Stiffness vs strength is a topic that often gets mixed up, even though the two properties describe very different behaviors in materials. This guide breaks down what stiffness and strength really mean, why the stiffness vs strength comparison matters in engineering, and how understanding the difference helps you choose the right material, avoid design failures, and improve overall performance in any project.

Get 20% offf

Your First Order

What is Strength

Strength is the material’s ability to resist failure under an applied force. When a material is loaded, it stretches, compresses, or changes shape. Strength defines the limit before irreversible damage occurs.

What is Stiffness

Stiffness describes a material’s ability to resist bending or deformation when a force is applied. When a part is pushed, pulled, or twisted, stiffness determines how much it will deflect before returning to its original shape. A stiffer material bends less under the same load.

Difference Between Stiffness and Strength

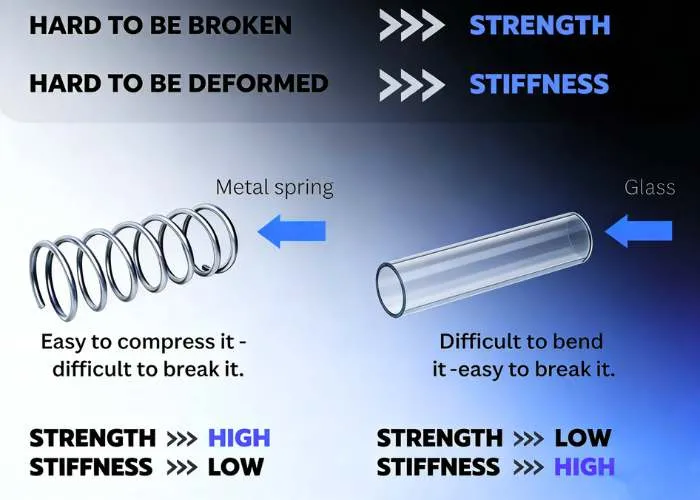

Stiffness and strength are two fundamental material properties that are often confused in engineering and design. In CNC machining manufacturing, understanding how each property responds to applied forces is essential, as they represent different behaviors and are evaluated in different ways.

Stiffness describes how much a material resists elastic deformation when a load is applied. A stiff material bends or deflects very little and returns to its original shape once the load is removed, as long as it stays within the elastic range.

Strength describes how much stress a material can withstand before it permanently deforms or breaks. A strong material resists failure, but it does not necessarily resist bending. If the applied stress exceeds its strength, the material will yield or fracture.

The key difference is simple:

-

Stiffness controls how much a material deforms

-

Strength controls when a material fails

A material can be stiff but weak, or strong but flexible. In engineering design, both properties must be considered to ensure parts do not deform excessively or fail under load.

What Affects Stiffness & Strength

Stiffness and strength depend on more than just the material—temperature, manufacturing methods, and part geometry all play key roles. Knowing these factors helps engineers design components that resist bending, deformation, and failure in real-world applications.

Temperature

Higher temperatures soften metals and reduce stiffness. As materials lose rigidity, they deform under loads more easily.

Example: Aluminum brackets inside an engine bay can lose 10–20% stiffness at 120–150°C.

Manufacturing Process

Different processes change grain structure and mechanical properties.

Forged parts: compressed grains → higher strength and fatigue resistance.

Cast parts: lower density → more brittle under stress.

Example: Forged steel suspension arms often outperform cast arms by 20–30% in fatigue life.

Shape & Thickness

Geometry strongly influences stiffness.

Box beams or tubes are stiffer than flat plates under the same load.

Increasing wall thickness improves rigidity and reduces vibration.

Example: A hollow tube of equal weight can be 2–3× stiffer than a solid flat bar.

How Do You Design for Strength vs. Stiffness

Choosing the right material during design isn’t just about strength—it’s about ensuring the part performs reliably under real-world loads, vibration, and environmental conditions. By understanding when stiffness or strength matters most, you can reduce failures, lower costs, and optimize part performance.

When to Choose High Stiffness

High stiffness is ideal when your part must resist bending, flexing, or vibration. A material with a higher Young’s Modulus (E) will deform less under the same load.

Best for:

Brackets and mounting plates

Machine frames and structural housings

Robot arms, automation fixtures, linear motion parts

Why:

Stiff materials keep shapes stable, reduce vibration, and maintain precision—critical in CNC machines, optical equipment, and robots.

When to Choose High Strength

Choose high-strength materials when your part must carry heavy loads without cracking or deforming, especially under repeated stress.

Best for:

Screws, bolts, and fasteners

Shafts, pins, drivetrain components

Lifting brackets, hooks, structural connectors

Why:

High strength prevents catastrophic failure and ensures safety and long-term durability—important for automotive and mechanical systems.

Optimize Geometry Before Changing Material

Improving part geometry often has more impact (and lower cost) than switching to a stronger or stiffer material.

Examples:

Adding ribs to increase stiffness without adding much weight

Increasing wall thickness in vibration-prone areas

Using fillets to reduce stress concentrations

Rounding internal corners to improve machining stability

Why:

Geometry changes cost nothing in terms of material and usually deliver the biggest performance improvement—faster machining, lower cost, higher stability.

Best Practices in Designing for Strength and Stiffness

Balancing stiffness and strength is a critical consideration in mechanical design and manufacturing. Applying the right design practices early helps prevent excessive deformation, premature failure, and costly redesigns. The following best practices can guide engineers throughout the design process.

1. Evaluate Expected Loads and Stresses

Begin by identifying the forces each component will experience in service. Estimate stress levels under static, dynamic, and impact loads, and consider environmental factors such as temperature, fatigue, and creep. Understanding how a design responds to varying loads helps determine whether stiffness or strength is the primary requirement.

2. Compare Materials Before Final Selection

Test or analyze a range of candidate materials with known mechanical properties. Brittle materials, such as ceramics, fail with little deformation, while ductile metals deform plastically before fracture. Comparing these behaviors allows designers to select materials that best match the required stiffness, strength, and failure mode.

3. Define Critical Design Factors Early

At the initial design stage, identify key performance drivers such as load distribution, boundary conditions, and stress concentration areas. Using CAD and early-stage simulations helps visualize how geometry affects stiffness and strength, guiding smarter design decisions from the start.

4. Validate Design Performance Before Prototyping

Before building prototypes, review the design through engineering analysis and simulation. Finite Element Analysis (FEA) can be used to optimize geometry, verify stress levels, and confirm deflection limits. Aligning analytical results before prototyping reduces risk and improves design efficiency.

FAQs

Is Stiffness the Same as Strength?

No. Stiffness describes resistance to bending and elastic deformation, while strength describes resistance to permanent deformation or failure. This is the core diference between strength and stifness.

What Is Stifness of a Material?

It defines how much a material resists elastic deformation under load and is measured by Young’s Modulus (E).

What Makes a Material Strong in Mechanical Design?

Strength depends on yield strength and tensile strength, indicating how much load a material can withstand before yielding or fracture.

Why Can a Material Be Stiff but Not Strong (or Vice Versa)?

Some materials resist bending but fracture easily, while others bend more but carry higher loads. This explains strength vs stifness in practice.

When Should You Choose Stiffness Instead of Strength?

Choose stiffness to limit deflection in frames or optical mounts, and choose strength for load-bearing parts such as shafts or fasteners.

Conclusion

Understanding stiffness vs strength is essential for making smart engineering decisions. When you know how each property affects deformation, load-bearing capability, vibration control, and long-term durability, you can select better materials, optimize geometry, and prevent costly design failures. A clear grasp of these principles leads to safer parts, longer service life, and more efficient production.

TiRapid helps engineers balance strength and stiffness through smart material selection, geometry optimization, and precision CNC machining. From design review to production, we ensure performance and reliability—send your drawings to start.