Understanding what machining is matters across modern manufacturing. Machining shapes metals and other materials into precise parts using controlled material removal. This article explains what machining is, how it works, common processes, tools, and where it’s used—giving you a clear, practical foundation before choosing the right method for your project.

What Is Machining

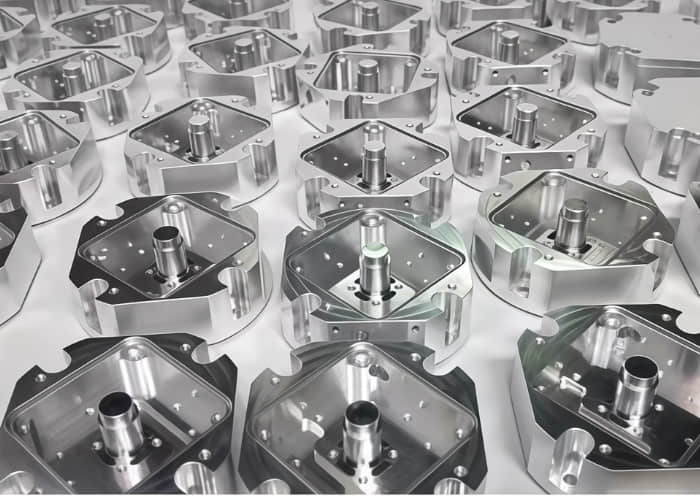

Machining is a subtractive manufacturing process that removes material through controlled cutting to create precise shapes and finishes. In practice, it delivers high accuracy and repeatability across metals and plastics, often reaching tolerances below ±0.01 mm, making it essential in aerospace, medical, and industrial manufacturing.

Get 20% offf

Your First Order

How Does Machining Work

Machining works by removing material from a solid workpiece using controlled cutting tools. In this article, we explain how machining turns designs into precise parts through structured steps—from design and programming to cutting, inspection, and finishing.

Machining follows a subtractive principle: excess material is removed to achieve the required shape, size, and surface quality.

In modern manufacturing, this process is mainly driven by CNC machines, which execute programmed toolpaths with high repeatability and accuracy.

A typical machining workflow includes:

1.Design and drawings that define geometry and tolerances

2.CAD/CAM modeling to generate machine-readable toolpaths

3.Machine setup and programming, including fixturing and tooling

4.Machining execution under automated CNC control

5.Inspection and finishing to verify dimensions and surface quality

From practical experience, each stage directly affects final accuracy. Even small setup or programming errors can lead to tolerance drift, which is why structured process control is critical in aerospace and precision manufacturing.

Types of Machining Processes

Machining processes form the foundation of subtractive manufacturing, shaping raw materials into accurate, functional parts. Each process removes material in a controlled manner to meet specific dimensional and surface requirements, and multiple processes are often combined to optimize precision, efficiency, and cost in real production.

CNC Milling

Milling uses a rotating cutting tool to remove material while the workpiece remains fixed or moves along controlled axes. This process is highly versatile and can create flat surfaces, pockets, slots, contours, and complex 3D shapes. Milling is essential in aerospace, energy, and general precision manufacturing.

CNC Turning

Turning involves rotating the workpiece while a stationary cutting tool removes material from the outer diameter. It is ideal for cylindrical or rotational parts such as shafts, pins, bushings, and threaded components. Turning is commonly used in automotive, industrial equipment, and fluid systems.

CNC Drilling

Drilling creates round holes by feeding a rotating drill bit into the material. It is typically the first step for fasteners, fluid passages, or assembly features. While drilling is simple, hole accuracy often depends on follow-up processes such as reaming or boring.

CNC Boring

Boring enlarges or refines an existing hole to improve accuracy and concentricity. It is commonly used for engine cylinders, bearing seats, and precision housings where tight internal tolerances are required.

CNC Reaming

Reaming is a finishing process used to achieve precise hole diameters and improved surface finish after drilling. It is frequently applied in applications requiring accurate alignment, such as dowel pin holes or precision assemblies.

CNC Grinding

Grinding removes very small amounts of material using an abrasive wheel to achieve high dimensional accuracy and smooth surface finishes. It is often used for hardened materials, precision shafts, and components requiring micron-level tolerances.

CNC Planing

Planing produces flat surfaces by moving the workpiece relative to a single-point cutting tool. While less common in modern CNC shops, it is still used for large flat components or specialized applications.

CNC Sawing

Sawing is typically used for cutting raw stock to length before further machining. It is a preparatory process that improves material handling efficiency and reduces waste.

CNC Broaching

Broaching uses a toothed cutting tool to remove material in a single pass. It is highly efficient for producing internal keyways, splines, and non-circular profiles with excellent repeatability in high-volume production.

Recommended Approach

For most modern manufacturing projects, a combination of turning, milling, drilling, and finishing processes delivers the best balance of precision, flexibility, and cost efficiency. Advanced CNC systems integrate these traditional operations into streamlined workflows, allowing complex parts to be produced accurately and consistently across industries such as aerospace, medical, automotive, and industrial manufacturing.

Machining Tools and Equipment

Machining tools and equipment determine how accurately, efficiently, and consistently material is removed during machining. The right tool selection directly affects tolerances, surface finish, tool life, and overall production cost. In practice, machinists combine different cutting tools and machine setups to match part geometry, material hardness, and batch size.

Cutting Tools

Cutting tools are designed to shear material in a controlled way.

Single-point tools are mainly used in turning operations, while multi-point tools dominate milling and drilling, offering higher material removal rates and better productivity.

Turning Tools

Turning tools shape rotating workpieces and are commonly used for shafts, threads, and cylindrical parts. In my experience, tool geometry and insert grade play a major role in controlling surface finish and dimensional stability.

Milling Tools

Milling tools such as end mills, face mills, and ball mills remove material with rotating cutters. They are essential for slots, pockets, contours, and complex 3D surfaces, especially in CNC machining.

Drilling and Boring Tools

Drilling tools create initial holes, while boring tools refine hole size and accuracy. Boring is often used when tight tolerances or improved roundness are required beyond standard drilling.

Grinding Tools

Grinding tools use abrasives to achieve high precision and fine surface finishes. They are commonly applied in finishing operations where micron-level accuracy is required.

Indexable and Hybrid Tools

Indexable tools use replaceable inserts to reduce downtime and tooling cost, while hybrid tools combine multiple operations in one setup. These tools are widely used to improve efficiency in high-volume and precision machining.

Recommended Approach

For most production environments, combining indexable milling tools with precision turning and finishing tools provides the best balance between accuracy, cost, and throughput.

What Types Of Materials Can Be Processed

One of the biggest advantages of machining is material flexibility. CNC machining can process a wide range of materials with high accuracy and stable quality, making it suitable for both functional prototypes and production parts across many industries.

Metals are the most commonly machined materials because they offer predictable cutting behavior, stable tolerances, and reliable mechanical performance. In practice, each metal behaves differently during machining and is selected based on strength, corrosion resistance, and dimensional stability:

Aluminum

Aluminum is widely used due to its excellent machinability and high strength-to-weight ratio. It allows fast cutting speeds, produces clean chips, and achieves good surface finishes, making it ideal for precision housings, brackets, and lightweight structural parts.

Stainless Steel

Stainless steel is chosen when corrosion resistance and mechanical strength are required. It is harder to machine than aluminum, generates more heat, and requires controlled cutting parameters, but delivers durable and dimensionally stable parts for demanding environments.

Carbon Steel

Carbon steel offers good strength and cost efficiency. Its machinability depends on carbon content, but it is commonly used for mechanical components, fixtures, and structural parts where wear resistance and load-bearing capacity are important.

Brass

Brass is one of the easiest metals to machine. It produces smooth surface finishes, minimal tool wear, and excellent dimensional accuracy. Brass is often selected for precision fittings, connectors, and components where appearance and accuracy matter.

Copper

Copper has excellent electrical and thermal conductivity but is relatively soft and ductile. During machining, it requires sharp tools and careful chip control to avoid smearing. It is commonly used for electrical components and thermal management parts.

Iron

Iron is typically machined for heavy-duty or industrial components. It offers good vibration damping and strength, but requires proper tooling and cutting conditions to manage tool wear and maintain surface quality.

Titanium

Titanium is selected for applications requiring high strength-to-weight ratio and corrosion resistance. It is more challenging to machine due to heat concentration and tool wear, but 5-axis machining helps maintain optimal tool angles and improves process stability for complex titanium parts.

Plastics are widely machined when high precision, dimensional consistency, or small-batch production is required. Compared with injection molding or 3D printing, CNC machining offers tighter tolerances, better surface control, and greater flexibility in material selection:

ABS

ABS is easy to machine and offers good impact resistance. It cuts cleanly at moderate speeds and is commonly used for functional prototypes, housings, and enclosures where strength and dimensional stability are needed.

PMMA (Acrylic)

PMMA is valued for its excellent optical clarity. During machining, controlled cutting angles and sharp tools are essential to prevent edge chipping and surface whitening. It is commonly used for optical parts, display components, and transparent covers.

POM (Acetal)

POM provides high stiffness, low friction, and excellent dimensional stability. It machines well with minimal deformation, making it suitable for precision gears, bushings, and mechanical components that require tight tolerances.

Nylon

Nylon is tough and wear-resistant but more flexible than POM. It requires careful control of cutting forces to avoid deformation. Nylon is often selected for gears, bearings, and sliding components.

Polycarbonate (PC)

Polycarbonate offers high impact resistance and good transparency. It is more sensitive to heat during machining, so lower cutting speeds and proper chip evacuation are important to maintain surface quality.

PET

PET machines cleanly and provides good dimensional stability and chemical resistance. It is commonly used for mechanical parts, electrical components, and food-related fixtures where consistency is critical.

PVC

PVC is easy to machine but requires attention to heat generation and fume control. It is typically used for industrial components, enclosures, and chemical-resistant parts.

Wood

Wood machining allows complex shapes that are difficult to achieve by manual methods. CNC machining is commonly used for repeatable wooden components with consistent geometry.

Common examples: hardwoods, softwoods, plywood, engineered wood

Key considerations: dust control, layer delamination in plywood

Typical uses: furniture components, decorative parts, prototypes

In practice, material selection is not only about machinability, but also about part function, tolerance, and production volume. CNC machining offers the flexibility to switch materials without changing the entire manufacturing process.

Applications of Machining

Machining plays a critical role in modern manufacturing by producing precise, repeatable parts across a wide range of industries. From heavy industrial equipment to high-precision medical components, machining enables tight tolerances, consistent quality, and scalable production.

| Application Category | Typical Machined Parts | Key Machining Requirements | Common Industries |

| Industrial & Mechanical Parts | Shafts, housings, brackets, gears | Dimensional accuracy, strength, repeatability | Industrial equipment, machinery manufacturing |

| Aerospace & Automotive Components | Engine parts, structural frames, precision mounts | Tight tolerances, lightweight materials, reliability | Aerospace, automotive, motorsport |

| Medical & Precision Components | Implants, surgical tools, instrument housings | Micron-level tolerances, surface finish, consistency | Medical devices, healthcare equipment |

| Consumer & Custom Products | Enclosures, connectors, prototypes | Aesthetic finish, customization, fast turnaround | Consumer electronics, custom manufacturing |

Machining remains a core manufacturing process because it delivers high precision, material flexibility, and reliable repeatability. At the same time, it has practical limitations related to cost, waste, and geometric constraints. Understanding both sides helps manufacturers choose machining where it delivers the most value.

Advantages vs Limitations of Machining

Machining is a core manufacturing process valued for its precision, reliability, and versatility. By removing material in a controlled way, machining enables tight tolerances, consistent quality, and compatibility with a wide range of materials. These strengths make it suitable for both rapid prototyping and high-volume production across demanding industries.

| Aspect | Advantages of Machining | Limitations of Machining |

| Accuracy & Consistency | Achieves tight tolerances down to ±0.01 mm with excellent repeatability | Accuracy depends on machine condition, tooling, and programming skill |

| Material Compatibility | Works with metals, plastics, composites, and hard alloys | Very hard or brittle materials increase tool wear and cost |

| Production Flexibility | Ideal for both prototyping and mass production | Not always cost-effective for very simple or low-volume parts |

| Surface Quality | Produces smooth finishes that may reduce secondary operations | Complex internal geometries may require multiple setups |

| Process Control | CNC automation reduces human error and ensures consistency | Requires skilled operators and CAM programming expertise |

| Cost Efficiency | Scales well for precision parts and high-value components | Generates material waste compared to additive manufacturing |

FAQs

What Are Types Of Machining?

From my experience, machining types mainly include turning, milling, drilling, grinding, boring, and broaching. Each process removes material differently to achieve specific shapes, tolerances, or surface finishes. In real production, these methods are often combined to balance accuracy, efficiency, and cost for industrial parts.

What Is The Difference Between CNC And Machining?

Machining is the general process of material removal, while CNC refers to how the machine is controlled. I see CNC as an automation method that uses programmed instructions to perform machining with higher accuracy, repeatability, and efficiency than manual machining.

What Is The CNC Machining Process?

The CNC machining process starts with design and CAD/CAM programming, followed by machine setup, automated cutting, and final inspection. In practice, CNC machining can achieve tolerances around ±0.01 mm, making it ideal for precision parts in aerospace and industrial applications.machining processes in manufacturing

Which One Is Better, Casting Or Machining?

Casting is better for complex shapes and high-volume production, while machining is better for precision and tight tolerances. In my projects, machining is preferred when accuracy, surface finish, and dimensional control are critical, even if the part starts as a casting.

Conclusion

Machining remains a cornerstone of modern manufacturing because it delivers reliable precision, repeatability, and material versatility. By combining proven processes with CNC automation, machining supports everything from prototypes to high-volume production. When accuracy, surface quality, and dimensional control matter, machining continues to be one of the most effective and trusted manufacturing solutions.