resist impact and abrasion from contacting objects. Usually the wear resistance of bronze is applied to parts such as slide rails, guide rails and bearings in pulley components.

- Salt tolerance. The oxide layer on the surface of the bronze protects against corrosion in high-salt environments such as in the ocean. Bronze is usually used in marine components to ensure reliable performance due to its salt resistance. Such as pump impeller, mast, chain plate, etc.

Grades of Bronze

C510

Bronze 510 is also called phosphor bronze because it has a large amount of phosphorus. It has high strength properties and toughness, and can handle the needs of high fatigue and load bearing in applications.

This grade of bronze is also elastic and conductive, and is usually used as a processing material for spring parts in industries such as electronics, automobiles, and machinery. But in ductility, this grade of bronze is weaker than other materials.

C954

Bronze 954 is a common bronze grade with a large aluminum element. It has good ductility and weldability due to the aluminum element. Aluminum can be machined to provide design space.

It also has the characteristics of anti-wear and corrosion resistance, and is often used in the manufacture of piston rods, cylinder heads, gland rings, etc. in hydraulic cylinder parts.in hydraulic cylinder parts.But C954 grades are more expensive in cost.

C655

Silicon bronze, as the name implies, is a silicon-copper alloy. Polished grade C655 has a beautiful golden color. It can become a metal material commonly used in the construction field and decorative parts through good ductility. Specific applications include railings, handles, window frames, etc. But it is worth noting that its strength is not as good as the general bronze alloy.

C675

Bronze 675 is also called high-manganese bronze because of its large proportion of manganese. It has high pressure resistance and machinability, and can handle the machining design of heavy-duty applications. At the same time, it has anti-corrosion performance and has a long service life in a corrosive environment. Common application parts include stems, sleeves, and collars. However, the bronze resource of this grade is less, and its cost is more expensive.

Copper

Copper metal is a natural metal with a reddish-brown color, so there is a pure copper material without impurities. It has a long history of application due to its multi-functional advantages.

Functions of Copper

- Antibacterial properties. Copper ions can destroy the growth process of microorganisms, and achieve the possibility of inhibiting the growth of bacteria, viruses and fungi on the metal surface. It is usually used in components such as tweezers, clips and endoscopes in medical instruments.

- Biocompatibility. Copper can be used in the medical field as a material for equipment or devices, and it can coexist with living bodies without causing harm. Prosthetics, bone plates, screws and joint replacement components in the general medical field.

- Conductivity. Copper enables efficient power transport while reducing power loss for electrical and electronic applications in different industries.Through this superior performance, it is widely used in electrical lines, cables and transformers.

- Copper has good plasticity and can cope with CNC drilling, sheet metal bending, stamping and other manufacturing processing methods. With its easy formability, it is commonly used in copper fins, pipes, printed circuit boards, etc.

Grades of Copper

C110

Copper 110, also known as electrolytic tough copper. Of all grades, it has excellent electrical and thermal conductivity. Usually manufacturers choose copper 110 as a cost-effective material for manufacturing. This grade of copper is also corrosion resistant, allowing it to be used in harsh, high-salt environments. Applications include solenoids, coils and windings. But for high-strength application requirements, it may not be the best choice.

C101

Copper 101 and copper 110 are common material options in CNC manufacturing, also known as oxygen-free copper. Through the characteristics of soft materials, C101 can meet the requirements of different shapes. And has superior high thermal conductivity and electrical conductivity, used in precision parts.

This grade of copper is commonly found in transmission cables, electronic enclosures, and generator components. It is worth noting that it can have its ideal performance, and its cost will be more expensive than ordinary grades.

C122

Copper 122, also known as copper phosphide, is a pinkish-brown metal with a small amount of phosphorus. It is usually used as a material for piping applications due to its ease of welding and resistance to dezincification. At the same time, it has good anti-corrosion function, which can ensure the long-term application of copper pipes.

But this grade is not as thermally conductive as other copper grades and can be challenging in electrical applications that require high performance.

C145

Copper 145 is a free-cutting metal with tellurium element and has good machinability. Therefore, time and cost can be saved during cutting operations, and the production cycle can be shortened. This grade of copper is commonly used for fasteners in mechanical parts such as nuts, screws and bolts. However, it is worth noting that it will cause embrittlement in high temperature applications.

Comparison Between Brass vs Copper vs Bronze

Density Comparison of Brass vs Copper vs Bronze

- Usually the density range of brass is about 8.4 ~8.7 (g/cm3)

- And if there is no impurity in copper metal, it is about 8.96 (g/cm3) when it is pure copper

- However, depending on the composition of the elements in the bronze, the density will vary greatly. Therefore, the density of bronze is usually in the range of 8.8 ~ 9.2 g/cm3

Melting Points of Brass vs Copper vs Bronze

- Different melting points can help manufacturers choose the appropriate process temperature for manufacturing and processing, and thus control the temperature adjustment.

- In general, the melting point of brass ranges from 900°C to ~940°C.

- The melting point of copper can range from 1,984°C to 1,988°C.

- The melting point of bronze generally ranges from 870°C to 1,040°C.

Durability Comparison of Brass vs Copper vs Bronze

- In general, bronze is the most durable of the three metals due to its tin element. It has high strength properties and salt corrosion resistance, so it can be used for a long time in the application.

- Brass is a more convincing alloy than copper in its ability to resist corrosion and fatigue.

- Although copper metal will form a patina oxide layer during application, it is less durable than the above two metals.

Cost Comparison of Brass vs Copper vs Bronze

- The manufacturer or supplier of metal materials will determine the cost according to the condition of the resource, the specific composition and the corresponding quantity.

- But in general, copper has the lowest cost among the three metals due to its abundance and recyclability.

- Brass has different cost variations due to the elemental composition of the alloy, and its cost is higher than that of copper.

- Bronze is the most expensive of the three, and it has incomparable performance advantages over brass vs copper. Therefore, in manufacturing and processing, bronze is often used as a material for professional components or parts.

Weld-ability of Brass vs Copper vs Bronze

- In general, copper welds better than brass and bronze. As pure copper, it has good thermal conductivity and a clean surface provides good handling preparation for soldering processes.

- Brass and bronze, on the other hand, are metal alloys that hinder soldering operations due to an oxide layer produced by certain metal elements, such as zinc and tin. Therefore, the solderability of brass and bronze is lower than that of copper, which can be improved by the use of flux.

Strength of Brass vs Copper vs Bronze

- Bronze’s excellent high-strength properties are due to the role of elements such as tin and aluminum.

- It is capable of neutral applications that brass vs copper cannot, so bronze is the strongest of the three metals.

- Brass ranks ahead of copper in strength. Because pure copper has good ductility, its strength is lower than that of brass.

Electrical Conductivity of Brass vs Copper vs Bronze

- The electrical conductivity of copper is the best among brass vs copper vs bronze. As a pure metal material, copper does not have other elements in brass and bronze alloys to block free electrons from dissociation.

- The conductivity of brass and bronze will have different degrees of conductivity depending on the composition. In contrast the electrical conductivity of bronze is lower due to having a more complex elemental composition than brass.

Machinability of Brass vs Copper vs Bronze

- In general, brass performs best in terms of machinability.

- Because the brass material can cope with general cutting requirements.

- The corresponding preparation of copper in machining can prevent thermal deformation during processing.

- Bronze has the lowest machinability and requires specialized tools for machining.

Thermal Conductivity of Brass vs Copper vs Bronze

They can be distinguished by an approximation in units of watts per meter Kelvin (W/m·K). The elements of the alloy lead to different values, but metals with higher approximations are better thermal conductors. Similar to electrical conductivity, copper conducts heat better than brass and bronze.

- Copper: estimated at 385 W/m K

- Brass: estimated to be 109-120 W/m K

- Bronze: Estimated to be 60-120 W/m·K

Hardness of Between Brass vs Copper vs Bronze

According to their hardness, they can be sorted from strong to weak:

- Bronze

- Brass

- Copper

Bronze can vary in hardness through the content of tin or other elements.

Brass is also used as an alloy, and its hardness is harder than pure copper.

Copper deforms due to high temperatures during processing, which also reflects that it is a softer metal.

Corrosion Resistance of Brass vs Copper vs Bronze

In general, bronze has excellent corrosion resistance due to its elemental content.

Copper, on the other hand, usually develops an oxide layer called patina in a humid environment to protect the surface from corrosion.

Brass has the weakest corrosion resistance compared to copper and bronze. It is susceptible to the attack of the element zinc in wet environments and forms an erosive surface.

Ductility of Brass vs Copper vs Bronze

Copper, being pure copper, is the most malleable metallic material in brass vs copper vs bronze. It has good ductility and can manufacture different parts in the form of wire, rod and plate.

The second most ductile is bronze. It can increase its own ductility through the aluminum element in the alloy to cope with special manufacturing conditions.

Brass is the least ductile compared to copper and bronze. But this does not mean that it is not ductile, and brass materials can still be used in general application conditions.

The above is the performance comparison of brass vs copper vs bronze. I believe you can choose the most suitable material for your project based on the above information.

A Quick Guide to Differentiating Brass vs Copper vs Bronze

The brass vs copper vs bronze comparison above highlights the advantages of the different metals. But in general, it is difficult for many people to quickly distinguish brass vs copper vs bronze in terms of performance. To help you quickly distinguish, there are several ways to quickly distinguish.

1. Spark test

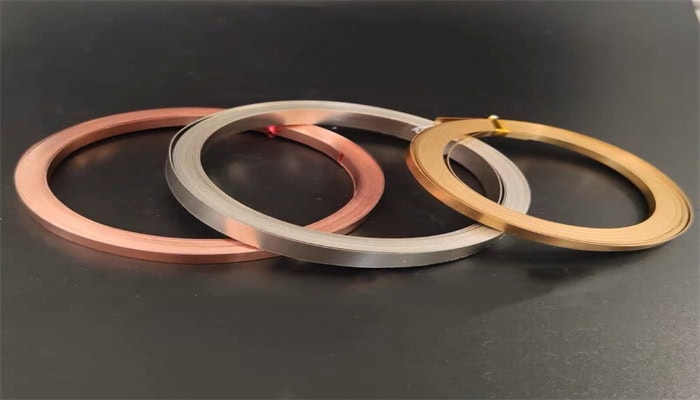

It distinguishes metals by the color of the rubbing sparks. The spark color of brass is usually bright yellow. Bronze is similar to brass, but its color varies depending on its composition. The spark color of copper is reddish orange.

It may not be possible to make a correct judgment based on the color of the spark, and you can choose to test the density of the metal or other methods to obtain correct information.

2. Appearance color

Oftentimes, looking at the color with the naked eye can quickly tell brass from copper from bronze because of the cool exterior color. Typically brass has a more yellowish bright gold or yellow color than bronze or copper. Bronze is a soft reddish-brown tone. Whereas copper has a reddish-orange color to a degree redder than brass and bronze.

3. Instruments And voices

Brass is a material often used in brass instruments, such as tubas, French horns, cornets, etc. Usually by blowing, it can produce a bright and penetrating sound.

Bronze is the material for making musical instruments such as bells, cymbals, and gongs, which can produce crisp and melodious sounds. Copper is generally not used as a metal material for musical instruments.

4. Surface Code

Each type of metal has a grade designation, which can be identified by the number after the letter “C” in the brass and bronze grade designation. If no numbers appear on the surface of the metal, then it is pure copper.

5. Patina

The metals of brass vs copper, as well as bronze, develop patinas of varying colors and degrees with prolonged exposure to moisture.

The patina of brass is green and copper is reddish brown. Although bronze has excellent anti-corrosion properties, it can develop a greenish-brown patina after a long history (such as cultural relics).

The differentiation guide above should give you a quick way to differentiate between brass vs copper vs bronze. But it is worth noting that the above three metals may not be able to be accurately distinguished due to different factors. Tirapid experts suggest that if you want to know the exact metal information, it is necessary to use professional and specific detection equipment.

Possible Challenges of Machining Brass vs Copper vs Bronze

In this Brass vs Copper vs Bronze blog post, Tirapid also walks you through some of the challenges you may encounter when machining brass vs copper and bronze. There are corresponding solutions below, hoping to bring tips and help to your project:

Brass

P1: The zinc element in brass will evaporate due to the high temperature environment during processing, which will affect the final effect of the part or assembly.

Solution: Reasonably use coolant during processing to reduce the heat generated by processing.

P2: Brass tends to harden during machining.

Solution: Usually machinists use carbide or other types of tools and adjust the cutting parameters to deal with this problem.

Copper

Problem: Sticky Chip Buildup: Chips from copper manufacturing operations stick to the cutting tool. This can lead to poor surface finish affecting metal components or parts and shorten tool life.

Solution: This uses high-pressure coolant to remove debris from the surface.

Bronze

Problem: Bronze usually has high strength properties, so its material will be more brittle. This can lead to cracks and gaps in the bronze during subsequent processing.

Solution: This can be done by optimizing processing parameters to reduce heat buildup that can damage the metal’s surface.

Adjusting the corresponding parameters and details when machining brass vs copper vs bronze can improve the efficiency of machining operations. It is worth noting that the problems in metal processing will be different according to the way of processing, and the problems should be communicated with experts in time when problems arise.

How to Choose Between Brass vs Copper vs Bronze

By comparing brass vs copper and bronze you may be able to see their strengths and weaknesses. And the following content can further help you how to choose metal materials.

Performance Requirements

The performance of each metal will be strong or weak. For example, bronze has the characteristics of high strength, but it is not as ductile as copper. Therefore, before choosing a metal, you should conduct a rigorous analysis of the performance requirements of the project (such as thermal conductivity, antibacterial performance, fatigue resistance, etc.).

Application Environment

Different application environments require different properties, which will affect the choice of metal type. For example, corrosion resistance is required in wet environments, but requires complex part design. Then bronze is a good choice, which can meet the various requirements of moisture resistance and machinability at the same time.

Budget Cost

Cost is a key factor considered by both companies and manufacturers. High-quality materials can do more with less, and cost-effective metals can handle difficult production purposes. Therefore, when choosing metal materials, it is necessary to consider whether the budgeted cost can be afforded.

Machinability

Brass vs copper vs bronze behave and function differently when machined. Different processing procedures will lead to changes in cost and final processing effect. Therefore, machinability is also one of the factors to be considered in the selection of metals.

Aesthetics

In the manufacture and processing of parts, good aesthetics is also one of the application requirements. Therefore, factors such as the luster, color, and texture of the material can be considered before choosing a metal.

There are many factors to consider in order for the project to be successfully completed. I believe that through the above points, you can understand the choice of materials. When you still have concerns and questions, you can ask Tirapid online.

Provide You with Processing Services

In the manufacture and processing of metals, the choice of materials is worthy of careful treatment. Whether it is brass vs copper or bronze, they can all play their respective advantages in different fields of application through experts.

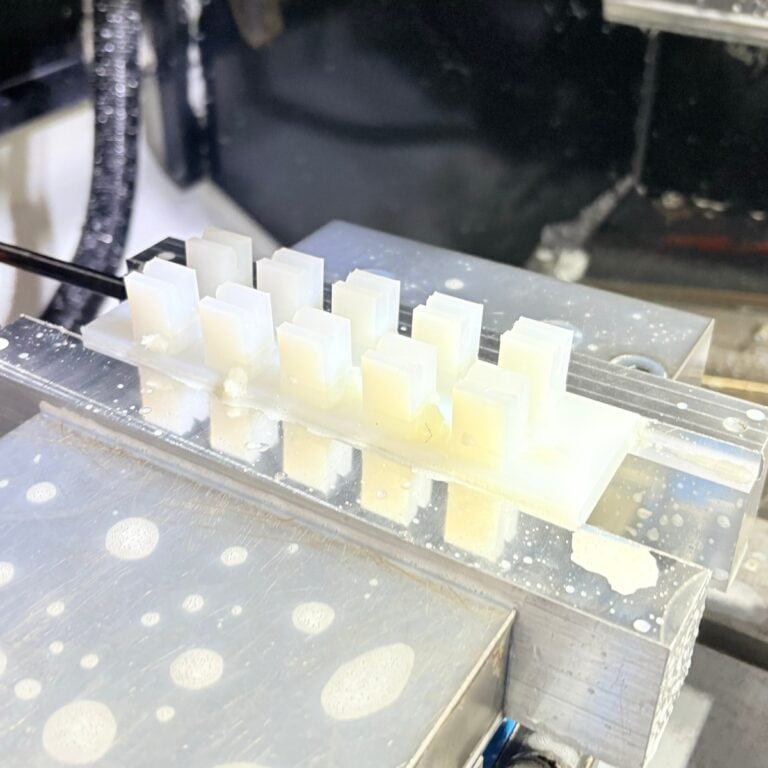

Tirapid manufacturing experts can provide you with customized services of CNC machining, sheet metal manufacturing and rapid prototyping, and its minimum precision can reach +/-0.01mm. In addition to brass vs copper vs bronze, we also offer precision metal machining in aluminum, steel, titanium, stainless steel and more.

We have a strict production process to ensure that metal components or parts meet ISO 90001 certification. You don’t need to worry about the unaffordable cost, we can provide the most practical and cost-effective solution. If you have ideas and doubts about the project, we will respond to your needs within 2 hours online. Welcome to contact Tirapid online.

FAQs

1. Which brass vs copper vs bronze material is suitable for my order?

First of all, the processing conditions and advantages that brass can handle are different from copper and bronze materials. Tirapid recommends that you consider factors such as mechanical properties, corrosion resistance, machinability and cost when selecting the correct metal material for a specific application. If you have doubts in this regard, please contact Tirapid CNC experts online.

2. In what applications can brass vs copper be used?

Brass and copper have many functions and advantages, so manufacturers can use them in many fields. For example, auto parts, ship parts, medical equipment, and jewelry are all involved. Specific parts include shift knobs, pistons, tweezers, necklaces, and more.

3. Which is cheaper, brass vs copper?

Generally, the price of brass is lower compared to copper. This is due to the fact that brass is an alloy, the composition of which consists of many elements. Copper is a natural pure metal, and its resources are relatively scarce. It is worth noting that its price will vary according to different market demands. Tirapid recommends requesting quotes from multiple suppliers to ensure you get an affordable price list for your project.

4. Can brass be used as jewelry?

First, brass has a similar golden yellow color to gold and is less expensive. Brass jewelry can be customized to get the desired design. It is worth noting that the ingredients in brass may cause skin irritation. Therefore, before choosing to wear it, please conduct a skin test in advance for allergies.

Conclusion

When comparing brass vs copper vs bronze, the performance advantages between metals can be fully understood. And they can meet the ideal manufacturing and processing plan through their own characteristics and actual processing needs.

Therefore, when hesitating which metal to choose, the comparison between metal materials is a good breakthrough.