6061-T6 aluminum is one of the most trusted engineering alloys, offering the ideal balance of strength, corrosion resistance, machinability, and cost. If you’re wondering what is 6061 T6 aluminum and why it’s so widely used, this guide explains how it delivers reliable performance for structural parts, CNC components, and high-precision assemblies—making it a go-to choice in modern manufacturing.

Get 20% offf

Your First Order

What Is 6061 Aluminum

6061 aluminum is a versatile magnesium–silicon alloy known for its balance of strength, corrosion resistance, and ease of machining. As one of the most widely used 6000-series alloys, it forms the foundation for structural parts, automotive components, and general engineering applications.

6061 aluminum belongs to the 6000 series, a family of aluminum alloys strengthened primarily through the addition of magnesium (Mg) and silicon (Si). These two elements combine to form magnesium silicide (Mg2Si), which improves both strength and corrosion resistance while keeping the alloy light and workable.

Typical Composition of 6061 Aluminum

- Magnesium (0.8–1.2%) → boosts strength

- Silicon (0.4–0.8%) → improves hardness and reduces melting point

- Copper (~0.15–0.4%) → enhances mechanical strength

- Chromium (~0.04–0.35%) → improves toughness and corrosion resistance

- Aluminum (balance)

These ingredients work together to create an alloy that is stronger than pure aluminum yet still easy to machine, weld, and extrude.

Why 6061 Is So Widely Used

6061 aluminum offers an ideal mix of:

- Good structural strength

- Excellent corrosion resistance

- Stable machining performance

- Lower cost compared to high-strength alloys like 7075

In my own projects machining machinery brackets and enclosures, 6061 consistently provides clean surface finishes and predictable cutting behavior—especially helpful for small-batch CNC jobs.

How Different Compositions Serve Different Applications

Depending on the application:

- Aircraft fittings may use slightly higher copper content for added strength

- Bearings and sliding parts may use higher silicon for improved wear resistance

- Consumer products rely on 6061 for its formability and good anodizing response

This adaptability is a major reason manufacturers choose 6061 for both structural and aesthetic components.

What Does the “T6” Temper Mean

The “T6” temper refers to a heat-treatment process that transforms raw 6061 aluminum into a much stronger and more durable material. It combines solution heat treatment and artificial aging to significantly boost hardness, stability, and mechanical performance.

1. What the T6 Process Involves

The T6 temper consists of:

- Solution Heat Treatment

6061 aluminum is heated to ~530°C (≈ 985°F) to dissolve alloying elements like magnesium and silicon into a uniform solid solution.

- Quenching

The metal is rapidly cooled—usually in water—to lock these elements in place.

- Artificial Aging

The material is then reheated to a lower temperature (160–180°C) for several hours. This allows magnesium-silicide (Mg₂Si) precipitates to form, increasing strength and hardness.

This controlled precipitation is what defines the T6 state.

2. How T6 Changes Aluminum Performance

The transformation from O-temper (soft/annealed) to T6 results in:

- Much higher tensile strength

- Greater hardness and wear resistance

- Improved dimensional stability

- Better suitability for load-bearing structures

For example, 6061-T6 tensile strength typically reaches 290–320 MPa, far higher than 6061-O.

3. Why T6 Is So Popular in Industry

Because of its excellent balance of machinability, strength, and weldability, 6061-T6 is widely used across:

- Aerospace fittings

- Automotive structural parts

- Machinery components

- Marine hardware

- Extrusions and precision frames

Many engineers prefer T6 because it offers steel-like strength at a much lower weight.

4.Practical Engineering Example

In my past CNC machining projects, switching from 6061-O to 6061-T6 improved deformation resistance significantly. T6 parts also held tighter tolerances during milling, especially in thin-wall sections, reducing scrap and improving assembly fit.

What Are the Mechanical Properties of 6061-T6 Aluminum

6061-T6 aluminum is known for its outstanding balance of strength, stiffness, and low weight. Its heat-treated structure gives it mechanical properties suitable for structural loads, precision parts, and high-performance applications across aerospace, automotive, and engineering industries.

1. Strength and Toughness

6061-T6 offers a high strength-to-weight ratio, with typical values of:

- Tensile strength: ~290 MPa

- Yield strength: ~240 MPa

These levels make it strong enough for load-bearing structures while remaining easier to machine than high-strength alloys like 7075.

Silicon in the alloy improves strength and contributes to excellent cold-working capabilities. This allows the metal to be bent or formed without cracking—useful for frames, brackets, curved structures, and welded assemblies.

2. Stiffness and Structural Stability

Though lighter than steel, 6061-T6 maintains mechanical stiffness suitable for precision and structural parts. Its stability under load makes it ideal for:

- Aircraft fuselage skins

- Structural beams

- Transportation components

- Fixtures and jigs

In industries I have worked with, 6061-T6 is frequently selected for CNC-machined frames where both rigidity and low mass are essential.

3. Fatigue Resistance

6061-T6 has reliable fatigue strength, enabling long-term use under repeated stress. This is important for components like:

- Bicycle frames

- Automotive suspensions

- Aerospace brackets

- Moving machine arms

Its resistance to deformation allows the material to maintain its shape over years of cyclical loading.

4. Lightweight Performance

With a density of only 2.70 g/cm³, it is much lighter than steels while offering comparable strength for many applications. This advantage reduces overall system weight—critical for aerospace and transportation efficiency.

5. Real Engineering Example

In a recent CNC machining project for an automation client, switching from steel to 6061-T6 reduced part weight by 48% while maintaining required rigidity. This change improved robot arm speed, lowered motor load, and reduced long-term maintenance.

Corrosion Resistance and Durability

6061-T6 aluminum is well-known for its excellent corrosion resistance, thanks to its magnesium-silicon alloy system and stable oxide layer. This combination gives it long-term durability in outdoor, marine, and industrial environments where moisture, salt, or chemicals are present.

Why 6061-T6 Resists Corrosion

- Protective oxide layer:

Aluminum naturally forms an Al₂O₃ oxide film. Mg and Si enrich this layer, making it harder, more stable, and more resistant to chemical attack.

- Resistance to atmospheric and water exposure:

6061-T6 performs well in rain, humidity, industrial pollution, and marine air—environments that often degrade other metals.

- Stress corrosion cracking resistance:

Unlike some high-strength alloys (e.g., 7xxx series), 6061-T6 maintains structural integrity even under stress + corrosion conditions, making it safer for welded assemblies.

Performance in Harsh Environments

- Marine & seawater:

The alloy maintains corrosion resistance in saltwater, making it suitable for boat structures, underwater housings, and cooling systems.

- Outdoor structures:

It withstands UV exposure, temperature changes, and industrial chemicals without rapid degradation.

- Industrial environments:

Resistant to mild acids, alkaline conditions, and environmental contaminants.

In marine hardware projects we’ve handled, 6061-T6 plates used for brackets and hull reinforcements maintained excellent performance after prolonged salt spray testing. Compared to 7075, which showed signs of pitting, 6061-T6 remained stable with minimal surface oxidation.

Surface Treatments That Enhance Durability

Although already corrosion-resistant, 6061-T6 benefits further from:

- Anodizing

- Powder coating

- Clear or hard-coat finishing

Used together, these treatments make the alloy suitable for long-term outdoor and marine conditions.

Machinability, Formability and Weldability

6061-T6 aluminum offers a strong balance of machinability, formability, and weldability, making it suitable for precision parts and structural applications. While its hardness provides strength, it still machines cleanly, bends predictably, and welds reliably when proper procedures are followed.

Machinability

The T6 temper improves cutting behavior, allowing cleaner chips, smoother surfaces, and reduced tool wear compared to the annealed (O) condition. Although harder than 6061-O, it machines predictably with standard carbide tools. In my CNC machining projects, 6061-T6 consistently delivers stable tolerances and low scrap rates, even with complex pocketing or thin-wall geometries.

Formability

Because T6 increases hardness, bending requires proper radii and planning. It is less formable than 6061-O, but still capable of controlled shaping for brackets, frames, and fixtures when guidelines are followed. For tight curves, we sometimes perform localized annealing before forming to minimize cracking.

Weldability

6061-T6 welds well with MIG and TIG processes, although weld zones lose some T6 strength due to heat. Post-weld aging or design compensation can restore or offset the reduction. Joining options also include riveting, threaded fasteners, and spot welding, making it suitable for assemblies requiring long-term durability.

Overall, 6061-T6 offers a valuable blend of strength and workability, making it a reliable choice for both lightweight structures and precision components.

Cost, Availability and Product Forms

- T6 aluminum is widely available, affordable, and offered in many product forms, making it one of the easiest alloys to source for engineering projects. Its combination of low cost, steady global supply, and diverse shapes allows designers to meet performance and budget needs.

6061-T6 aluminum is one of the most cost-effective and widely stocked alloys on the global market. Its popularity in automotive, aerospace, construction, marine, and consumer product industries ensures a steady demand, which in turn stabilizes production and reduces material cost. Compared with higher-strength alloys such as 7075, 6061-T6 delivers excellent performance at a significantly lower price point.

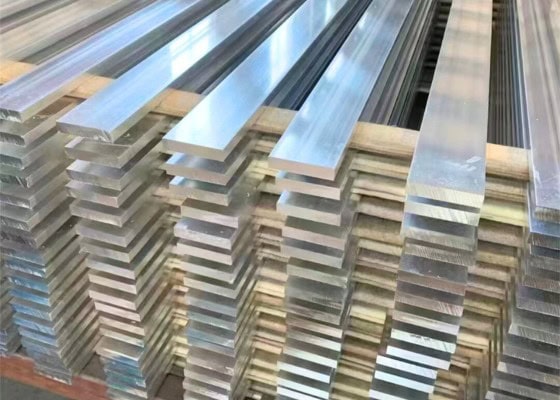

Its availability is another advantage. Manufacturers commonly supply 6061-T6 in a full range of product forms, including:

- Sheet & Plate – ideal for structural panels and machined components

- Bars (round, square, hex) – used for shafts, fixtures, and precision parts

- Tubes – common in frames, supports, and lightweight structures

- Extruded Profiles – custom shapes for engineering assemblies

Because machining shops and extrusion mills produce 6061 in high volume, lead times are short and production costs remain low.

From our experience supplying CNC-machined components, 6061-T6 is often the most economical choice—especially when clients need a balance of strength, corrosion resistance, and fabrication flexibility. Whether for prototypes or mass production, its cost efficiency and broad availability make it a reliable material for nearly any industry.

What Are the Key Applications of 6061-T6 Aluminum

6061-T6 aluminum is used across countless industries because it offers the rare combination of strength, corrosion resistance, and light weight. These advantages make it suitable for structural components, transportation systems, marine equipment, consumer products, and high-performance engineering projects.

| Application Area | Description | Typical Parts | Notes |

|---|---|---|---|

| Marine & Offshore | Excellent saltwater resistance due to Mg-Si oxide layer | Boat hulls, marine frames, underwater parts | Performs reliably in long-term moisture environments |

| Structural Engineering | High strength-to-weight ratio for load-bearing parts | Frames, fixtures, brackets, ladders | T6 temper improves stiffness & fatigue resistance |

| Automotive & Transportation | Ideal for lightweight structures with good machinability | Vehicle frames, truck bodies, trailers, railway parts | Helps reduce vehicle weight without sacrificing strength |

| Consumer & Sporting Goods | Durable with premium finish; excellent anodizing response | Bicycle frames, reels, firearms, camera/drone parts | Combines strength with aesthetic quality |

| Piping & Tubing Systems | Corrosion resistance & cleanliness for fluid systems | Hydraulic tubes, air/fluid pipes, cooling systems | Preferred where moisture or mild chemicals exist |

| Aerospace & Engineering | Cost-effective alternative to 7075 for non-critical structures | Fittings, interior structures, jigs & fixtures | Common in aerospace tooling & fixtures |

How to Decide If 6061-T6 Is Right for Your Project

Choosing 6061-T6 aluminum depends on whether your project needs a lightweight material with solid strength, corrosion resistance, and good machinability. Its balance of performance and cost makes it suitable for many structural, marine, and general engineering applications.

1. Evaluate Required Strength-to-Weight Ratio

6061-T6 offers a high mechanical strength while remaining lightweight. For designs where weight reduction matters—such as frames, fixtures, automotive brackets, machinery arms, or consumer products—its strength-to-weight advantage makes it a top candidate.

2. Consider Corrosion Exposure

With added magnesium and silicon, 6061-T6 naturally resists oxidation and stress corrosion. It performs reliably in outdoor, humidity, and even moderate salt-spray environments. For projects exposed to marine or moisture, 6061-T6 is a trusted material.

3. Examine Machining & Forming Requirements

From our machining experience, 6061-T6 cuts cleanly, leaves smooth finishes, and supports high-precision CNC operations. While T6 temper reduces formability compared to annealed states, it works well for machining-intensive projects and welded assemblies when strength is required post-fabrication.

4. Fit With Project Budget & Availability

6061-T6 is cost-effective because of mass availability in sheet, plate, bar, and extrusion profiles. For large batch production or rapid prototyping, its wide supply range helps keep material and lead-time costs low.

5. Common Project Scenarios Where 6061-T6 Is Ideal

- Lightweight structural parts

- Frames, brackets, and support arms

- Marine components needing durability

- Consumer goods requiring strength + aesthetics

- Piping, tubing, and mechanical fixtures

When weight, durability, and corrosion resistance matter simultaneously, 6061-T6 is typically the most economical and high-performing choice.

FAQs

What Is The Difference Between 6061 And 6061 T6?

The difference lies in heat treatment. In my work, 6061-O has a tensile strength around 18 ksi, while 6061-T6 reaches 42 ksi due to solution heat treatment and artificial aging. T6 provides far better hardness, stiffness, and dimensional stability, making it the preferred choice for structural and load-bearing applications.

What Does T6 Stand For In Aluminum?

T6 refers to a specific temper involving solution heat treatment + artificial aging. In practice, I heat 6061 to about 530°C, rapidly quench it, then age it at 160–180°C for several hours. This process increases yield strength to roughly 35 ksi, dramatically improving durability and mechanical performance.

What Is Aluminium 6061 T6 Used For?

In my manufacturing projects, 6061-T6 is used for parts requiring strength, corrosion resistance, and low weight. It appears in aircraft fittings, marine frames, automotive components, bicycle parts, jigs, fixtures, and precision CNC-machined housings. Its 42 ksi tensile strength and excellent machinability make it extremely versatile.

What Is 6061-T6 Aluminum Equivalent To?

Based on engineering equivalency charts I use, 6061-T6 is comparable to ASTM B221, EN AW-6061 T6, and ISO AlMg1SiCu grades. Mechanically, it sits between 5052-H32 and 7075-T6, offering a balanced tensile strength around 42 ksi, good corrosion resistance, and reliable weldability across global standards.

How To Tell If My Aluminum Is 6061?

I typically confirm 6061 by checking markings, machining behavior, and hardness. 6061 machines cleanly, shows a T6 tensile strength near 290 MPa, and contains Mg-Si in spectrometer tests. When in doubt, I verify using a material certificate or handheld XRF to ensure accurate alloy identification.

Conclusion

6061-T6 aluminum is a magnesium–silicon alloy strengthened through T6 heat treatment, giving it an excellent balance of strength, corrosion resistance, machinability, and low weight. Its mechanical performance, wide availability, and durability make it ideal for structural, automotive, marine, aerospace, and general engineering applications.