In today’s fast-paced manufacturing landscape, the demand for precision, efficiency, and customization is higher than ever. For businesses across industries, finding the right CNC machining company is a pivotal step toward innovation and success. TIRAPID (abbreviated as TIRAPID) has emerged as a leader in the field, setting benchmarks for quality and customer satisfaction. This article explores the core attributes that make TIRAPID an ideal partner for custom components, while also touching on the importance of rapid prototyping and low volume production in modern manufacturing.

Why Custom Components Matter

Custom components are the backbone of specialized machinery and products. Unlike off-the-shelf parts, custom components are designed to meet unique specifications, ensuring optimal performance and integration. Companies in aerospace, automotive, medical, and electronics sectors rely on CNC machining companies like TIRAPID to deliver precision-engineered parts that adhere to stringent quality standards.

Precision and Flexibility in CNC Machining

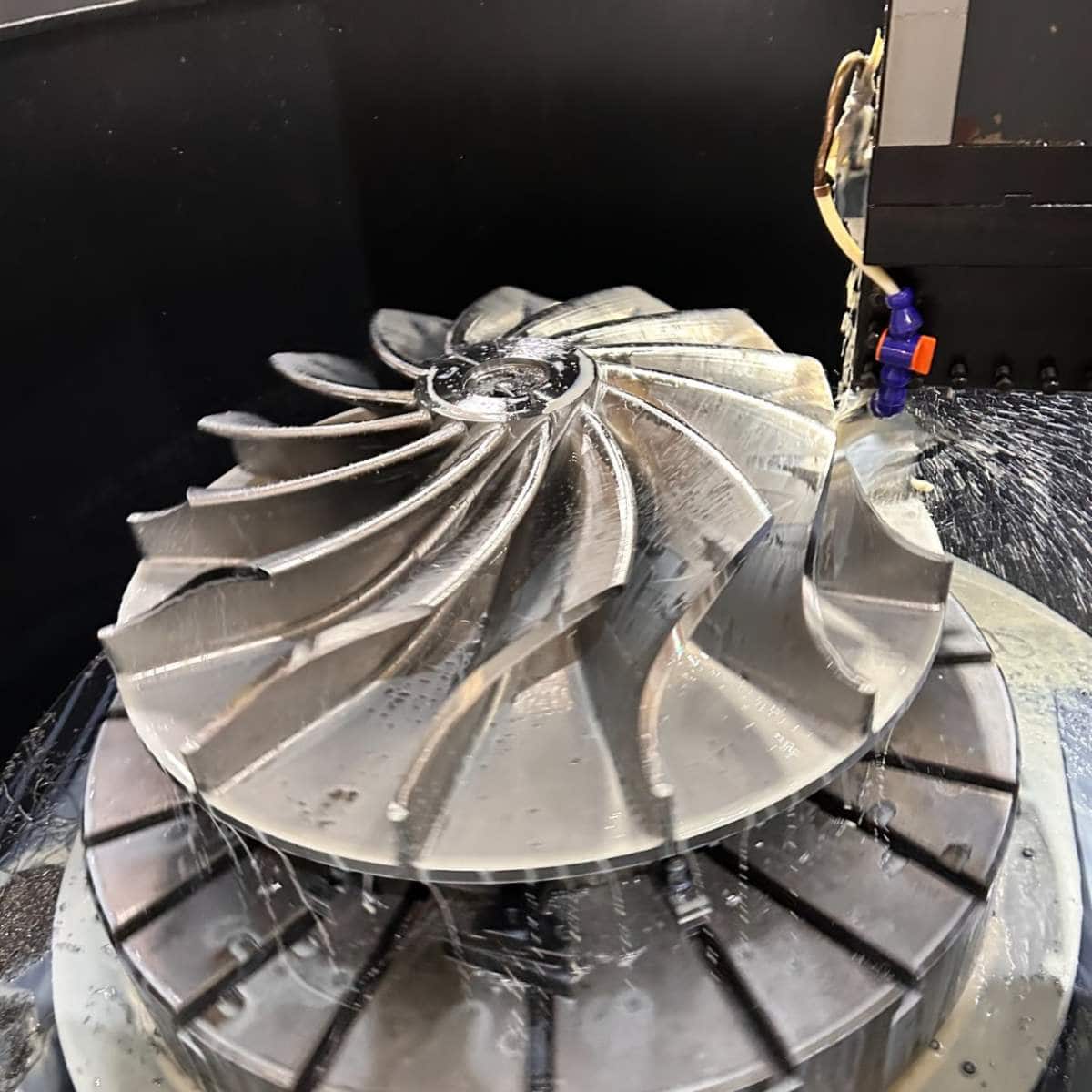

The hallmark of a reliable CNC machining company is its ability to deliver precision and flexibility. TIRAPID leverages advanced CNC equipment and state-of-the-art software to manufacture components with tight tolerances and intricate geometries. Whether it’s a single prototype or a batch of complex parts, TIRAPID’s expertise ensures every component meets or exceeds client expectations.

Key Features of an Ideal CNC Machining Company

- Technical Expertise: Skilled engineers and machinists are essential for interpreting blueprints and transforming designs into functional parts.

- Advanced Equipment: Modern CNC machines with multi-axis capabilities enable the production of complex shapes and high-precision features.

- Quality Assurance: Rigorous inspection protocols and certifications such as ISO 9001 guarantee consistent quality.

- Material Versatility: The ability to work with a wide range of metals and plastics expands the possibilities for custom solutions.

- Customer Collaboration: Direct communication and collaborative problem-solving ensure that the final product aligns with the client’s vision.

Embracing Rapid Prototyping

One of the significant advantages offered by TIRAPID is rapid prototyping. In the competitive world of product development, speed is crucial. Rapid prototyping allows designers and engineers to quickly turn ideas into tangible models, facilitating faster testing, iteration, and refinement. TIRAPID’s streamlined processes and efficient workflows mean that clients can validate their designs and move to production with confidence.

nylon machining service

CNC machining China

CNC machining Company

The integration of rapid prototyping not only accelerates time-to-market but also reduces development costs by identifying potential issues early in the design phase. This approach is especially valuable in industries where innovation cycles are short and the ability to adapt is a key differentiator.

Low Volume Production: Bridging the Gap

Another area where TIRAPID excels is low volume production. Traditional manufacturing methods often require large minimum order quantities, which can be prohibitive for startups or companies developing niche products. TIRAPID addresses this challenge by offering flexible low volume production services, allowing clients to order small batches without compromising on quality or lead time.

Low volume production is particularly beneficial for market testing, pilot runs, and limited-edition products. It enables businesses to respond to market feedback and make design adjustments before committing to full-scale manufacturing.

Industry Trends Shaping CNC Machining

The CNC machining industry is undergoing rapid transformation, driven by advancements in automation, digitalization, and materials science. Companies like TIRAPID are at the forefront of these changes, adopting smart manufacturing practices and investing in cutting-edge technologies.

- Automation: Automated tool changers, in-line inspection, and robotic loading systems are enhancing productivity and reducing human error.

- Digital Twins: The use of digital twins allows for real-time monitoring and simulation of machining processes, improving accuracy and efficiency.

- Sustainable Manufacturing: Eco-friendly practices, such as recycling metal shavings and optimizing energy consumption, are gaining traction.

- Customization at Scale: With the rise of Industry 4.0, mass customization is becoming a reality, enabling companies to offer bespoke solutions without sacrificing economies of scale.

TIRAPID’s commitment to continuous improvement and innovation ensures that clients benefit from the latest industry developments, maintaining a competitive edge in their respective markets.

Choosing TIRAPID for Your Custom CNC Machining Needs

Selecting a CNC machining partner is a strategic decision that can impact product quality, cost, and time-to-market. TIRAPID stands out for its dedication to customer satisfaction, technical prowess, and adaptability. The company’s holistic approach—encompassing design consultation, rapid prototyping, low volume production, and rigorous quality control—makes it an ideal choice for businesses seeking reliable custom components.

With a proven track record across multiple industries, TIRAPID continues to set the standard for excellence in CNC machining. Whether you’re developing a groundbreaking medical device or refining an automotive component, partnering with TIRAPID ensures your project is in expert hands.

Conclusion

The ideal CNC machining company is more than just a service provider—it is a collaborative partner invested in your success. From embracing rapid prototyping to facilitating low volume production, TIRAPID exemplifies the qualities that drive innovation and quality in custom component manufacturing. As industry trends evolve, TIRAPID remains committed to delivering precision, flexibility, and value to clients worldwide.