What is G10 material? It is a fiberglass epoxy laminate with high strength, low moisture absorption, and excellent durability, widely used in insulation, aerospace, marine, and knife handles.

What Is G10 Material

G10 is an epoxy fiberglass laminate defined by NEMA standards. Made from glass cloth and epoxy under heat and pressure, it offers high strength, insulation, and stability. Unlike flame-retardant FR-4, G10 is typically non-retardant, supplied in sheets, rods, or tubes, and widely used in mechanical jigs, tools, and structural parts.

Get 20% offf

Your First Order

G10 Material Standard

G10 material is strictly defined and regulated by several international standards to ensure consistency in composition, mechanical strength, electrical insulation, and thermal performance. These standards are the benchmark for engineers when selecting G10 for critical applications.

NEMA G-10 and FR-4

Issued by the National Electrical Manufacturers Association (NEMA).

G-10 specifies non-flame-retardant epoxy fiberglass laminates, while FR-4 defines the flame-retardant variant.

Typical dielectric strength: 19–50 kV/mm.

Mechanical strength requirements include tensile ≥ 310 MPa, flexural ≥ 450 MPa, and compressive ≥ 450 MPa.

MIL-I-24768/2

U.S. military standard for epoxy-resin glass-cloth laminates.

Known as Type GEE, this standard ensures traceability, batch consistency, and qualification testing.

Specifies properties such as water absorption ≤ 0.1%, operating temperature −60 °C to +140 °C, and flammability limits.

IEC 60893

International standard by the International Electrotechnical Commission.

Defines thermosetting resin-based industrial laminates, including G10 and FR-4 grades.

Key requirements: relative permittivity ≤ 5.4, dissipation factor ≤ 0.035, thermal index ≥ 130 °C, ensuring suitability for electrical insulation in global markets.

Together, these standards guarantee that G10 laminates meet uniform electrical, thermal, and mechanical benchmarks, making them suitable for high-reliability sectors such as aerospace, defense, power generation, and electronics manufacturing.

What Are The Core Properties Of G10 Materials

G10 offers outstanding electrical, mechanical, thermal, and chemical properties: high dielectric strength, excellent strength-to-weight ratio, low water absorption, and chemical resistance, though less flame-retardant than FR-4.

| Property Category | Key Values / Performance | Notes / Applications |

| Electrical | Dielectric strength 19–50 kV/mm, Volume resistivity 10¹²–10¹⁴ Ω·cm | Excellent insulation, stable in humid environments |

| Mechanical | Tensile 250–350 MPa, Flexural 300–500 MPa, Compressive 400–500 MPa, Density 1.8–1.95 g/cm³ | Strong, stiff, and dimensionally stable |

| Thermal | Glass transition (Tg) 130–180 °C, Continuous use 120–140 °C (G11 higher), Thermal conductivity ~0.3 W/m·K | Reliable for medium-temperature applications |

| Chemical / Environmental | Water absorption 0.05–0.3%, Resistant to oils and weak acids | Long-term outdoor use limited—UV causes yellowing |

| Fire Behavior | G10: UL94 HB, FR-4: UL94 V-0 | FR-4 preferred for flame-retardant requirements |

G10 Material Appearance and Supply Form

G10 is not only known for its excellent electrical and mechanical properties but also for its standardized and diversified appearance and supply forms. This versatility allows G10 to meet the needs of both industrial and consumer applications.

Supply Forms

Sheets: The most common form, with thicknesses typically ranging from 0.2–50 mm. Standard sheet sizes include 1020 × 1220 mm and 1220 × 2440 mm. Special orders may provide ultra-thick panels (>100 mm) or oversized sheets for specific applications.

Rods: Diameters from 6–200 mm, with lengths usually 1000 mm or 2000 mm. Often used for electrical insulators, positioning pins, and wear-resistant parts.

Tubes: Inner diameters from 10–500 mm, wall thicknesses 1–20 mm, and lengths up to 1–2 m. Suitable for motor insulation sleeves, structural supports, and chemical-resistant bushings.

Appearance

Standard Colors: Natural jade green is the most common NEMA G10 color.

Industrial Colors: Black, khaki, and gray are widely used for technical and industrial applications.

Layered Decorative Patterns: By stacking fiberglass cloth of different colors, G10 sheets can produce striped or wavy patterns. This makes them popular for knife handles, firearm grips, and outdoor tools, where machining reveals colorful layers.

Custom Colors: Some suppliers provide over 20 options, including red, blue, orange, purple, and even glow-in-the-dark variants, catering to consumer markets that value aesthetics.·

Tolerances and Quality

Thickness tolerance: typically ±0.10 mm for thin sheets and ±0.30 mm for thicker ones.

Surface finishes: ground, matte, or glossy.

Flatness: usually ≤ 0.5 mm per meter.

The variety in appearance and supply forms makes G10 suitable for applications ranging from high-voltage insulation components to aesthetic consumer products. Its customizable colors and layered structures add visual value while maintaining its high-performance standards.

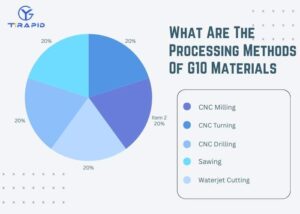

What Are The Processing Methods Of G10 Materials

G10 is a glass fiber reinforced epoxy laminate with high strength, strong abrasiveness, and a certain degree of brittleness. These characteristics directly determine its processing methods and process parameters. Common processing methods for G10 include CNC milling, turning, drilling, sawing, and water jet cutting.

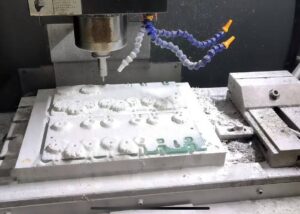

CNC Milling

Milling is widely used for creating slots, pockets, and contours in G10 sheets.

Due to its abrasive glass fibers, carbide or diamond-coated end mills are recommended.

Typical cutting speed: 50–150 m/min.

Depth of cut: 0.2–0.5 mm/pass to prevent delamination.

Feed rate: 0.05–0.20 mm/rev, depending on tool geometry and thickness.

Using mist lubrication or coolant reduces tool wear and fiberglass dust.

CNC Turning

Applied for rods or tubular G10 components.

Requires high spindle speeds (2000–4000 rpm) with light depth of cut to minimize chipping.

Carbide inserts are preferred, diamond-coated inserts improve tool life by up to 5–10 times compared to HSS tools.

Typical feed: 0.03–0.08 mm/rev.

Proper fixturing is critical to reduce vibration and prevent surface cracking.

CNC Drilling

Drilling G10 requires specific techniques to prevent fiber breakout and delamination at hole exits.

Recommended drill type: carbide twist drills with 135° split points.

Cutting speed: 30–60 m/min.

Peck drilling with short step depths (<2× diameter) reduces heat and improves hole quality.

For threaded holes, metal inserts are advised since direct threads wear quickly in G10.

Sawing

Suitable for initial sheet sizing or straight cuts.

Requires carbide-tipped circular saw blades with fine tooth pitch (e.g., 8–12 teeth per inch).

Cutting speed: 600–1000 m/min.

Feed rate must be controlled to avoid overheating, which can cause resin burn or edge chipping.

Dust extraction is essential, as sawing generates large volumes of fine fiberglass dust.

Waterjet Cutting

Best method for thick plates (>10 mm) and complex profiles.

Provides ±0.10 mm dimensional accuracy with no heat-affected zone.

Eliminates edge burning and reduces delamination compared to laser cutting.

Typical pressure: 3000–4000 bar (ultra-high-pressure waterjet).

Commonly applied in aerospace fixtures, industrial insulation panels, and mechanical structures.

What Are The Cutting Tips For G10 Materials

Because G10 contains a high proportion of fiberglass reinforcement, it is highly abrasive and difficult to machine. Proper cutting strategies are essential to ensure dimensional accuracy and extend tool life.

Tool Selection

Use carbide tools as a baseline, for high-volume or precision machining, diamond-coated tools are recommended, offering 5–10 times longer life compared with standard HSS tools.

Spindle Speed and Feed Rate

Recommended spindle speeds: 6000–12,000 rpm. Depth of cut per pass: 0.2–0.5 mm to minimize tool loading and delamination. Feed rate should be controlled at 0.02–0.08 mm/rev, balancing efficiency with reduced fiber pull-out.

Cutting Method

Apply multiple shallow passes instead of a single deep cut. This reduces heat buildup, preventing resin burning or glass fiber breakout. All edges should be chamfered and deburred to avoid corona discharge in electrical parts or stress concentration in mechanical components.

Threaded Holes

Since G10 is relatively brittle, direct tapping often leads to wear or cracking. Embedding metal inserts (stainless steel, brass, or aluminum) increases thread life by 3–5 times and improves reliability under repeated assembly/disassembly.

By applying these optimized cutting practices, manufacturers can achieve higher-quality G10 parts for electrical insulation, precision fixtures, and knife/tool handles, while lowering tool costs and scrap rates.

How Are G10 Materials Joined and Finished

G10 is a thermoset composite with low surface energy, which makes bonding challenging without proper preparation. For reliable structural performance, specific adhesives and surface treatments are required.

Adhesive Selection

Epoxy adhesives: Preferred for structural joints, with lap shear strengths typically in the range of 18–25 MPa.

Acrylic adhesives: Offer faster curing times and good impact resistance, though their shear strength is slightly lower, around 12–18 MPa.

Cyanoacrylates: Sometimes used for quick fixes but not recommended for load-bearing applications due to poor long-term durability.

Surface Preparation

Proper surface treatment can increase bond strength by 30–50%. Recommended methods include:

Mechanical roughening: Sanding or grit blasting with 80–120 mesh alumina particles to increase surface area.

Plasma or flame treatment: Improves surface energy, enhancing resin wetting and chemical adhesion.

Cleaning: Remove contaminants with isopropanol or acetone before bonding.

Surface Finishes

G10 can be customized for both functional and aesthetic purposes:

Polishing: Achieves smooth, glossy surfaces with Ra < 0.8 μm, suitable for decorative or ergonomic parts.

Brushing / Sandblasting: Produces matte or textured finishes that enhance grip, commonly used in knife handles and firearm grips.

Layered decorative laminates: By stacking colored fiberglass fabrics, manufacturers create striped or patterned effects. After machining, these layers reveal unique multi-color textures. Over 20 color variations are available, including black, khaki, red, blue, and glow-in-the-dark options.

By combining the right adhesive system with proper surface preparation and finishing techniques, G10 components can achieve high mechanical reliability in industrial assemblies while also meeting aesthetic demands in consumer products.

What Is the Lamination Process of G10 Material

The G10 lamination process involves fiberglass cloth impregnation with epoxy, prepreg stacking, hot pressing at ≥1000 psi and 160–180 °C, followed by post-curing at 150–170 °C. Glass content is ~55–65 wt%, thickness ranges 0.2–50 mm, with customizable fiber orientation and colors. The final laminates offer high strength, low water absorption, and excellent insulation, widely used in electrical, aerospace, and mechanical structures.

Fiberglass Cloth Impregnation with Epoxy Resin

Electrical-grade fiberglass cloth is impregnated with difunctional or trifunctional epoxy resin. The final glass content is typically 55–65 wt%, ensuring both strength and insulation.

Prepreg Preparation

The impregnated cloth is partially dried to form prepreg in a semi-cured state. Resin content is usually controlled at 35–45% to allow proper resin flow during lamination.

Prepreg Stacking

Layers are stacked to the designed thickness and orientation, using unidirectional, cross-ply, or multi-axial layups. Fiber orientation directly affects tensile strength and flexural modulus. For example, a 90°/0° cross-ply layup enhances in-plane strength.

Hot Press Curing

Consolidation is performed under ≥1000 psi (≈6.9 MPa) and 160–180 °C. The epoxy undergoes crosslinking, tightly bonding fibers and resin to form a dense laminate.

Post Curing

Laminates are reheated at 150–170 °C for several hours to increase crosslinking density, improving heat deflection temperature (HDT) and dielectric strength.

Customization

Fiber orientation, thickness (0.2–50 mm), and surface appearance (e.g., multi-color decorative laminates) can be tailored for specific applications.

This process ensures G10 laminates exhibit high strength, low moisture absorption, and excellent dimensional stability, making them widely used in electrical insulation, aerospace, and mechanical structures.

What Is The Advantages And Limitations Of G10 Materials

G10 offers a high strength-to-weight ratio, excellent electrical insulation, dimensional stability, chemical resistance, and decorative layered patterns. However, it is non-recyclable, prone to UV degradation, has low thermal conductivity, can be brittle under impact, and generates hazardous dust during machining.

Advantages Of G10 Materials

High Strength-to-Weight Ratio

G10 exhibits a tensile strength of 250–350 MPa and flexural strength of 300–500 MPa, while maintaining a relatively low density of ~1.8–1.95 g/cm³.

This combination ensures lightweight structures with excellent load-bearing capability, making it suitable for aerospace and precision mechanical parts.

Excellent Electrical Insulation

Dielectric strength typically ranges from 19–50 kV/mm.

Volume resistivity: 10¹²–10¹⁴ Ω·cm, even under humid conditions.

Widely applied in high-voltage electrical insulation boards, PCB substrates, and transformer components.

Dimensional Stability & Low Water Absorption

Water absorption is low, around 0.05–0.30%, preventing swelling and dimensional distortion.

This property makes G10 ideal for marine and humid environments where stability is critical.

Good Chemical Resistance

Resistant to oils, lubricants, weak acids, and bases.

Maintains mechanical and dielectric performance in chemically aggressive environments, suitable for chemical plants and offshore applications.

Decorative Aesthetic Options

Produced in multi-layer laminates with varied colors.

Machining reveals layered patterns, enabling custom handles and consumer products with functional and aesthetic value.

Limitations Of G10 Materials

Not Recyclable (Thermoset)

G10 is a thermosetting material, once cured, it cannot be remelted or reshaped.

Disposal or recycling options are limited compared to thermoplastics, impacting sustainability.

UV Degradation

Prolonged exposure to UV light causes surface yellowing, chalking, and mechanical property loss.

Outdoor applications require UV-resistant coatings or protective paints.

Low Thermal Conductivity

Typical thermal conductivity is ~0.3 W/m·K, far lower than metals.

Heat dissipation is poor, restricting use in applications requiring thermal management.

Brittleness Under Extreme Impact

Despite its strength, G10 lacks ductility and may crack or chip under sudden high loads or sharp impacts.

Edge reinforcement or hybrid composites may be needed for shock-resistant designs.

Dust Hazard During Cutting

Machining generates fine fiberglass dust that can irritate skin, eyes, and respiratory systems.

Requires P100 respirators, dust extraction systems, and coolant/lubricant use during cutting.

How Does G10 Compare To Other Materials

G10 offers balanced performance among alternatives: FR-4 is flame-retardant and required in electronics, Micarta is cheaper but weaker, carbon fiber is stronger yet costly and conductive, engineering plastics are easier to process but lack insulation and moisture resistance.

| Material | Key Characteristics | Typical Applications |

| G10 (Reference) | Balanced performance with high strength, insulation, moisture resistance, and cost-effectiveness | Mechanical jigs, insulation boards, tool handles |

| FR-4 | Similar to G10 but with flame-retardant properties (UL94 V-0 certified) | Electronics, defense electronics (mandatory) |

| Micarta / Phenolic Laminates | Low-cost, but weaker mechanical/electrical strength and higher moisture absorption | Budget knife handles, basic insulation parts |

| Carbon Fiber Prepreg | Higher strength-to-weight ratio, lightweight, but conductive and very expensive | Aerospace, racing, high-end consumer goods |

| Engineering Plastics (PA, PEEK, PEI) | Easy to process (injection molding), but weaker insulation and moisture resistance | Mechanical parts, housings, general plastics |

What Specifications And Standards Should You Consider

Sourcing G10 requires checking specifications: thickness 0.2–50 mm, common sheet sizes 1020×1220 mm / 1220×2440 mm, certifications (UL, RoHS/REACH, MIL-spec), and cost drivers including grade, color, and machining tolerances.

Thickness & Size

G10 sheets are typically available in a thickness range of 0.2 mm to 50 mm, making them suitable for both precision electronic insulation parts and heavy-duty structural components.

Standard sheet sizes include 1020 × 1220 mm and 1220 × 2440 mm, with dimensional tolerances often controlled within ±0.1 mm for thin laminates and ±0.3 mm for thicker boards.

Custom sizes and cut-to-shape blanks are also available for CNC machining, minimizing material waste and improving cost-efficiency.

Certifications & Compliance

UL Flammability Ratings: G10 is generally classified as UL94 HB, while FR-4 variants achieve UL94 V-0, required for flame-retardant applications.

RoHS & REACH Compliance: Ensures G10 materials are free from hazardous substances (e.g., lead, cadmium, hexavalent chromium), meeting global environmental regulations.

Military & Aerospace Standards: Many G10 grades align with MIL-I-24768/2 and IEC 60893, ensuring material traceability, mechanical reliability, and dielectric performance for defense and aerospace projects.

Cost Drivers

Thickness: Costs increase significantly for boards above 20 mm due to higher resin usage and extended curing cycles.

Flame-Retardant Grade: FR-4 and halogen-free flame-retardant grades are typically 15–25% more expensive than standard G10.

Color & Texture: Specialty laminates with decorative layered patterns, glow-in-the-dark pigments, or custom surface finishes may add 10–30% to unit price.

Machining Tolerances: Tight dimensional tolerances (e.g., hole diameter ±0.05 mm, flatness <0.2 mm/m) increase machining complexity and production cost, especially for CNC-drilled or waterjet-cut components.

By considering these specifications and standards, engineers can ensure that the selected G10 material not only meets performance requirements but also achieves the best balance of compliance, reliability, and cost-effectiveness for its intended application.

How To Maintain G10 For Longevity

Proper maintenance extends G10’s lifespan: keep it dry, avoid UV exposure, and seal edges to limit moisture. For high-voltage use, inspect insulation regularly, UV coatings can significantly improve outdoor durability.

Proper Storage

G10 should be stored in dry environments with relative humidity below 60% to minimize moisture absorption.

Direct sunlight and UV radiation accelerate epoxy matrix degradation, causing yellowing, chalking, and up to 20–30% loss of dielectric strength over prolonged exposure.

Recommended storage: indoor, temperature-controlled warehouses at 15–25 °C, away from windows or UV sources.

Edge Sealing Against Moisture

Although G10 has a low water absorption rate (0.05–0.30%), prolonged exposure can still cause dimensional instability and reduced insulation.

Applying epoxy-based sealants or polyurethane coatings to exposed edges reduces moisture ingress by 50–70%, critical for marine and humid applications.

Routine Electrical Inspections

In high-voltage applications, dielectric properties must be monitored.

Standard checks include insulation resistance (≥10¹² Ω·cm) and dielectric breakdown tests (19–50 kV/mm) at scheduled maintenance intervals (e.g., every 12–18 months).

Early detection of performance drop prevents catastrophic failures in transformers, switchgear, and PCB fixtures.

UV Protection Measures

Outdoor G10 installations should use UV-resistant coatings (e.g., polyurethane or fluoropolymer paints).

Field data shows that applying a thin UV-blocking layer can extend service life by 2×, reducing surface degradation and maintaining mechanical integrity.

For example, in one marine project, coating G10 panels doubled their outdoor operational lifespan from 5 years to nearly 10 years.

What Is The Typical Applications Of G10 Materials

G10 has wide applications: in electronics for PCBs and insulation, in industry for jigs and spacers, in aerospace for non-conductive structures, in marine/chemical fields for corrosion resistance, and in consumer goods like knife and tool handles.

| Application Area | Key Requirements | Typical Uses |

| Electronics & Electrical | High dielectric strength, moisture resistance, dimensional stability | PCB substrates, insulation boards, transformer spacers, switchgear components |

| Industrial & Mechanical | High strength-to-weight ratio, chemical resistance, wear resistance | Jigs, fixtures, machine spacers, gears, washers, gaskets |

| Aerospace & Defense | Lightweight, non-conductive, thermal stability | Aircraft interior panels, non-conductive tooling fixtures, radar insulation |

| Marine & Chemical | Corrosion resistance, low water absorption | Pump supports, marine insulation panels, chemical plant fixtures |

| Consumer Products | Aesthetics, grip, durability | Knife handles, firearm grips, tool handles, sporting goods |

| 3D Printing & Tooling | Heat resistance, flatness, durability | Heated print beds, soldering/wave solder fixtures, reflow solder carriers |

FAQs

What Is G10 material Equivalent To?

From my engineering perspective, G10 is equivalent to FR-4 fiberglass laminate, except FR-4 includes flame-retardant additives (UL94 V-0). Both share tensile strength around 250–350 MPa, dielectric strength 19–50 kV/mm, and density near 1.9 g/cm³, making them interchangeable in many structural or insulation applications unless flame safety is critical.

Is G10 Plastic Or Metal?

I always explain that G10 is neither a pure plastic nor metal—it’s a thermoset composite made from woven fiberglass and epoxy resin. Its density (1.8–1.95 g/cm³) is lighter than aluminum yet stronger than many plastics. Unlike metals, it is non-conductive and corrosion-resistant, with dielectric strength up to 50 kV/mm, ideal for insulation parts.

Can G10 Be Used Outdoors?

Yes, but with precautions. In my projects, G10 performs well outdoors due to low water absorption (0.05–0.30%) and chemical resistance. However, prolonged UV exposure causes yellowing and 20–30% dielectric loss over time. I recommend UV-resistant coatings, which in one marine case doubled the panel’s service life from 5 to nearly 10 years.

Is G10 Food Safe?

From a materials compliance standpoint, G10 is not certified food-safe. Its epoxy matrix can release residues under high heat or contact with acids. While it’s durable for tool handles, I never recommend it for direct food contact. For food processing equipment, FDA-approved plastics like PEEK or HDPE are the safer choice.

What’s The Difference Between G10 And Fiberglass Sheets?

I clarify that G10 is a specific fiberglass epoxy laminate defined by NEMA standards, with controlled mechanical (tensile 250–350 MPa) and electrical properties (dielectric 19–50 kV/mm). Generic fiberglass sheets vary widely, sometimes polyester-based, with lower strength and higher water absorption. In short, G10 ensures consistency and certification, while fiberglass sheets may not.

Conclusion

G10 is a high-performance fiberglass epoxy laminate with exceptional electrical insulation, mechanical strength, and chemical resistance. While not flame-retardant like FR-4, it remains a top choice for electrical, mechanical, aerospace, and consumer applications. When processed correctly and maintained well, G10 delivers outstanding performance and value across industries.What are your thoughts on G10? Welcome to message us sharing your idea.