3-axis CNC machining is a fundamental manufacturing process widely used for producing precise and reliable machined parts. By controlling tool movement along the X, Y, and Z axes, this method enables efficient material removal and consistent accuracy for a wide range of geometries.

This article explains how 3-axis CNC machining works, what its core capabilities and limitations are, and where it is most commonly applied, helping engineers and buyers understand when 3-axis machining is the right choice for their projects.

What Is 3 Axis CNC Machining?

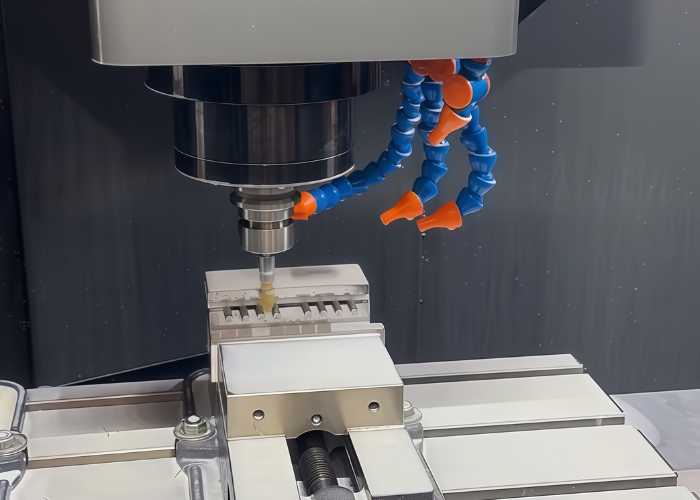

3 Axis CNC machining is a subtractive manufacturing process where cutting tools move along three linear axes—X, Y, and Z—to shape parts from solid material. It is one of the most widely used CNC machining manufacturing methods due to its simplicity, reliability, and cost efficiency.

Get 20% offf

Your First Order

3-Axis CNC Machining Workflow

The 3-axis CNC machining workflow follows a clear and structured sequence, from digital design to final inspection. Understanding each step helps engineers and buyers evaluate manufacturability, control quality, and ensure consistent machining results throughout the production process.

Design and CAD Modeling

The process starts with a detailed 3D CAD model defining geometry, dimensions, and tolerances. Proper 3 axis CNC design ensures all critical features are accessible from a top-down machining direction.

Key considerations include:

- Feature orientation to minimize part re-clamping

- Appropriate wall thickness and corner radii

- Tolerance allocation based on function

- Design-for-machinability to reduce cost and lead time

CAM Programming

CAM software translates the CAD model into precise toolpaths for 3-axis milling. This stage directly affects machining efficiency and surface quality.

Typical CAM tasks include:

- Tool selection based on material and feature type

- Optimization of spindle speed and feed rate

- Roughing and finishing strategy planning

- Collision checking and toolpath simulation

Machine Setup and Fixturing

The workpiece is securely mounted on the machine table using vises, clamps, or custom fixtures. Proper setup is critical for maintaining dimensional accuracy.

Key setup factors include:

- Stable clamping without part deformation

- Accurate work coordinate alignment

- Repeatable positioning for batch production

- Fixture design to support multi-operation machining

Machining Execution

The CNC machine follows programmed toolpaths to remove material layer by layer. 3-axis machining is well suited for prismatic parts with features accessible from one direction.

Common operations include:

- Face milling for flat reference surfaces

- Pocket milling and slotting

- Drilling and tapping threaded holes

- Contouring for external profiles

Inspection and Post-Processing

After machining, parts undergo inspection to verify dimensional accuracy and surface finish. Quality control ensures consistency with design specifications.

Post-processing may include:

- Dimensional measurement using CMM or gauges

- Surface finishing such as polishing or anodizing

- Functional checks for fit and assembly

Final cleaning and packaging

Machines and Tools Used in 3 Axis CNC Machining

3 axis CNC machining commonly uses vertical machining centers (VMCs), CNC milling machines, and CNC routers. Cutting tools include end mills, face mills, drills, reamers, and taps, selected based on material type and feature requirements.

Common machines include:

- Vertical Machining Centers (VMCs)– The most widely used machines for 3-axis milling, offering high rigidity and accuracy

- CNC Milling Machines– Suitable for general-purpose machining and low to medium production volumes

- CNC Routers– Commonly used for aluminum, plastics, and composite panels with larger working areas

Typical cutting tools include:

- End mills– For profiling, slotting, and pocket milling

- Face mills– For facing operations and flat surface generation

- Drills– For creating holes of various diameters

- Reamers– For improving hole accuracy and surface finish

- Taps– For internal thread machining

Materials Supported by 3-Axis CNC Machining

3-axis CNC machining supports a wide range of metals and engineering plastics, such as aluminum alloys, stainless steel, brass, ABS, POM, and PEEK. Proper material selection and cutting parameters ensure stable accuracy, surface quality, and cost-effective production.

Commonly machined metals include:

- Aluminum alloys such as 6061, 6063, and 7075, valued for their excellent machinability and strength-to-weight ratio

- Carbon steel and alloy steel, used for structural and load-bearing components

- Stainless steel including 304 and 316, selected for corrosion resistance and durability

- Brass and copper, often chosen for electrical components and precision fittings

Commonly machined plastics include:

- ABS and POM, suitable for functional prototypes and mechanical components

- Nylon (PA), offering good strength and wear resistance

- PEEK, a high-performance thermoplastic used for demanding applications requiring high temperature resistance, chemical stability, and mechanical strength

- PMMA and PC, commonly used for transparent or impact-resistant parts

Overall, 3-axis CNC machining is best suited for materials and part designs that can be accessed from a single direction, making it ideal for flat and prismatic components in prototype and low-to-medium volume production.

Advantages of 3 Axis CNC Machining

3-axis CNC machining offers a cost-effective, reliable, and widely accessible solution for producing accurate machined parts. It is especially well suited for prismatic components, prototype development, and small-to-medium batch production where speed, stability, and precision are key requirements.

Simple And Proven Machining Technology

3-axis CNC machining is a mature and widely adopted manufacturing process used across many industries. Its straightforward motion along the X, Y, and Z axes makes it highly reliable for both prototyping and production.

- Simple machine structure with stable mechanical performance

- Easy-to-understand motion logic, reducing programming and operation errors

- Lower process complexity, minimizing machining risks

- Well-suited for long-term, repeatable production tasks

Lower Equipment And Programming Costs

Compared with 4-axis or 5-axis CNC systems, 3-axis machines offer a more cost-effective manufacturing solution, especially for standard parts and small-to-medium batch production.

- Lower initial machine investment and maintenance costs

- Simpler CAM programming with shorter learning curves

- Reduced tooling and fixture complexity

- Ideal for cost-sensitive prototype and low-volume projects

Faster Setup Compared To Multi-Axis Machining

3-axis CNC machining typically requires simpler fixturing and fewer setup variables, which helps shorten preparation time and improve overall efficiency.

- Standard vises and fixtures are often sufficient

- Fewer machine adjustments between operations

- Reduced setup time for repeat jobs

- Higher throughput for prismatic and flat components

Excellent Accuracy For Top-Down Features

With tools approaching the workpiece from a fixed vertical direction, 3-axis CNC machining delivers consistent and reliable precision for many common features.

- High accuracy for flat surfaces and planar faces

- Stable tolerances for pockets, slots, and drilled holes

- Good surface finish with proper tool selection

- Suitable for tight-fit assemblies and functional testing

Widely Available Expertise And Tooling

3-axis CNC machining benefits from a large global knowledge base and standardized tooling ecosystem, ensuring predictable quality and delivery.

- Skilled operators widely available in the market

- Standard cutting tools compatible with most materials

- Broad CAM software support and post-processor availability

- Stable lead times and scalable production capacity

Limitations of 3-Axis CNC Machining

3-axis CNC machining is reliable and cost-effective, but it has limitations when part geometry becomes more complex. Because tool movement is restricted to the X, Y, and Z axes, certain features and machining scenarios are less efficient or not feasible.

Limited Access To Undercuts And Side Features

Because the cutting tool approaches the part from a fixed vertical direction, 3-axis CNC machining has inherent limitations when accessing certain geometries.

- Angled holes and side features are difficult to machine directly

- Undercuts usually require secondary operations or manual processing

- Part repositioning is often needed to reach non-vertical features

- Overall geometric freedom is limited compared to multi-axis machining

Multiple Setups Required For Complex Parts

Parts with features distributed across multiple faces typically require reorientation during machining.

- Additional setups increase preparation and handling time

- Re-fixturing introduces potential alignment deviations

- Tight-tolerance parts are more sensitive to cumulative setup errors

- Process consistency becomes harder to maintain for complex designs

Not Suitable For Highly Contoured Or Freeform Geometries

3-axis CNC machining is less efficient when dealing with complex surface profiles.

- Deep curves and organic shapes are difficult to machine accurately

- Acceptable surface quality often requires longer cycle times

- Additional finishing processes may be necessary

- Overall machining efficiency is reduced for freeform geometries

Lower Efficiency For Multi-Face Machining

When a part requires machining from multiple angles or faces, 3-axis CNC machining becomes less effective.

- Sequential repositioning slows down the machining process

- Setup changes increase labor input and machine downtime

- Single-setup machining is not achievable for multi-sided features

- 4-axis or 5-axis CNC machining is generally a better solution

Applications of 3 Axis CNC Machining

3-axis CNC machining is widely used in automotive, aerospace, electronics, medical devices, industrial equipment, and prototyping applications, where prismatic parts require accurate, repeatable, and cost-effective machining from a top-down approach.

Common application industries include:

- Automotive– Used for brackets, housings, mounts, and fixtures where dimensional accuracy and repeatability are required.

- Aerospace– Applied to structural components, covers, and tooling that demand tight tolerances and stable machining quality.

- Electronics– Commonly used for enclosures, heat sinks, and frames requiring precise pocketing and surface flatness.

- Medical Devices– Supports instrument components and housings where consistency, precision, and surface quality are critical.

- Industrial Equipment– Used for plates, bases, and mechanical parts that require durability and reliable machining performance.

- Prototyping and R&D– Enables fast validation of part designs and functional testing before production.

| Industry | Typical 3-Axis CNC Machined Parts | Primary Purpose |

| Automotive | Brackets, housings, mounts, fixtures | Functional testing, assembly validation |

| Aerospace | Structural components, covers, tooling | Lightweight structures, precision fit |

| Electronics | Enclosures, heat sinks, frames | Thermal management, dimensional accuracy |

| Medical Devices | Instrument components, housings | Precision, repeatability, compliance support |

| Industrial Equipment | Plates, bases, mechanical parts | Durability, stable performance |

| Prototyping & R&D | Prototype parts, test components | Fast design validation and iteration |

FAQs

What Is The Difference Between 3 And 5-Axis CNC?

The main difference between 3-axis CNC vs 5-axis machining is tool accessibility. In our shop, 3-axis CNC machines cut from a single vertical direction, while 5-axis machines allow multi-angle machining in one setup. Although 5-axis machining handles complex geometries, 3-axis machining remains more cost-effective for simpler parts.

What Is The Difference Between 2 Axis And 3 Axis CNC?

2-axis CNC controls only two linear movements, limiting feature depth and geometry. By adding the Z axis, 3-axis CNC machining supports pockets, slots, and depth-controlled features, enabling more flexible 3-axis milling and making it suitable for functional mechanical parts.

What Is The Difference Between 3 And 4-Axis CNC?

4-axis CNC machining adds a rotational axis, allowing side features to be machined without re-clamping. In comparison, 3-axis CNC machining relies on simpler setups and is better suited for flat or prismatic components when 3 axis CNC design allows features to be accessed from one direction.

What Can You Make With A 3-Axis CNC?

With 3-axis CNC machining, we commonly produce brackets, housings, plates, enclosures, fixtures, and prototype parts. These parts are typically made through 3-axis milling in aluminum, steel, and engineering plastics, where features are accessible from a top-down machining approach.

Conclusion

3 axis CNC machining remains a reliable and cost-effective solution for producing precise machined parts. By understanding its process, capabilities, and limitations, engineers and buyers can confidently choose the right machining approach for their applications.

TiRapid provides reliable 3-axis CNC machining with stable accuracy and fast turnaround. We support prototypes and low-to-medium volume production. Contact us to start your project.