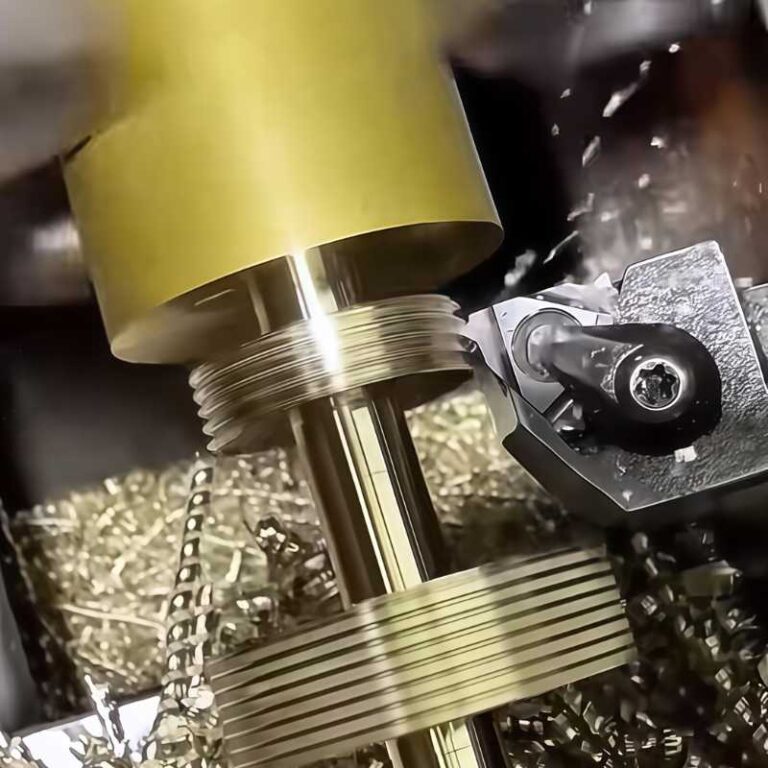

If you’re looking for a versatile machining process that can handle both small and large parts, CNC turning machining may be the right option for you. In this post, we’ll

Bead blasting is a surface treatment process that uses high-speed spherical media to clean, strengthen and beautify the surface of materials. Compared with traditional sandblasting, it is gentler and does

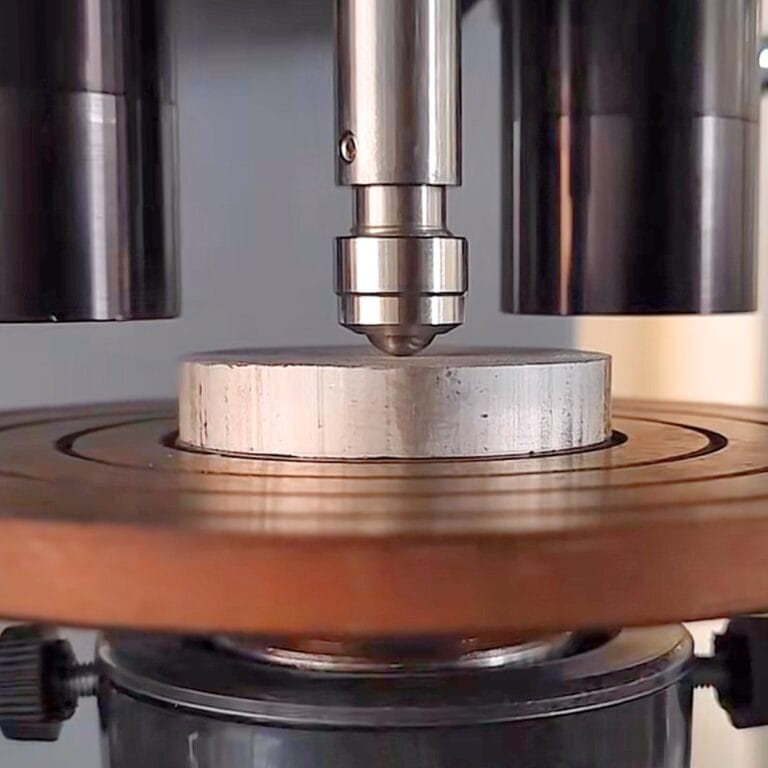

Grinding machines are key equipment for precision machining in the manufacturing industry and are widely used in surface treatment and finishing of materials such as metals, ceramics, and glass. There

CNC machined components play a vital role in modern manufacturing. From basic machining principles to the precise control of machine tools, they encompass processes like milling, turning, and drilling. These

In metal processing and manufacturing, I often focus on a critical issue: how heat affects the properties of metals. Different temperature conditions can trigger significant changes in the properties of

Aging heat treatment is a technique that changes the physical and chemical properties of metal alloys through heating and cooling processes, thereby enhancing their hardness, strength, wear resistance and dimensional

ABS plastic has good toughness, impact resistance and plasticity, and is suitable for various processing needs. Cutting ABS plastic is a key step that directly affects the subsequent processing and

Electrospark machining is a non-contact machining technology based on the principle of discharge, which is widely used to manufacture parts with high hardness and complex geometry. Compared with traditional mechanical

Tolerance is used to ensure that the size of our parts meets functional requirements. It allows for a certain degree of error in the manufacturing process while maintaining the product’s

Aluminum alloy 6061 and 7075 are widely used in aerospace, automotive, shipbuilding, and construction due to their excellent performance. Among key properties, aluminum Rockwell hardness is crucial for evaluating resistance

A well-chosen machining lubricant can significantly improve metalworking results by enhancing accuracy, extending tool life, and reducing scrap. Through effective lubrication, cooling, and corrosion protection, these fluids ensure smoother operations

What is cnc?In modern manufacturing, CNC (computer numerical control) technology has become an indispensable part of efficient and precise processing. It replaces traditional manual operations through automated control systems, providing