What Is Composite Material?In the fields of engineering and manufacturing, a common question arises: What are composite materials ? Simply put, composite materials are made by combining two or more materials with different properties, combining advantages such as lightweight, high strength, and corrosion resistance. They are widely used in industries such as aviation, automotive, medical, and energy. This article will provide a quick introduction to the definition, types, and application scenarios of composite materials.

What Are Composite Materials

Composite materials are novel engineering materials composed of two or more materials with different properties. By leveraging complementary advantages, they combine the strengths of each material while also addressing the shortcomings of each. For example, reinforcing fibers provide strength and rigidity, while the matrix ensures toughness and integrity.

Composite materials are becoming increasingly important in modern manufacturing. They offer advantages such as lightweight (higher specific strength than steel), high strength (tensile strength up to 2000 MPa), corrosion resistance (suitable for harsh environments), and customizable properties (performance can be adjusted by varying fiber and matrix types). They are also widely used in high-end industries such as aerospace, automotive, medical devices, and sustainable energy , becoming a key material driving industrial upgrading and green manufacturing.

As early as ancient times, humans have used natural composite materials. For example, mud bricks (mud and straw), bamboo (natural fiber structure), and wood (cellulose + lignin) are all typical natural composite materials.

glass fiber and resin-based composite materials emerged and were rapidly applied in the fields of construction, shipbuilding and military industry, marking the entry of composite materials into the engineering and industrialization stage.

Composite materials are now widely used in aerospace (aircraft wings, satellite structures), automotive (lightweight car bodies), energy (wind turbine blades), and healthcare (implants, prosthetics). Furthermore, with growing demands for environmental protection and sustainable development, bio-based and recyclable composite materials are becoming a new development trend.

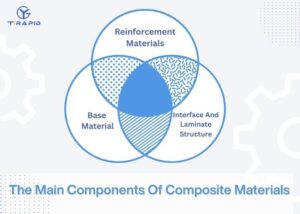

The Main Components Of Composite Materials

The core reason composite materials exhibit superior overall performance compared to single materials lies in their composition and structure. Typically, composite materials consist of three main components: reinforcement, matrix, and interface/laminate structure. The reinforcement phase determines the material’s strength and rigidity, the matrix provides overall support and toughness, and the interface structure ensures the effective integration of the two, resulting in a “1+1 > 2” performance advantage.

Reinforcement Materials

Reinforcement materials are the skeleton of composite materials and directly determine their mechanical properties and usage scenarios. Common reinforcement materials include:

Carbon fiber (CFRP): has extremely high specific strength and specific modulus and is widely used in aerospace and high-end automobiles.

Glass fiber (GFRP): low cost, good corrosion resistance, is one of the most common reinforcement materials.

Ceramic fiber: With high temperature resistance, it is suitable for use in engine hot end components.

Base Material

The matrix material is the carrier of the composite material, which fixes the reinforcement materials together and transmits external loads. Common matrix types are:

Polymer matrix: such as epoxy resin and thermoplastics, which are light in weight and have mature technology.

Metal matrix: such as aluminum alloy and titanium alloy, which has high strength and thermal conductivity.

Ceramic substrate: has high hardness and high temperature resistance, suitable for extreme working conditions.

Interface And Laminate Structure

The interface is the bond between the reinforcement and the matrix, and its quality directly impacts the overall performance of the composite. A good interface ensures effective stress transfer and prevents material delamination.

Composite materials often exist in a laminated structure, with alternating layers of reinforcement and matrix. By adjusting the lamination angle, thickness, and stacking sequence, the mechanical properties and crack resistance of the composite can be optimized.

What Types Of Composite Materials Are There

Common types of composite materials include polymer matrix composites (PMCs), metal matrix composites (MMCs), ceramic matrix composites (CMCs), carbon fiber reinforced composites (CFRPs), glass fiber reinforced composites (GFRPs), aramid fiber reinforced composites (AFRPs), hybrid composites, nanocomposites, natural fiber composites (NFCs) and functionally graded composites (FGCs) .

In the following sections, we will introduce the characteristics and typical applications of these composite materials one by one, and provide intuitive comparisons through tables to help engineers and designers quickly understand how to choose the appropriate composite materials for different engineering requirements :

Polymer Matrix Composites (PMCs)

Thermosetting or thermoplastic polymers are used as the matrix, and the reinforcement materials are often glass fibers or carbon fibers.

Features: lightweight, corrosion-resistant, easy to form and process, and adjustable mechanical properties.

Applications: automobile bodies, sports equipment, pressure vessels.

Metal Matrix Composites (MMCs)

The matrix is made of metals such as aluminum, magnesium, and titanium, and the reinforcement is usually ceramic particles, carbon fiber or boron fiber.

Features: It has both the toughness of metal and the high strength of fiber, with good wear resistance and thermal conductivity.

Applications: aircraft engine components, brake discs, radiators.

Ceramic Matrix Composites (CMCs)

The matrix is ceramic and the reinforcement is ceramic fiber or carbon fiber.

Features: high temperature resistance (>1200℃), creep resistance, and thermal shock resistance.

Applications: gas turbine blades, aircraft brakes, aerospace thermal protection systems

Carbon Fiber Reinforced Composites (CFRPs)

Carbon fiber is the main reinforcement and resin or metal is the matrix.

Features: Extremely high specific strength and specific modulus, weighing only 1/4 of steel, but can reach or even exceed the strength of steel.

Applications: aircraft wings, racing car chassis, satellite structures.

Glass Fiber Reinforced Composites (GFRPs)

The matrix is mostly polymer and the reinforcement material is glass fiber.

Features: low cost, corrosion resistance, and good insulation.

Applications: wind turbine blades, ships, and building reinforcement.

Aramid Fiber Reinforced Composites (AFRPs)

Aramid (such as Kevlar) is used as the reinforcement material.

Features: high toughness, excellent impact resistance and wear resistance.

Applications: bulletproof vests, aviation structural parts, sports protective equipment.

Hybrid Composites

Use two or more fiber hybrid reinforcements, such as carbon fiber + glass fiber.

Features: Balance of performance and cost, optimized design flexibility.

Applications: automotive structural parts, sports equipment.

Nanocomposites

By introducing nanoparticles (such as nanoclay, carbon nanotubes) into the matrix.

Features: Improve mechanical, electrical and thermal properties without significantly increasing weight.

Applications: Electronic packaging, energy storage devices, sensors.

Natural Fiber Composites (NFCs)

Hemp, bamboo and wood fibers are used as reinforcements and polymer is used as the matrix.

Features: Environmentally friendly, renewable, biodegradable.

Applications: green building materials, automotive interior panels.

Functionally Graded Composites (FGCs)

Material properties change gradually along the thickness direction or structural direction.

Features: Avoid interface stress concentration and improve thermal shock resistance and crack resistance.

Application: aircraft engines, nuclear power equipment.

| type | matrix | Enhanced | Performance characteristics | Typical Applications |

| PMCs | polymer | Glass fiber/carbon fiber | Lightweight, corrosion-resistant, low cost | Automobiles, sports equipment |

| MMCs | Metals (aluminum, titanium, etc.) | Ceramic particles/fibers | High strength, wear resistance, good thermal conductivity | Aircraft engines, brake discs |

| CMCs | ceramics | Ceramic/carbon fiber | High temperature resistance, creep resistance, thermal shock resistance | Gas turbines, spacecraft |

| CFRPs | Resin/Metal | carbon fiber | High specific strength and lightweight | Airplanes, racing cars, satellites |

| GFRPs | resin | fiberglass | Low cost, corrosion resistant | Ships, wind turbine blades |

| AFRPs | resin | Aramid fiber | High toughness and impact resistance | Bulletproof vests, aviation parts |

| Hybrid | Resin/Metal | blended fibers | Balanced performance and cost optimization | Automobile, composite structure |

| Nanocomposites | Polymer/Metal | Nanoparticles | Diverse functions and enhanced performance | Electronic devices and sensors |

| NFCs | polymer | natural fibers | Environmentally friendly and biodegradable | Green building materials, automotive interiors |

| FGCs | Composite matrix | Various fibers/particles | Gradient performance, strong crack resistance | Aviation and nuclear energy equipment |

What Are The Properties Of Composite Materials

Composites are a new class of engineering materials that combine two or more materials with distinct properties to achieve comprehensive performance. They combine lightweighting, high strength, corrosion resistance, and designability. In many cases, composites outperform traditional single materials like metals, plastics, or ceramics.

In terms of performance analysis, the characteristics of composite materials can be systematically evaluated from multiple dimensions including physics, chemistry, mechanics, thermal and electrical :

Physical properties: low density, high specific strength and high specific stiffness, making it outstanding in the field of lightweighting

Chemical properties: good corrosion resistance and resistance to chemical media erosion

Mechanical properties: high impact toughness, excellent fatigue life and fracture toughness

Thermal and electrical properties: Various properties such as thermal conductivity or insulation, electrical conductivity or insulation can be achieved according to the material combination

What Are The Advantages And Disadvantages Of Composite Materials

The value of composite materials lies in their ability to achieve an optimal balance between weight, performance, and functionality. However, they also have limitations, such as cost, recycling, and difficulty in testing. For designers and engineers, a thorough understanding of these advantages and disadvantages can help them make more rational material selection and structural design.

Advantages

High specific strength and high specific modulus: significantly reduce weight while maintaining or increasing strength

Strong corrosion resistance: suitable for harsh environments such as ocean and chemical industries

Designability: Fiber orientation and lamination methods can customize performance

Multifunctionality: While meeting the load-bearing requirements, it can also take into account the functions of conductivity, heat insulation, etc.

Disadvantages

High cost: expensive raw materials and complicated processing technology

Anisotropy: Performance varies significantly with direction

Poor recyclability: insufficient environmental friendliness

Difficult to repair and inspect: Microcracks or delamination defects are not easy to detect

What Are The Processing Technologies Of Composite Materials

Composite materials, characterized by anisotropy, layered structures, and brittleness, are significantly more difficult to process than metals. Therefore, selecting the appropriate processing technology is crucial for ensuring part performance, production efficiency, and cost-effectiveness. Modern manufacturing utilizes a variety of processes, including CNC precision machining, molding, pultrusion, injection molding, 3D printing, and automated layup, each suited to different scenarios and needs.

CNC Machining

a high-precision post-processing method for composite parts .

Features: Suitable for cutting, grooving, drilling, trimming and other operations, especially suitable for complex surfaces and small batch customized parts.

Accuracy: ±0.01 mm tolerance can be stably achieved, and surface roughness can reach Ra 1.6 μm.

PCD (polycrystalline diamond) tools or diamond-coated tools are required to reduce tool wear.

Difficulty: Composite materials are prone to burrs, delamination, fiber pullout, and thermal damage during the cutting process , requiring a strategy of low cutting force, high speed, and small feed .

Applications: Aviation composite skins, F1 racing carbon fiber parts, medical device housings.

Compression Molding

Process: Composite prepreg or molding compound is placed in a metal mold and cured under high temperature and pressure.

Advantages: good surface quality and high efficiency in mass production.

Disadvantages: High mold cost, suitable for medium and large batch production.

Applications: automotive interior parts, electronic housings, sports equipment.

Pultrusion

Process: Continuous fibers are impregnated with resin and then pultruded through a heated die.

Advantages: Long, constant-section profiles can be manufactured with high strength.

Applications: building structures, cable trays, and wind turbine blade beams.

Injection And Compression Molding

Injection molding: suitable for short fiber composite materials and has high production efficiency.

Compression molding: suitable for thermosetting composite materials, product size is stable.

Applications: electronic components, small automotive parts.

Automated Layup

ATL (Automated Tape Laying) and AFP (Automated Fiber Placement) are the mainstream processes for advanced composite material manufacturing.

Advantages: Accurate layer laying, high efficiency, suitable for large aerospace parts.

Disadvantages: Expensive equipment and high investment.

Additive Manufacturing (3D printing)

Process: Additive manufacturing using continuous carbon fiber or chopped fiber reinforcements.

Advantages: flexible design, high degree of freedom, and can realize complex topology optimization structure.

Applications: Rapid prototyping, drone parts, medical implants.

Composite Material Processing Technology Comparison Table

| Process Type | Accuracy grade | Cost level | Suitable for production | Typical application areas |

| CNC machining | ±0.01 mm | medium to high | Small batches | Aerospace, medical, automotive prototypes |

| Compression molding | ±0.1 mm | high | Medium and large batches | Auto parts, consumer electronics |

| Pultrusion | ±0.2 mm | middle | Batch continuous | Construction, wind power |

| Injection/Compression Molding | ±0.1 mm | middle | Large quantities | Consumer goods, automobiles |

| Automated Lamination ATL/AFP | ±0.05 mm | Very high | Large pieces | Aircraft wings, rocket structures |

| 3D printing | ±0.05 mm | medium to high | Small batches | Medical, drones, rapid prototyping |

What Are The Industrial Applications Of Composite Materials

Against the backdrop of carbon neutrality and energy conservation and emission reduction, composite materials are becoming a key material for achieving both high performance and sustainable development in industries such as aerospace, automotive, and energy. Whether in high-end equipment manufacturing or everyday consumer goods, the application of composite materials is constantly expanding and driving industrial upgrading.

Specifically:

Aerospace : Composite materials can reduce the overall weight of aircraft by 20–30%. Typical applications include wing skins, tail planes, fuselage frames, and satellite structures. Carbon fiber reinforced composites (CFRP) are particularly popular due to their high specific strength and fatigue resistance.

Automotive Manufacturing : Composite materials are used in body panels, drive shafts, and suspension components, helping to reduce fuel consumption and improve vehicle safety. Electric vehicles such as the BMW i series and Tesla all use carbon fiber or glass fiber components.

Medical Field : used in prostheses, implants, dental restorations, etc., due to its good biocompatibility, corrosion resistance and lightness, it can improve patient comfort and durability.

Construction Engineering : Widely used in bridge reinforcement, building facades and structural enhancement, FRP reinforcement technology has become an important means of concrete repair and reinforcement.

Energy Industry : Wind turbine blades, pressure vessels, and hydrogen storage tanks almost all rely on high-performance composite materials to achieve high strength and lightweight.

Consumer Electronics And Sports Equipment : From smartphone casings and laptop support structures to high-end bicycles, tennis rackets and skis, composite materials enable lightweight and high-performance products.

Future Trends

The research and application of composite materials have evolved from basic structures to high-performance functionalization. Future development will place greater emphasis on sustainability, functionality, and intelligence . This is not only a requirement for technological innovation but also an inevitable trend in response to global energy conservation, emission reduction, and industrial upgrading.

As new manufacturing processes (such as additive manufacturing and intelligent manufacturing) continue to mature, composite materials will demonstrate breakthrough potential in a wider range of industrial scenarios. The following trends are particularly worthy of attention:

Sustainable And Recyclable Composites:

One of the biggest challenges facing composite materials today is recycling. In the future, the use of biodegradable resins, bio-based fibers, and thermoplastic matrices will be increasingly adopted to achieve material recycling and promote green manufacturing and a circular economy.

Self-Healing Composite Materials,

using technologies such as microcapsules and shape memory polymers, can automatically repair cracks after damage, extending their service life. These materials have broad application prospects in aerospace, bridge engineering, and medical implants.

Smart Composites (sensing and conductive functions)

integrate sensors, nanomaterials, or conductive fibers into composite materials, giving them structural health monitoring, electrical conductivity, or thermal conductivity. These materials can be used in high-end applications such as smart aircraft wings and wearable device casings.

Machining

excels at high precision, while 3D printing excels at rapid prototyping. The future trend is to merge additive manufacturing (3D printing) with subtractive Manufacturing (CNC machining) to achieve rapid production of complex parts with high precision. This model has already emerged in the aerospace and medical custom implant and mold manufacturing industries.

FAQs

What Is Meant By A Composite Material?

A composite material is a combination of two or more distinct constituents, typically a reinforcement (fiber, particle, or whisker) and a matrix (metal, polymer, or ceramic). This design maximizes properties such as strength-to-weight ratio, corrosion resistance, and durability, allowing performance levels that single materials cannot achieve alone.

What Are Examples Of Composite Materials?

Examples include carbon fiber reinforced polymer (CFRP), glass fiber reinforced polymer (GFRP), aramid fiber composites, and metal matrix composites (MMCs). In aerospace, CFRP accounts for over 50% of Boeing 787’s structure, while GFRP dominates in wind turbine blades, offering excellent cost-to-performance balance.

Is Composite Plastic Or Metal?

A composite is neither purely plastic nor purely metal. It is a multi-phase engineered material where polymers, metals, or ceramics serve as matrices, while fibers provide reinforcement. For instance, CFRPs use polymer resins, MMCs use aluminum or titanium, and CMCs use ceramic matrices for high-temperature resistance.

What Are The Four Types Of Composites?

The four principal types are polymer matrix composites (PMCs), metal matrix composites (MMCs), ceramic matrix composites (CMCs), and carbon-carbon composites. Each is tailored for specific properties: PMCs for lightweight design, MMCs for structural strength, CMCs for heat resistance, and carbon-carbon for aerospace thermal shielding.

What Are The First 10 Composites?

The first 10 recognized composites include mud bricks, bamboo, plywood, fiberglass, CFRPs, GFRPs, AFRPs, MMCs, CMCs, and hybrid composites. Historically, mud bricks with straw date back over 6,000 years, while modern CFRPs are now standard in aircraft, showing how composites evolved from simple to advanced forms.

Conclusion

In my work, I’ve come to realize that composite materials, thanks to their lightweight, high-performance, and multifunctionality, have become an indispensable core material in modern manufacturing. From aerospace to automotive, from medical to energy, they are ubiquitous. Looking ahead, with stricter environmental regulations and evolving manufacturing technologies, the development of composite materials will inevitably focus more on green sustainability, self-healing capabilities, and intelligent performance, integrating them with advanced processes like CNC machining and additive manufacturing. As a manufacturer, I believe that only by correctly understanding and flexibly applying composite materials can our companies maintain their long-term competitiveness.