In my years of CNC programming and production experience, the Post processors remains a crucial yet often overlooked aspect. Many assume that tool paths generated by CAM software can be run directly, but different machine tools and controllers have varying code format requirements . This article will provide a practical understanding of what a CNC Post processors is, why it’s so important, its evolution, and how to edit and optimize it for different machines. Through this experience, you’ll understand that a customized Post processors is more than just a “translator”; it’s a key tool for improving efficiency, stability, and scalability.

What Is A CNC Post processors

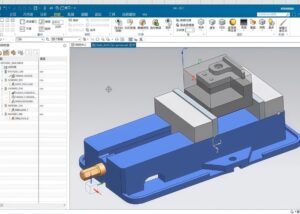

During CNC machining, designers typically use CAD/CAM software to model and generate tool paths, but machine tools cannot directly understand this data. CNC post processors are a key component in solving this problem. Their core function is to convert tool path files in neutral formats (such as CLDATA or APT) into G-code that can be executed by specific machine tool controllers , automatically adjusting to the characteristics of different machines, machining practices, and safety regulations.

In my years of experience in process programming, I’ve learned that the impact of a Post processors goes far beyond the mere “translator.” It can automatically optimize tool paths, predict coding errors, and match spindle gears and coolant types, thereby mitigating operational risks and improving production efficiency. An optimized Post processors can reduce redundant program motion by 10% to 30%, extend tool life by approximately 15%, and increase overall production cycle time by 5% to 20%.

In other words, without a post-processor, even the most advanced CAD/CAM software cannot directly drive a machine tool. A good post-processor is the core tool for ensuring machining stability, precision consistency, and optimized production capacity.

How CNC post processors Work

Understanding how a CNC Post processors works means understanding how it converts generic tool path data into G-code executable by a specific machine tool. CAM software typically outputs neutral language files (such as CLDATA or APT) containing information such as tool motion, feedrate, and cutting parameters. However, this data cannot be directly executed on a machine tool because different CNC systems (such as Fanuc, Siemens, and Heidenhain) use different G-code formats, function commands, and safety logic.

The core function of a Post processors is to “translate and optimize” the neutral file based on the characteristics of the target machine tool. It not only outputs the correct code syntax but also adjusts tool change sequence, spindle speed, coolant on/off logic, and other parameters based on the machine’s characteristics. For example, the G-code segments commonly used in Fanuc systems are completely different from the cycle instructions used by Siemens. If run directly without processing, they are prone to tool collisions or program errors.

Furthermore, modern post processors are more than just “translators”; they can also intelligently optimize the entire program, such as merging idle strokes, selecting the next tool in advance, and optimizing the tool feed and retract paths, thereby improving machining efficiency and machine tool life. For multi-axis machine tools, post processors also need to consider factors such as kinematic differences, tool axis linkage limitations, and coordinate system compensation to ensure that the output path is both efficient and safe.

This is why the same tool path file requires different post-processors on different control systems – it ensures seamless connection from virtual machining simulation to actual machine tool operation, while bringing machining efficiency and stability to a new level.

Why Are CNC post processors So Important

In CNC machining, many people focus on tools, machines, and programming, but often overlook a crucial role: the CNC Post processors . It not only “translates” the tool path files generated by CAM software into G-code understood by the machine tool, but also serves as an intelligent optimization tool that automatically adjusts spindle gears, optimizes tool paths, sets coolant parameters, and proactively detects potential logic errors during program generation. For businesses, a high-quality Post processors not only mitigates operational risks but also improves efficiency, extends tool life, and ensures machining stability. It is a key component in achieving efficient and precise manufacturing.

For example, it will automatically optimize the tool path , reduce unnecessary idling and repeated cutting. According to my experience, this can shorten the idle time of the machine tool by 10% to 25% . It will automatically adjust the spindle gear so that the equipment always operates in the appropriate speed and torque range to avoid power overload or poor cutting . At the same time, it can also optimize coolant usage and feed parameters according to the processing material and tool characteristics to improve cutting stability.

More importantly, the Post processors can also detect potential errors in advance , such as tool compensation not being activated, feed motion being executed when the spindle is stopped, program segment logic conflicts, etc. If these problems are sent directly to the machine tool, at best they will cause downtime and rework, at worst they will damage the tool or even the workpiece.

From a business perspective, an optimized CNC Post processors can bring significant production benefits : productivity increases of 5% to 20%, tool life extensions of 10% to 15%, and program debugging time reductions of 30% to 50%. This translates to faster delivery, lower scrap rates, and more stable quality output, all crucial for a manufacturing company’s competitiveness.

Common Post –Processor Types

In daily production, CNC post processors can be divided into two categories: general-purpose and customized. General-purpose post processors are typically included with CAM software and can quickly generate usable G-code for common three-axis milling machines or lathes, making them suitable for general machining scenarios. Their advantages are ease of use and wide compatibility. However, when encountering complex parts, specialized cutting strategies, or multi-axis machining, manual code modification is often required, increasing debugging time.

In contrast, customized post processors are optimized for specific machine models, control systems, and machining processes. For example, Fanuc, Siemens, and Heidenhain control systems have different syntaxes. Using a common Post processors can lead to macro incompatibility or tool path execution errors. Customized post processors ensure that the code perfectly matches the machine’s characteristics and implement automatic tool compensation, coordinate transformations, and safety strategies according to company standards.

As the demands of complex manufacturing grow, specialized post processors for robotics, five-axis machine tools, and mill-turn machines are becoming increasingly important. Robotic machining requires multi-degree-of-freedom trajectory optimization and workspace constraints, five-axis machine tools involve tool axis vector control and dynamic rotation compensation, and mill-turn machines must handle a mix of rotational and linear interpolation instructions. These advanced applications place higher demands on post processors, requiring them to go beyond simply “translating” code and instead integrate mathematical algorithms with machine tool kinematics to create comprehensive solutions.

From my experience, if companies want to improve production efficiency and stability, customized post-processors are almost a must, especially for five-axis and robot machining projects. They can significantly reduce debugging time and increase the success rate of first-time machining.

The Development History Of CNC post processors

In the field of CNC machining, the concept of post processors is not new. Early CNC post processors were simply “translators,” converting neutral tool path data (such as APT and CLDATA) generated by CAM software into G-code and M-code understandable by machine tools. However, with the increasing popularity of five-axis machining, automatic tool changers, robotic machining, and unmanned production, simple interface conversion can no longer meet the demands of modern manufacturing.

Throughout this process, post processors have gradually evolved into the core of intelligent machining code optimization . Today’s post processors not only perform basic language conversion but also offer capabilities such as dynamic tool path adjustment, automatic optimization of spindle speed and gear, coolant parameter selection, and cycle instruction optimization. They can even precheck for logical errors during code generation to prevent machine tool shutdowns or collisions due to erroneous instructions.

International efforts have attempted to unify output formats and control languages through standards such as ISO, ANSI, and EIA . However, due to the significant differences between machine tool brands, controller models, and process practices, these standards have always been unable to fully resolve compatibility issues. Consequently, demand for customized post processors is growing . Data shows that among manufacturers with multi-brand and multi-model equipment, over 70% of CAM programs require post processors to be adjusted or rewritten based on the machine tool’s characteristics to ensure stable and secure operation.

This development process shows that the post-processor has been upgraded from an “auxiliary role” to one of the core tools of modern intelligent manufacturing . Its role is not only “connection”, but also “optimization” and “guarantee”.

How To Edit A Post Processor

In CNC machining, editing the Post processors is a critical step in ensuring that programs run seamlessly on different machine tools. While most CAM software comes with universal Post processors templates, these templates are often just “standard versions” and don’t fully meet the individual needs of all equipment and processes. Therefore, learning how to edit the Post processors not only improves machining efficiency but also reduces the risk of errors.

Common Editing Methods

The mainstream editing methods on the market currently include:

Fusion 360 / Auto desk : Built-in Visual Studio Code extension, which can directly modify and debug post-processor logic, support parametric adjustment and customized processing strategies.

CAM Works / Solid CAM : Equipped with a graphical Universal Post Generator, it is suitable for engineers who do not understand programming. Customized post-processors can be generated by dragging and dropping on the interface and selecting parameters.

RoboDK : Provides an independent post-processor editor for robots and CNC equipment, supports cross-platform and multi-axis machining, and is highly flexible.

Power MILL, Bob CAD-CAM, Gibbs CAM : Most of them use text or special software editing methods, which are biased towards traditional programmers and require understanding of specific syntax structures.

Application Purpose And Value:

The ultimate goal of editing a Post processors is to ensure that the generated G-code perfectly matches the specific machine characteristics and on-site process requirements. For example, this can include optimizing tool change sequences, adjusting spindle speed logic, controlling coolant commands, or adding safe move instructions. A tuned Post processors not only avoids invalid motions and potential errors but also improves tool path smoothness and execution efficiency.

In my experience, a Post processors optimized for a five-axis machine tool reduced program execution time by approximately 12% and reduced the risk of two machine emergency stops, which is particularly critical for mass production.

The Impact Of Post-Processors On Production Efficiency

In my work, the productivity gains of a CNC Post processors are obvious. It’s more than just a translation of neutral CLDATA or APT code into machine-readable G-code; it acts as a tailor-made optimization expert for the machining process. The Post processors automatically optimizes tool paths, minimizing idle strokes and reducing unnecessary tool changes.

For example, in a complex five-axis part machining project, by optimizing the tool path, we shortened the tool change time by approximately 20% and increased the overall machining cycle by more than 15%.

Furthermore, the Post processors automatically detects potential logic errors during code generation, such as unselected tools or incompatible coolant types, eliminating risks before the machine even starts. Common problems such as tool collisions and air cuts have decreased by over 80% since the Post processors with intelligent verification was enabled. This preventative capability directly translates into improved production efficiency and stability, while also reducing downtime and repair costs caused by errors.

From a business perspective, a Post processors is more than just a software tool; it’s a critical component in ensuring smooth production line operation. Whether it’s complex multi-axis parts or batch production of standard parts, a properly tuned Post processors maximizes the potential of machine tools, enabling faster and more stable production.

| Impact Area | Optimization Measures | Results |

| tool path Optimization | Automatically optimizes tool paths, reduces idle travel | Shorter cycle times, overall efficiency improved by 15% |

| Reduced Tool Change Time | Adjusts tool change sequence, eliminates unnecessary changes | Tool change time reduced by about 20% |

| Logic Error Detection | Automatically checks for tool selection and coolant type mismatches | Collisions and air cuts reduced by 80%+ |

| Risk Prevention | Eliminates potential issues before machine start | Reduced downtime, tool damage, and scrap risk |

| Stability and Cost | Optimizes process flow and reduces downtime | Improved stability and lower maintenance/repair costs |

| Overall Business Value | Applicable to complex multi-axis and batch production | Maximizes machine potential for faster, more stable production |

Choosing The Right Post processors

How do you choose the right CNC Post processors? This is a question I’m often asked. The answer isn’t a one-size-fits-all approach; it depends on a comprehensive assessment based on your machine type, process complexity, and your company’s technical capabilities. A Post processors does more than simply convert the neutral code generated by CAM software into G-code that the machine can understand. It also directly impacts machining efficiency, accuracy, and scalability.

I will judge from three perspectives:

The matching degree between the machine tool and the control system : Different control systems (such as Fanuc, Siemens, and Heidenhain) have significant differences in instructions. Choosing a post-processor with a high matching degree can avoid additional manual modifications.

Functionality and scalability : Does the factory support five-axis simultaneous machining, mill-turning, or robotic machining? Is it easy to upgrade in the future? These factors determine the factory’s technological potential.

Maintenance cost and ease of use : Graphical and parametric post-processors are easier to use and have low subsequent maintenance costs, while complex custom codes may require dedicated maintenance.

The choice can be to build your own (complete control over functionality, but high costs), outsource (mature and stable, suitable for most companies), or develop a third-party (flexible customization, moderate cost and risk).

In my experience, choosing the right post-processor can often reduce debugging time by more than 30% and improve overall production stability.

Application Scenarios And Value Realization

In modern manufacturing, the application of CNC post processors has expanded far beyond traditional three-axis machine tools. From desktop high-precision devices like the Pocket NC to complex five-axis machine tools and robotic machining systems, nearly all CNC equipment requires a customized Post processors to match its unique kinematic characteristics and control logic. Without a properly configured Post processors, even the most advanced machine tools can experience machining path anomalies, low operating efficiency, or even sudden machine stops.

In my experience, using a Post processors optimized for five-axis machine tools can reduce tool changes by 20% and optimize redundant motion in machining paths, increasing production efficiency by 10% to 15%. On smaller machines like the Pocket NC, adjusting the tool compensation logic and tool change safety position in the Post processors can eliminate over 90% of program errors, ensuring the continuity of teaching and R&D projects.

Value

Improved production efficiency : Post-processors can reduce ineffective motion and optimize path logic, significantly shortening actual processing time. For mass production, this improvement often means increased output for the entire production line.

Improved stability : Customized post-processors can proactively detect and avoid logic conflicts, such as incorrect coolant calls or unusual coordinate jumps, thereby reducing the risk of emergency stops and workpiece scrapping.

Enhanced scalability : As new machine tools and new processes are introduced, the Post processors can be adapted with only minor adjustments, reducing switching costs when companies update equipment.

For me, a post-processor isn’t just a simple software plug-in, but rather an invisible guarantee of workshop efficiency and stability. The operational data from each optimization directly impacts production capacity and costs, benefiting both customers and the company.

FAQs

What Does A Post-Processor Do?

A post-processor converts neutral CAM output (like CLDATA or APT) into machine-specific G-code that matches the controller’s syntax and motion logic. In my experience, it also optimizes tool paths, spindle speeds, and coolant commands. A well-configured post-processor reduces programming time by up to 30% and improves machining accuracy and efficiency by 10%–20%.

What Is The Purpose Of The Post-Processor File?

The post-processor file defines how CAM-generated tool paths are translated into the exact G-code required for a specific CNC machine. From my work, it ensures compatibility with different controllers like Fanuc or Siemens, avoiding syntax errors and unsafe moves. This file is crucial for consistent precision and can reduce manual code edits by over 50%.

What Is NC Post Processing?

NC post processing is the process of converting CAM tool path data into machine-ready NC code. In my projects, it involves mapping motions, feed rates, and tool changes to match machine kinematics and controller capabilities. Effective NC post processing improves productivity by 10%–15% and minimizes risk of programming errors during production.

What Does A Postal Processor Do?

(This seems to be a typo; likely meant “post-processor.”) A post-processor tailors CAM output to a CNC machine’s unique requirements, producing optimized and safe G-code. I use it to ensure accurate execution of tool paths, spindle commands, and coolant settings, which saves debugging time and enhances production stability by up to 20%.

Conclusion

CNC post processors may seem like mere software tools, but they determine whether programs can run safely and efficiently on machine tools. By optimizing tool paths, reducing errors, and adapting to different equipment, they can significantly improve efficiency and stability. For manufacturers striving for high precision and high productivity, investing in Post processors optimization is not only necessary but also a key step in gaining a competitive advantage.