Anodizing is an electrochemical process that forms a durable oxide layer on metals, boosting corrosion and wear resistance while enabling diverse finishes. In this article, I will explain the principles of anodizing, materials, processes, types, key parameters, quality control, and troubleshooting for optimal results.

What Is Anodizing

Anodizing is a metal surface treatment process that transforms the metal surface material into a durable, corrosion-resistant oxide layer that bonds tightly to the metal surface. By controlling the process parameters, anodizing can achieve customized thickness, hardness, and color. This process is widely used in aerospace, medical, electronics, and construction.

Get 20% offf

Your First Order

The Principle Of Anodizing

Anodizing works by using electricity and chemistry to create a protective oxide layer on the surface of metals, most commonly aluminum. Here’s how it happens in practice:

Electrochemical Reaction

The workpiece acts as the anode in an electrolytic cell, immersed in an acidic electrolyte (usually sulfuric acid). A cathode is also placed in the cell.

For example, in the case of aluminum anodic oxidation, the aluminum workpiece acts as the anode in the cell. When direct current is applied, oxygen ions released from the electrolyte react with aluminum atoms on the aluminum surface, forming a dense film of aluminum oxide (Al₂O₃).

Layer Formation and Structure

Unlike paint or plating, the oxide layer grows from the metal itself—about half penetrates inward, and half builds outward. This makes it integral to the substrate and resistant to peeling. The layer is porous, allowing for dyeing or sealing in later steps.

Controlled Parameters

Factors like current density, voltage, electrolyte composition, temperature, and time directly affect oxide thickness, hardness, and porosity.

Functional Benefits

This dense oxide layer greatly improves corrosion resistance, wear resistance, electrical insulation, and allows for decorative coloring. It is also UV-stable, making it ideal for outdoor and high-performance applications.

What Are The Types Of Anodizing

There are seven main types of anodizing: Type I, Type II, Type III, Type IC, Type IIB, Type IIB, and phosphoric acid anodizing. Different types of anodizing vary in thickness, hardness, and durability – understanding these differences can help you choose the right process based on your performance and appearance needs.

| Type | Electrolyte | Thickness (μm) | Hardness (HV) | Main Properties |

| Type I (Chromic Acid Anodizing) | Chromic acid | 0.2–0.5 | — | Excellent corrosion resistance, retains conductivity |

| Type II (Sulfuric Acid Anodizing) | Sulfuric acid | 5–25 | — | Good decorative finish, dyeable, moderate wear resistance |

| Type III (Hard Anodizing) | Low-temperature sulfuric acid | 25–150 | 400–500+ | High hardness, excellent wear and corrosion resistance |

| Type IC | Boric–sulfuric acid | 0.2–0.5 | — | Chromic acid replacement, good corrosion resistance |

| Type IIB (Thin-Film Sulfuric Anodizing) | Sulfuric acid | 1–5 | — | Thin decorative coating, minimal dimensional change |

| Phosphoric Acid Anodizing | Phosphoric acid | 0.5–3 | — | Increases surface energy, used for bonding preparation |

The Difference Between Anodizing And Other Surface Treatment Processes

| Process Type | Main Principle | Structural Features | Thickness Range | Wear Resistance | Adhesion | Salt Spray Resistance (ASTM B117) |

| Anodizing | Electrochemical oxidation forms aluminum oxide integrated with the substrate | Dense barrier layer (protection) + porous layer (coloring/sealing) | 5–50 μm (up to 150 μm for hard anodizing) | High | Very high (won’t peel) | 500–1000 hours |

| Electroplating | Deposits an external metal layer on the surface through electrochemical reduction | Solid external coating dependent on adhesion, prone to peeling | 5–25 μm | Medium | Medium | Depends on plating material |

| Powder Coating | Melted powder particles fuse to form a protective and decorative film | Thick organic layer, uniform coverage but softer than anodized oxide | 60–120 μm | Medium | High | Depends on coating type |

| Chromate Conversion | Chemical conversion reaction creates a thin protective conversion film | Very thin layer with minimal mechanical strength, mainly for temporary or supplementary protection | 0.2–0.4 μm | Low | Medium | Low |

What Materials Are Suitable For Anodizing

From my experience in anodizing production and quality control, material selection is the first step to ensuring consistent coating performance and appearance. Not all metals are suitable for anodizing—it depends on their oxidation behavior and the stability of the oxide film.

Below, I’ll analyze suitable metals, unsuitable or special cases, and the impact of alloy composition on anodized layers.

Metals suitable For Anodizing

Aluminum & Alloys

Aluminum (e.g., 6061, 7075, 2024) is the most common anodizing material. Its aluminum oxide (Al₂O₃) film is dense, strongly adherent, and can achieve thicknesses of 5–50 μm, significantly enhancing corrosion resistance—salt spray testing can reach 500–1000 hours (ASTM B117). Widely used in aerospace, electronics, and architecture.

Titanium & Alloys

Titanium (e.g., Ti-6Al-4V) anodizing can produce multi-colored interference films, with thickness precisely controlled between 20–200 nm. Commonly used for medical implants and aerospace components due to excellent biocompatibility and corrosion resistance.

Magnesium & Alloys

Magnesium forms a brittle, porous oxide film. It requires combined chemical conversion or sealing to achieve adequate corrosion resistance. Often used for lightweight structural components.

Niobium / Tantalum / Zinc

Niobium and tantalum are often anodized for electronics and high-end decorative applications, forming stable oxide films. Zinc can be anodized under specific electrolyte conditions, mainly for decorative purposes.

Metals Unsuitable For anodizing

Steel / Iron

Mild steel rusts rapidly in acidic electrolytes, producing unstable oxide films—making conventional anodizing impractical.

Stainless Steel

Due to the passivating nature of chromium oxide films, stainless steel requires special electrolytes (e.g., sulfuric–fluoride mixtures) for anodizing. The resulting layer is mostly decorative, with limited corrosion improvement, higher cost, and strict environmental requirements.

Impact Of Alloy Composition On The Oxide Layer

Purity

High-purity aluminum (≥99.5%) produces uniform, transparent films with excellent color consistency, ideal for architectural and optical uses.

Alloying Elements

Silicon: Increases film grayness and reduces gloss, common in casting alloys.

Copper: Reduces corrosion resistance and darkens the film—requires optimized sealing.

Magnesium / Zinc: Improves hardness but darkens the oxide layer and reduces dye uniformity.

Microstructure

Grain size and second-phase distribution directly influence color variation and film uniformity. In production, I recommend keeping alloy grades and heat-treatment states consistent within batches to minimize color variation.

What Are The Process Flows Of Anodizing

The anodizing process enhances the metal surface through a series of precise steps. Pretreatment begins. The electrolyte formulation, temperature, current density, and voltage are carefully controlled to produce a coating with the desired thickness, hardness, and porosity. A heat seal, cold seal, or nickel acetate seal ensures corrosion resistance. A final rinse and drying ensure consistent appearance and performance across all parts.

Pre–treatment Of Workpiece

Degreasing

To remove oil, fingerprints, and surface contaminants for uniform oxide film adhesion, clean the workpiece with an alkaline solution (such as sodium carbonate-based cleaners) at 50–70 °C for 2–5 minutes, then rinse thoroughly.

Mechanical Or Chemical Polishing

Mechanical: Buffing or abrasive belts to achieve desired surface roughness (Ra 0.2–1.0 µm).

Chemical: Acid polishing (phosphoric–nitric acid mix) to enhance reflectivity.

Etching

To remove scratches and casting defects, uniformly etch away 5–15 µm of material by immersing the workpiece in a sodium hydroxide bath maintained at 40–60 °C, ensuring precise control to prevent over-etching.

Desmut

After etching, remove alloy residues such as copper or silicon by immersing the workpiece in a nitric acid solution or a sulfuric–ferric mixture for 30–90 seconds, ensuring complete cleaning before anodizing.

Anodizing

Preparation of electrolyte in the tank

When preparing the electrolyte in the anodizing tank, the standard Type II process typically uses 15–20% sulfuric acid as the main component. Additives such as oxalic acid may be introduced to enhance surface brightness or adjust pore size, ensuring a more uniform and refined oxide layer formation.

Temperature control

Regulates oxide layer growth rate, hardness, and pore structure during anodizing.Prevents localized overheating, which can cause soft spots, discoloration, or inconsistent film properties.

Conventional Sulfuric Acid Anodizing:Conventional sulfuric acid anodizing should keep the bath temperature between 18-22 °C. This ensures uniform oxide formation, good hardness and stable pore size, thus achieving uniform dye absorption and sealing.

Hard Anodizing: To achieve hard anodizing, the process should be carried out at a relatively low temperature of 0-5 ° C. In this temperature range, the dissolution of the oxide is slowed down, allowing the coating thickness to reach 50-100 µm or more, thus achieving higher hardness and wear resistance of the oxide layer.

Control of current density and voltage

Controlling current density and voltage is crucial for achieving ideal anodized layer properties.

Decorative anodizing: For decorative anodizing, a current density of 1.0–1.5 A/dm² is typically used to produce a uniform, well-colored oxide layer.

Hard anodizing: Hard anodizing requires a higher current density of 2.5–3.0 A/dm² to achieve thicker, harder coatings.

The voltage is typically increased gradually during the process rather than applied immediately to maximum voltage—this prevents localized overheating and burning, ensures uniform oxide growth, and reduces the risk of pitting or discoloration.

Proper control ensures consistent hardness, thickness, and surface quality across all parts.

Time Control

In my anodizing work, I strictly control processing time based on the 720 Rule, where 720 amp-minutes per square foot yields approximately 1 mil (25.4 µm) of oxide thickness. For example, a target of 2 mil (≈50 µm) requires about 1,440 amp-min/ft², adjusted for current density and surface area.

I monitor both amperage and elapsed time in real-time to ensure uniform growth across complex geometries, avoiding over-oxidation or thin spots. Precise time control directly influences film hardness, porosity, and color consistency, making it a critical parameter for repeatable high-performance results.

Agitation & Fixturing

Agitation

Maintain constant electrolyte movement using air sparging or mechanical pumps to ensure uniform temperature and acid concentration throughout the tank.Prevents localized overheating and uneven oxide growth, improving film thickness consistency across all surfaces.

Fixturing

Use non-contaminating, corrosion-resistant titanium or highly conductive aluminum as fixture materials to ensure reliable electrical contact. Clamping points should be located in non-critical or hidden areas to avoid leaving noticeable marks on functional or aesthetic surfaces.

The fixture must ensure a secure mechanical grip on the workpiece while minimizing electrical resistance to prevent arcing or uneven oxidation.

Coloring Of workpieces(Optional)

Organic Dyeing

In organic dyeing, the anodized aluminum’s porous oxide layer acts like a sponge, absorbing dye molecules deeply into its structure. This allows for a broad spectrum of vivid colors and precise color matching for decorative purposes.

However, because organic dyes have lower UV stability compared to inorganic pigments, prolonged sunlight exposure may cause fading. To maximize durability, I control pore size and dye bath temperature (typically 50–60 °C), followed by immediate sealing to lock in the color and improve resistance to environmental degradation.

Electrolytic Coloring

In electrolytic coloring, I immerse the anodized part in a bath containing metal salts such as stannous tin or cobalt. An alternating current drives these metal ions into the base of the oxide pores, producing stable bronze-to-black shades.

This method offers exceptional UV resistance and color uniformity, with typical process voltages of 12–18 V and immersion times of 1–3 minutes, ensuring long-lasting, fade-resistant finishes suitable for architectural and outdoor applications.

Interference Colors

In interference coloring, I use titanium or stainless steel as the cathodes and precisely control the pore sealing stage to create optical interference effects. By adjusting sealing parameters and pore geometry, I can produce vivid blues, greens, and purples without dyes.

These colors result from light wave interference in the oxide layer, offering excellent UV stability and corrosion resistance, with thickness control typically within ±0.1 µm for consistent visual quality.

Sealing

In the sealing stage, I choose the method based on the required corrosion resistance, color stability, and production efficiency.

Hot DI Water Sealing (≥95 °C, 15–30 min): I hydrate the alumina layer to form boehmite [AlO(OH)], effectively closing pores and providing exceptional corrosion resistance—often exceeding 1,000 hours in ASTM B117 salt spray tests.

Nickel Acetate Sealing (85–90 °C): This offers strong corrosion protection while minimizing color shift, making it ideal for decorative anodizing where visual consistency is critical.

Cold Sealing (~25 °C, fluoride-based): I use this when energy savings and high throughput are priorities. While it seals faster, the resulting layer may have slightly reduced hardness (by 5–10%) compared to hot sealing.

Rinsing And Drying

In the rinsing and drying stage, both contamination control and part integrity are critical to achieving the desired anodized layer performance.

Rinsing: Multiple cascaded rinses with deionized (DI) water between each process stage prevent electrolyte carryover and cross-contamination. DI water conductivity is typically maintained below 5 µS/cm, with flow rates sufficient to fully exchange bath volume within 1–2 minutes.

Drying: Depending on part geometry and finish requirements, hot-air dryers at 60–80 °C or centrifugal dryers for small components are used. Measures are taken to avoid water spotting, especially on decorative parts.

Rack Design: Racks are designed to maintain strong, stable electrical contact while minimizing visible contact marks. Flexible titanium or aluminum fingers are used for small or delicate parts to prevent deformation, and clamp positions are adjusted in multi-pass anodizing to distribute marks and maintain consistent appearance.

Advantages And Limitations Of Anodizing

This section I will explores how anodizing enhances durability, appearance, and longevity, while also revealing the design and manufacturing considerations it introduces. You’ll see why anodized aluminum is valued for corrosion resistance, wear protection, and decorative potential, and also understand how electrical insulation, color consistency, and dimensional shifts can influence its suitability for precision applications.

Advantages

Corrosion Resistance : Anodized aluminum forms an Al₂O₃ oxide layer with a typical thickness of 5–25 µm (Type II) or 25–150 µm (Type III). This dense, stable layer can extend corrosion resistance to over 1,000 hours in ASTM B117 salt spray tests, making it suitable for marine and industrial environments.

Wear Resistance : Type III hard anodizing achieves hardness levels of HV 400–500+, significantly increasing surface durability and reducing friction-related wear in moving or abrasive contact applications.

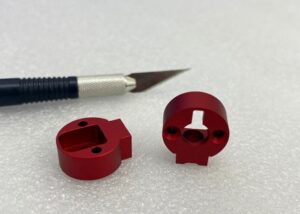

Aesthetics : The porous oxide structure allows uniform coloring through organic dyes or electrolytic metal deposition, enabling a wide range of decorative finishes while maintaining metallic luster.

Low Maintenance :The chemically inert oxide layer reduces the need for frequent cleaning or coating reapplication, lowering life-cycle maintenance costs.

Limitations.

Reduced Electrical Conductivity – The oxide layer is a dielectric, with surface resistivity exceeding 10¹¹ Ω·cm, this limits its use in applications requiring electrical grounding or current flow without secondary processing.

Color Matching Challenges – Dye absorption can vary with alloy composition, film thickness, and sealing method, leading to slight shade differences between batches, tolerances for architectural projects may require ΔE < 2.0 in CIE Lab color space.

Dimensional Changes – Approximately 50% of the oxide layer grows outward and 50% inward (Type III), altering dimensions by ~0.5× coating thickness, precision-machined parts may require pre-compensation in design to maintain tolerances within ±0.01 mm.

Production Line Considerations

In anodizing production lines, cost and cycle time are critical factors affecting both profitability and delivery performance. Requirements for coating performance, batch size, equipment setup, energy consumption, and labor input collectively determine efficiency and unit cost. For high-spec or high-aesthetic parts, tighter process controls increase equipment load and lengthen cycle times, which raises overall production costs.

Cycle Time Composition

Pre-treatment (degreasing, polishing, etching, desmutting): ~20–30% of total time

Main anodizing stage: Type II typically 20–40 min, Type III hard coat 60–120 min, accounting for up to 50%+ of total time

Post-treatment (coloring, sealing, drying): ~20–30%

Handling and fixturing: ~5–15% per batch

Impact Of Oxide Film Thickness On Cost

Type II (5–25 μm): Shorter processing time, lower energy demand, reduced chemical consumption, lower unit cost

Type III (25–150 μm): Requires low temperature (0–5 °C), high current density (2.5–3.0 A/dm²), higher energy and cooling costs, heavier rectifier loads, slower throughput, increasing unit cost by 30–50%

Thicker films also demand more frequent chemical replenishment and raise bath maintenance costs

Environmental Safety

During anodizing, electrolyte agitation and electrolysis generate acid mist (e.g., sulfuric or chromic acid vapors), which must be captured and neutralized via localized exhaust systems and acid mist scrubbers to meet regulatory emission limits. Processes involving chromic acid, tin salts, or nickel salts require strict segregation and stabilization of heavy metal waste to prevent water contamination. Wastewater must be neutralized to pH 6–9 and treated through precipitation, filtration, and recycling systems to recover water and certain chemicals, reducing both discharge volume and operating costs.

Operational Safety And Chemical Compliance

Personnel must wear acid-alkali resistant gloves, safety goggles, acid-resistant aprons, and protective footwear and work in well-ventilated areas to minimize inhalation or skin contact risks. All chemical procurement, storage, and handling must comply with GHS (Globally Harmonized System of Classification and Labelling of Chemicals) and local hazardous material regulations. Facilities should maintain MSDS (Material Safety Data Sheet) records and conduct annual safety training. Emergency preparedness includes neutralizing agents, emergency showers, and eyewash stations, with regular drills to ensure rapid and effective incident response.

key Parameters In Anodizing

Key anodizing parameters—such as the 720 Rule, thickness–time/current ratio, bath temperature, acid concentration, and growth pattern—directly affect coating quality and precision. Optimal current density and duration achieve target thickness without defects, while precise temperature and acid control prevent soft or brittle films. Understanding Type II and Type III growth ratios supports accurate tolerance planning.

720 Rule

1 mil (25.4 μm) oxide thickness ≈ 720 amp-minutes per square foot.

Serves as the fundamental reference for planning anodizing duration and current load.

Thickness–Time/Current Relationship

Thickness is directly proportional to current density × processing time.

Oxide thickness in anodizing grows in direct proportion to the product of current density and processing time. For example, doubling current density from 1.2 A/dm² to 2.4 A/dm² roughly doubles the growth rate.

However, excessive current or prolonged duration can overheat the surface, causing burns, cracks, or overly porous films. Balanced control ensures uniform thickness, stable hardness, and consistent appearance across all parts.

Temperature & Acid Concentration Control

Excessively high bath temperature can soften the oxide layer and increase porosity.

Excessively high acid concentrations can accelerate dissolution, making the oxide film brittle and fragile.

Thus, maintaining the temperature and acid concentration within precise operating ranges is crucial to ensure stability and quality.

Dimensional Growth & Tolerance Impact

Type II sulfuric anodizing

About 50% of the oxide layer grows outward from the metal surface, increasing part dimensions.

The remaining 50% penetrates inward into the substrate, strengthening the bond between coating and base material.

Type III hard anodizing

Growth ratio is also 50% outward and 50% inward, but with greater thickness (25–150 μm) and higher density.

Delivers superior wear resistance, hardness (HV 400–500+), and dimensional stability.

Dimensional impact example

A 50 μm coating adds approximately 25 μm to each surface.

This must be considered when machining to maintain tight tolerances.

Tolerance control

Known growth ratios enable pre-anodizing machining offsets to within ±0.005 mm, ensuring final dimensions meet specifications without extra finishing.

Equipment And Consumables For Anodizing

Equipment and consumables for anodizing require acid-resistant tanks (PP, PVC, or lead-lined), stable programmable DC power supplies, and conductive copper or aluminum racks with insulation. Effective ventilation systems capture and scrub acid mist. Regular chemical analysis maintains proper acid concentration and aluminum ion levels, ensuring consistent coating quality and safe operation.

Tanks

Constructed from acid-resistant materials such as polypropylene (PP), polyvinyl chloride (PVC), or lead-lined steel to withstand sulfuric acid and other electrolytes. Tanks should have adequate mechanical strength, temperature resistance, and may include insulation or cooling systems to maintain stable operating temperatures.

Power Supply

A stable direct current (DC) rectifier with programmable control is essential for precise regulation of current density, output voltage, and ramp-up profiles. High power factor and low ripple rate contribute to uniform oxide film formation and process repeatability.

Racks/Fixtures

Made from highly conductive copper or aluminum, with insulation applied to non-contact areas to prevent chemical attack and arcing marks. Fixtures should ensure firm electrical contact, stable conductivity, and clamp placement in non-critical or hidden areas to avoid visible surface defects.

Ventilation & Bath Maintenance

Install efficient ventilation systems with acid mist capture and scrubbing units to reduce airborne contaminants. Bath chemistry must be routinely monitored for acid concentration and aluminum ion content, with adjustments made through solution replenishment and impurity filtration to maintain stability.

Chemical Management & Replenishment

Implement a chemical inventory log to track electrolyte batches, additive ratios, and replacement schedules. Replenishment should be based on analytical results to prevent concentration fluctuations that could affect coating quality.

Maintenance, Repair, And Overhaul

Establish a preventive maintenance schedule, including tank inspection, corrosion layer repair, rectifier performance testing, fixture cleaning, and ventilation filter replacement, ensuring long-term operational reliability and consistent anodizing quality.

How To Control Production Line Quality

A well-structured anodizing quality program doesn’t just measure—it ensures long-term performance. From precise thickness checks to rigorous corrosion, wear, and sealing tests, every inspection step validates coating integrity, aesthetics, and durability, helping manufacturers deliver consistently reliable and visually flawless parts.

Thickness

Thickness is verified using eddy current gauges for non-destructive, real-time measurement or gravimetric methods for high-accuracy sampling. For example, I target ±2 µm tolerance on a 25 µm Type II coating.

Sealing quality

Sealing quality is checked with dye stain tests or conductivity measurements, ensuring pore closure to prevent corrosion pathways, conductivity is maintained below 30 µS/cm for optimal performance.

Corrosion resistance

Corrosion resistance is validated via ASTM B117 salt spray testing, aiming for over 1,000 hours without pitting for architectural-grade finishes.

Wear resistance

Wear resistance is measured using the Taber abrasion test, with performance benchmarks set at ≤5 mg weight loss per 1,000 cycles for hard anodizing.

Color and gloss

Color and gloss consistency is verified with spectrophotometers, maintaining ΔE < 1.0 for color-critical parts and ±3 gloss units for surface uniformity.

This integrated testing approach ensures every batch not only meets but often exceeds industry specifications.

Common Defects And Troubleshooting

Common anodizing defects—such as burning, pitting, graying, color variation, and poor sealing—often stem from process control issues. Understanding their causes, visual indicators, and corrective actions is essential for maintaining consistent coating quality and minimizing costly rework.

Burning

Cause: Excessive current density (>3.0 A/dm² for hard anodizing) or inadequate electrical contact leading to localized overheating.

Indicators: Dark, rough, or powdery patches on the coating surface.

Solution: Reduce current ramp rate, ensure firm, clean contact points, and maintain uniform electrolyte agitation to dissipate heat.

Pitting

Cause: Poor water quality (high chloride ion content >25 ppm) or electrolyte contamination with copper, iron, or silicon particles.

Indicators: Small, deep craters in the oxide film, often clustered.

Solution: Use deionized water for rinsing, filter electrolyte continuously, and monitor impurity levels weekly.

Graying

Cause: Alloy impurities such as high silicon (>0.5%) or copper (>4%) content in the substrate.

Indicators: Dull, gray surface with reduced gloss after anodizing.

Solution: Use high-purity alloys (e.g., 6061, 6063) or pre-treat with optimized desmut cycles to remove residual alloying elements.

Color Variation

Cause: Inconsistent bath temperature (±2 °C), voltage fluctuations, or uneven sealing times.

Indicators: Visible shade differences between parts in the same batch.

Solution: Maintain bath temperature within ±1 °C, calibrate power supply output, and synchronize dyeing/sealing durations across all parts.

Poor Sealing

Cause: Incomplete hydration of alumina pores due to insufficient time, low temperature, or contaminated sealing bath.

Indicators: High conductivity readings (>25 µS/cm) or poor corrosion resistance in salt spray tests.

Solution: Extend sealing time (≥15 min for hot DI water), maintain temperature control, and replace sealing bath when contamination exceeds limits.

FAQ

Does Anodizing Wear Off?

Yes, but it depends on the service conditions. Type III coatings I produce are 25–100 µm thick with hardness of HV 400–500 and Taber abrasion loss < 20 mg/1000 cycles, they can last for many years under normal use, though edges may thin in high-load or abrasive environments.

Does Rubbing Alcohol Remove Anodizing?

No, isopropyl rubbing alcohol does not chemically strip anodizing. The anodized layer is aluminum oxide (Al₂O₃) with hardness around HV 300–500 and thickness of 5–150 µm, which is highly resistant to mild solvents. However, prolonged contact can remove organic dyes in decorative anodizing, especially if sealing is poor, causing visible fading without removing the oxide itself.

How Does Anodizing Increase Corrosion Resistance?

The Al₂O₃ layer acts as a barrier to O₂ and Cl⁻ penetration. My Type II (10–20 µm) or Type III (up to 50 µm) coatings can exceed 500–1000 h in ASTM B117 salt spray tests. Polarization resistance rises significantly, and corrosion current density can drop below 1 µA/cm².

How Can I Tell If Metal Is Anodized?

I identify anodizing by a metallic look with a slight ceramic feel, high surface resistivity (> 10¹¹ Ω·cm), and thickness readings of 5–50 µm via eddy current. Dye testing can also reveal whether the pores are sealed—well-sealed coatings resist color uptake.

What Causes Anodized Aluminum To Fade?

Fading is typically caused by UV exposure, low lightfastness dyes, poor sealing, or aggressive alkaline cleaning. I use electrolytic coloring with tin or cobalt for high UV stability and seal in 95–100 °C deionized water for 15–30 minutes, keeping batch color variation under ΔE < 2.0.

Conclusion

Anodizing is a multifunctional and aesthetic finishing process, ideal for non-ferrous metals—especially aluminum and its alloys. By controlling process parameters, selecting the right type, and applying proper post-treatment, you can meet the most demanding industrial requirements while delivering premium visual appeal.