CNC manufacturing is the backbone of modern precision production. By combining digital design with automated machining, it reduces human error, shortens lead times, and ensures consistent part quality—making it a preferred solution for cost-effective and scalable manufacturing.

Get 20% offf

Your First Order

CNC Manufacturing Definition

CNC manufacturing is a modern production method that uses computer-controlled machines to create precise, repeatable parts. Understanding its definition helps engineers and buyers evaluate accuracy, cost, and production scalability.

CNC manufacturing, short for Computer Numerical Control manufacturing, is a production process in which machine tools are operated by computer programs rather than manual control. These programs define critical parameters such as tool paths, cutting speeds, feed rates, and machining sequences.

By following digital instructions, CNC machines—including milling machines, lathes, routers, and grinders—can consistently achieve tight tolerances, often around ±0.01mm.

How CNC Manufacturing Works

CNC manufacturing works by converting digital designs into precise machine movements. Through software-driven control, CNC systems automate cutting, positioning, and inspection to deliver consistent, high-accuracy parts efficiently.

CNC manufacturing follows a structured digital workflow that begins with CAD design and ends with final inspection. Engineers first create a detailed 3D model using CAD software. This design is then processed in CAM software, which generates G-code—numerical instructions that define tool paths, spindle speeds, feed rates, and cutting depths.

Once the CNC machine is set up and the correct tools are loaded, the control system executes machining operations such as milling, turning, drilling, or tapping along the X, Y, and Z axes. Servo motors, ball screws, and encoders ensure precise positioning, often achieving tolerances around ±0.01 mm. During machining, sensors continuously monitor position and performance, reducing deviation and human error.

From my experience, this digital-to-physical workflow is what makes CNC manufacturing ideal for repeat production. After a program is validated, the same process can be reused, adjusted, and scaled without rebuilding tooling, ensuring stable quality from prototypes to mass production.

What Are the Types of CNC Manufacturing Processes

CNC manufacturing consists of multiple fundamental processes, each optimized for particular part shapes, accuracy requirements, and manufacturing objectives. By understanding how these CNC processes differ, engineers can select the most effective approach, control production costs, and consistently achieve high-precision outcomes.

CNC Milling

In CNC milling, material is removed using rotating multi-point cutting tools while the workpiece is securely held in place.. It supports 3-axis, 4-axis, and 5-axis motion, making it ideal for complex surfaces, pockets, slots, and precision contours. In real projects, I often rely on 5-axis milling to reduce setups and improve accuracy on complex parts.

CNC Turning

CNC turning is performed on lathes where the workpiece rotates and a stationary tool cuts material. This process is best suited for cylindrical parts such as shafts, bushings, flanges, and threaded components. Turning delivers excellent roundness, surface finish, and high repeatability in volume production.

Drilling, Tapping, and Secondary Operations

Modern CNC machines integrate drilling, tapping, reaming, and countersinking into a single setup. These operations ensure accurate hole placement and thread quality, reducing manual intervention and improving efficiency for assemblies and functional parts.

CNC Grinding

Grinding is a finishing process used to achieve tight tolerances and smooth surfaces, often below Ra0.4μm. It is commonly applied to hardened steels, bearings, and precision tooling.

Hybrid CNC Manufacturing

Hybrid CNC systems combine subtractive machining with additive manufacturing or laser processes in one machine. This enables complex internal structures, fewer setups, and shorter lead times—especially valuable for advanced prototypes and low-volume production.

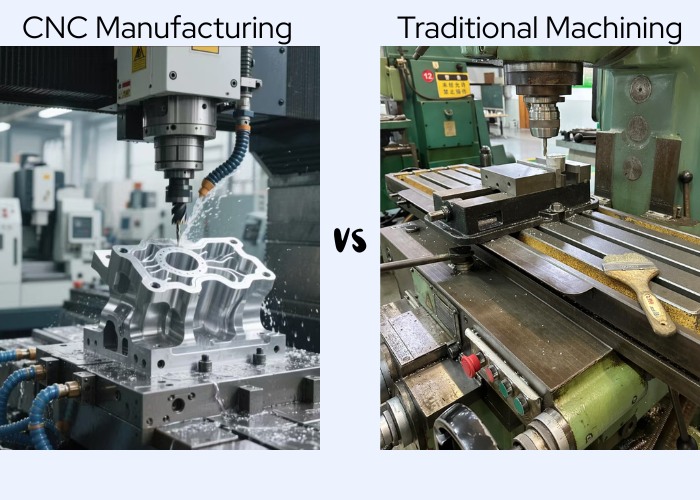

CNC Manufacturing vs. Traditional Machining: What’s the Difference?

CNC manufacturing and traditional machining both remove material to create parts, but they differ greatly in accuracy, efficiency, and scalability. Understanding these differences helps manufacturers choose the right process based on tolerance requirements, production volume, and cost control. The table below compares CNC manufacturing and traditional machining across key performance factors.

| Comparison Aspect | CNC Manufacturing | Traditional Machining |

| Control Method | Computer-programmed control (G-code) | Manual operation by skilled machinists |

| Precision & Tolerance | Very high precision, repeatability up to ±0.01mm or better | Precision depends heavily on operator skill |

| Consistency | Excellent consistency across batches | Variations common between parts |

| Production Speed | High speed, supports 24/7 automated operation | Slower, limited by human fatigue |

| Complex Geometry | Easily handles complex and multi-axis geometries | Difficult and time-consuming for complex shapes |

| Labor Dependence | Lower direct labor involvement | High reliance on skilled manual labor |

| Setup & Programming | Higher upfront programming and setup cost | Lower initial setup, faster for simple one-offs |

| Scalability | Ideal for prototypes to mass production | Better suited for small batches or repairs |

| Error Rate | Low, software-controlled and repeatable | Higher risk of human error |

| Overall Efficiency | High efficiency and predictable output | Lower efficiency for complex or high-volume work |

Advantages of CNC Manufacturing

CNC manufacturing has become the backbone of modern precision production. By replacing manual control with computer programming, it delivers unmatched accuracy, consistency, and efficiency—making it the preferred choice for industries that demand reliability at scale.

Exceptional Precision and Accuracy

CNC machines are capable of consistently holding tolerances as tight as ±0.005 mm (±0.0002 in).Because tool paths are controlled by digital programs rather than human hands, dimensional errors are dramatically reduced—critical for aerospace, medical, and electronics parts.

Outstanding Repeatability and Consistency

After a CNC program is proven and approved, identical parts can be manufactured in large quantities with consistent results. This degree of repeatability cannot be achieved through manual machining and is critical for high-volume production and components with strict quality requirements.

Faster Production and Shorter Lead Times

High spindle speeds, optimized tool paths, and automated tool changes allow CNC machines to operate continuously with minimal downtime. Compared to manual machining, production speed can increase by 2–5× for complex parts.

Ability to Produce Complex Geometries

Multi-axis CNC machines, including 3-axis, 4-axis, and 5-axis systems, are capable of producing intricate geometries, deep pockets, and undercut features that are difficult or inefficient to achieve with conventional machining. This expanded machining capability supports the creation of lightweight, high-performance components.

Reduced Human Error and Improved Efficiency

Automation minimizes operator intervention, reducing mistakes caused by fatigue or skill variation. One skilled operator can supervise multiple machines, significantly improving labor efficiency and lowering production costs.

Broad Material Compatibility

CNC manufacturing is capable of processing a broad range of materials, such as aluminum, stainless steel, titanium, brass, plastics, and advanced composite materials. This flexibility enables manufacturers to support diverse industries using one unified and standardized manufacturing workflow.

Scalable From Prototypes to Mass Production

A single CNC process can support rapid prototyping, small-batch production, and large-scale manufacturing. Because machining is driven by digital files, design updates can be implemented quickly and economically without the need to restart tooling.

Applications of CNC Manufacturing

CNC manufacturing is widely used across industries that demand precision, consistency, and scalability. Its ability to machine complex parts with tight tolerances makes it essential from prototyping to high-volume production.

Aerospace

CNC manufacturing is critical for producing lightweight, high-strength parts such as engine housings, structural brackets, landing gear components, and hydraulic system parts. Tolerances can reach ±0.005mm, ensuring safety, reliability, and compliance with aerospace standards. From my experience, multi-axis CNC machining significantly reduces setup time for complex aerospace geometries.

Automotive

Automotive manufacturers rely on CNC machining for engine blocks, transmission housings, suspension components, and custom prototypes. CNC allows rapid design iteration during R&D while maintaining stable quality in mass production, helping reduce defect rates and improve overall vehicle performance.

Medical

In the medical industry, CNC manufacturing is used for surgical instruments, orthopedic implants, dental components, and prosthetics. The ability to machine titanium, stainless steel, and medical plastics with micron-level accuracy supports patient safety and regulatory compliance.

Electronics and Industrial Manufacturing

CNC manufacturing is also widely applied in electronics, defense, telecommunications, and general manufacturing. Typical parts include enclosures, heat sinks, gears, shafts, and brackets. Its flexibility allows manufacturers to serve multiple industries using a single production platform.

FAQs

What Is CNC Manufacturing?

I define CNC manufacturing as a computer-controlled production method where machines such as mills, lathes, and routers execute programmed instructions to produce precise, repeatable parts. By using CAD/CAM software and G-code, CNC systems control tool paths, speeds, and feeds with high accuracy—often achieving tolerances of ±0.01mm or better. In my experience, CNC manufacturing significantly reduces human error, improves consistency, and supports everything from rapid prototyping to high-volume production across aerospace, automotive, medical, and industrial applications.

What Does CNC Mean in Manufacturing?

CNC stands for Computer Numerical Control. From my perspective, it means machine movements are driven by digital code rather than manual operation. CAD and CAM files convert designs into G-code, which controls speed, position, and tool paths. This automation boosts accuracy by up to 10× compared with manual machining and allows 24/7 production with minimal operator intervention.

What Is CNC Used For?

I use CNC mainly for producing high-precision, repeatable parts that are difficult or inefficient to make manually. Typical applications include housings, shafts, gears, molds, and medical components. CNC is used for milling, turning, drilling, and tapping across materials like aluminum, steel, titanium, and engineering plastics. In real production, CNC can cut lead times by 30–60% while maintaining tight tolerances.

Is CNC Machining the Same as CNC Manufacturing?

In my experience, they are related but not identical. CNC machining refers specifically to subtractive operations like milling and turning. CNC manufacturing is broader—it includes CNC machining plus design, programming, inspection, and sometimes additive or hybrid processes. Machining is one step, manufacturing is the full workflow. This distinction matters when evaluating suppliers, costs, and production capabilities.

What Two Processes Can Hybrid CNC Perform?

Hybrid CNC machines can perform both subtractive and additive manufacturing in one system. From what I’ve seen, they combine CNC machining with processes like metal 3D printing or laser deposition. This allows parts to be built up and then precisely machined in a single setup. The result is higher accuracy, fewer fixtures, and up to 40% reduction in overall production time for complex parts.

Conclusion

CNC manufacturing is an automated production approach driven by computer control, delivering high levels of precision, consistency, and efficiency throughout the entire process—from digital design to final quality inspection. Compared to conventional machining, CNC manufacturing achieves tighter tolerances, shorter production cycles, and more complex part geometries while reducing human error. Its adaptability supports rapid prototyping as well as full-scale manufacturing, making it a fundamental technology across aerospace, automotive, medical, and industrial sectors.