5-Axis-Milling is an advanced manufacturing method that allows tools to move and rotate around a part from multiple directions. This added freedom makes it possible to machine complex shapes with higher accuracy, smoother surfaces, and fewer setups—ideal for precision parts that standard CNC methods struggle to produce.

What Is 5 Axis Milling

5-Axis-Milling is an advanced manufacturing process where the cutting tool and workpiece move along five different axes. This allows the tool to reach complex angles and surfaces that traditional 3-axis machining cannot, making it ideal for producing precise and intricate parts.

Get 20% offf

Your First Order

What Does “5-Axis” Mean in CNC Machining

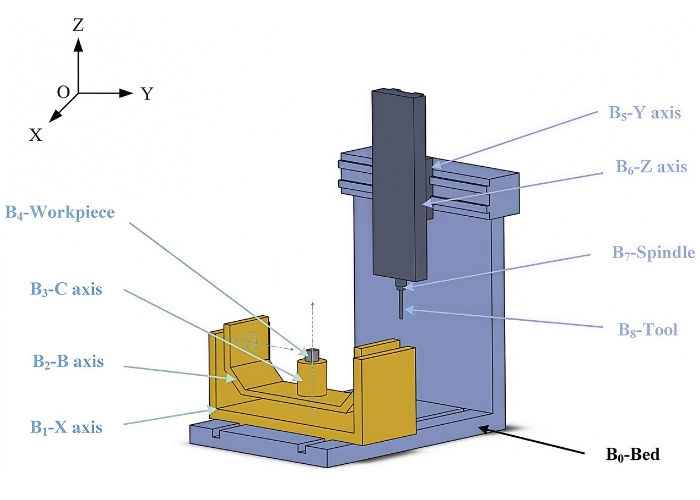

In CNC machining, “5-axis” refers to how a machine moves while cutting a part. Beyond the standard X, Y, and Z directions, two rotational axes are added, allowing the tool to approach complex features from multiple angles with higher precision.

Main Content

In a standard CNC setup, the cutting tool moves along three linear axes:

X-axis: left to right

Y-axis: front to back

Z-axis: up and down

These movements are sufficient for flat surfaces and simple geometries. However, once a part includes angled holes, curved surfaces, or deep pockets, access becomes limited.

A 5-axis CNC machine solves this by adding two rotational axes, commonly:

A-axis: rotation around the X-axis

B-axis or C-axis: rotation around the Y-axis or Z-axis

By rotating either the tool or the workpiece, the cutter can maintain the optimal angle during machining. This reduces the need to stop, re-clamp, or flip the part, improving accuracy, surface finish, and overall efficiency—especially for complex precision components.

Types of 5-Axis-Milling

Not all 5-axis CNC machines work the same way. Depending on how the axes move during cutting, 5-axis machining is commonly divided into indexed (3+2), continuous, and mill-turn configurations. Each type offers different levels of precision, flexibility, and cost efficiency.

Indexed (3+2) 5-Axis Machining

Indexed 5-axis machining, often called 3+2 machining, uses five axes but not all at the same time. During cutting, the machine moves only along the three linear axes (X, Y, Z). The two rotational axes are used to position the tool or workpiece at a fixed angle before cutting begins.

Once the position is set, machining proceeds like a standard 3-axis operation. When another angle is needed, cutting pauses briefly, the part or spindle reorients, and machining resumes.

Tool & part movement logic:

Linear cutting: X, Y, Z

Rotational positioning: typically A and C axes

Rotation happens between cuts, not during cutting

From real production experience, indexed 5-axis is often chosen for prismatic parts with angled features. It delivers better access and accuracy than 3-axis machining, while keeping programming complexity and cost under control.

Continuous 5-Axis Machining

Continuous 5-axis machining allows all five axes to move simultaneously while cutting. There are no pauses to reposition the part. Instead, the tool and workpiece move together in a smooth, coordinated motion.

This continuous movement keeps the cutting tool at an optimal angle throughout the process, which is especially important for complex curves, freeform surfaces, and deep cavities.

Tool & part movement logic:

Linear axes and rotational axes move at the same time

Tool orientation changes dynamically during cutting

Either the spindle, the table, or both may rotate

In practice, continuous 5-axis machining is preferred for aerospace components, turbine blades, and medical parts where surface quality and dimensional consistency are critical. It offers higher capability—but also requires advanced programming and higher machining costs.

Mill-Turn 5-Axis CNC Centers

5-axis mill-turn centers combine turning and milling operations in a single machine. The workpiece rotates like a lathe while a multi-axis milling head performs complex cutting operations.

This setup allows cylindrical and prismatic features to be machined in one continuous workflow, eliminating multiple machines and re-clamping steps.

Tool & part movement logic:

Workpiece rotation: typically around the A-axis

Milling head: linear X, Y, Z + rotational B-axis

Turning and milling occur in one setup

From a manufacturing perspective, mill-turn 5-axis centers are ideal for high-precision shafts, aerospace connectors, and complex rotational parts where concentricity and positional accuracy are essential.

5-Axis-Milling vs Other CNC Machining Processes

Not all 5-Axis-Milling methods offer the same capabilities or cost efficiency. Depending on how the tool and workpiece move during cutting, 5-axis machining can be classified into indexed, continuous, and mill-turn configurations—each suited to different part complexities and production needs.

| Machining Process | Movement Axes | Tool & Part Movement | Cost Efficiency | Best For | Limitations |

| 3-Axis CNC Milling | X, Y, Z | Tool moves linearly; workpiece remains fixed | Low to medium | General-purpose parts with flat or simple geometries | Requires manual repositioning for angled or multi-sided features; limits accuracy on complex parts |

| CNC Turning (Lathe) | X, Z | Workpiece rotates; tool moves linearly | Lowest cost per part | High-volume, rotationally symmetric parts | Limited to round or simple geometries |

| Mill-Turn CNC Centers | X, Y, Z + rotation | Workpiece rotates while milling head moves linearly | Medium | Cylindrical or hybrid parts requiring both turning and milling | Not ideal for large freeform surfaces |

| Indexed (3+2) 5-Axis Machining | X, Y, Z + 2 rotational axes | Part or tool is rotated between cuts; cutting uses 3 axes | Medium to high | Parts with angled features and multi-face machining | Rotational axes do not move during cutting |

| Continuous 5-Axis Machining | X, Y, Z + 2 rotational axes | All axes move simultaneously during cutting | Highest cost | Complex freeform surfaces and organic geometries | Higher machining cost and programming complexity |

Key Advantages of 5-Axis-Milling

5-Axis-Milling offers more than just additional movement. By allowing the tool to approach a part from multiple angles in a single setup, it improves precision, surface quality, and efficiency—especially for complex, high-value components.

Complex Part Geometries

5-axis machining enables the production of shapes that are difficult or impossible with 3-axis systems, such as deep cavities, compound curves, and freeform surfaces. Parts like impellers, turbine blades, and medical implants benefit directly from this capability.

Higher Precision and Consistency

Because multiple surfaces are machined in one setup, alignment errors caused by re-clamping are minimized. In practice, this leads to tighter tolerances and better part-to-part consistency, particularly on complex geometries.

Reduced Setups and Shorter Lead Times

Fewer setups mean fewer tool changes, less manual intervention, and shorter machining cycles. Jobs that require several operations on a 3-axis machine can often be completed in a single run on a 5-axis system.

Superior Surface Finish

The ability to maintain optimal tool angles reduces vibration and tool deflection. This results in smoother surfaces and less post-processing, which is especially valuable for precision and aesthetic-critical parts.

Limitations and Challenges of 5-Axis Machining

While 5-Axis-Milling delivers clear advantages, it is not always the best solution. Higher equipment costs, advanced programming requirements, and volume-related cost considerations must be evaluated before choosing this process.

High Equipment and Setup Costs

5-axis CNC machines are significantly more expensive than 3-axis systems. Initial investment, tooling, and maintenance costs are higher, making them less suitable for simple or low-value parts.

Complex Programming Requirements

Advanced CAM software and experienced programmers are required to generate accurate tool paths. Poor programming can negate the benefits of 5-axis machining or increase the risk of errors.

Cost Considerations in High-Volume Production

For large-volume production of simple parts, the per-part cost advantage of 5-axis machining may diminish. In such cases, dedicated fixtures and optimized 3-axis workflows can be more cost-effective.

What Materials Are Suitable for 5-Axis-Milling

5-axis CNC machining supports a wide range of materials, from common metals to engineering plastics and advanced materials. Its multi-directional cutting capability is especially valuable when machining hard-to-reach features, tight tolerances, or complex geometries that demand stable tool control.

Aluminum

Aluminum is one of the most commonly machined materials in 5-Axis-Milling due to its excellent machinability and high strength-to-weight ratio. It supports high cutting speeds and produces clean chips, making it ideal for complex housings, brackets, and precision structural parts.

Stainless Steel

Stainless steel is selected when corrosion resistance and mechanical strength are critical. It generates more heat during cutting and requires controlled tool paths, but 5-axis machining helps maintain consistent engagement on angled or contoured features.

Carbon Steel

Carbon steel offers good strength and cost efficiency. Its machinability varies by carbon content, but it is widely used for mechanical components, fixtures, and load-bearing parts where dimensional stability matters.

Brass

Brass is one of the easiest metals to machine. It produces excellent surface finishes with minimal tool wear. Brass is often used for precision fittings, connectors, and components where accuracy and appearance are important.

Copper

Copper has excellent electrical and thermal conductivity but is soft and ductile. Precise tool orientation in 5-axis machining helps reduce smearing and improves surface quality for electrical and thermal management components.

Titanium

Titanium is used when high strength, low weight, and corrosion resistance are required. It is challenging to machine due to heat concentration and tool wear, but 5-axis machining improves stability by maintaining optimal cutting angles on complex geometries.

ABS

ABS is easy to machine and offers good impact resistance. It is commonly used for functional prototypes, enclosures, and housings where moderate strength and dimensional consistency are required.

PMMA (Acrylic)

PMMA is valued for its optical clarity. Controlled cutting angles and stable tool orientation are essential to prevent edge chipping and surface whitening. It is widely used for optical parts and transparent covers.

POM (Acetal)

POM provides high stiffness, low friction, and excellent dimensional stability. It machines cleanly and is commonly used for precision gears, bushings, and mechanical components.

Nylon

Nylon is tough and wear-resistant but more flexible than POM. Careful control of cutting forces is required to prevent deformation, making it suitable for bearings, gears, and sliding parts.

Polycarbonate (PC)

Polycarbonate offers high impact resistance and transparency. It is sensitive to heat during machining, so optimized tool paths help maintain surface quality and dimensional accuracy.

CFRP

CFRP is lightweight and extremely strong but prone to delamination. 5-axis machining allows the cutter to follow fiber directions, improving edge integrity for automotive and aerospace components.

GFRP

GFRP is commonly used for structural and industrial parts. Controlled tool angles in 5-axis machining help reduce fiber pull-out and improve surface consistency.

Ceramics

Ceramics are hard and heat-resistant but brittle. 5-axis machining improves access to complex features while allowing precise control of cutting forces for specialty components.

Graphite

Graphite is widely used for electrical and thermal applications. Its brittle structure benefits from stable tool orientation, making 5-axis machining ideal for intricate electrodes and fixtures.

Wood And Engineered Wood

Hardwoods, softwoods, plywood, and engineered wood can also be CNC machined. Key considerations include dust control and avoiding layer delamination, especially for complex or repeatable shapes.

Practical Insight

In real manufacturing, material selection depends on part geometry, tolerance requirements, and production volume. The flexibility of 5-Axis-Milling allows manufacturers to process diverse materials without redesigning the entire production workflow—making it especially valuable for complex, high-precision parts.

What Can You Make with a 5-Axis CNC Machine

A 5-axis CNC machine can produce far more than standard prismatic parts. By machining multiple surfaces and angles in a single setup, it enables complex geometries, smooth contours, and high-precision components that are difficult or inefficient to make with traditional CNC methods.

Typical Part Examples

5-Axis-Milling is commonly used to manufacture parts that require multi-angle access, tight tolerances, or complex surface transitions. Typical examples include:

1.Precision housings with angled holes and internal features

2.Mold and die components with deep cavities and contoured surfaces

3.Mechanical brackets and connectors with compound angles

4.Medical and industrial components requiring consistent accuracy

From real production experience, these parts often become cost-effective on a 5-axis machine because fewer setups mean fewer alignment errors and less manual handling.

Complex Features & Contours

The real strength of 5-axis machining lies in its ability to handle complex features:

1.Freeform and curved surfaces

2.Deep pockets with limited tool access

3.Undercuts and features at non-orthogonal angles

4.Smooth surface transitions across multiple faces

By maintaining optimal tool orientation, the machine reduces vibration and tool deflection, which directly improves surface finish and dimensional stability.

Common Applications of 5-Axis-Milling

5-Axis-Milling is widely adopted across industries where complex geometry, tight tolerances, and consistent quality are critical. By machining multiple faces and angles in one setup, it improves accuracy, efficiency, and design freedom for high-value components.

Aerospace

In aerospace manufacturing, components often feature complex contours, thin walls, and strict tolerance requirements. 5-axis machining allows continuous tool orientation, reducing vibration and ensuring consistent accuracy on parts such as structural components, housings, and precision brackets.

Automotive

Automotive manufacturers use 5-Axis-Milling for rapid prototyping, tooling, and low-volume production. Complex engine parts, custom fixtures, and mold components benefit from fewer setups and faster iteration during design validation stages.

Medical Devices

Medical parts demand exceptional precision and repeatability. 5-axis machining supports the production of surgical instruments, implant components, and medical housings by enabling smooth surfaces and accurate multi-angle features in a single setup.

Energy

In the energy sector, parts often include deep cavities, angled ports, and complex flow paths. 5-Axis-Milling improves access to these features, making it suitable for components used in power generation, fluid systems, and industrial equipment.

Military & Defense

Defense applications require reliable manufacturing of complex parts under strict quality control. 5-axis machining enables consistent production of precision components with intricate geometries, while minimizing manual handling and alignment risk.

Prototyping & Custom Manufacturing

For prototypes and custom parts, 5-Axis-Milling reduces lead time by eliminating multiple fixtures and setups. This makes it ideal for validating complex designs and producing functional prototypes directly from CAD data.

FAQs

What Does 5 Axis Milling Mean?

5 axis milling, also known as 5th axis machining, means machining parts using three linear axes (X, Y, Z) plus two rotational axes. This allows the cutting tool to maintain the optimal angle, reduce setups by about 50%, and machine complex surfaces in a single setup with higher accuracy.

What Are The 5 Axis On A CNC Machine?

The 5 axis on a CNC machine include three linear axes (X, Y, Z) and two rotational axes, commonly A and B or A and C. These axes allow the tool or workpiece to rotate, enabling multi-angle machining without manual repositioning. A typical 5 axis diagram shows how this motion improves access to complex features.

How Does A 5 Axis CNC Machine Work?

To understand how a 5 axis CNC machine works, consider how linear and rotational axes move together. During machining, the machine continuously adjusts tool orientation while cutting, allowing multiple faces and angles to be machined in one setup. This defines what 5 axis CNC machining is in practice.

What Is The Difference Between 3 Axis And 5 Axis Milling?

The difference lies in tool access and flexibility. With 3 axis milling, parts must be repositioned multiple times. With a 5 axis milling machine, multiple faces are machined in one setup, reducing lead time by 20–40% and improving positional accuracy for complex parts.

What Are The Types Of 5 Axis CNC Machine?

There are several types of 5 axis CNC machine, including indexed (3+2), continuous, and mill-turn configurations. Each type offers different levels of motion control, precision, and cost efficiency depending on part geometry and production requirements.

What Are The Disadvantages Of 5 Axis Machining?

The main disadvantages of 5 axis machining are higher equipment cost and increased programming complexity. Machines often cost 2–3 times more than 3 axis systems, and advanced CAM software and skilled programmers are required. For simple, high-volume parts, this can increase unit cost.

What Are Common 5 Axis CNC Projects?

Common 5 axis CNC projects include parts with complex curves, angled holes, and tight tolerances. Typical examples are mold cores, medical components, and aerospace brackets—applications where 5 axis machining enables geometry and accuracy that 3 axis systems struggle to achieve.

Conclusion

5-Axis-Milling is best suited for parts with complex geometry, tight tolerances, and multi-angle features. It reduces setups, improves accuracy, and delivers better surface quality—but only when the part design truly requires it. The key is choosing the right machining process based on geometry, tolerance, and production volume, not just machine capability.