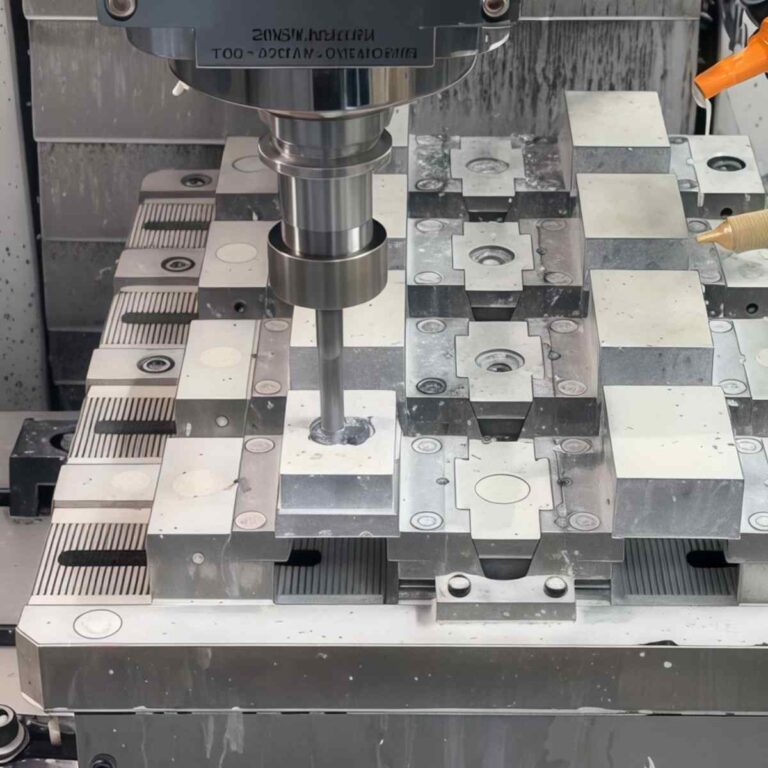

Fixtures are core tools to ensure workpiece stability and machining accuracy. Whether it is a simple fixture or a complex modular fixture, selecting and designing the right fixture can greatly

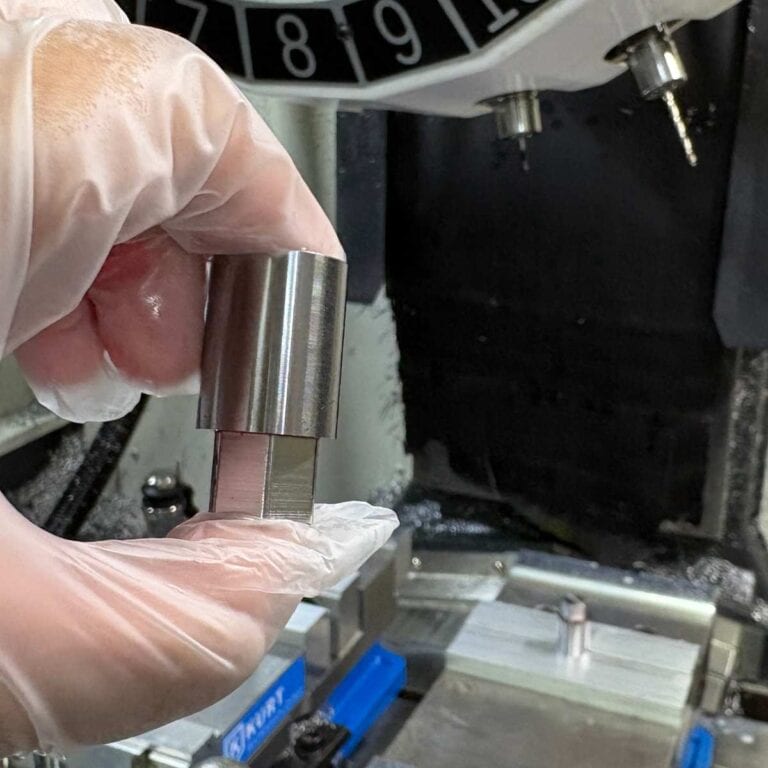

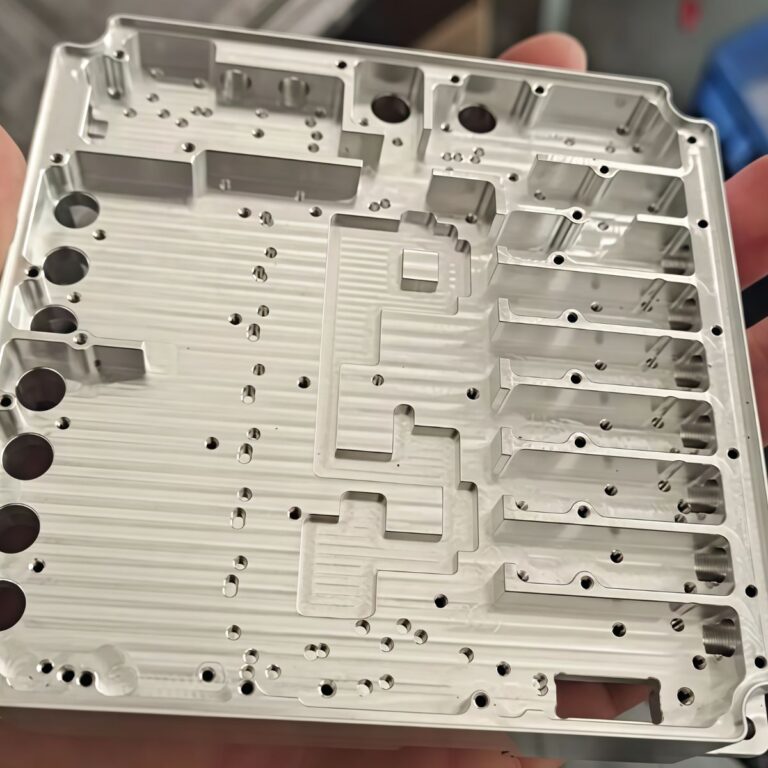

Small batch CNC machining is a manufacturing method that balances speed, flexibility, and high precision. In this article, I’ll systematically cover processes, materials, cost evaluation, design considerations, quality assurance, and

What is rapid tooling? Using 3D-printed tools and CNC molds—direct or indirect—delivers production-like parts in hours–days, cuts cost/lead time 40–60%, validates designs, and bridges prototype-to-production.In this article, I will take

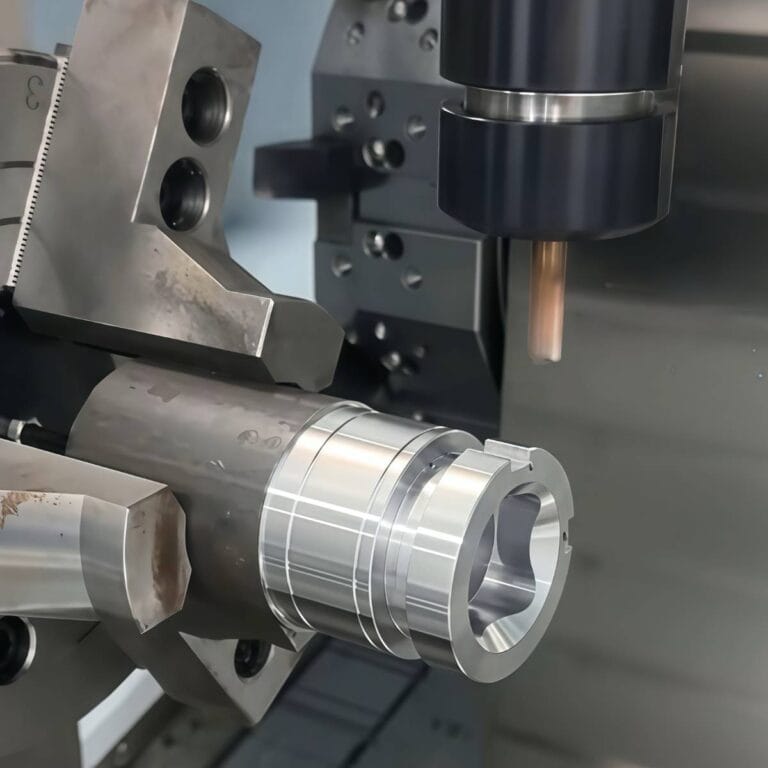

CNC milling is crucial in modern manufacturing, applied in aerospace, medical, and automotive fields. Faster and more precise than traditional methods, it lowers costs, shortens lead times, and enhances quality.

Outsourcing CNC machining helps reduce costs, access advanced capabilities, and speed time-to-market. By choosing to outsource CNC machining to trusted suppliers, companies avoid heavy investment, increase flexibility, and focus on

As a longtime manufacturer, I’m often asked by clients: What is insert molding? Insert-molded parts not only combine the strength of metal with the lightweight of plastic, but also reduce

Chromic Acid Anodizing (CAA, Type I) is a classical aluminum alloy surface treatment process that significantly improves corrosion resistance and bonding performance without altering part dimensions. This process is widely

Shoulder milling creates flat surfaces and precise 90° shoulders in one pass. Widely used in mold, automotive, aerospace, and medical machining, it’s essential for steps, slots, and cavity edges. In

Milling is a widely used process in manufacturing, using a rotating tool to remove material and precisely machine a part’s surface. With the continuous advancement of technology, milling operations have

In modern manufacturing, CNC (computer numerical control) machine tools have long been a core component of production. With technological advancements, the range of types of CNC machines has continued to

What is Passivation?Among the many processes used to prevent metal corrosion, passivation is one of the most widely used and effective. By forming a dense, protective oxide film on the

Anodizing is an electrochemical process that forms a durable oxide layer on metals, boosting corrosion and wear resistance while enabling diverse finishes. In this article, I will explain the principles