Aluminum prototypes are essential in modern product development, allowing engineers to verify form, fit, and function using a material close to final production parts. With CNC machining, these prototypes can

Metal prototyping allows engineers and buyers to test performance, fit, and durability before production. This guide breaks down key manufacturing methods, material options, and cost factors to help you choose

Micro gears are critical to modern compact systems, where space is limited but precision cannot be compromised. Micro gear manufacturing focuses on producing miniature gears with micron-level accuracy to ensure

Aluminum machining cost isn’t just about machine time. Material grade, tolerances, quantity, and design choices all affect final pricing. In this guide, I show how to estimate aluminum CNC costs

Metal doesn’t always mean hard. Some metals are so soft that they challenge everything we think we know about strength and durability. What is the softest metal on Earth, and

Aluminum mill finish and anodized aluminum may look similar but perform very differently in real applications. Comparing aluminum mill finish vs anodized helps engineers balance durability, machining impact, cost, and

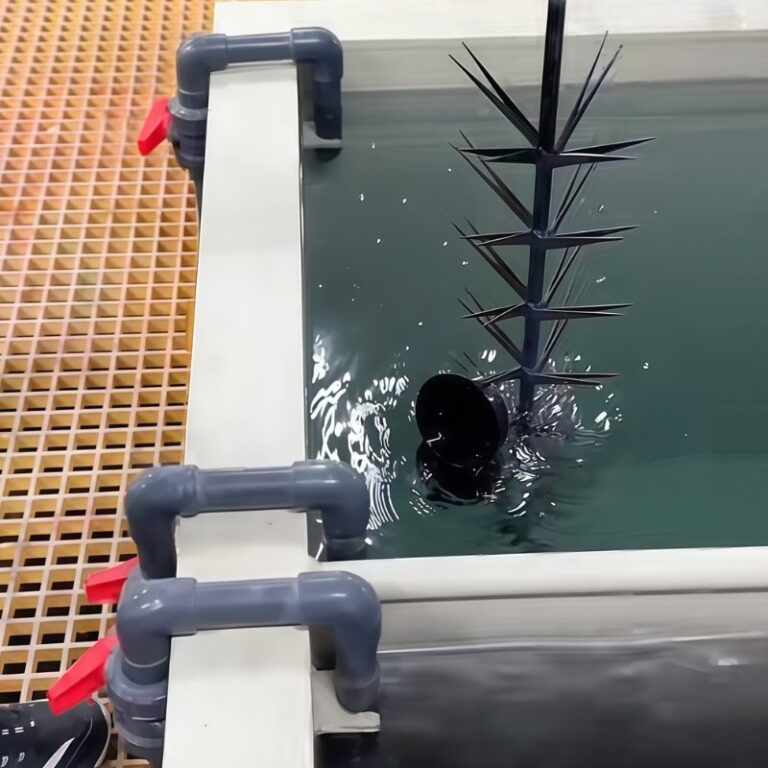

Aluminum naturally forms a thin oxide layer that protects it from corrosion. Satin Aluminum Anodizing enhances this layer through a controlled electrochemical process, creating a smooth, low-gloss surface that improves

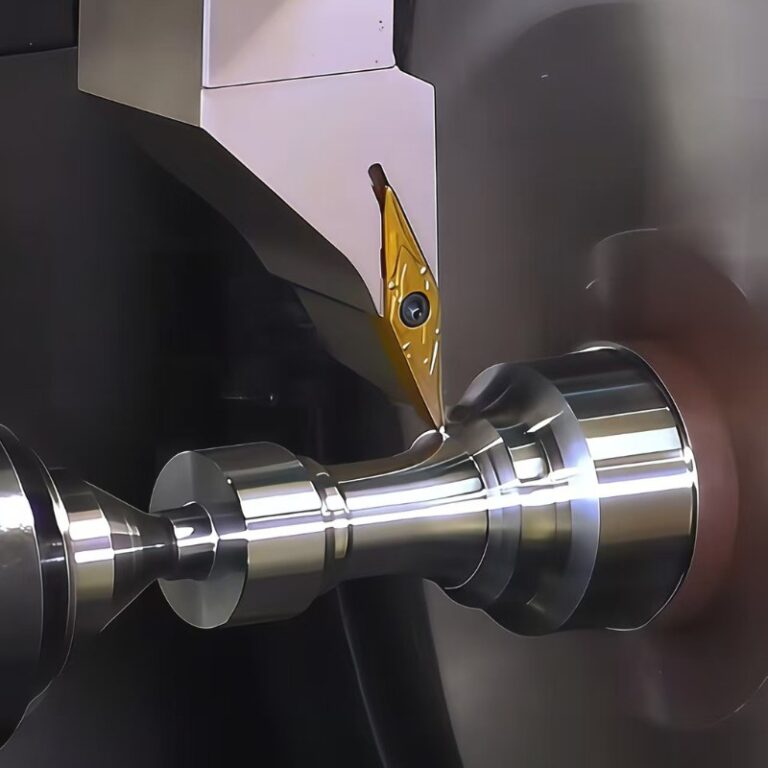

Precision manufacturing is the foundation of modern high-accuracy production. This guide explains what precision manufacturing is, how it works, and why industries rely on it to achieve tight tolerances, consistent

6-axis CNC machining enables simultaneous linear and rotational motion to machine complex parts in one setup. This article explains how it works, its capabilities, benefits, and applications to help engineers

This article explains what black hardcoat anodize is, how the Type III anodizing process works, and why it is chosen over standard anodizing. It also covers key performance benefits, limitations,

Precision hole machining is critical for tight-tolerance assemblies. Drilling vs Boring highlights how these two processes differ in accuracy, surface finish, and dimensional control, helping engineers choose the right method

Milling and drilling may look similar, but choosing the wrong CNC process can increase cost, extend lead time, and compromise accuracy. This guide breaks down the real differences between CNC