In today’s fast-paced manufacturing sector, achieving high precision and efficiency has become the cornerstone of competitive advantage. As global demand for intricate and reliable components rises, CNC Machining China Factory solutions have emerged as a game changer for businesses seeking to optimize their precision parts production. TIRAPID, a renowned leader in this sector, continues to set new standards in quality, speed, and cost-effectiveness.

The Rise of CNC Machining in China: A Global Perspective

China has long been recognized as the world’s manufacturing powerhouse. Over the past decade, the country has invested heavily in advanced manufacturing technologies, particularly in CNC machining. This investment has enabled Chinese factories to offer world-class precision, scalability, and flexibility at highly competitive prices. TIRAPID stands out among these, consistently delivering exceptional results for clients worldwide.

With the integration of cutting-edge software, automation, and skilled labor, China’s CNC machining factories are bridging the gap between rapid prototyping and full-scale production. This means businesses can quickly iterate product designs, reduce time-to-market, and respond more effectively to changing market demands.

uhmw machining

large cnc machining services

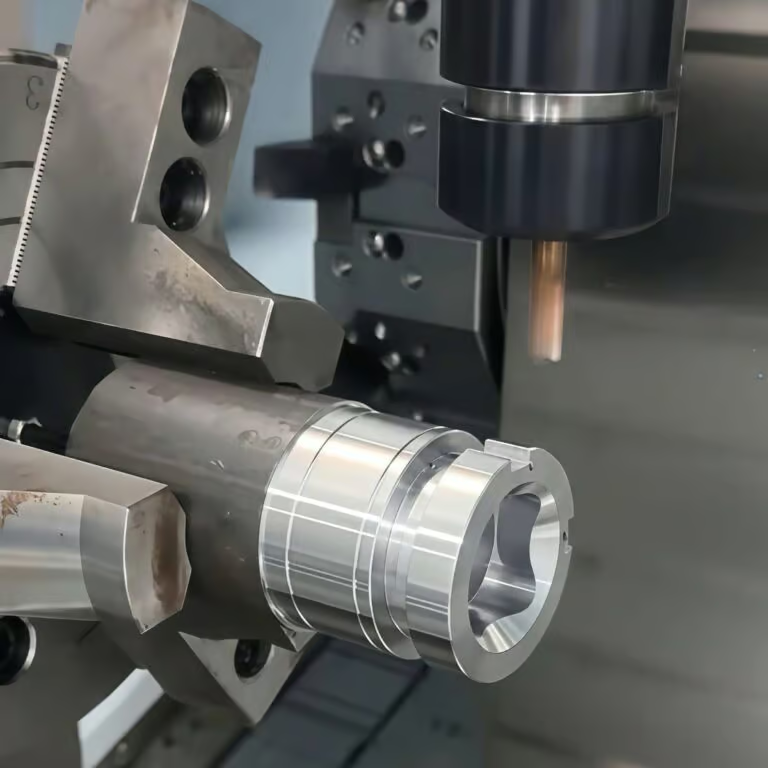

CNC machining

cnc machining services

What Sets TIRAPID Apart?

- State-of-the-art Equipment: TIRAPID invests in the latest CNC machines, including 3, 4, and 5-axis machining centers, ensuring exceptional accuracy and surface finish.

- Experienced Engineering Team: Their engineers possess deep expertise in materials science, CAD/CAM programming, and process optimization.

- Comprehensive Quality Control: TIRAPID employs rigorous inspection protocols, including CMM (Coordinate Measuring Machine) and advanced metrology tools, to guarantee every part meets exact specifications.

- Flexible Production Volumes: Whether you need a single prototype or thousands of end-use parts, TIRAPID can scale production seamlessly.

- Global Logistics Support: Efficient supply chain management ensures timely delivery to clients across North America, Europe, and beyond.

Precision Parts Production: Meeting Modern Industry Demands

Precision parts are essential in sectors like aerospace, automotive, medical devices, and electronics. These industries demand components with tight tolerances, complex geometries, and impeccable surface finishes. TIRAPID’s CNC Machining China Factory excels in meeting these stringent requirements, thanks to continuous investment in technology and a culture of quality excellence.

One of the most significant advantages of partnering with TIRAPID is their ability to work with a wide range of materials, including aluminum, stainless steel, titanium, plastics, and exotic alloys. This versatility allows clients to select the optimal material for their application, balancing performance, cost, and manufacturability.

Industry Expansion: The Role of Rapid Prototyping and On-Demand Manufacturing

As industries strive for innovation, the need for rapid prototyping and on-demand manufacturing has never been greater. TIRAPID integrates these services seamlessly into their CNC machining workflow. By leveraging advanced digital manufacturing, they can produce functional prototypes in days rather than weeks, enabling faster design validation and market entry.

Furthermore, the adoption of rapid prototyping and on-demand manufacturing aligns with the global shift towards mass customization, where products are tailored to specific customer requirements. This trend is particularly prominent in sectors like medical devices and consumer electronics, where personalized solutions are increasingly in demand.

How TIRAPID’s CNC Machining China Factory Drives Your Business Forward

- Reduced Lead Times: Automated workflows and streamlined processes minimize production delays, ensuring your parts are delivered on schedule.

- Cost Efficiency: Competitive labor rates, material sourcing, and optimized machine utilization translate into lower production costs without compromising quality.

- Scalability: TIRAPID’s flexible manufacturing model supports everything from low-volume prototypes to high-volume production runs.

- Quality Assurance: Every part undergoes strict inspection, with detailed reports provided for full traceability and peace of mind.

Industry Trends: Automation, Digitalization, and Sustainability

The CNC machining industry is rapidly evolving, with automation and digitalization at the forefront. Smart factories, IoT-enabled machines, and AI-driven process optimization are transforming traditional manufacturing into a more agile, efficient, and sustainable operation. TIRAPID is at the vanguard of this transformation, continually upgrading their facilities and adopting eco-friendly practices to reduce waste and energy consumption.

Sustainability is becoming a key differentiator in the global supply chain. By embracing green manufacturing techniques and responsible material sourcing, TIRAPID not only supports environmental goals but also helps clients meet regulatory and corporate social responsibility requirements.

Why Choose TIRAPID for Your CNC Machining Needs?

- Proven track record with global clients across diverse industries

- Advanced technology and continuous innovation

- Transparent communication and responsive customer service

- Commitment to quality, speed, and reliability

In conclusion, leveraging a CNC Machining China Factory like TIRAPID offers unparalleled advantages for businesses seeking to elevate their precision parts production. With a focus on innovation, quality, and customer satisfaction, TIRAPID is your trusted partner in navigating the complexities of modern manufacturing. For those looking to stay ahead in a competitive marketplace, the choice is clear—partner with TIRAPID and unlock the full potential of precision engineering.