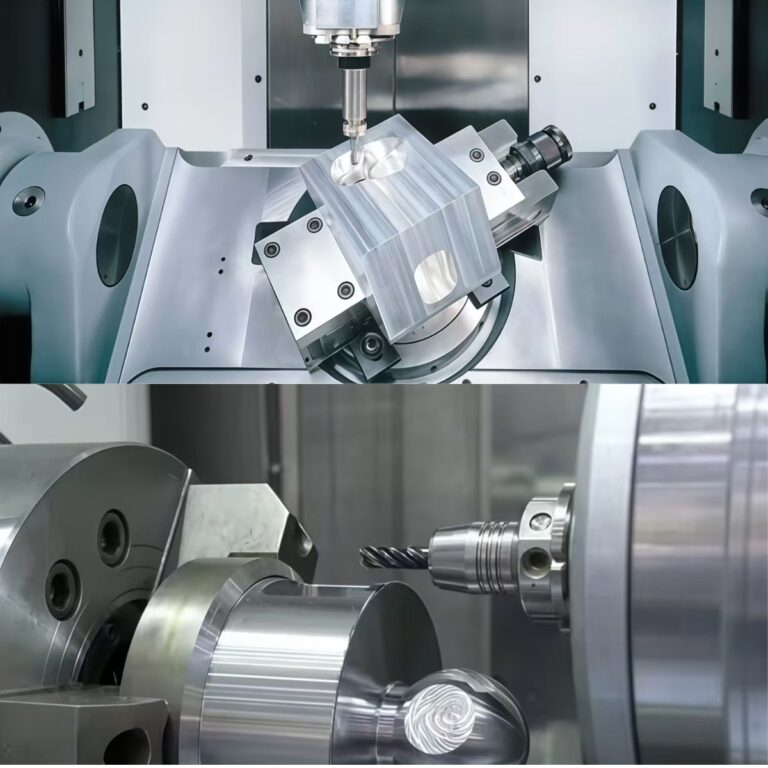

Choosing between CNC milling and turning directly affects part accuracy, cost, and lead time. While both are core CNC processes, they work in very different ways. This guide breaks down

Machining is a core part of modern manufacturing, used to transform raw materials into precise parts. But how many types of machining processes actually exist? This guide breaks down the

CNC manufacturing is the backbone of modern precision production. By combining digital design with automated machining, it reduces human error, shortens lead times, and ensures consistent part quality—making it a

Chem film, also known as Alodine, is a chemical conversion coating used mainly on aluminum to improve corrosion resistance and paint adhesion. This guide explains how chem film works, why

5-Axis-Milling is an advanced manufacturing method that allows tools to move and rotate around a part from multiple directions. This added freedom makes it possible to machine complex shapes with

Understanding what machining is matters across modern manufacturing. Machining shapes metals and other materials into precise parts using controlled material removal. This article explains what machining is, how it works,

Black anodized aluminum is a popular surface finish that combines durability with a sleek black appearance. Through an electrochemical anodizing process, aluminum gains improved corrosion resistance, wear resistance, and visual

7 axis CNC machining enables unmatched flexibility and precision by allowing simultaneous multi-directional movement in a single setup. This capability is critical for aerospace, medical, and complex structural parts. In

Need metal parts that stand out in blue without sacrificing durability? Blue anodized aluminum delivers both performance and aesthetics. In this guide, I’ll break down how the blue color is

Aerospace CNC machining delivers ultra-precise components for aircraft and space systems, where safety and accuracy are non-negotiable. From engines to structural parts, this guide explains processes, materials, challenges, and why

Anodized aluminum colors offer a unique combination of durability, corrosion resistance, and aesthetic versatility. The anodizing process strengthens the metal while enabling long-lasting, fade-resistant color options for engineering, consumer products,

Achieving tight tolerance in CNC machining is all about controlling the smallest possible deviations—from tool deflection to thermal shifts, everything counts.I’ll walk you through how I approach tight tolerance projects