What Is 5 Axis CNC?5 axis CNC machining is an advanced process that moves a tool or workpiece in five directions at once, enabling high precision, speed, and complex geometry.This guide covers key points — principles, machine types, materials, programming, and quality — helping you quickly grasp and master the essentials of 5-axis machining.

What Is 5 Axis CNC Machining

5-axis CNC machining allows a tool or workpiece to move in five directions simultaneously. Unlike 3-axis machining, it performs multi-surface cutting in one setup, achieving higher accuracy and efficiency. It’s widely used in aerospace, medical, and precision mold industries.

Get 20% offf

Your First Order

What Are the Five Axes of a 5 Axis CNC Machine

Understanding the five motion axes is the first step to mastering 5-axis machining:

X-axis: Left and right movement

Y-axis: Front and back movement

Z-axis: Up and down movement

A-axis: Rotation around the X-axis

B-axis: Rotation around the Y-axis

These rotations allow the tool to cut from multiple angles, ideal for deep cavities and curved surfaces.

We use 5-axis machines to achieve ±0.01 mm precision on titanium components.

Common Types and Structures of 5 Axis Machines

Based on rotation configuration, 5-axis machines are commonly divided into:

Table/Table: Two rotating tables — best for small precision parts.

Head/Table: A tilting spindle and rotating table — the most versatile structure.

Head/Head: Dual-rotating spindle with fixed workpiece — ideal for large aerospace parts.

In one project for a European client, we used a Head/Head setup to machine an aircraft bracket, maintaining rigidity while performing continuous 5-axis cutting.

What’s the Difference Between 5 Axis, 3 Axis, and Mill-Turn Machining

3-axis: 3-axis machining is limited to linear motion and requires multiple setups for complex shapes.

5-axis: 5-axis machines, however, finish all sides in one operation, reducing time and human error.

Mill-turn combines turning and milling, suitable for cylindrical parts, while 5-axis machining focuses on multi-angle freeform surfaces.

For example, we use 5-axis CNC to produce turbine blades with flawless contour transitions — impossible on traditional 3-axis systems.

What Are The Main Processes In 5 Axis CNC Machining

The 5-axis CNC machining process—from design and setup to programming, cutting, and inspection—determines the precision and efficiency of every part. A well-structured workflow minimizes rework, improves consistency, and ensures reliable, high-quality production results.

From Design To Workholding

The process begins with converting the customer’s 3D model into a manufacturable design.

Design Phase: Engineers evaluate geometry, undercuts, wall thickness, and hole orientation to ensure rigidity and avoid tool collisions.

Workholding: Custom 5-axis fixtures or self-centering vises are used to secure the part during multi-angle rotation.

For instance, when machining a titanium housing for an aerospace client, optimizing the clamping position reduced repositioning steps by two and improved cycle time by 25%.

CAM Programming And Toolpath Simulation

CAM programming acts as the “brain” of 5-axis machining.

Toolpath Strategy: Includes constant scallop, side milling, adaptive roughing, and contour finishing—each tailored for specific surfaces.

Simulation: Using software like PowerMill, HyperMill, or NX CAM, engineers simulate the cutting path to prevent collisions before machining.

For example, when producing a medical implant, our team used PowerMill’s multi-axis toolpath optimization and achieved a machining tolerance of ±0.003 mm.

Cutting, Inspection, And Feedback Optimization

Precision machining depends on fine control of feed rate, tool speed, and cooling systems.

Cutting Control: Adaptive Feed Control maintains consistent chip load and surface finish.

Measurement & Feedback: In-machine probing or CMM inspection data helps automatically adjust tool offsets.

In an energy impeller project, we used Renishaw probes for live calibration, enabling 24-hour lights-out machining with a 99.8% yield rate.

What Are The Core Components Of A 5 Axis CNC Machine

The performance of a 5-axis CNC machine depends on the synergy of its core components. The spindle defines cutting power, the rotary and drive systems control motion precision, and clamping and cooling systems ensure accuracy and tool life. Together, they determine machining quality and reliability.

Spindle, Rotary Axes, and Drive System

The spindle is the heart of any CNC machine—it defines speed, torque, and surface finish.

Spindle Speed: High-speed spindles (18,000–30,000 rpm) suit aluminum and resin, high-torque low-speed ones are ideal for titanium and steel.

Rotary Axes (A/B/C): Enable complex motion with positioning accuracy of ±5 arc seconds, ensuring smooth 5-axis contouring.

Drive System: Uses ball screws or linear motors with encoder feedback for sub-micron precision.

For a medical implant project, our 24,000 rpm spindle combined with a rigid B-axis achieved mirror-level surface finishing.

Tool Holding And Workholding Systems

Stable tool and workpiece clamping ensure machining accuracy.

Tool Holders: Common types include HSK and BT. HSK holders provide shorter taper and higher rigidity—perfect for high-speed machining.

Workholding: Zero-point systems, vacuum fixtures, or custom jigs minimize repositioning errors.

For a robotic joint component, we used a zero-point fixture that enabled 3-second setups with 0.002 mm repeatability.

Cooling System, Thermal Control, And Rigidity Design

Thermal stability plays a vital role in precision cutting.

Cooling System: Internal coolant tools with 70-bar high-pressure flow remove heat efficiently.

Thermal Compensation: Sensors automatically adjust for thermal drift.

Rigidity: Cast iron or mineral-filled beds absorb vibration for stable cutting.

When machining Inconel X-750, we used oil mist cooling and bed temperature control to maintain ±0.003 mm dimensional consistency.

How Is 5 Axis Programming Different From 3 Axis Programming

5-axis CNC programming is more complex yet far more capable than 3-axis. It involves multi-directional motion, dynamic tool orientation, and collision management. Understanding the key differences helps engineers achieve higher accuracy, smoother finishes, and reduced setup time.

Multi-Axis Toolpath Strategies

The heart of 5-axis programming lies in toolpath control.

Flank Milling: Uses the tool’s side edge to cut along a curved surface—ideal for impellers and blades. Compared with 3-axis point cutting, it produces smoother surfaces and shorter cycle times.

Constant Scallop: Maintains equal toolpath spacing for a consistent surface texture. In our medical implant machining, this reduced roughness from Ra 0.8 μm to 0.3 μm.

Compound Drilling: Combines A/B-axis tilting for angled holes without reclamping.

In an automotive project, we applied 5-axis compound drilling to cut re-clamping by 40% and improve accuracy to ±0.005 mm.

Post-Processing And Collision Simulation

These two steps safeguard precision and equipment.

Post-Processing: Converts CAM toolpaths into machine-readable G-codes compatible with different CNC controllers (Heidenhain, Fanuc, Siemens).

Collision Simulation: Detects interference between tools, fixtures, and spindles before actual cutting.

I’d use HyperMill’s virtual simulation to identify tool-holder collisions in advance—saving nearly $2,000 per project in potential rework costs.

Which Materials And Industries Benefit Most From 5 Axis Machining

5-axis CNC machining handles diverse materials—from aluminum and titanium to stainless steel, composites, and plastics. Each fits specific industries: aerospace needs strength and lightness, medical demands precision, and automotive values efficiency. Proper material choice ensures performance and cost control.

| Category | Common Types | Key Features & Advantages | Typical Industries |

| Aluminum Alloys | 6061, 7075, 2024 | Lightweight, thermally conductive, easy to machine, ideal for high-speed 5-axis operations | Aerospace, Automotive, Robotics |

| Titanium Alloys | Ti-6Al-4V, TC4 | High strength-to-weight ratio, corrosion resistant, requires rigid setup and cooling | Aerospace, Medical Implants, Energy |

| Stainless Steel | 304, 316L, 17-4PH | High strength, excellent wear and corrosion resistance | Medical, Automotive, Defense, Molds |

| Composites | Carbon Fiber, Glass Fiber | Lightweight with high stiffness, needs special tooling for machining | Aerospace, Drones, Sports Equipment |

| Copper & Brass | H62, C11000 | Excellent conductivity, ideal for electrical components | Electronics, Energy, Instrumentation |

| Engineering Plastics | PEEK, PA66+GF, Delrin | Lightweight, insulating, great for prototypes and testing parts | Medical, Robotics, Rapid Prototyping |

What Are The Main Advantages And Challenges Of 5 Axis Machining

5-axis CNC machining is key to modern manufacturing. By moving tools along five axes at once, it enables precise multi-angle machining for parts like turbine blades, medical implants, and molds. However, it also brings challenges—high machine cost, complex programming, and skilled labor demands.

Advantages

Multi-Side Machining in One Setup

Unlike 3-axis machining, which requires multiple clamping operations, 5-axis machining completes several faces in a single setup, cutting 30–50% of total production time and minimizing cumulative errors.

Capability for Complex Geometries

Rotational A and B axes allow the cutting tool to approach from any angle, ideal for intricate surfaces, undercuts, and deep cavities — common in aerospace blades, molds, and orthopedic components.

Superior Surface Finish & Tool Longevity

Maintaining tool alignment with surface normals reduces chatter and heat, resulting in finishes as fine as Ra 0.2 μm and extending tool life by over 20%.

Higher Automation and Consistency

Less manual repositioning means fewer human errors and more consistent quality across large production batches.

Challenges

High Equipment and Maintenance Costs

Premium 5-axis machines range from $200,000 to $800,000, with top-tier brands exceeding $1 million. Regular calibration and maintenance also add to long-term expenses.

Complex Programming and CAM Costs

Advanced CAM software (e.g., Mastercam, Siemens NX, HyperMill) is required for precise toolpath simulation and collision avoidance. Skilled programmers are essential to fully utilize the technology.

Skilled Operator Requirement

5-axis machining demands a solid understanding of multi-axis kinematics, setup optimization, and cutting strategies — usually requiring 3–6 months of training before stable operation.

Longer ROI Cycle

While offering superior productivity and precision, ROI typically takes 2–3 years, making 5-axis ideal for high-value industries such as aerospace, energy, and medical manufacturing.

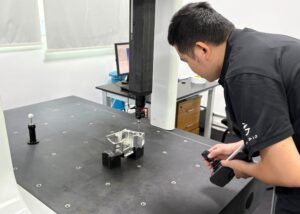

How to Ensure the Quality of 5 Axis CNC Machining

In 5-axis CNC machining, quality control ensures both precision and reliability. Using in-machine probing, CMM inspection, and tolerance calibration, every step is data-driven. A closed-loop system keeps dimensional deviation within ±0.005mm, guaranteeing consistent accuracy and smooth surface finishes.

In-Machine Probing And CMM Inspection

In-Machine Probing

Modern 5-axis CNC machines use Renishaw or Blum probes for automatic measurement during machining.

For instance, systems can check five key dimensions in under 60 seconds, applying real-time tool compensation to prevent size drift.

This approach eliminates re-clamping errors and increases production efficiency by over 20% in batch manufacturing.

Coordinate Measuring Machine (CMM) Inspection

After machining, parts undergo precision inspection in a temperature-controlled environment using CMMs.

These systems achieve 0.002mm accuracy, ideal for complex aerospace blades or medical implants.

By comparing CAD models with measured data, CMMs provide full traceability reports, reinforcing trust and transparency with clients.

How To Choose the Right 5 Axis CNC Machine

Choosing the right 5-axis CNC machine impacts both precision and efficiency while defining long-term competitiveness. The ideal setup balances travel, spindle power, control, and service. With smart configuration, businesses can recover investment within 2–3 years and ensure stable, high-quality production.

Key Factors

Travel Range & Part Size Compatibility

The machine’s X/Y/Z travel defines the maximum part size. Large aerospace or energy components require X >1000mm and Z >600mm, while smaller medical or electronics parts benefit from fine resolution and higher spindle speeds.

Spindle Power & Speed

The spindle is the machine’s core. High-torque spindles suit tough materials like titanium or stainless steel, while high-speed spindles (20,000+ rpm) are best for aluminum and mold machining. I commonly uses BT40 / HSK63 spindles for both strength and precision.

Control System Intelligence & Compatibility

Advanced systems like Fanuc, Siemens, or Heidenhain ensure smoother motion and error compensation. For example, the Fanuc 31i-B5 controller offers 1000-block look-ahead, reducing vibration and improving curved surface accuracy.

After-Sales Service & Technical Support

Buying a 5-axis machine means investing in service reliability. Rapid response, spare parts supply, and remote diagnostics directly affect uptime. Brands like Mazak and DMG MORI provide 24/7 support—essential for high-volume production.

Evaluating ROI And Long-Term Efficiency

Investment and Payback Period

Typical ROI for a 5-axis machine is 24–36 months. Formula:

ROI = (Annual Cost Savings ÷ Total Investment) × 100%.

For example, saving $120,000 annually on a $300,000 machine gives a 40% ROI with a 2.5-year payback period.

Efficiency & Productivity Gains

A 5-axis setup can cut 70% of fixture changes and boost throughput by 30–50%. In common situation, one 5-axis unit replaces two 3-axis machines, delivering superior surface finish and dimensional consistency.

Maintenance & Upgrade Value

Machines with modular designs allow control, spindle, and automation upgrades. With proper maintenance, a 5-axis CNC can last 10–15 years, and strong after-sales support extends long-term value.

Tolerance, Surface Finish, And Calibration

Tolerance Control

Typical 5-axis tolerances range from ±0.005–0.01mm. Our precision ball screws and temperature-stabilized spindles reduce thermal deformation impact by up to 30%, ensuring repeatable accuracy in every production run.

Surface Finish Optimization

By adjusting cutter radius, feed rate, and toolpath strategy, aluminum parts can reach Ra 0.6 μm or better.

For optical or medical-grade components, we adds polishing or anodizing steps for enhanced aesthetics and durability.

Machine Calibration and Maintenance

Regular calibration sustains accuracy. I performs laser interferometer calibration and spindle runout testing every six months to maintain ISO 230 compliance. Preventive maintenance lowers downtime and extends machine lifespan by over 25%.

FAQs

What Is The Difference Between 4 And 5-Axis CNC?

The key difference between 4-axis and 5-axis CNC machining is the number of rotational axes. In 4-axis machining, the workpiece rotates on a single axis, while 5-axis machining allows both the tool and workpiece to rotate along two separate axes. This added rotational movement in 5-axis CNC enables the production of more complex parts with greater precision and shorter setup times.

How Many Axis Can A CNC Have?

CNC machines come in different configurations, with standard 3-axis models being the most common, while more advanced systems feature 5, 6, or even 9 axes for greater versatility and precision. The more axes a machine has, the more complex the shapes and geometries it can produce.

What Are The Types Of 5-Axis CNC Machines?

The common types of 5-axis CNC machines include indexed 5-axis, continuous 5-axis, and mill-turning centers, each offering distinct capabilities for different machining requirements. Each type offers different capabilities, with continuous 5-axis being the most advanced.

What Size Parts Can A 5-Axis Machining Center Process?

A 5-axis machining center can handle parts ranging from 5 mm precision components to 2,000 mm large structures, depending on the machine’s travel range and spindle power. In my experience, compact trunnion models suit aerospace brackets, while large gantry systems efficiently process molds up to 2 tons in weight.

Is 5-Axis Machining Suitable For Small Batch Production?

Yes, 5-axis machining is ideal for small and medium batch production due to its ability to complete multiple operations in one setup. I often achieve 30–40% faster lead times and reduce fixture costs by half, making it cost-effective for prototypes, medical implants, and precision tooling runs under 100 pieces.

Conclusion

5 axis CNC machining is reshaping the future of precision manufacturing.

It not only improves efficiency but also unlocks design freedom once thought impossible.

From my experience, mastering 5-axis machining means delivering faster, more accurate, and more complex parts — and that’s exactly what defines the next generation of global manufacturing.Tell me your needs for five-axis CNC machining, and I will provide the perfect solution!