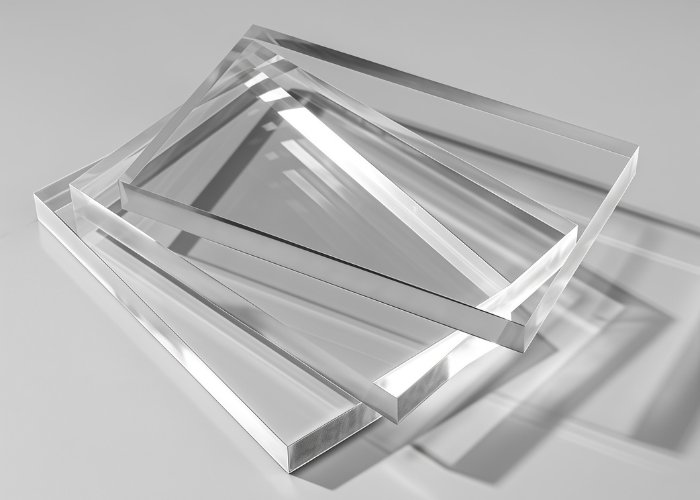

Acrylic is a lightweight, crystal-clear, and highly durable plastic widely used across industries. Known for its glass-like clarity, strong impact resistance, and easy machinability, it has become a preferred material for signage, displays, lighting, furniture, and protective panels. This guide explores the essential properties of acrylic, its benefits, major types, and the many ways it is used in modern manufacturing and design.

What Is Acrylic Material

Acrylic, also known as PMMA, is a transparent thermoplastic widely used as a lightweight and durable alternative to glass. Its high clarity, impact resistance, and easy formability make it ideal for signage, displays, lighting, and countless commercial and industrial applications.

Get 20% offf

Your First Order

Acrylic is a synthetic polymer made from methyl methacrylate (MMA) monomers. As a thermoplastic, it softens when heated and returns to a solid, rigid state once cooled, allowing it to be molded into sheets, rods, tubes, and custom shapes. Acrylic provides optical clarity of up to 92% light transmission, which is higher than standard glass, and maintains transparency without yellowing over time.

Compared with polycarbonate, acrylic offers better clarity and scratch resistance, though with slightly lower impact strength—making it suitable for applications where visibility and aesthetics matter more than heavy-duty impact resistance. Since its invention in 1928, acrylic has become essential in industries such as retail displays, aquariums, automotive lighting, and architectural design.

Acrylic is produced through the polymerization of hydrocarbon derivatives, combining MMA monomers with catalysts to form PMMA resin. This resin is then processed into cast or extruded acrylic sheets, each offering different tolerances, clarity, and structural behavior. In my own experience working with display fabrication clients, acrylic is often preferred because it provides reliable dimensional stability while still being easy to laser-cut, CNC-machine, polish, or thermoform.

Key Material Properties of Acrylic

Acrylic is valued for its clarity, strength, and versatility, making it a preferred material for displays, lighting, protective covers, and engineering components. Understanding its key material properties helps determine where acrylic performs best and why it is widely used across industries.

Optical Clarity (Up to 92% Light Transmission)

Acrylic provides outstanding optical transparency, allowing up to 92% of visible light to pass through—higher than most glass materials. This exceptional clarity makes it ideal for signage, display cases, lenses, and lighting panels, and it maintains excellent transparency even after CNC machining or polishing.

Impact Resistance (10–17× Stronger Than Glass)

Acrylic is far more impact-resistant than glass, offering 10× the strength of standard glass and up to 17× for modified grades. It does not shatter easily, making it suitable for protective barriers, machine guards, museum enclosures, and applications requiring both clarity and durability.

Lightweight Structure (50% Lighter Than Glass)

Acrylic weighs only half as much as glass, making it easier to transport, lift, and install. This lightweight advantage is especially beneficial for large signage systems, architectural panels, and retail displays where weight reduction improves handling and safety.

UV and Weather Resistance

Acrylic resists UV radiation and long-term weathering, maintaining clarity without yellowing. This durability makes it a reliable choice for outdoor signage, skylights, marine panels, and exterior lighting components that must withstand harsh environmental conditions.

Temperature Stability

Acrylic performs well under temperature changes, with a typical operating range of –20°C to 80°C. It resists warping or cracking when exposed to hot–cold cycles, which is why it is used in medical devices, laboratory equipment, and food-service components that face frequent thermal variation.

Chemical Resistance

Acrylic withstands exposure to many acids, salts, and cleaning solutions, making it suitable for laboratory manifolds, microfluidic components, and equipment housings. Its chemical stability also enables easy cleaning and sterilization without material degradation.

Machinability and Formability

As a thermoplastic, acrylic softens when heated and hardens when cooled, allowing for precise CNC machining, laser cutting, thermoforming, bending, and polishing. It offers excellent dimensional stability and smooth surface finishes, making it ideal for custom display parts, engineering prototypes, and architectural designs.

Chemical Properties of Acrylic

Acrylic’s chemical properties play a major role in its durability, clarity, and versatility. As a polymer made from methyl methacrylate (MMA), acrylic forms long molecular chains that create a strong, stable thermoplastic. These chemical characteristics make acrylic suitable for signage, medical devices, lighting, and fluid-handling applications.

Polymer Structure and MMA Composition

Acrylic (PMMA) is produced by polymerizing methyl methacrylate monomers into long, repeating chains. This structure gives acrylic its rigidity, excellent clarity, and strong resistance to environmental stress. Its chemical formula, C₅H₈O₂, explains why it maintains optical purity without yellowing over time.

High Chemical Resistance

Acrylic resists a wide range of chemicals, including diluted acids, alkalis, detergents, and salts. This makes it useful for laboratory manifolds, display covers, food-service containers, and microfluidic devices. However, strong solvents such as acetone and alcohols may cause crazing or surface whitening.

Hydrophobic and Non-Absorbent Properties

Acrylic is naturally hydrophobic, meaning it does not absorb water or swell when exposed to moisture. This allows acrylic signage, display cases, and outdoor panels to remain stable in humid or rainy environments without degrading, warping, or clouding.

Thermal Sensitivity and Operating Range

Acrylic softens when heated, with a melting point around 160°C and a heat-deflection temperature near 95°C. While it handles typical temperature changes well, extreme heat can cause deformation. In my CNC machining experience, maintaining coolant flow and slow feed rates prevents thermal cracking during milling.

UV Stability and Weather Resistance

Unlike many plastics, acrylic has strong natural resistance to UV radiation. It does not yellow or break down easily, making it ideal for skylights, outdoor signs, machine guards, and aquarium windows. UV-modified PMMA grades can extend lifespan to over 10+ years outdoors.

Electrical and Static Properties

Acrylic is an electrical insulator, which makes it suitable for electronic housings, lighting diffusers, and protective covers. Anti-static acrylic sheets—used often in automation equipment I’ve handled—reduce dust attraction, improving clarity and product performance.

Types of Acrylic Material

Acrylic materials come in several types, each engineered for different performance needs such as clarity, strength, flexibility, and weather resistance. From cast acrylic with superior optical quality to impact-modified versions used in high-stress environments, choosing the right type ensures the best results for signage, displays, engineering parts, and consumer products.

Cast Acrylic (Cell-Cast PMMA)

Cast acrylic is produced by pouring liquid MMA into molds and allowing it to cure. This slow curing process creates a material with excellent optical clarity, high surface hardness, and minimal internal stress. I often use cast acrylic for CNC-machined displays and premium signage because it cuts cleanly and resists cracking.

Key Characteristics:

• Superior clarity (92% light transmission)

• Better scratch resistance

• Ideal for machining, laser cutting, and polishing

Typical Applications:

• High-end retail displays

• Aquariums

• Light diffusers

• Precision optical components

Extruded Acrylic

Extruded acrylic is manufactured by pushing molten acrylic through rollers to form sheets. This process makes it more cost-effective and easier to thermoform, but slightly lower in hardness compared to cast acrylic.

Key Characteristics:

• Lower cost

• Consistent thickness

• Easier to bend and thermoform

Typical Applications:

• Brochure holders

• Point-of-sale displays

• Protective covers

• Acrylic sign holders (e.g., 8.5 x 11 displays)

Colored, Frosted, Mirrored Acrylic

Acrylic sheets can be modified with pigments, surface textures, or reflective coatings. These variations enhance both aesthetics and functionality. In signage projects I’ve handled, frosted sheets always perform well in environments needing soft, diffused lighting.

Key Characteristics:

• Wide color range

• Optional matte, glossy, or reflective surfaces

• Excellent for brand visuals and decorative purposes

Typical Applications:

• Retail signage and lettering

• Interior décor

• Light diffusing panels

• Display cases

Specialty Acrylic (Impact-Modified, UV-Protected, Anti-Static)

Specialty acrylics are engineered for demanding environments. Impact-modified acrylic provides toughness similar to polycarbonate, while UV-protected grades resist yellowing for long-term outdoor exposure. Anti-static sheets are widely used in electronics manufacturing.

Key Characteristics:

• Up to 10–15× the impact resistance of standard acrylic

• Long-term UV stability (over 10+ years outdoors)

• Reduced dust attraction for clean environments

Typical Applications:

• Machine guards

• Outdoor signboards

• LED lighting fixtures

• Electronic equipment covers

Benefits of Acrylic

Acrylic stands out as one of the most versatile materials thanks to its clarity, strength, and ease of fabrication. Whether used in signage, displays, engineering components, or consumer décor, acrylic delivers a unique blend of performance and affordability that makes it a preferred alternative to glass in many industries.

Glass-Like Clarity

Acrylic offers exceptional optical transparency, transmitting up to 92% of visible light, surpassing standard glass in clarity. This makes it ideal for signage, display covers, windows, and lighting applications where visual quality is critical.

Half the Weight of Glass

Even with similar transparency, acrylic weighs 50% less than glass, making it easier to handle, transport, and install. This also reduces structural load in architectural and furniture uses.

Shatter-Resistant

Acrylic is 10–17× more impact-resistant than glass, significantly reducing the risk of breakage. Instead of shattering into sharp pieces, it tends to crack safely—making it suitable for public spaces, retail, and protective barriers.

Easy to Cut, Machine, Bend

Acrylic is one of the most fabrication-friendly plastics. It can be CNC-machined, laser-cut, drilled, or thermoformed with consistent results. I’ve seen acrylic maintain excellent edge quality during CNC routing, even in intricate display designs.

Cost-Effective

Compared to glass or polycarbonate, acrylic provides an excellent balance of cost and performance. It offers premium clarity and strength without the high cost of engineering plastics.

Strong Indoor & Outdoor Durability

Acrylic is resistant to UV radiation, moisture, and temperature changes. High-quality sheets can remain clear for 10+ years outdoors without yellowing, making them ideal for outdoor signs, lightboxes, and architectural glazing.

Applications of Acrylic

Acrylic is widely used across industrial, commercial, consumer, and artistic fields thanks to its clarity, durability, and easy fabrication. From automotive lighting to museum displays and large aquariums, acrylic provides a lightweight yet strong solution where visibility and impact resistance are essential.

| Category | Typical Applications | Examples / Why Acrylic Is Used |

| Industrial Applications | Automotive lighting & panels | High clarity, excellent impact resistance, lightweight for better vehicle efficiency |

| Aerospace windows | UV resistance, reduced weight compared to glass, high optical clarity | |

| Machine guards | Shatter-resistant, safe for operators, easy to fabricate into protective covers | |

| Consumer Products | Home décor & furniture | Modern appearance, customizable colors, easy shaping for creative designs |

| Storage boxes | Lightweight, durable, moisture-resistant for long-term use | |

| DIY crafts | Easy to cut and engrave; ideal for personalized projects | |

| Commercial Uses | Signage & displays | 92% light transmission enhances visibility; long-lasting for indoor/outdoor use |

| Retail fixtures | Elegant look, strong enough for daily commercial wear | |

| Menu holders & brochure stands | Clear visibility, easy to clean, widely used in restaurants and hotels | |

| Art and Design | Sculptures | Allows vibrant colors and complex shapes; highly durable |

| Lighting diffusers | Distributes light evenly; used in LED fixtures | |

| Museum display cases | High clarity, protects artifacts, offers UV resistance | |

| Aquarium Applications | Large tanks | Stronger and lighter than glass; can form seamless curved panels |

| Seamless clear panels | Better viewing experience, superior impact resistance |

Design and Processing Considerations

Designing with acrylic requires understanding its material behavior—how it bends, bonds, expands, and reacts to heat. Proper thickness selection, machining allowances, and surface finishing methods ensure clarity, accuracy, and long-term durability in both structural and decorative applications.

| Design / Processing Aspect | Key Points | Why It Matters |

| Thickness Selection | Common thickness ranges: 2–20 mm; structural parts often 8 mm+ | Thicker sheets offer higher strength and reduce bending; ideal for signage, aquariums, and load-bearing panels |

| Bending & Heat Forming Limits | Heat forming temperature: 140–170°C; minimum bend radius ≈ sheet thickness × 150% | Prevents cracking or whitening; ensures smooth curves for displays, lightboxes, and covers |

| Machining Tolerances | Typical CNC tolerance: ±0.1–0.2 mm; laser-cut edges highly accurate | Ensures precision fit for fixtures, holders, and assembled components |

| Bonding & Joining | Solvent welding, UV glue, and mechanical fasteners | Achieves invisible joints in displays; proper bonding prevents stress cracks |

| Surface Finishing Options | Polishing, flame polishing, sanding, matte finishing | Enhances transparency, removes machining marks, improves aesthetics |

Acrylic vs Other Transparent Materials

Acrylic is often compared with polycarbonate and glass because all three offer transparency but differ greatly in weight, strength, cost, and processing behavior. Understanding these differences helps you select the best material for displays, protective covers, lighting panels, and architectural applications.

Acrylic vs Polycarbonate

Acrylic provides exceptional clarity, transmitting up to 92% visible light—higher than polycarbonate. While PC is far stronger, offering 200–250× the impact resistance of glass, acrylic is easier to cut, laser, and polish. Polycarbonate tends to scratch easily unless coated, whereas acrylic maintains better surface clarity. Acrylic is also significantly more cost-effective, making it ideal for displays, signage, and decorative applications, while PC is preferred for safety shields and high-impact environments.

Acrylic vs Glass

Acrylic is about 50% lighter than glass yet up to 17× more impact-resistant, offering much safer performance when breakage is a concern. Glass is more scratch-resistant and provides excellent heat stability, but it is heavier, brittle, and harder to machine. Acrylic’s lighter weight and easier fabrication make it the preferred choice for large signs, retail fixtures, aquariums, and architectural panels where custom shapes or reduced load are needed.

Cost, Clarity, and Strength Comparison

Acrylic offers the best balance among the three materials. It has the highest optical clarity, lower cost than polycarbonate, and far better impact resistance than glass. For projects requiring excellent transparency, lower weight, and customization flexibility, acrylic provides strong performance without high cost. When maximum strength is required, polycarbonate wins; when scratch resistance and heat tolerance matter most, glass may be preferred.

How to Choose the Right Acrylic Type

Selecting the right acrylic type depends on clarity requirements, mechanical strength, fabrication method, budget, and whether the material will be used indoors or outdoors. Understanding these factors ensures that the final product meets both visual and functional expectations.

Based on Clarity, Strength, and Application

For the highest clarity and visual performance, cast acrylic is the better choice because it offers superior optical purity. For applications requiring higher impact resistance—such as protective shields or machine guards—impact-modified acrylic or polycarbonate may be more appropriate. Decorative uses can rely on colored, frosted, or textured acrylics for enhanced aesthetics.

Cast vs Extruded Acrylic

Cast acrylic is known for better transparency, stability, and machinability. It performs well in CNC cutting and polishing without melting. Extruded acrylic is more affordable and has consistent thickness, making it suitable for large-volume projects or simple laser-cut shapes. If you need deep bending or uniform heating, extruded acrylic may be easier to work with.

Indoor vs Outdoor Requirements

For outdoor signage, lightboxes, and architectural panels, UV-resistant cast acrylic provides better weathering performance and resists yellowing for many years. For indoor displays, menu holders, furniture parts, or DIY crafts, standard cast or extruded acrylic is usually sufficient. Outdoor environments benefit from thicker sheets (6–10 mm+), while indoor decorative pieces can use

FAQs

What Are The Properties Of Acrylic?

The properties of acrylic include high optical clarity, light weight, good mechanical strength, and excellent weather resistance. Acrylic offers up to 92% light transmission, is about 50% lighter than glass, and maintains stable performance in indoor and outdoor environments. These material properties of acrylic make it ideal for transparent structural and display applications.

What Are The Physical And Chemical Properties Of Acrylic?

The physical properties of acrylic plastic include high transparency, low water absorption (around 0.2–0.5%), good surface hardness, and dimensional stability.

The chemical properties of acrylic include strong resistance to UV radiation, moisture, and many mild chemicals, while remaining BPA-free and non-toxic. Together, these physical and chemical properties of acrylic support long-term durability and safe use in commercial products.

What Are The Mechanical Properties Of Acrylic Sheet?

The mechanical properties of acrylic sheet include good tensile strength, moderate impact resistance, and rigidity suitable for structural panels. Acrylic provides approximately 10–17 times the impact resistance of glass, though it is less impact-resistant than polycarbonate. These mechanical properties of acrylic make it suitable for guards, covers, and enclosures where clarity and strength must be balanced.

What Is One Important Property Of Acrylic?

One important property of acrylic is its exceptional optical clarity combined with ease of fabrication. Acrylic can be cut, machined, thermoformed, and polished without losing transparency, which is why it is widely used for displays, signage, and light-diffusing components

What Are 3 Properties Of Acrylic?

Three key properties of acrylic are:

• High light transmission (up to 92%)

• Low water absorption and good weather resistance

• Easy machining and thermoforming

These properties explain why acrylic glass is widely used in both industrial and consumer products.

What Are 4 Properties Of Acrylic?

Four commonly recognized properties and characteristics of acrylic are:

• Excellent transparency and surface finish

• Lightweight compared to glass

• Good mechanical strength and rigidity

• Resistance to UV aging and yellowing

These properties of acrylic plastic support long service life in outdoor and indoor applications.

What Is The Properties And Uses Of Acrylic?

The properties and uses of acrylic are closely connected. Because acrylic is clear, lightweight, and easy to fabricate, it is widely used for signage, display stands, aquariums, lighting panels, machine guards, and architectural glazing. The uses and properties of acrylic plastic make it one of the most versatile transparent materials in manufacturing.

What Is Acrylic State And Material Structure?

Acrylic is a solid thermoplastic polymer, commonly known as acrylic glass or PMMA. The properties of acrylic polymer come from its amorphous structure, which allows high transparency and uniform mechanical performance without crystallization.

Is Acrylic Healthier Than Plastic?

Acrylic is considered safer than many plastics because it is BPA-free, non-toxic, and releases very low VOCs during normal use. I often recommend acrylic sheets for food displays, medical housings, and cosmetic organizers. However, it should not be used for hot food containers due to thermal softening above 90–100°C

Is Acrylic Plastic Unbreakable?

Acrylic is not unbreakable, but it is significantly stronger than glass. Its mechanical properties allow it to resist impact far better than standard glass, making it safer for protective panels and guards, although extreme force can still cause cracking.

Does Acrylic Absorb Water?

Acrylic has very low water absorption, typically below 0.5%. This physical property of acrylic sheet prevents swelling, warping, and degradation, which is why acrylic performs well in aquariums, outdoor signage, and laboratory environments.

Conclusion

Acrylic has proven itself as one of the most versatile transparent materials used today, offering a unique balance of clarity, strength, light weight, and easy processing. Whether used in signage, consumer products, industrial components, or architectural designs, its performance continues to stand out across applications.