Copper is a metal widely used in industry. A key characteristic of copper for precision manufacturing is its density. At room temperature, the density of pure copper is approximately 8.96 g/cm³. This value — often referred to as the density of copper — not only affects part weight but also directly impacts CNC machining cutting parameters, material selection, and cost control. This article will help you understand the density of copper and its influencing factors, enabling engineers to optimize designs during the design phase, ensuring that parts meet performance requirements while improving processing efficiency.

What Is The Density Of Copper

Copper’s density is 8.96 g/cm³ (standard value for pure copper at room temperature), a key characteristic that distinguishes it from many metals. The higher the density, the heavier the material per unit volume, directly impacting part design and processing methods.

In my work, copper is often used in electrical components, heat sinks, architectural ornaments, and artwork. Its high density, combined with excellent electrical conductivity and corrosion resistance, makes it widely used in cables, motor windings, and highly thermally conductive components. Copper’s density is over three times higher than aluminum (2.71 g/cm³) and close to that of iron (7.86 g/cm³), meaning that copper parts are heavier and more stable for the same volume.

Key Factors Affecting Copper Density

In the CNC machining and material selection projects I’ve been involved in, the density of copper, while standard at 8.96 g/cm³ , is not fixed. It fluctuates depending on material purity , alloy composition , processing methods , and temperature (high temperatures cause volume expansion and a decrease in density).

Here are a few key influencing factors I have summarized:

- Material Purity:

Pure copper has a standard density of 8.96 g/cm³ , making it an ideal material for electrical conductivity and heat dissipation. However, recycled copper or copper containing impurities typically has a density drop of 1%–3% due to the presence of oxides or other metals , which canalso affect mechanical properties and processing performance. - Alloying Composition

Copper is often alloyed with other metals:

Brass (copper + zinc) : density 8.4–8.7 g/cm³ , suitable for structural and decorative parts .

Bronze (copper + tin) : density 8.0–8.9 g/cm³ , strong corrosion resistance ,

Copper-nickel alloy : Density 8.7–8.9 g/cm³ , excellent seawater corrosion resistance.

Different ratios directly affect the overall density and determine the application scenario of the part.

- Processing And Forming Methods

There may be pores inside the casting, resulting in the actual density being lower than the theoretical value . Forging, hot rolling or extrusion processes can significantly increase the density, making the parts stronger and with stable performance. - Temperature And Environmental Influence:

Copper expands at high temperatures, with its volume increasing by approximately 0.2% for every 100°C increase in temperature , and its density decreasing accordingly. This effect cannot be ignored for components used in high-temperature applications, such as heat sinks and electrodes.

These factors together determine the performance of copper and its alloys in different scenarios.

Density changes And applications Of Copper

8.96 g/cm³ under standard conditions , its actual density fluctuates due to variations in alloying, processing methods, and ambient temperature. For example, brass (copper + zinc) has a density of approximately 8.4–8.7 g/cm³ , bronze (copper + tin) has a density of approximately 8.0–8.9 g/cm³ , and copper-nickel alloys have a density of approximately 8.7–8.9 g/cm³ . These differences not only affect part weight and cost but also determine a material’s suitability for specific applications.

In actual production, I will choose copper materials of different densities according to design requirements:

Electrical Parts : prefer high-purity, high-density pure copper to ensure excellent conductivity and stable mechanical strength .

Structural Parts : bronze or brass is preferred to reduce weight and improve wear resistance .

Complex Functional Parts : Choose a copper-nickel alloy with moderate density to achieve a balance between strength and corrosion resistance.

By understanding the variation of copper density and rationally selecting alloy types, it is possible to balance performance, cost, and manufacturability in CNC machining, enabling more efficient product development and manufacturing.

Density Comparison Of Copper And Other Common Metals

Copper has a standard density of 8.96 g/cm³ , which is medium-high for common engineering metals. It is approximately three times heavier than aluminum (2.71 g/cm³), slightly heavier than steel (7.85 g/cm³), and more than twice as heavy as titanium (4.51 g/cm³). This “medium-high” density makes copper excellent for parts requiring electrical and thermal conductivity, while also maintaining sufficient mass and stability for smaller precision components, making it less susceptible to vibration and resonance.

In practical applications, understanding this density difference helps us:

Estimate the weight of parts in advance and optimize transportation and assembly plans .

Reasonable selection of cutting tools and feed speeds to reduce processing costs ,

Make more precise material decisions based on application scenarios such as heat sinks, electrical terminals, or decorative parts.

| Common Metal Density Comparison Table Materials | Density (g/cm³) | Typical Applications |

| Aluminum (Al) | 2.71 | Aviation structural parts, automotive lightweight components |

| Titanium (Ti) | 4.51 | Aerospace engines, medical implants |

| Steel | 7.85 | Structural parts, mechanical parts |

| Copper (Cu) | 8.96 | Electrical components, radiators, decorative parts |

| Silver (Ag) | 10.50 | Highly conductive contacts, decorations |

| Gold (Au) | 19.32 | Jewelry, electronic high-end contact parts |

How To Calculate The Density Of Copper

Calculating the density of copper in CNC machining is straightforward. Simply knowing the part’s mass and volume provides the density formula: Density = Mass ÷ Volume . For regular shapes (such as cuboids or cylinders), the volume can be calculated using geometric formulas, then combined with the weight to determine the density . For complex shapes, the displacement method can be used to measure the volume, then combined with the weight to calculate the density.

regular geometry formula and irregular part drainage method :

1. Formula Calculation For Regular Geometric Bodies

When the part is a regular cuboid, cylinder, or sphere, the weight can be calculated directly using the basic volume formula and material density.

Rectangular prism : Volume V = length × width × height V = length × width × height V = length × width × height

Cylinder : Volume V = π × (radius²) × height V = π × (radius²) × height V = π × (radius²) × height

Sphere : Volume V = 43π × Radius 3V = \frac{4}{3}π × Radius ³V = 34π × Radius 3

Combined with the standard density of copper (8.96 g/cm³) , the weight of the part can be calculated. For example, a pure copper block measuring 10 × 5 × 2 cm has a volume of 100 cm³ and weighs approximately 896 g . This method is simple to calculate and is suitable for parts with regular structures, such as copper plates, copper rods, and some standard parts.

2. Drainage Method For Irregular Parts

For complex parts (such as those with cavities, curved surfaces, and special-shaped structures), the commonly used calculation method is the drainage method :

into the measuring cylinder and record the initial water level.

Completely submerge the part in water and read the new water level.

Volume = New water level – difference between initial water level.

Divide the mass (g) by the volume (cm³) to get the density (g/cm³).

This method can handle complex geometries, but requires ensuring that the part surface is free of bubbles and that the material does not react with water.

3. Error Control And Practical Application

In the actual measurement process, the main factors affecting accuracy include:

Accuracy Of Measuring Tools : graduated cylinder scale, electronic balance accuracy.

Temperature Changes : Thermal expansion of copper affects its volume.

Surface Condition : Plating and oxide layers may slightly change the quality.

For CNC-machined parts, these errors typically range from 1% to 3% , which is sufficient for engineering applications. Only in extremely high-precision applications, such as aerospace and medical equipment, is it necessary to further verify the volume using 3D scanning combined with CAD modeling.

Brass Density For CNC Machining

Throughout my career in CNC machining and material selection, the density of copper has always been a topic I’ve come across. Many people only know that the standard density of copper is 8.96 g/cm³, but this value is actually not fixed. Material purity, alloy composition, processing methods, and even temperature and storage conditions can all lead to subtle variations in this number. These subtle variations are often amplified during CNC machining, directly affecting design accuracy, machining parameters, and even production costs.

First, density directly impacts weight calculations . Based on the standard density of copper (approximately 8.96 g/cm³ for pure copper) and the part volume, accurate predictions of both blank and finished product weights are possible. This is crucial for fixture selection and clamping methods: heavier workpieces require more rigid fixtures and appropriate support structures, which also impacts the load capacity and speed of automated feeding equipment. Furthermore, shipping relies on accurate weight data to assess logistics costs and packaging methods, thereby avoiding overloading and additional costs.

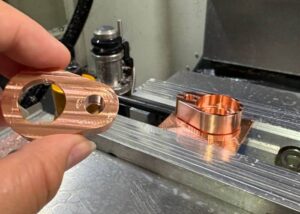

Secondly, density is closely related to cutting parameters . The higher the density, the greater the material’s resistance during cutting, resulting in faster tool wear and greater heat generation. When machining pure copper, we typically increase cutting speeds, but reduce feed rates and enhance cooling to reduce tool sticking and surface scratches. However, when machining brass (density approximately 8.4–8.7 g/cm³) or bronze (density approximately 8.0–8.9 g/cm³), due to differences in hardness and friction properties, speed and feed parameters can be appropriately adjusted to improve production efficiency. For complex structural parts, we also use CAM software to optimize tool paths to reduce cutting forces and avoid deformation or machining vibration caused by density differences.

Finally, density affects the material’s application scenarios and processing focus . Copper and its alloys are widely used in the CNC industry:

Pure copper : Commonly used in electrical terminals, radiators, and heat exchangers. Due to its high electrical and thermal conductivity, it requires extremely high surface quality and dimensional accuracy.

Brass : Widely used in valve bodies, wear-resistant bushings and musical instrument parts due to its good cutting performance and corrosion resistance. It is suitable for mass production and reduces the subsequent polishing process.

Bronze : It plays an important role in mechanical parts, marine accessories and high-load sliding parts due to its high strength and wear resistance.

Art Sculptures And Ornaments : Utilizing the unique color of copper alloy, through CNC precision carving and surface treatment, we present finished products that are both beautiful and structurally strong.

Understanding the importance of density in CNC machining not only helps us develop optimal process parameters but also optimizes production processes, reducing risks and costs. Whether it’s high-volume industrial parts or high-value custom crafts, a correct understanding of material density is a crucial prerequisite for successful machining.

FAQs

What Is The Density Of Copper In Kg M3 ?

The Density Of Pure Copper At Room Temperature Is 8,960 Kg/M³ (8.96 g/cm³) .

In My CNC Material Selection Work, I Use This Value To Accurately Calculate Part Weights, Which Helps Determine Fixturing Stability And Shipping Costs, Especially For High-Volume Copper Components.

What Is The Density Of Copper In Lb/In3 ?

Copper’s Density Is 0.324 Lb/In³ (Based On 8.96 g/cm³).

I Often Use This Conversion When Working With U.S.-Based Drawings Or Suppliers, Allowing Me To Ensure Compatibility Of Specifications And Precise Weight Estimation For Machined Copper Parts.

Is Copper Denser Than Steel?

Yes, Copper (8.96 g/cm³) Is Slightly Denser Than Carbon Steel (~7.85 g/cm³).

In My Experience, This Means Copper Parts Of The Same Volume Weigh ~14% More, Affecting Handling And CNC Fixturing, Especially When Machining Large Heat Exchangers Or Electrical Busbars.

What Is The Density Of Copper In Grams Per ML?

The Density Of Copper Is 8.96 Grams Per Milliliter (g/mL).

I Use This Direct Conversion When Designing Small Precision Parts, Allowing Quick Mass Calculations From CAD Volumes, Which Is Essential In Prototyping And Mass Production.

How Does Copper Have A High Density?

Copper’s High Density Comes From Its Atomic Mass (63.55 u) And Closely Packed FCC Crystal Structure.

In Practice, This Gives Copper High Strength And Thermal Conductivity, Making It Ideal For Electrical Connectors And Heat Sinks That I Frequently Machine.

Why Is Aluminum Denser Than Copper?

This Is Incorrect— Aluminum (2.70 g/cm³) Is Less Dense Than Copper (8.96 g/cm³).

In My Projects, This Density Difference Allows Aluminum To Be Chosen For Lightweight Structural Parts, While Copper Is Used Where High Conductivity And Mass Are Required.

Conclusion

Copper density is not only a physical parameter but also a crucial factor in CNC machining design, process planning, and cost control . In my work, a precise understanding of density and its varying factors enables me to better evaluate material properties, optimize machining strategies, and prevent potential issues early in product design. Ultimately, understanding copper’s density characteristics and applying them flexibly is a critical step in achieving high-quality CNC machining and mitigating overall manufacturing risk.