TiRapid (TR) is a leading provider of CNC machining services for plastic manufacturing, empowering industries such as automotive, medical devices, electronics, and aerospace with precision, speed, and design flexibility. CNC machining offers advantages over traditional methods, including tight tolerances, material versatility, rapid prototyping, and minimized waste. TR’s customer-centric approach begins with detailed consultations and material selection, leveraging advanced equipment and skilled engineers to meet strict specifications. Quality assurance is paramount, with rigorous inspection and compliance to industry standards. TR supports clients in evaluating CNC machining against other processes like injection molding and 3D printing, often integrating hybrid solutions for optimal results. Sustainability initiatives include efficient material use, recycling, and selection of eco-friendly plastics. TR also provides value-added services such as part finishing, assembly, and consulting. Success stories highlight accelerated product launches, lightweight automotive solutions, and innovative aerospace components. With ongoing investment in digital transformation, advanced materials, and automation, TiRapid ensures clients remain at the cutting edge of plastic manufacturing.

TiRapid (TR), an industry-leading provider of advanced manufacturing solutions, is at the forefront of transforming plastic manufacturing through precision CNC machining services. In today’s fast-paced industrial landscape, the demand for high-quality plastic components spans across sectors such as automotive, electronics, medical devices, aerospace, and consumer goods. The evolution of CNC machining unlocks new possibilities for plastic part production, offering unparalleled accuracy, repeatability, and efficiency compared to traditional methods. This comprehensive article explores every facet of CNC machining for plastics, focusing on how TiRapid’s expertise and resources are redefining what manufacturers can achieve.

The Fundamentals of CNC Machining for Plastics

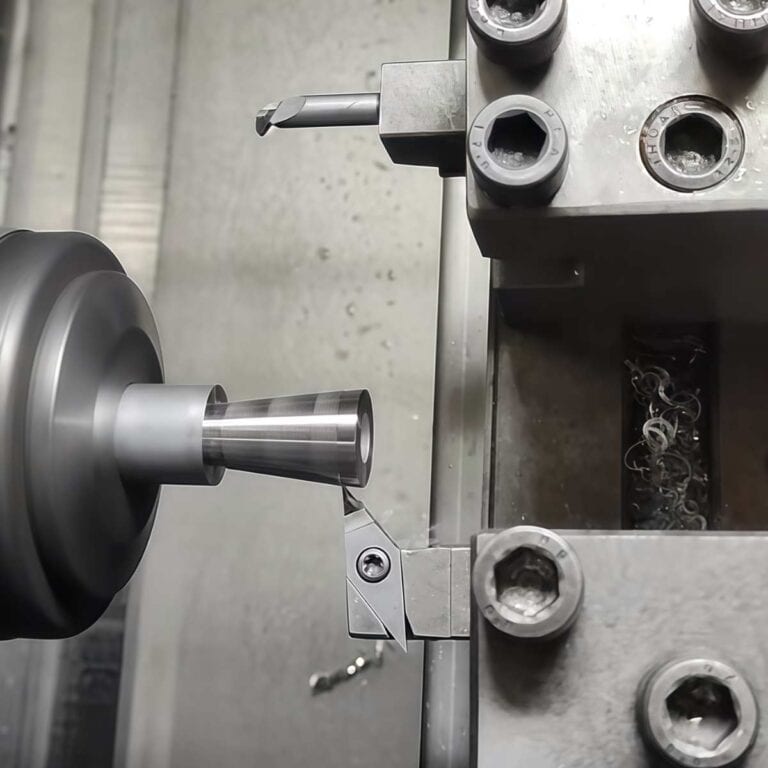

CNC (Computer Numerical Control) machining is a process where computers dictate the movement and operation of factory tools, enabling precise and repeatable manufacture of parts. Unlike manual machining, CNC allows for complex geometries, high precision, and consistent quality. TR leverages state-of-the-art CNC equipment, software, and highly skilled operators to deliver plastic components that meet stringent specifications.

Plastic materials have unique characteristics that require specific machining strategies. Common plastics used in CNC machining include ABS, polycarbonate, nylon, POM (Delrin), PMMA (acrylic), PE, PVC, and high-performance engineering plastics like PEEK and PTFE. Each material presents its own machinability challenges, which TiRapid overcomes through expert tool selection, optimized processing parameters, and advanced programming.

large cnc machining

cnc machining China

nylon machining service

rapid prototyping services

billet aluminum CNC machining

Advantages of CNC Machining Services for Plastic Parts

- Precision and Consistency: CNC machining provides tight tolerances, ensuring uniformity across production batches—a vital factor for industries with strict regulations, like medical or aerospace.

- Design Flexibility: Complex shapes, undercuts, and intricate geometries can be realized efficiently, especially in prototyping and custom production.

- Material Versatility: The ability to machine a wide range of plastics—from commodity to engineering grades—enables TR to match materials to application needs.

- Fast Turnaround: CNC machining streamlines workflows, reducing lead times especially for rapid prototyping or urgent production runs.

- Reduced Waste: Precision machining minimizes material waste, supporting sustainability goals and cost efficiency.

TiRapid’s CNC service is tailored to leverage these advantages, helping clients enhance their product development cycles and operational efficiency.

TiRapid’s Approach to CNC Machining for Plastics

TR emphasizes a customer-centric approach, incorporating close collaboration from design inception through final production. The process begins with detailed consultation, where TR engineers assess the client’s requirements, suggest suitable plastic materials, and propose design optimizations for manufacturability. Advanced CAD/CAM platforms are then used to program the machining process, ensuring every detail is accounted for.

The company’s modern facility is equipped with multi-axis CNC mills, lathes, and routers, capable of handling both small and large-scale projects. Quality assurance is integral, with stringent inspection routines using CMM (Coordinate Measuring Machines), laser scanners, and digital microscopy. TR’s commitment to continuous improvement, investment in automation, and ongoing staff training further enhance the reliability and quality of CNC machined plastic parts.

Plastic Prototyping: Accelerating Innovation

One of the most significant contributions of CNC machining to plastic manufacturing is rapid prototyping. TR offers quick-turn prototyping services for clients seeking to validate designs, test assembly, and control product quality before mass production. CNC’s direct-from-CAD manufacturing means prototypes can be produced in days, not weeks, using the actual production materials—allowing for functional testing and regulatory compliance evaluation.

- Speed to Market: Accelerates product development cycles by eliminating tooling delays, providing immediate feedback and design iteration.

- Material Authenticity: Prototypes match final production material properties, delivering accurate performance data.

- Customization: Enables rapid changes and personalization for specific applications or market segments.

Applications in Various Industries

Automotive

TR produces precision plastic components such as gears, housings, dashboard assemblies, and sensor enclosures for automotive OEMs and Tier 1 suppliers. CNC machining ensures dimensional accuracy and material performance essential for safety and reliability.

Medical Devices

Medical manufacturers rely on TR’s expertise for parts like instrument handles, diagnostic housings, and implant prototypes. The company’s adherence to ISO 13485 quality standards and biocompatible plastics makes it a preferred partner for healthcare innovation.

Electronics

Enclosures, insulators, and custom connectors for electronics require tight tolerances and intricate features, which CNC machining delivers. TR works with flame-retardant and ESD-safe plastics to meet industry standards.

Aerospace

Lightweight, high-strength plastic components for aerospace applications must meet rigorous specifications. TiRapid’s precision CNC capabilities provide mission-critical reliability for cabin interiors, UAVs, and instrumentation panels.

Process Optimization and Automation

TR continually refines its CNC machining processes to enhance efficiency and reduce costs. Automation technologies such as robotic part loading/unloading, real-time condition monitoring, and predictive maintenance are integrated into production lines. Advanced simulation tools enable virtual prototyping, reducing risk and time-to-market for new plastic products.

Lean manufacturing principles are embedded in TR’s operations—reducing setup times, improving workflow, and maximizing resource utilization. These strategies help clients achieve competitive pricing without compromising quality or lead time.

Material Selection and Machinability Considerations

The choice of plastic material is crucial for the functional and aesthetic properties of machined parts. TiRapid supports clients in selecting the optimal polymer based on mechanical strength, chemical resistance, thermal stability, and cost-effectiveness.

| Plastic Type | Characteristics | Typical Applications |

|---|---|---|

| ABS | Impact resistance, easy to machine | Prototypes, enclosures |

| Polycarbonate | High strength, clear, tough | Windows, shields, medical devices |

| Nylon | Low friction, good wear resistance | Gears, bushings |

| POM (Delrin) | High stiffness, dimensional stability | Precision parts |

| PEEK | Excellent chemical/thermal resistance | Aerospace, medical implants |

Each material requires unique tooling, spindle speeds, and cooling strategies. TR’s experience ensures optimal outcomes regardless of material complexity.

Design Guidelines for CNC Machined Plastic Parts

To maximize manufacturability and reduce costs, TiRapid works with clients to adhere to best-practice design guidelines. These include:

- Maintain uniform wall thickness to prevent warping or stress concentrations.

- Avoid excessively thin sections, which can lead to breakage or deformation during machining.

- Incorporate radii in corners to reduce tool wear and improve material flow.

- Design for accessibility, ensuring features can be reached by cutting tools.

- Specify tolerances realistically, balancing precision and production efficiency.

TR provides DFM (Design for Manufacturability) feedback to optimize plastic parts for CNC machining, shortening lead times and ensuring reliable production.

Quality Assurance and Traceability

Quality is the cornerstone of TiRapid’s CNC machining service. The company employs rigorous inspection protocols at every stage of production, from material verification to in-process measurements and final part audits.

- Use of calibrated metrology equipment, including CMMs and optical scanners.

- Lot traceability for materials and process parameters.

- Documented first-article inspection reports for critical applications.

- Compliance with industry standards (ISO 9001, ISO 13485).

Client satisfaction is ensured through transparent communication, detailed reporting, and continuous improvement initiatives.

Comparing CNC Machining to Other Plastic Manufacturing Techniques

While CNC machining offers distinct advantages, it is essential to understand its position relative to alternative plastic manufacturing methods such as injection molding, 3D printing, and vacuum forming.

| Method | Strengths | Limitations |

|---|---|---|

| CNC Machining | Precision, flexibility, material range, no tooling required | Higher per-part cost for large volumes |

| Injection Molding | Low cost for high volumes, repeatability | High upfront tooling cost, less design flexibility |

| 3D Printing | Rapid iteration, complex shapes | Limited material properties, slower for production runs |

| Vacuum Forming | Low tooling cost, suitable for large parts | Limited detail, material thickness constraints |

TiRapid assists clients in evaluating these options, often integrating CNC machining with other processes to create hybrid solutions that balance cost, quality, and lead time.

Environmental and Sustainability Considerations

Modern manufacturing must address environmental impact and sustainability. TR minimizes waste through efficient toolpaths, recycling initiatives, and responsible material sourcing. The precision of CNC machining means less scrap and greater utilization of raw materials. Additionally, TR supports clients in selecting recyclable and biocompatible plastics, contributing to circular economy goals.

Aftermarket Support and Value-Added Services

TiRapid’s commitment extends beyond production. Clients benefit from post-machining services including part finishing, assembly, packaging, and logistics. Secondary operations such as polishing, painting, laser engraving, and ultrasonic welding ensure that machined plastic parts meet cosmetic and functional requirements.

TR also offers consulting on regulatory compliance, supply chain optimization, and inventory management, helping clients streamline their operations and reduce total cost of ownership.

Case Studies: Success Stories from TiRapid

TiRapid’s portfolio features collaborations with industry leaders on projects where CNC machining for plastics proved transformative. Examples include:

- Medical Device Launch: Accelerated prototyping and regulatory testing for a new diagnostic instrument, reducing time-to-market by 30%.

- Automotive Lightweighting: High-precision nylon gears replacing metal equivalents, lowering vehicle weight and improving fuel efficiency.

- Aerospace Innovation: Machined PEEK brackets for avionics, meeting stringent thermal and structural requirements.

- Consumer Electronics: Custom polycarbonate enclosures for a next-gen smart device, merging functionality with sleek aesthetics.

These stories demonstrate TR’s role as a strategic partner, enabling clients to achieve breakthroughs through advanced CNC plastic machining.

Future Trends: The Evolution of CNC Machining for Plastics

The future of CNC machining for plastics is driven by digital transformation, material innovation, and integration with emerging manufacturing technologies. TiRapid embraces trends such as:

- Digital Twins and IoT: Real-time monitoring and adaptive control of CNC machines, enhancing process reliability and data-driven decision-making.

- Advanced Materials: Machining of composites, nanomaterials, and bio-based plastics for next-generation applications.

- Hybrid Manufacturing: Integration of CNC machining with additive manufacturing for complex assemblies and functional prototyping.

- Automation and AI: Intelligent scheduling, predictive maintenance, and autonomous quality inspection.

TR’s ongoing investment in research, technology, and talent ensures its clients are ready to capitalize on these opportunities as the landscape evolves.

Partnering with TiRapid: Why Choose TR for CNC Machined Plastics?

Choosing TiRapid means partnering with a company that combines technological leadership, deep expertise, and a relentless commitment to customer success. Whether for prototyping, custom production, or large-scale manufacturing, TR delivers solutions that meet the highest standards for quality, speed, and value. Clients benefit from transparent communication, flexible engagement models, and access to the latest innovations in CNC plastic machining.