Aluminum is a widely used engineering material, valued for its light weight, corrosion resistance, and excellent machinability. In modern manufacturing, it plays an essential role—especially when combined with advanced CNC

what is rapid prototyping?Rapid prototyping has become a key component in shortening R&D cycles and reducing trial-and-error costs during product development. By rapidly transforming digital designs into physical models, design

Copper is a metal widely used in industry. A key characteristic of copper for precision manufacturing is its density. At room temperature, the density of pure copper is approximately 8.96

304 stainless steel is the most widely used austenitic grade thanks to its excellent corrosion resistance, durability, and reasonable machinability.In this article, I will explain what 304 stainless steel is,

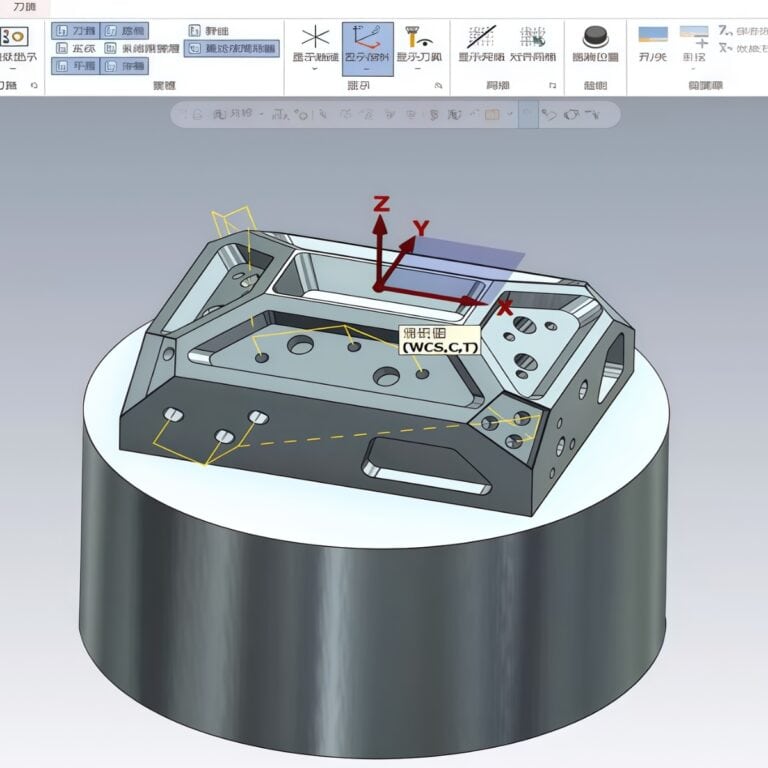

In my years of CNC programming and production experience, the Post processors remains a crucial yet often overlooked aspect. Many assume that tool paths generated by CAM software can be

Taps break during use due to improper handling or other reasons. And you don’t want to waste products or parts due to broken taps. It is important to know how

How to clean aluminum engine parts?Aluminum engine parts are lightweight, corrosion-resistant, and widely used in modern vehicles. However, they are prone to oxidation and the buildup of grease, dirt, and

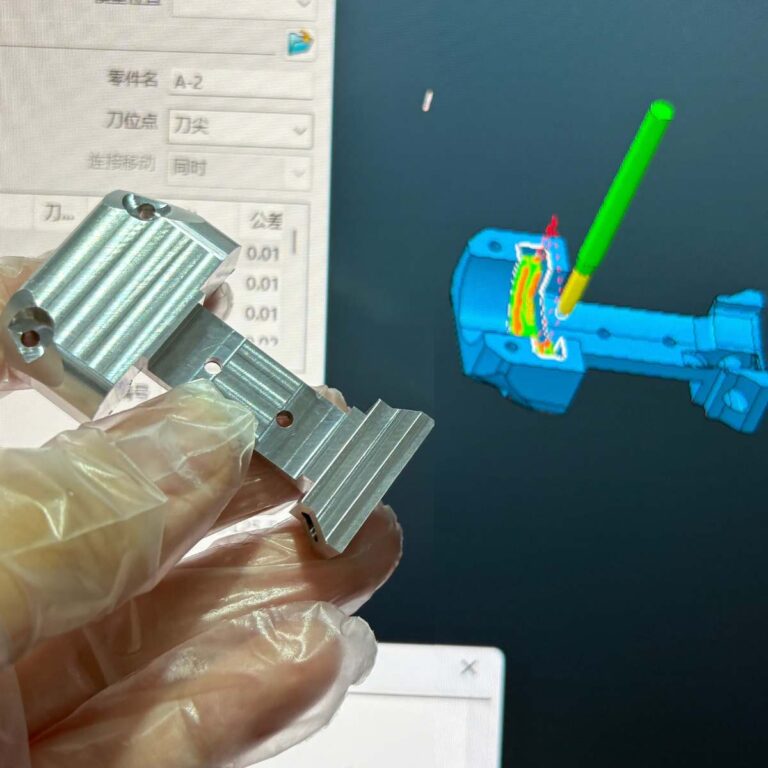

As the top representative of modern manufacturing technology, 5-axis CNC machining can realize the synchronous movement of tools in five directions, which can better ensure the high-precision machining of complex

PEEK plastic is one of the finest high performance plastics on the market due to its unique combination of excellent properties, maintaining superior strength and dimensional stability under load and

Garolite G10 is an impressive insulating material that plays an important role in modern industry. It combines a number of outstanding properties: its high strength enables it to withstand enormous

Stainless steel is not a type of steel that does not rust, but a type of metal that does not rust as easily. In this article, we explore the various

Gold is famous for its glittering appearance and expensive price. Gold symbolizes wealth, and many people buy it for preservation and appreciation purposes. If you have bought gold, or are