As a longtime manufacturer, I’m often asked by clients: What is insert molding? Insert-molded parts not only combine the strength of metal with the lightweight of plastic, but also reduce the number of complex assembly steps, improving reliability and appearance consistency. In this article, I’ll provide an in-depth understanding of insert molding’s core principles, applications, and the advantages it brings to manufacturing. I hope to help you quickly understand why it’s becoming a key technology in modern manufacturing.

What Is Insert Molding

Insert molding involves placing metal or other insert parts into a mold during the injection molding process, then surrounding them with plastic through the injection molding process to form a single, integrated unit. This process is like “inserting nuts, electrical connectors, or small parts into a mold in advance” to create a one-piece mold, eliminating the need for subsequent assembly steps.

The core concept of this process is straightforward: metal + plastic or non-plastic + plastic . This combination not only allows the product to combine the advantages of different materials but also enhances overall strength and functionality. For example, metal provides structural strength, while plastic contributes to lightweighting and electrical insulation.

Here are a few common examples:

Nut inserts : In automotive parts or mechanical components, metal nuts embedded in plastic parts can improve wear resistance and fastening strength.

Electronic connectors : The metal pins commonly found in electrical connectors are integrally molded with the plastic housing to ensure stable conductivity and good insulation.

Medical devices : Some medical device parts require the lightness of plastic and the stability of metal, and insert molding can meet this need.

To me, insert molding is more than just a “manufacturing method”; it’s a solution that simplifies complex designs and optimizes assembly . It saves labor, reduces errors, and elevates product performance, reliability, and aesthetics. As the manufacturing industry’s demand for efficient, lightweight, and multifunctional parts continues to grow, insert molding is becoming the process of choice in a growing number of industries.

Key Points Of Design And Process Of Insert Molding

In the actual production of insert molding, the process is more than just placing a metal insert into a mold and then injecting it. Achieving high-quality, consistent, and mass-produced finished products requires rigorous design and process control. From insert shape design and mold positioning to controlling plastic flow and shrinkage, and even implementing automated production, each step directly impacts the finished product’s strength, appearance, and assembly reliability.

Insert Design Requires

that the insert surface be clean and rust-proofed. At the same time, the design must consider preventing displacement (such as adding positioning grooves or textures) and ensure that the molten plastic can be filled smoothly to avoid bubbles or gaps.

Mold Design:

The mold needs to have appropriate positioning grooves and fixtures to ensure the stability of the insert during the injection molding process. For mass production, the mold cooling system and runner design also need to be optimized to improve efficiency.

Shrinkage And Tolerance Control:

Plastics have a certain shrinkage rate after injection molding, which usually needs to be controlled within the range of ±0.05 mm to ±0.005 mm depending on the material to meet the assembly and functional requirements of high-precision products.

Automation And Robotic Insert Placement

In mass production, robotic automatic insert placement can significantly improve efficiency and consistency and reduce human error. It is especially suitable for industries with extremely high precision requirements such as electronic connectors and automotive parts.

Insert Molding Process

Insert molding is a widely used advanced process in the manufacturing industry . Its core concept is to combine an insert of metal or other materials with plastic in a single step, creating a solid, integrated part. Compared to traditional secondary assembly methods, insert molding not only significantly improves the mechanical strength and durability of parts, but also reduces assembly steps, lowering production costs and shortening manufacturing cycles. As such, it plays a key role in industries such as automotive parts, consumer electronics, medical devices, and aerospace.

Insert Molding In Injection Molding

In the injection molding scenario, the insert molding process is clear and highly automated:

Insert design and preparation

Before entering the molding process, metal parts or non-plastic inserts must be cleaned, rust-proofed and positioned to ensure a firm bond with the plastic during the molding process.

Inserts

can be placed manually or by automated robotic arms to achieve precise positioning of batch inserts, ensuring efficiency and consistency.

Plastic Injection :

The heated, molten thermoplastic is injected into the mold cavity under high pressure, quickly filling and wrapping the insert to form a preliminary bond.

Cooling And Demoulding

After the plastic cools and solidifies, the mold is opened and the product is taken out. At this time, the insert and the plastic have become a firmly integrated finished product.

The most common applications of this approach include:

Nut inserts (to enhance the connection strength of plastic parts)

Electronic connectors (to improve electrical performance and reliability)

Medical devices (meeting high cleanliness and corrosion resistance requirements)

With its high efficiency and stability, insert molding under the injection molding process is the first choice for mass production.

The Role Of CNC Machining In Insert Molding

Although the core of insert molding is injection molding, CNC machining is also indispensable in the front-end and back-end processes:

Insert Manufacturing

Metal inserts are often produced by CNC turning or milling. For example, stainless steel nuts, brass electrodes or aluminum heat sinks all require CNC to ensure high-precision dimensions in order to perfectly integrate with the plastic.

molds

are a prerequisite for successful insert molding. Mold cavities are usually completed by CNC milling and EDM to ensure the accuracy of complex surfaces and tiny details.

Subsequent finishing

Some high-demand products require CNC secondary processing after demoulding, such as removing flash, drilling micro holes or adding assembly slots to meet final assembly or functional requirements.

Therefore, Insert Molding Can Be Seen As A Combination Of Injection Molding And CNC Machining :

Injection molding : responsible for achieving material coating and efficient molding.

CNC : Responsible for insert manufacturing, mold accuracy assurance, and necessary post-processing.

The two complement each other and jointly ensure that the product meets both structural strength and high-precision requirements of appearance and function.

In summary, insert molding is not simply an injection molding process, but rather a comprehensive solution that integrates multiple manufacturing methods. Injection molding offers the advantages of efficiency and mass production, while CNC machining ensures precision and quality. For industries pursuing lightweighting, strength, and functionality, insert molding is undoubtedly one of the most competitive solutions.

Common Materials For Insert Molding

Insert molding is a widely used advanced process in the manufacturing industry. It combines metal, ceramic, or electronic components with plastics in a single process, creating a strong, integrated part. Compared to traditional secondary assembly methods, this process not only significantly improves the mechanical strength and durability of parts but also reduces assembly steps, thereby reducing production costs and shortening manufacturing cycles. Consequently, insert molding plays a key role in automotive parts, consumer electronics, medical devices, aerospace, and other fields.

In practical applications, the materials used in insert molding are primarily divided into two categories: insert material and plastic matrix. The proper combination of these materials determines the ultimate performance of the part. The following table summarizes commonly used insert and plastic materials and their characteristics, providing a more intuitive understanding of material selection :

| Classification | Material | Features | Common Applications |

| Insert materials | Stainless Steel | High strength, corrosion resistance, high temperature resistance | Medical devices, structural parts, electronic connectors |

| Copper | Excellent electrical and thermal conductivity | Electrical components and connectors | |

| Brass | Easy to process, good wear resistance, high cost performance | Fasteners, valves, electronic connectors | |

| Aluminum | Lightweight, corrosion-resistant, moderate strength | Auto parts, electronic housings, aviation components | |

| Ceramic | High temperature resistance, wear resistance, electrical insulation | Sensors, medical, electronic insulation components | |

| Electronic Components | Function integration and enhanced intelligence | Sensor chips, connectors | |

| Plastics | ABS | Easy to form, impact resistant, low cost | Automotive interiors, consumer electronics |

| PBT | Chemical resistance and good electrical properties | Automotive electronic control, electronic connectors | |

| PC | High strength, transparent, impact resistant | Medical devices, optical parts | |

| PEEK | High temperature resistance, corrosion resistance, excellent performance | Aerospace, medical implants | |

| Nylon (PA6, PA66+GF) | High strength, wear resistance, and dimensional stability | Auto parts, mechanical parts | |

| LCP (Liquid Crystal Polymer) | High fluidity, high temperature resistance, electrical insulation | Electronic connectors, micro-structures |

The advantages of insert molding lie not only in the molding process itself but also in the choice of materials. The metal insert typically provides strength, conductivity, or wear resistance, while the plastic matrix offers lightweighting, insulation, and design flexibility. This combination makes insert molding an ideal solution for manufacturing high-performance parts across a wide range of industries.

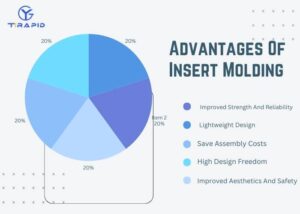

Advantages Of Insert Molding

In modern manufacturing, insert molding, with its unique process advantages, has become a common solution in industries such as automotive, electronics, medical, and aerospace. Compared to traditional separate processing and secondary assembly, insert molding efficiently combines multiple materials in a single process, improving product performance while optimizing production efficiency and design.

Below, we analyze the main advantages of insert molding from five key aspects :

Improved Strength And Reliability

The metal and plastic are combined in one step in the mold, avoiding the loosening or shifting problems in traditional assembly, and significantly improving the mechanical strength and long-term stability of the parts.

Lightweight Design

replaces part of the metal structure with plastic, making the overall weight lighter. It is particularly suitable for industries with strict requirements on lightweighting, such as automobiles, drones and consumer electronics.

Save Assembly Costs

Parts are formed in the mold at one time, eliminating the need for secondary assembly, reducing labor costs, and reducing potential errors in the production process.

High Design Freedom

Insert molding allows multiple functions to be integrated into limited spaces, such as electrical connections, screw fixation or heat dissipation structures, thereby reducing part size and improving functionality.

Improved Aesthetics And Safety

: The metal inserts are completely wrapped in plastic, giving them a smoother and more beautiful appearance while reducing safety hazards caused by loose parts or exposed metal.

In summary: Insert molding is not only a manufacturing process, but also a solution to improve product performance, reduce production costs, and enhance market competitiveness . Its advantages allow manufacturers to achieve the best balance between efficiency and quality.

While insert molding offers significant advantages in structural strength, lightweight design, and production efficiency, it is not without limitations. In practical applications, the process places higher demands on insert precision, material matching, and mold design, while also presenting challenges in terms of cost and production flexibility. Understanding these limitations can help engineers make more informed trade-offs when selecting designs and processes.

Limitations And Challenges Of Insert Molding

While insert molding offers significant advantages in structural strength, lightweight design, and production efficiency, it is not without limitations. In practical applications, the process places higher demands on insert precision, material matching, and mold design, while also presenting challenges in terms of cost and production flexibility. Understanding these limitations can help engineers make more informed trade-offs when selecting designs and processes.

| Challenges | illustrate | Typical impact |

| High requirements for insert alignment accuracy | If the insert is not positioned correctly in the mold, it will cause uneven plastic coating or the finished product to be scrapped. | Increase scrap rate and affect batch consistency |

| Thermal expansion differences | Metals and plastics have different coefficients of thermal expansion, which may cause stress or deformation after cooling | Affects the dimensional accuracy and long-term stability of the finished product |

| High cost | Compared with traditional injection molding, it requires special molds and additional processes such as CNC insert processing and mold positioning. | Higher initial mold investment and production costs |

| Process complexity | Comprehensive process involving injection molding + insert positioning + mold design | Higher requirements for factory automation level and technical personnel |

| Limited scope of application | Not all parts are suitable for insert molding, such as those that are subject to excessive force or require extremely lightweight structures. | It is necessary to judge whether to adopt it in combination with the specific application scenario. |

The Difference Between Insert Molding And Overmolding

In the field of plastic injection molding, insert molding and overmolding are two common and often confused processes. While both utilize the injection molding process to combine different materials, they differ significantly in the process steps, applicable materials, and end applications. Understanding the differences between the two helps designers and manufacturers choose the most appropriate production method based on their specific needs, achieving the optimal balance between performance and cost.

| Comparison Dimension | Insert Molding | Overmolding |

| Craftsmanship | The metal or non-plastic insert (such as nuts, electronic components) is placed in the mold cavity, and then the plastic is injected to wrap it, completing the molding in one step. | First, a plastic matrix is formed, and then another plastic is secondary-injected on its surface to achieve the combination of plastic + plastic. |

| application | Commonly used in nut inserts, electronic connectors, medical devices and other products that require structural strength and electrical performance. | Commonly found in tool handles, electronic housings, and consumer products (such as toothbrush handles), they enhance comfort, slip resistance, and appearance. |

| Material | The typical combination is “metal + plastic”, which can also include ceramic + plastic. | Typical combinations are “hard plastic + soft plastic” or “between different plastics”. |

| cost | Relatively low, suitable for mass production, reducing secondary assembly costs. | The cost is slightly higher and requires multiple injection moldings, but it can enhance product added value and user experience. |

Insert molding emphasizes structural strength and functionality and is suitable for engineering and industrial parts . Overmolding, on the other hand, focuses on comfort, aesthetics, and user experience and is commonly found in consumer products and handheld devices. Each has its advantages, and the choice of process depends on the product’s end-use application .

Typical Application Industries

Insert molding has become one of the most widely used injection molding processes in the manufacturing industry due to its structural reliability, design flexibility, and cost advantages . By combining metal parts or other inserts with plastic in a single molding process, this technology achieves an ideal balance between lightweighting, increased strength, and functional integration. As a result, it plays a key role in a wide range of industries, from everyday consumer goods to high-end aerospace components.

Automotive

sensors, electronic connectors, gears, nuts and other components are widely used in engine systems, vehicle electronic controls and safety components to improve reliability and durability.

Medical

surgical instruments, syringe accessories, and medical plugs meet high cleanliness, corrosion resistance, and precision requirements to ensure safety and stability in the medical environment.

Electronic

USB interfaces, plugs, power modules, etc. ensure electrical performance and connection stability and are commonly used in consumer electronics and communication equipment.

Household Appliances And Industrial

motor housings, plastic handles, switches, etc., to improve product life and safety while reducing assembly processes.

Lightweight electronic connectors and structural parts in aerospace ensure strength while reducing weight, and are an important part of the lightweight design of aircraft and aerospace equipment.

FAQs

How Does Insert Molding Work?

Insert Molding Combines Metal Or Other Inserts With Molten Plastic In A Single Injection Cycle. I First Prepare The Inserts By Cleaning And Positioning Them, Then Place Them Into The Mold Cavity. Heated Plastic At 220–280°C Flows Around The Inserts Under High Pressure, Creating A Strong Bond. After Cooling For About 30–60 Seconds, The Mold Opens And A Finished One-Piece Part With ±0.05 mm Accuracy Is Released.

What Is The Difference Between Over Molding And Insert Molding?

Insert Molding Uses Pre-Manufactured Inserts Like Metal Nuts Or Pins, Which I Place Into The Mold Before Plastic Injection. Over Molding, By Contrast, Involves Molding One Plastic Layer Over Another, Often Soft TPE Over Rigid ABS Or PC. Insert Molding Reduces Secondary Assembly, While Over Molding Improves Grip, Aesthetics, And Comfort. Typically, Insert Molding Handles ±0.05 mm Tolerance, While Over Molding Focuses On Ergonomic Performance.

What Are The Four Types Of Molding?

In Manufacturing, I Commonly Work With Four Key Types: Injection Molding, Compression Molding, Blow Molding, And Rotational Molding. Injection Molding Handles High-Volume Plastic Parts With ±0.05 mm Precision. Compression Molding Shapes Thermoset Plastics Like Rubber Under High Pressure. Blow Molding Creates Hollow Parts Such As Bottles. Rotational Molding Uses Heated Molds Rotated At Multiple Axes To Form Large Hollow Parts. Each Offers Distinct Cost, Tolerance, And Application Profiles.

Does Your Part Require Overmolding Or Inserts?

I Decide Based On Function, Volume, And Material. If The Part Requires Electrical Conductivity, Threads, Or Structural Reinforcement, Insert Molding With Brass, Steel, Or Aluminum Inserts Is Best. If The Part Needs Comfort, Anti-Slip, Or Aesthetic Enhancements, Overmolding With Soft TPE Or TPU Is Ideal. In Prototyping Runs, Inserts Save Assembly Costs; In Consumer Products, Overmolding Boosts Ergonomics. The Right Choice Can Cut Costs By 20–30% While Enhancing Usability.

Conclusion

I believe insert molding truly demonstrates the value of combining the strength of metal with the flexibility of plastic. It not only allows me to efficiently produce lightweight yet strong parts, but also maintains consistent quality across both small-batch precision parts and high-volume consumer products. With the advancement of automation and smart manufacturing, I believe insert molding will play a role in even more areas, helping customers achieve more efficient and reliable product manufacturing.