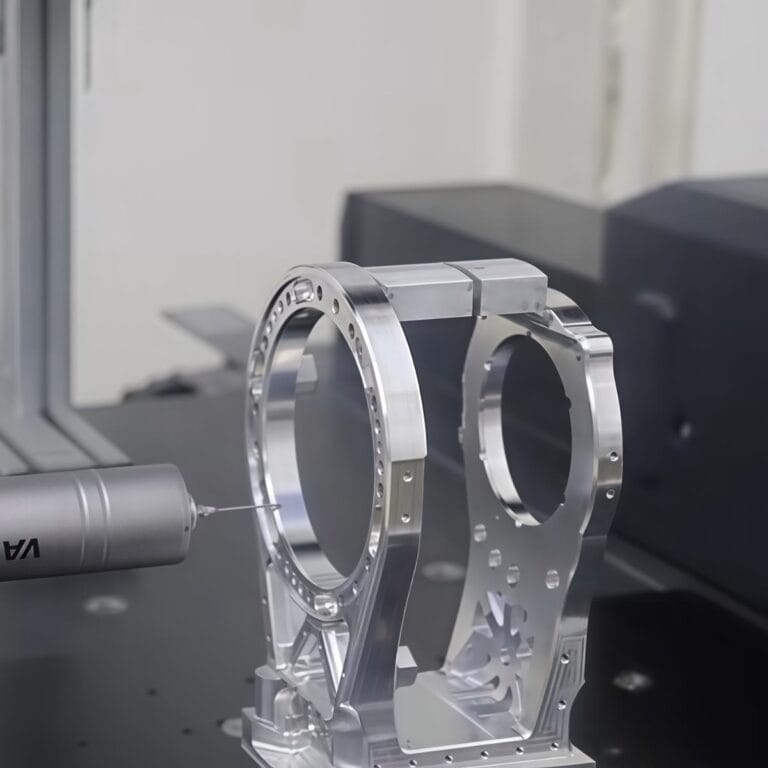

What is product prototype?A product prototype serves as a vital bridge between concept and production, allowing teams to test design, performance, and functionality before mass manufacturing. This article explores the

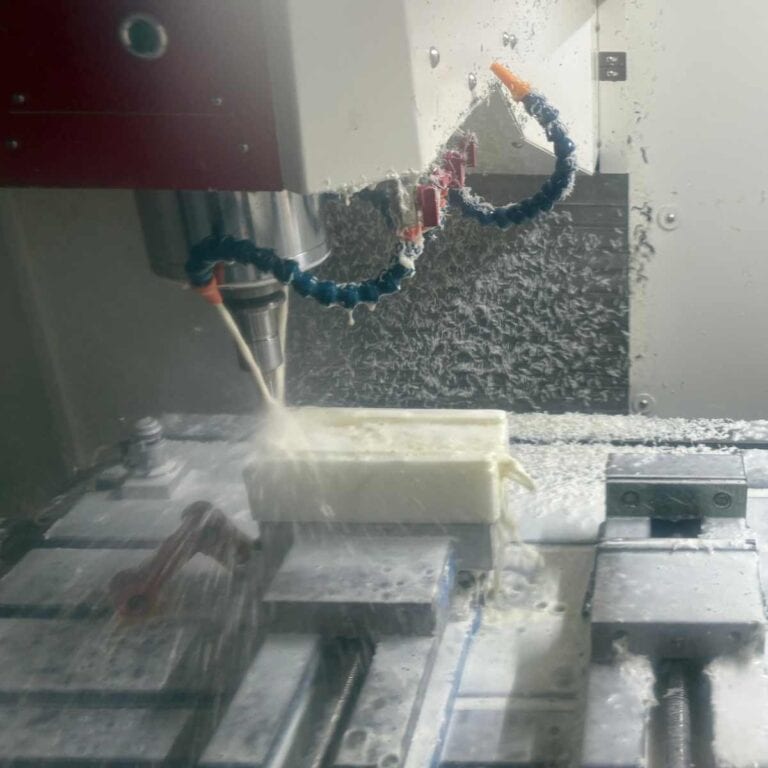

Both HLH Prototypes and TiRapid provide CNC machining and rapid prototyping, but TiRapid stands apart with in-house manufacturing, faster lead times, and higher process transparency. While HLH focuses on scalable

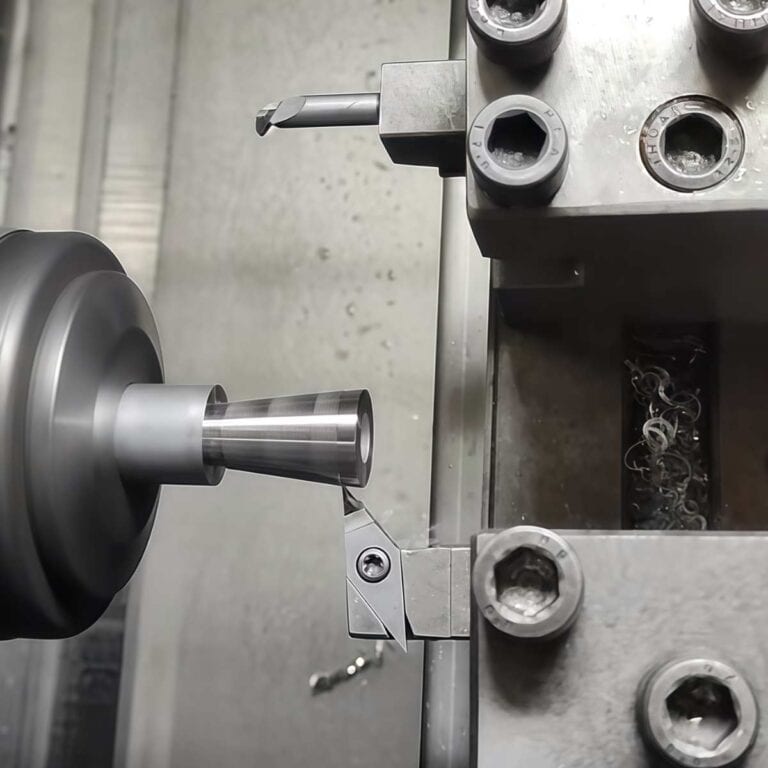

Aluminum parts are among the most commonly used components in modern manufacturing, appearing in industries ranging from advanced aerospace engineering to everyday consumer electronics. But do you know how to

Australia’s CNC machining industry continues to grow in 2026, driven by precision, innovation, and strong local expertise. From Melbourne to Sydney, leading CNC machining companies in Australia are delivering world-class

Both RapidDirect and TiRapid offer CNC machining and rapid prototyping, but TiRapid goes further with hands-on engineering, faster lead times, and stricter quality control. As a true rapiddirect competitor alternative,

Humanoid Robots in Manufacturing are shifting from labs to factory floors, handling assembly, inspection, and collaboration. Unlike traditional robots, they deliver flexibility, adaptability, and safer human-robot teamwork. This article,I will

In 2025, rapid prototyping tools are vital for designers and engineers to create, test, and refine ideas quickly. Here are the 10 best-value rapid prototyping tools that balance cost, usability,

In the world of advanced manufacturing, companies often compare different service providers to find the best fit for their projects. Both 3ERP and TiRapid are well-known names in rapid prototyping

What is Rapid Prototyping? It’s the fastest way to bridge the gap between ideas and real products. By leveraging CNC machining, 3D printing, injection molding, and vacuum casting, you can

For decades, rapid prototyping services China has been a driving force in precision engineering, fueling innovation across aerospace, automotive, medical, electronics, and energy industries. In 2025, the demand for high-precision,

What is G10 material? It is a fiberglass epoxy laminate with high strength, low moisture absorption, and excellent durability, widely used in insulation, aerospace, marine, and knife handles. What Is

In the race for speed and precision, TiRapid outshines platform models. While Xometry offers instant quoting through a large network, TiRapid stands as a better xometry competitor alternative by delivering