Milling is a widely used process in manufacturing, using a rotating tool to remove material and precisely machine a part’s surface. With the continuous advancement of technology, milling operations have evolved into various types, each with its own specific applications and advantages. This article will detail 24 Types Of Milling Operations, ranging from basic face milling and slot milling to more specialized micro milling and thread milling. Whether you’re an engineer, designer, or manufacturer, understanding these milling types will help you make more accurate decisions in your operations, optimizing your production processes and boosting your competitiveness.

What Is Milling

Milling is a common machining process in which a rotating milling cutter cuts the workpiece surface to achieve the desired shape and size. Milling is widely used in a variety of fields, including metalworking, plastics processing, and composite materials processing, and is particularly important in the production of high-precision parts. Milling can produce a variety of complex parts, including planes, slots, gears, holes, and other shapes.

In the manufacturing industry, milling not only improves production efficiency but also meets the requirements of high precision and complexity. It is an indispensable part of many processing processes. The wide application of milling has made it occupy a pivotal position in modern manufacturing.

In milling, face milling and external milling are two common processing methods. The difference between them lies in the working direction and action surface of the tool :

Face Milling : The axis of the tool is perpendicular to the workpiece surface and is mainly used for machining flat surfaces. It is suitable for machining larger planes, especially when high surface quality is required.

External Milling : The axis of the tool is parallel to the workpiece surface and is mainly used to machine the outer contour or shape of the workpiece. External milling is more common in machining the outside of the workpiece and is suitable for machining longer or deeper surfaces.

These two milling methods have their own advantages and applicable scopes in application. Choosing the appropriate milling method is crucial to improving processing efficiency and precision.

What Are The Common Types Of Milling

In milling, different milling methods are suitable for different processing needs. These range from basic face milling to more specialized micro milling and thread milling. With a deep understanding of these milling types, you can better address real-world processing challenges, optimize production processes, and select the most appropriate milling method to achieve the desired processing results.

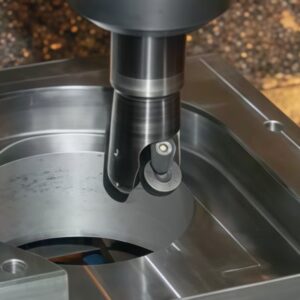

1. Face Milling

Face milling is a common milling method in which the tool axis is perpendicular to the workpiece surface. It is primarily used to machine planes, steps, grooves, and other complex surfaces. Face milling typically uses a milling cutter with multiple teeth, which can remove a large amount of material in a single pass, making it suitable for mass production. Due to the tool structure and feed method, face milling can produce a very flat and smooth surface quality, making it particularly suitable for large surfaces and fine processing.

Application:

Plane Machining : Face milling is often used to machine the flat surface of a workpiece, especially when machining larger or wider planes. It has high machining efficiency. It can remove a large amount of material in a short time while keeping the workpiece surface smooth and flat.

Step And Groove Machining : Face milling is also widely used to machine features such as steps, grooves, and blind holes, and is particularly essential in mold manufacturing, automotive parts, and precision parts processing. It provides precise control of step size and depth, ensuring that the finished workpiece meets design requirements.

Precision Machining : When machining requires high precision and flatness, face milling is the ideal choice. Especially in industries such as aerospace, automotive manufacturing, and precision instruments, face milling can not only meet stringent dimensional requirements but also ensure the smoothness and precision of the machined surface .

Face milling has become an indispensable processing method in the industrial field due to its high efficiency, strong applicability and ability to provide good surface quality, and is widely used in various processing scenarios.

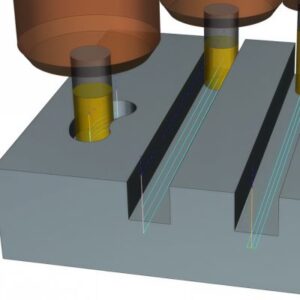

2. Slot Milling

Slot milling is a common type of milling process, primarily used to create grooves or recesses of varying shapes on a workpiece surface. The tool used for slot milling is typically a milling cutter with multiple teeth, whose axis is parallel to the workpiece surface, removing the desired material. Slot milling is not only suitable for producing straight grooves, but can also be used to create complex grooves and holes, offering high efficiency and flexibility.

Application:

Straight Groove And Groove Processing : Slot milling is most commonly used to process straight grooves and grooves, and is widely used in mold manufacturing, mechanical structure parts and other fields. It can accurately control the width, depth and shape of the groove according to design requirements.

Complex Groove Processing : In addition to straight grooves, slot milling is also suitable for processing grooves of various complex shapes, such as rounded grooves, U-shaped grooves, etc., which can meet the processing needs of some special parts.

Hole Machining : Slot milling is also commonly used to process holes and blind holes. Especially in parts that require multiple hole positions or complex hole shapes, slot milling can provide an efficient processing method.

Slot milling has become an important processing method in many industrial fields due to its high efficiency and wide applicability, especially when parts with precise groove shapes and porous structures need to be processed.

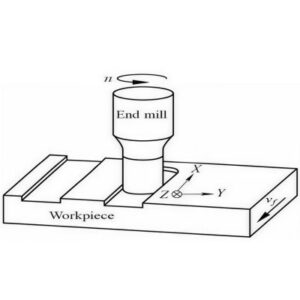

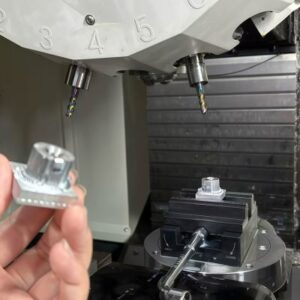

3. End Milling

End milling is a milling process typically performed with a face milling cutter, where the tool axis is perpendicular to the workpiece surface. End milling is primarily used to machine workpiece faces, grooves, contours, and other complex surfaces. Unlike face milling, end milling tools can not only machine flat surfaces but also perform deeper cuts, offering exceptional flexibility in complex and diverse machining tasks.

Application:

End Face Machining : End milling is often used to machine the end face of a workpiece. It can achieve fine plane machining and is suitable for machining deeper parts or small areas.

Grooving And Hole Machining : End milling effectively creates deep grooves, U-shaped slots, and various hole positions by cutting the end face of the end mill. End milling provides precise control of slot width and depth, making it commonly used in the machining of precision parts.

Complex Contours And Shapes : The structure of end milling tools makes it play an important role in the processing of more complex contours. Especially in industries such as mold manufacturing, automotive parts and aerospace parts, end milling can process a variety of complex geometries to meet diverse processing needs.

End milling is widely used in parts processing requiring multi-function and deep cutting due to its high precision and flexibility, especially in fine processing of complex surfaces and small areas.

4. Thread Milling

Thread milling is a milling method used to produce threads. A specialized thread milling cutter is used to cut the surface of a workpiece, creating internal or external threads. Unlike traditional turning, thread milling can be performed on a milling machine, enabling the simultaneous production of multiple threads or the cutting of complex thread shapes. The advantages of thread milling lie in its ability to achieve higher precision and better surface quality, making it particularly suitable for applications involving complex materials or requiring high precision.

Application:

Internal And External Thread Processing : Thread milling is suitable for machining internal and external threads, especially in applications requiring high precision, such as precision instruments and mechanical connection components. Thread milling produces a smoother thread surface, ensuring a tight and stable fit.

High-Precision Thread Processing : Thread milling is an ideal choice for workpieces that require high thread accuracy and surface quality. Thread milling can provide very precise cutting results, especially when processing workpieces with complex thread structures, such as variable pitch or irregular threads.

Mass Production : Thread milling is suitable for mass production, which can improve production efficiency and reduce tool wear, making mass production more efficient.

Thread milling is widely used in various manufacturing fields requiring threaded connections due to its high precision, good surface quality and processing flexibility.

5. Shoulder Milling

Shoulder milling is a common milling process primarily used to create 90-degree shoulders on workpieces. The tool typically uses a flat-edged milling cutter, with the tool axis perpendicular to the workpiece surface. This process achieves precise, perpendicular cuts and is widely used on parts requiring right-angled shoulders. This process is particularly well-suited for workpieces with sharp boundaries or where right-angled surfaces are required.

Application:

Square Shoulder Machining : Square shoulder milling is widely used to machine shoulders with a 90-degree right angle, which is common in the manufacture of mechanical parts, molds and structural parts. In these parts, precise right-angle shoulders are important features to ensure fit and functionality.

Step And Groove Processing : Shoulder milling is also suitable for processing steps and grooves. It can provide high-precision step shape control and is widely used in the production of mechanical equipment and parts.

High-Precision Machining : In precision machining, shoulder milling is often used for workpieces that require precise dimensions and clear boundaries, especially in aerospace, automotive manufacturing and other precision manufacturing industries.

Shoulder milling has become an indispensable milling method in many industries because it can produce precise right-angle surfaces and clear shoulder boundaries.

6. Side Milling

Side milling is a milling process in which the tool axis is parallel to the workpiece surface and is primarily used to machine the sides or edges of a workpiece. Side milling typically uses a longer cutter, enabling the creation of deeper slots or more complex shapes. It is not only suitable for flat surfaces but also for narrow slots, edges, or contours, offering a high degree of machining flexibility.

Application:

Side Machining : Side milling is widely used to machine the side of the workpiece, especially in workpieces that require deeper cutting. It can accurately control the cutting depth and ensure that the edge of the workpiece is flat.

Groove And Groove Processing : Side milling is often used to process workpieces with deeper grooves or grooves. Especially when precise groove width and depth need to be processed, side milling is an ideal choice.

Contour And Edge Processing : Side milling can process complex workpiece contours and edges. It is widely used in mold manufacturing, mechanical parts processing and aerospace component production. Especially when fine edges are required, side milling can provide higher precision.

Side milling has become a commonly used milling method in many industrial fields due to its excellent processing depth control and flexibility. It shows extremely high efficiency and precision, especially when processing sides and complex contours.

7. Contour Milling

Contour milling is a milling method primarily used to produce the outer contours or complex shapes of a workpiece. The tool follows the contours of the workpiece during machining, often used to produce parts with unusual shapes or curves. Contour milling utilizes multi-axis CNC equipment to precisely control tool paths, enabling the creation of highly complex geometries. Unlike other milling methods, contour milling emphasizes precise cutting of workpiece surfaces and edges, making it suitable for custom parts across a wide range of industries.

Application:

Complex Shape Processing : Contour milling is widely used to process parts with complex geometric shapes, such as curves, curved edges, etc. It is widely used in mold manufacturing, aerospace and automotive parts production, especially in parts that require high precision and complex design.

Contour Milling : Contour milling can accurately replicate or machine the contours of a workpiece and is suitable for parts that require external edges or contours to be machined according to a specific design. This process is often used to produce parts with complex shapes.

Precision And High Surface Quality Requirements : Contour milling can provide higher processing accuracy and surface quality, and is often used in scenarios that require fine surface processing, such as the manufacture of precision instruments, medical equipment and high-end electronic parts.

Contour milling has become an indispensable processing method in modern manufacturing due to its high precision, flexibility and wide applicability. It is particularly suitable for processing tasks with complex shapes and high surface quality requirements.

8. Sawing And Milling

Saw milling is a specialized milling process that typically uses a thin blade, with the tool axis parallel to the workpiece surface. It’s primarily used to create narrow cuts or slots in workpieces. Compared to traditional milling methods, saw milling uses thinner tools and produces a smaller cutting width, making it ideal for applications requiring precise cuts or narrow slits. Saw milling can be performed at higher cutting speeds, significantly improving production efficiency.

Application:

Slit And Slot Processing : Saw milling is often used to process narrow cuts, slots or slots with complex shapes. It is widely used in workpieces that require a small cutting width, such as slot processing in electrical components, precision parts and molds.

Material Removal : Saw milling is suitable for rapid material removal, especially when processing longer or deeper cutting grooves, which can ensure high processing efficiency and cutting accuracy.

High-Precision Cutting : Due to the thinner tool, saw milling is very suitable for workpieces that require high-precision and fine cutting. Especially in the processing of micro parts and details, saw milling provides good processing results.

Saw milling is widely used in many industries due to its suitability for narrow grooves and fine cutting, especially in mold manufacturing, precision parts processing and processing of complex shapes, where it plays an important role.

9. Copy Milling

Copy Milling (Computer-Aided Manufacturing Milling) is a technology that uses a computer-aided manufacturing (CAM) system to guide milling operations. Using a computer program, the CAM system generates tool paths and controls the milling machine for precise machining. Copy Milling automates complex milling tasks and optimizes tool motion and machining paths based on a 3D part model, ensuring precision and efficiency.

Application:

Complex Parts Processing : Copy Milling is particularly suitable for processing parts with complex geometric shapes, such as three-dimensional surfaces, complex contours, and multi-axis processing. It is widely used in aerospace, automobile, mold manufacturing and other industries, and can efficiently process parts that require high precision and complex shapes.

High-Precision And Efficient Production : By using a CAM system to generate tool paths, manual operation errors and time can be significantly reduced, improving machining accuracy and efficiency. Copy Milling is widely used in mass production, especially in situations where fine details and high productivity are required, showing significant advantages.

Customization And Low-Volume Production : Copy Milling is ideal for custom parts and low-volume production. It allows for flexible adjustments to machining methods based on customer needs while ensuring consistency and quality for each part.

Copy Milling has become an indispensable processing method in modern manufacturing due to its high degree of automation, high precision and high efficiency. It is particularly suitable for scenarios requiring high precision and complex processing.

10. Gear Milling

Gear milling is a milling method specifically designed for producing gear teeth. Gear milling uses a gear milling cutter to create the gear tooth surface on a workpiece. Gear milling can produce both internal and external gears, and is suitable for producing a variety of tooth shapes, such as spur, helical, and spiral. This process is typically performed using a CNC milling machine, which precisely controls the tooth profile, pitch, and height, ensuring gear accuracy and performance.

Application:

Gear Manufacturing : Gear milling is widely used in the manufacturing of gears in various mechanical equipment, automobiles, industrial transmission devices and other fields. It can produce high-precision gears, ensuring smooth transmission and long-term use of the gears during operation.

Internal And External Gear Machining : Gear milling can not only process external gears, but also produce internal gears. For gear systems that need to transmit in confined spaces, internal gear machining is crucial.

Customized Gear Production : Gear milling can meet the customization needs of various gear shapes and sizes, and is particularly suitable for small-batch, high-precision gear production.

Gear milling is widely used in the manufacture of various transmission devices due to its high precision and flexibility. It plays an irreplaceable role, especially in gear applications that require high performance and long life.

11. Angle Milling

Angled milling is a milling method used to machine inclined surfaces or workpieces with specific angles. Using a specially designed milling cutter, the tool can create a face along the workpiece surface at an angle to the tool axis. This machining method can be adapted to various inclined surfaces or complex angles by adjusting the tool angle, adapting to different materials and machining requirements. Angled milling provides high-precision angular control, ensuring that the workpiece geometry meets design requirements.

Application:

Machining Inclined Surfaces : Angle milling is widely used to machine surfaces or inclined surfaces with specific angles, especially in mold manufacturing, mechanical parts processing and aerospace components, which often require machining precise inclined surfaces.

Step and angle cutting : In some parts processing, angle milling can be used to cut step shapes or features with complex angles, especially in the automotive manufacturing and precision instrument industries.

Precision Angle Processing : Angle milling is suitable for processing parts that require high-precision angles. For example, in some assembly structures, precise angle cutting is the key to ensuring part fit and function.

Angle milling is widely used in the processing of parts that require bevels, steps or complex angles because it can accurately control the processing angle. It is especially important in the fields of precision manufacturing and special design.

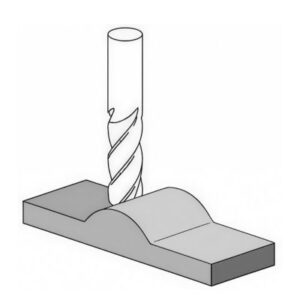

12. Profile Milling

Profile milling is a milling method that uses specialized cutting tools to create specific shapes or complex geometries. Unlike traditional milling, profile milling uses a tool with a specific shape, creating a specific shape on the workpiece that matches the tool’s profile, such as grooves, contours, or concave and convex surfaces. This method allows for the precise production of complex curved or irregular surfaces, making it widely used in applications requiring high-precision shape processing.

Application:

Complex Shape Processing : Profile milling is suitable for processing parts with complex geometric shapes, such as special contours, concave and convex surfaces, etc. It is widely used in mold manufacturing, automotive parts and precision instruments, and can accurately cut complex surfaces according to the shape of the tool.

Precision Part Machining : When precise contours and high surface quality are required, profile milling provides an ideal machining method, especially when manufacturing precision molds and accessories, which can achieve very high form accuracy.

Molds And Mechanical Parts : Forming milling is often used in mold manufacturing and the production of mechanical parts. It can process very fine shapes according to design requirements to ensure the functionality and assembly accuracy of the parts.

Form milling is widely used in the manufacture of complex parts and high-precision molds due to its unique tool shape and precise processing capabilities. It is an indispensable milling technology in many industries.

13. Duplex Milling

Twin milling is a milling method that uses two cutting tools simultaneously, typically mounted on the same axis. This method improves machining efficiency by simultaneously cutting two different locations on the workpiece. This method can process multiple surfaces or features simultaneously, making it suitable for high-volume production. The advantages of twin milling include faster machining, reduced cycle time, and improved precision.

Application:

Efficient Processing Of Large Quantities Of Parts : Duplex Milling is often used in large-scale production, especially when multiple surfaces need to be processed simultaneously, which can greatly improve production efficiency. It is widely used in fields such as automotive manufacturing, electronics and mechanical parts.

Simultaneous Machining Of Multiple Features : Dual milling allows for simultaneous machining of multiple surfaces or features on a workpiece, such as planes and steps. This method is suitable for situations where complex machining tasks need to be completed in a short period of time.

Improved Precision And Consistency : Since two tools work simultaneously, twin milling can maintain higher consistency and processing accuracy, especially in batch production, ensuring consistent processing results for each part.

Due to its high efficiency and high precision, Duplex Milling has become a commonly used milling method in mass production. It is particularly suitable for use in environments with complex processing requirements and high production requirements.

14. Plain Milling

Plain Milling is a common milling method used to remove a layer of material from a workpiece surface. The tool axis is parallel to the workpiece surface and is suitable for machining larger flat surfaces. Plain Milling typically uses a milling cutter with wide teeth. By feeding the workpiece horizontally, Plain Milling can remove large amounts of material in a short period of time. It is widely used for machining tasks that require removing thick metal layers or smoothing surfaces.

Application:

Plain Milling is widely used for machining large surfaces, especially when smoothing and removing excess material is required. It is commonly used in mold manufacturing, automotive parts, mechanical parts and other fields.

Material Removal : Plain Milling is suitable for removing thicker materials on the surface of the workpiece, especially in the rough machining stage. It can quickly remove excess material and provide a good foundation for subsequent precision machining.

Machining With Lower Precision Requirements : Plain Milling is suitable for machining workpieces with lower surface precision requirements, especially when large surface areas need to be processed quickly and flattened. It is an ideal choice.

Plain Milling has become a commonly used milling method in many industrial productions due to its high efficiency and wide applicability. It shows extremely high efficiency, especially when it is necessary to flatten large surfaces and remove more materials.

15. Combined Milling

Gang milling is a machining method that uses multiple cutters, typically mounted on a single axis, to simultaneously cut multiple workpiece surfaces. This method is ideal for rapidly machining multiple surfaces or features on the same workpiece, significantly improving machining efficiency. Gang milling is often used in mass production to meet high-volume production demands by reducing machining time and improving efficiency.

Application:

Mass Production : Combined milling is particularly suitable for mass production because it can cut multiple surfaces simultaneously in a single operation, thus reducing the number of workpiece clamping times and processing time. It is widely used in industries such as automobiles, electronics, and mechanical parts.

Multi-Surface Machining : When multiple surfaces or features need to be machined simultaneously on certain workpieces, combined milling can effectively improve production efficiency. For example, when machining complex parts, combined milling can complete multiple processes at once, reducing waiting and switching time.

Improve Machining Accuracy And Consistency : Combined milling can process multiple surfaces at the same time, ensuring the parallelism and consistency of the workpiece surface. It is suitable for machining tasks that require high precision and high consistency.

Combined milling has become an important milling method in mass production due to its significant efficiency advantages and high-precision control, especially in situations where multiple surfaces and features need to be processed simultaneously. It has irreplaceable advantages.

What Are The Special Milling Processes

Specialized milling is a milling technology developed for specific machining requirements, often used to solve unique workpiece machining challenges. Compared to conventional milling, specialized milling can handle more complex machining requirements, such as high-precision parts with complex shapes or specialized functions. With technological advancements, specialized milling has become increasingly important in modern manufacturing, with widespread application in high-end industries such as aerospace, automotive, mold manufacturing, and precision instruments.

16. Micro-Milling

Micro-milling is a milling process used to produce extremely small parts or minute details, typically using very fine cutting tools and high-precision machine tools. Micro-milling can produce extremely small details and precise geometries, making it suitable for industries such as micro parts, electronic components, and medical devices. Through high-precision control, micro-milling can cut at the micron level, ensuring high quality and accuracy.

Application:

Micro-Parts Processing : Micro-milling is widely used in electronics, communications, medical and other industries to process micro-parts such as tiny gears, contact points, conductive wires, etc.

Fine Detail Processing : Micro milling can provide precise cutting in the processing of parts that require extremely small details and complex structures. It is widely used in the manufacture of micro machinery, precision molds and microelectronic components.

High-Precision Parts Production : Micro-milling can achieve micron-level accuracy and is suitable for high-end parts that require extremely high surface quality and processing accuracy, such as biomedical equipment, optical instruments and high-precision sensors.

Micro milling has become an important technology in the field of micro machining due to its excellent precision and capabilities, and can meet the processing needs of high-precision and small-sized parts.

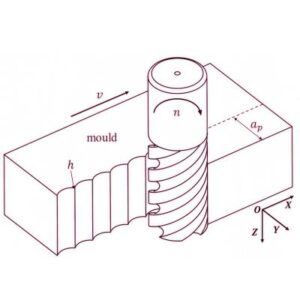

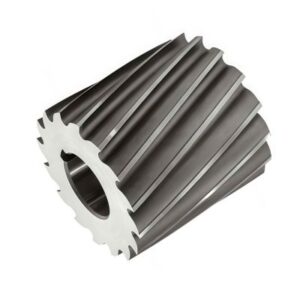

17. Cylindrical Milling

Cylindrical milling is a milling process specifically designed for machining circular parts. Using a cylindrical milling cutter, the tool is aligned parallel to the workpiece axis, enabling cutting along the workpiece’s circumference. This machining method is primarily used to manufacture parts with circular or annular surfaces and is widely used in the production of various mechanical equipment, bearings, gears, and other components. Cylindrical milling can not only machine external circular surfaces, but also internal holes, slots, and other circular features.

Application:

Circular Parts Processing : Cylindrical milling is widely used to process parts with a circular appearance, such as shafts, rings, sleeves, etc. These parts are usually used in mechanical transmission, bearings and automobiles.

Internal And External Circle Processing : Cylindrical milling is not only suitable for processing external circles, but also can be used to process internal circles of workpieces, such as inner holes, annular grooves, etc. It is especially suitable for processing circular parts with higher processing requirements.

Precision And Mass Production : For circular parts produced in large quantities, cylindrical milling provides an efficient processing method that can improve production efficiency while ensuring processing accuracy. It is widely used in the automotive, machinery, aerospace and other fields.

Cylindrical milling plays an important role in the production of various parts requiring circular geometries due to its ability to accurately process circular surfaces, and has significant advantages especially in mass production.

18. Down Milling

Down milling is a milling method in which the tool is fed downward along the workpiece surface, rotating in the same direction as the workpiece. Unlike traditional up milling (where the tool is fed from above the workpiece surface), down milling directs the cutting force toward the workpiece, reducing tool wear and vibration during machining. This method is often used for precision machining, particularly for softer materials or thinner workpieces.

Application:

Precision Surface Processing : Down milling is suitable for processing tasks with high requirements on surface quality, especially when a flat and smooth surface is required, it can provide better cutting effect and surface accuracy.

Thin Material Processing : Down milling is suitable for processing thin materials or workpieces that are easily deformed, because the downward feeding of the tool can effectively reduce workpiece deformation and tool vibration, and improve processing stability.

Precision Parts Processing : In aerospace, automotive and electronic equipment manufacturing, down milling is used for precision parts processing, especially under conditions that require careful and stable cutting, to ensure high precision and high quality processing results.

Down milling has become a common method in many precision machining fields due to its cutting stability and wide applicability, especially in high-quality surface treatment and thin material processing.

19. Deep Hole Milling

Deep Hole Milling is a milling method used to create holes deeper than conventional holes. Unlike conventional drilling, Deep Hole Milling uses the milling cutter to cut along the workpiece’s axial direction, enabling deep holes to be created within deeper workpieces. Deep Hole Milling is typically used to precisely control hole depth and diameter, and is particularly suitable for deep hole machining requiring high precision.

Application:

Deep Hole Machining : Deep Hole Milling is widely used to machine deep holes, especially when the hole depth exceeds the hole diameter. Deep Hole Milling provides a more accurate machining method. It is commonly used in the automotive, aerospace, and precision instrument industries.

Large-Size Hole Processing : Deep Hole Milling is suitable for processing deep holes with larger diameters, especially when deep cutting is required by Deep Hole Milling cutters in some complex parts, which can achieve precise control of hole depth and hole diameter.

Precision Parts Processing : When it is necessary to process precise deep holes, especially when workpieces require high-precision hole positions and hole shapes, Deep Hole Milling can provide higher processing accuracy and stability.

Due to its high precision and stability in deep hole processing, Deep Hole Milling has become an indispensable technology in the processing of many high-precision parts. It is particularly suitable for processing tasks that require precise control of hole depth and hole shape.

20. Longitudinal Milling

Longitudinal milling is a milling method that primarily cuts along the longitudinal direction of the workpiece. In this machining method, the tool moves along the longitudinal direction of the workpiece and is typically used to machine long workpieces or large flat surfaces. Longitudinal milling offers high material removal efficiency and is suitable for flat machining of large parts or the creation of stepped shapes.

Application:

Plane Machining : Longitudinal milling is often used to machine the plane of larger workpieces, especially in situations where long cutting times are required, which can improve machining efficiency.

Step And Groove Processing : When processing larger steps and grooves, longitudinal milling can effectively control the cutting depth and ensure processing accuracy.

Large-Scale Production : Longitudinal milling is particularly suitable for large-scale production scenarios. It can remove a large amount of material in a short time and ensure efficient production.

21. Grooving

Grooving milling is a milling method specifically designed for creating grooves or recesses on a part’s surface. By cutting along the workpiece surface, a milling cutter can create grooves of various shapes and sizes, typically used in parts for assembly, transmission, or connection functions. Grooving milling is often used to create parts with straight, U-shaped, or T-shaped grooves, and is widely used in mold processing, mechanical component manufacturing, and precision parts manufacturing.

Application:

Groove And Groove Processing : Groove milling is widely used to process parts with straight grooves, U-shaped grooves or other complex groove shapes, and is commonly seen in the processing of mechanical parts, molds and connectors.

Connection And Fit : On parts that need to be connected or fitted, grooving and milling can accurately machine the required groove shape to ensure precise fit between parts.

Transmission Component Processing : Grooving milling is also commonly used to process grooves or grooves in transmission systems, especially in the manufacture of components such as gears and couplings.

Grooving milling is widely used in the processing of parts that require precise groove shapes and high-strength connections because it can accurately process grooves of various shapes. It plays an important role in mold manufacturing and mechanical parts.

Milling Operations Classified By Milling Control Method

Milling control methods refer to the different control methods used to drive the relative motion between the tool and the workpiece during the milling process. Different control methods affect machining accuracy, efficiency, and applicability. Milling operations can be categorized as manual milling, CNC milling, and conventional milling, depending on the control method. Each control method has its own unique advantages and application scenarios.

22. Manual Milling

Manual milling is a milling method that uses manually controlled machine tools. During manual milling, the operator directly controls the milling machine’s motion, including tool feed, tool depth, and cutting direction. Although modern machining relies heavily on numerical control (CNC) technology, manual milling is still widely used in some specialized scenarios, particularly for low-volume production or complex part processing.

Application:

Small-Batch Production : Manual milling is often used for processing small batches or customized parts, especially when demand is small or the design is complex. The operator can flexibly adjust according to actual conditions.

Prototyping And Repair : Manual milling provides a fast and flexible processing method when making prototype parts or repairing equipment. For some small repair work, manual operation often has advantages over automation.

Precision Detail Processing : For details that require highly fine adjustments, manual milling can provide higher operational flexibility and is suitable for processing parts with complex geometries or special process requirements.

Manual milling remains an indispensable processing method for some special and small-batch production tasks due to its flexibility and control, especially when fine manual operation is required.

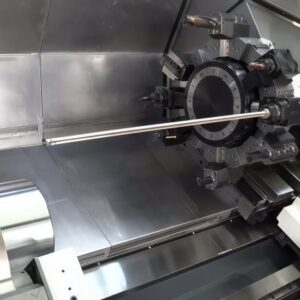

23. CNC Milling

CNC milling (computer numerical control milling) is a milling operation based on computer numerical control technology. In CNC milling, the milling machine’s motion and the tool’s cutting path are pre-programmed and controlled by a computer program. Unlike manual milling, CNC milling allows for a high degree of automation and precise control, making it suitable for large-scale production and the machining of complex parts. CNC milling offers high efficiency, precision, and repeatability, enabling the completion of complex machining tasks in a short time.

Application:

High-Precision Machining : CNC milling is particularly suitable for precision machining and is widely used in the production of parts requiring high precision and high quality, such as in aerospace, medical equipment, and automotive parts.

Complex Parts Processing : Through CNC programming, milling machines are able to process parts with complex geometries and multi-axis cutting, such as curved surfaces, deep holes and complex grooves, which are suitable for mold manufacturing, precision machinery and other industries.

Mass Production : CNC milling can process a large number of parts quickly and consistently, and is widely used in mass production to ensure processing quality and production efficiency.

CNC milling has become an indispensable technology in modern manufacturing due to its high precision, high efficiency and automation, showing great advantages especially in the processing of complex parts and mass production.

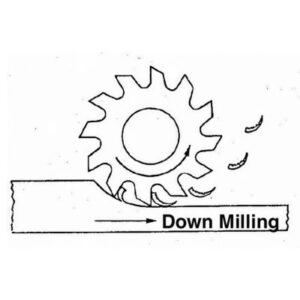

24. Conventional (Up) Milling & Climb (Down) Milling

Conventional milling and climb milling are two common milling operations. The main difference between them lies in the cutting direction of the tool and the feed method on the workpiece surface.

Conventional Milling (also known as up-cut milling) involves rotating the tool in the opposite direction of the workpiece feed. In other words, the tool engages the workpiece from the surface, gradually increasing cutting forces. Conventional milling produces a fine surface finish, but due to the erratic cutting forces, it can lead to accelerated tool wear. Conventional milling is typically suitable for hard or brittle materials.

Climb Milling (also known as down milling) involves rotating the tool in the same direction as the workpiece feed. During down milling, the tool engages the workpiece from the cutting surface, gradually reducing cutting forces. This method helps reduce vibration and improves machining stability and surface quality. Climb milling is often used for machining soft materials or when high-quality surface finishes are required.

Application:

Conventional Milling : Conventional milling is generally used to process hard or special materials and is suitable for roughing stages with large material removal. It is suitable for applications that require strong cutting capabilities, such as mold manufacturing and mechanical parts processing.

Climb Milling : Climb milling is suitable for precision machining with high surface quality requirements, especially when machining soft or medium-hard materials. Climb milling is widely used in industries such as precision parts manufacturing, aluminum alloy processing, and thin-walled parts processing.

Conventional milling and down milling each have their advantages and disadvantages. The choice of method depends on the material, processing requirements and the required surface quality. In practical applications, the appropriate milling method is often selected based on the processing stage and material characteristics.

How To Choose The Appropriate Milling Method

Choosing the right milling method is crucial, as it directly impacts machining efficiency, accuracy, and cost. Different milling methods are suitable for different materials, part geometries, and production requirements. When selecting a method, consider several factors, including material type, surface finish requirements, part geometry, machine capabilities, and tool selection.

The following table briefly summarizes the key factors and their influence when choosing a milling method:

| factor | describe | Influence | Milling method |

| Material Type | The hardness and properties of the material determine the cutting method. | Hard materials are suitable for conventional milling, while soft materials are suitable for down milling or micro milling. | Climb milling , conventional milling , micro milling |

| Surface treatment effect | Surface quality requirements affect cutting methods. | High surface quality requires climb milling or precision milling. | Climb milling , micro milling |

| Part shape | Complex shapes require more precise control. | CNC milling and profile milling are commonly used for complex parts. | CNC milling , profile milling |

| Machine tool parameters | The accuracy and capability of the machine tool limit the choice of milling method. | Precision machine tools are suitable for high-precision processing, while ordinary machine tools are suitable for routine parts processing. | CNC milling , manual milling |

| Tool selection | The material and shape of the tool determine the cutting effect. | Suitable tools improve efficiency and processing quality. | Carbide tools , coated tools |

By considering these factors, you can choose the most suitable milling method to ensure that the machining process is both efficient and accurate.

FAQs

What Are Different Types Of Milling Operations?

Milling Operations Include Various Techniques Used To Machine Materials Using Rotating Tools. The Common Types Of Milling Operations Are Face Milling, Slot Milling, End Milling, Thread Milling, Shoulder Milling, Side Milling, Profile Milling, Saw Milling, Gang Milling, And Form Milling. These Operations Are Used Based On The Desired Shape, Material, And Precision Requirements Of The Workpiece, Enabling Complex And Precise Cutting Tasks Across Multiple Industries.

What Is A CNC Milling Operation?

A CNC Milling Operation Involves The Use Of Computer Numerical Control (CNC) Machines To Automate The Milling Process. This Technology Allows For Precise Control Over The Cutting Tool’s Movements, Enabling Complex Parts To Be Manufactured With High Accuracy. CNC Milling Is Widely Used For Producing Metal, Plastic, And Composite Parts Across Various Industries, Offering Efficiency, Precision, And Flexibility, Especially For Repetitive Tasks And Complex Designs.

What Is A Form Milling Operation?

Form Milling Is A Type Of Milling Operation Where The Tool Is Designed To Match The Desired Shape Of The Workpiece. In This Process, A Cutter With A Specific Profile Is Used To Create Complex Shapes Or Contours, Such As Keyways, Gears, And Other Intricate Features. This Operation Is Essential In Manufacturing Parts With Non-standard Shapes And High Precision, Making It Valuable In The Production Of Specialized Components And Tools.

What Kind Of Manufacturing Is Milling?

Milling Is A Subtractive Manufacturing Process In Which Material Is Removed From A Workpiece Using Rotating Cutters. It Is Primarily Used For Shaping Metal, Plastic, And Other Materials Into Precise Parts. Milling Falls Under The Category Of Traditional Machining And Is Used For A Wide Range Of Applications, From Prototyping To Mass Production, In Various Industries, Including Aerospace, Automotive, Medical, And Industrial Equipment Manufacturing.

Conclusion

Understanding and mastering the 24 milling operation types is crucial for improving production efficiency, optimizing machining processes, and ensuring product quality. Each milling method has its own unique advantages and applications, ranging from simple planar machining to complex multi-axis cutting, to meet the processing needs of different materials and parts. Whether it’s traditional manual milling or modern CNC milling, understanding these techniques and applying them appropriately will help you make more precise and efficient decisions in actual production, driving the manufacturing industry towards a more efficient and precise direction.