Steel CNC Machining combines precision engineering with the incredible strength of steel to produce high-performance components across industries. With advanced computer-controlled tools, it transforms raw steel into durable, dimensionally accurate parts used in automotive, aerospace, robotics, and energy systems. This guide explores key processes, material grades, surface finishes, and real-world applications that define the power of CNC-machined steel.

Get 20% offf

Your First Order

What Is Steel CNC Machining

Steel CNC Machining uses computer-controlled tools to cut, shape, and refine steel materials with incredible precision. As one of the most durable metals, steel can be transformed into complex, high-tolerance parts for demanding industries like automotive, aerospace, and robotics.

Key CNC Machining Processes for Steel

Steel CNC Machining covers a wide range of processes that shape and refine steel into functional parts with precision and consistency. From cutting and drilling to grinding and EDM, each process has its unique advantages. Understanding their roles helps you choose the best method for your part’s geometry, tolerance, and cost target.

1. Cutting Processes

CNC Milling

Milling uses multi-axis rotating cutters to shape complex steel parts by removing material layer by layer.

Applications: Engine brackets, gear housings, hydraulic blocks, and molds.

Accuracy: ±0.02–0.05 mm; Ra 1.6–3.2 μm.

Tips: Use variable-pitch end mills to reduce chatter; climb milling yields better surface finish.

Example: TiRapid produced a 304 stainless steel housing with 0.03 mm flatness across 100 mm, ensuring tight assembly fit.

CNC Turning

Turning is the foundation of Steel CNC Machining. The workpiece rotates on a lathe while a stationary cutting tool removes material, forming precise cylindrical shapes.

Applications: Shafts, pins, bushings, couplings, threaded components.

Accuracy: ±0.01–0.03 mm; surface roughness Ra 0.8–3.2 μm.

Tooling & Material: Carbide inserts with CVD coatings for carbon and alloy steels (1045, 4140). Stainless steels (304, 316) require sharp inserts and flood coolant.

Example: TiRapid machines 4140 steel drive shafts to ±0.01 mm tolerance, ensuring perfect bearing fits for automotive systems.

Drilling & Tapping

Drilling creates precise round holes; tapping cuts internal threads.

Applications: Bolt holes, threaded fittings, and precision alignment pins.

Accuracy: Holes to H7 tolerance; threads to class 6H.

Technique: Use high-speed steel drills for carbon steel, carbide drills for hardened alloys, and form taps for ductile materials.

Example: For a stainless manifold, TiRapid applied synchronized tapping to cut M8 threads at 0.02 mm pitch accuracy, improving thread strength by 30%.

Boring

Boring enlarges pre-drilled holes to achieve tight internal diameters and alignment.

Applications: Bearing housings, hydraulic cylinders, and spindle bores.

Accuracy: Roundness ≤0.01 mm; coaxiality ≤0.02 mm.

Example: TiRapid bored 1045 steel hydraulic sleeves to 0.01 mm tolerance, maintaining perfect fit for high-pressure applications.

Grinding

Grinding refines surface texture and precision beyond typical machining limits.

Applications: Precision shafts, sealing faces, and tool components.

Accuracy: ±0.002–0.008 mm; Ra 0.2–0.8 μm.

Example: Surface grinding hardened 42CrMo4 gear faces to Ra 0.4 μm, eliminating post-polishing.

2. Advanced Machining Processes

Broaching

Broaching removes material with multi-tooth cutters in one stroke.

Applications: Keyways, internal splines, gear hubs.

Advantages: Extremely consistent profile accuracy and fast production.

Example: TiRapid broached internal splines in 8620 steel hubs for a robotic actuator, achieving micron-level uniformity.

Electrical Discharge Machining (EDM)

EDM uses controlled sparks to erode material, perfect for hard steels or sharp corners unreachable by tools.

Applications: Tool steels, molds, medical implants, aerospace components.

Accuracy: ±0.005–0.01 mm.

Example: TiRapid used sinker EDM to machine sharp 0.1 mm internal corners on H13 steel molds for microfluidic components.

Laser Cutting

Laser cutting employs a focused beam to cut or engrave steel sheets precisely.

Applications: Thin to mid-thickness sheets, enclosures, decorative panels.

Benefits: Non-contact, clean edges, minimal burr.

Example: TiRapid laser-cut 2 mm stainless nameplates with serial engraving, reducing post-process time by 40%.

Waterjet Cutting

Waterjet cutting uses high-pressure water mixed with abrasive for cold cutting.

Applications: Thick plates and heat-treated materials.

Benefits: No thermal distortion; preserves metallurgy.

Example: For 50 mm 304 steel plates, TiRapid achieved precise edges (±0.1 mm) without altering grain structure.

3. Forming Processes

Bending

Bending reshapes steel sheets or tubes into precise angles using CNC press brakes.

Applications: Frames, enclosures, architectural brackets.

Example: TiRapid bent 2 mm 316 stainless panels with ±0.5° accuracy for medical equipment.

Stamping

Stamping presses a die into steel to form high-volume parts efficiently.

Applications: Automotive body panels, appliance parts.

Example: Automotive bracket stamping with ±0.05 mm repeatability.

Rolling

Rolling reduces thickness and produces long sheets or profiles with uniform structure.

Applications: Construction steel sheets, tubing.

Data: Flatness deviation <0.2 mm across 1 m width.

Forging & Extrusion

Forging compresses steel at high temperature to enhance strength; extrusion pushes steel through dies for long profiles.

Applications: Crankshafts, levers, and structural rods.

Example: 42CrMo forged levers show 25% higher fatigue strength compared to machined parts.

Deep Drawing

Deep drawing pulls steel sheets into seamless hollow forms.

Applications: Automotive tanks, sinks, and pressure housings.

Example: TiRapid deep-drew 1.5 mm stainless steel covers, ensuring wall uniformity within ±0.05 mm.

4. Choosing the Right Process

Selecting the right steel machining process depends on geometry, tolerance, material, and cost goals:

Prototype: Milling + drilling

High volume: Broaching or stamping

Tight tolerance: Grinding + EDM

Heat-sensitive material: Waterjet cutting

Aesthetic finish: Laser + polishing

Combining multiple processes under one roof, TiRapid delivers steel components that meet precision, durability, and performance standards across industries.

Common Steel Grades Used in CNC Machining

Selecting the right steel grade is essential for successful Steel CNC Machining. Each grade differs in composition, strength, machinability, and corrosion resistance. Understanding these characteristics helps engineers and buyers balance performance, cost, and precision in every machining project.

| Steel Grade | Composition & Type | Key Properties | Machinability / Weldability | Typical Applications | TiRapid Notes & Example |

| 1018 (Low Carbon Steel) | Fe, ~0.18% C, Mn | High ductility, easily carburized, good toughness | Good machinability, excellent weldability | Fixtures, shafts, bushings, carburized parts | Used for locating fixtures and shafts requiring H7 tolerance (±0.01 mm). |

| 1215 (Free-Machining Steel) | Fe, C, Mn, high S | Generates small chips, supports high cutting speed, lower strength | Excellent machinability, poor weldability | Fittings, pins, screws, automatic lathe parts | Ideal for mass-production screws; saves 25% cycle time. |

| 1045 (Medium Carbon Steel) | Fe, ~0.45% C, Mn, Si | Tough, affordable, moderately hardenable | Moderate machinability, fair weldability | Shafts, gears, bolts, pins | Machined hydraulic rods, surface ground to Ra ≤ 0.4 µm. |

| 4130 (Cr-Mo Alloy Steel) | Fe, Cr, Mo, Mn | High strength-to-weight ratio, heat-treatable | Average machinability, good weldability | Welded frames, aircraft parts | Used in welded control arms; bores kept ≤ 0.01 mm coaxiality. |

| 4140 (Cr-Mo Alloy Steel) | Fe, Cr, Mo, Mn | Excellent fatigue and wear resistance; pre-hard machinable | Good machinability, moderate weldability | Couplings, spindles, gears | Pre-hardened 4140 hubs ±0.01 mm; induction-hardened teeth. |

| 304 Stainless Steel | 18 Cr – 8 Ni (Austenitic) | Excellent corrosion resistance, high formability | Fair machinability, excellent weldability | Food equipment, housings, clamps | Enclosures with 0.03 mm flatness over 100 mm. |

| 316 / 316L Stainless Steel | 17 Cr – 12 Ni – 2.5 Mo | Superior corrosion resistance in marine or chemical environments | Fair machinability, excellent weldability | Marine valves, chemical equipment | 316L valve blocks, Ra ≤ 0.8 µm after grind, leak-free. |

| 17-4PH Stainless Steel | Fe, Cr, Ni, Cu | High strength and corrosion resistance, age-hardenable | Moderate machinability, good weldability | Aerospace parts, pump shafts | Machined then H900-aged pins, positional tol ≤ 0.02 mm. |

| Tool Steels (D2, H13, O1, A2) | High C + Cr / Mo | Extreme wear and heat resistance, stable at high temp | Difficult machinability, poor weldability | Dies, molds, cutting tools | H13 mold cavities EDM-finished Ra ≤ 0.4 µm, corner radius ≤ 0.2 mm. |

Selection Guide

| Purpose / Requirement | Recommended Grade | Key Advantage |

| Rapid machining, prototypes | 1215 / 1018 | High cutting efficiency, low tool wear |

| High strength & fatigue parts | 4140 / 4130 | Excellent mechanical endurance |

| Corrosion-critical environments | 316L / 17-4PH | Superior corrosion resistance |

| Food & medical components | 304 / 316L | Hygienic and easy to weld |

| Wear-resistant molds & dies | D2 / H13 | High hardness and heat stability |

| Economic general-purpose shafts | 1045 | Tough and cost-effective |

Design and Tolerance Considerations for Steel CNC Machining

Design and tolerance planning are critical to achieving precision and cost efficiency in Steel CNC Machining. Each steel grade reacts differently to cutting forces, temperature, and stress. Understanding these factors ensures optimal fits, stability, and performance across all production volumes.

Design Factors in Steel CNC Machining

Material Behavior:

Steel expands under heat (average thermal expansion ≈ 12 µm/m·°C). Designers must account for dimensional shifts in tight-tolerance parts, especially during high-speed milling or turning.

Example: For a 200 mm 4140 steel shaft, a 30°C rise could cause ~0.072 mm expansion — small, but enough to affect assembly fits.

Geometry Optimization:

Avoid sharp internal corners (recommend R ≥ 0.5 mm). Use fillets to reduce stress concentration and tool wear. Thin walls (<2 mm) in steel tend to deform; stiffening ribs or fixturing is advised.

Machinability vs. Tolerance:

Carbon steels (e.g., 1018, 1045) can easily maintain ±0.02 mm; alloy steels like 4140 require tighter control due to hardness. Stainless steels (304/316) often demand looser fits (±0.05 mm) because of work hardening.

Surface Flatness & Perpendicularity:

For precision assemblies, standard flatness of 0.03 mm/100 mm and perpendicularity ≤0.02 mm are recommended.

TiRapid achieves even tighter flatness (≤0.015 mm) for optical and automation components.

Heat Treatment & Deformation Control:

After quenching or tempering, distortion of 0.05–0.2 mm per 100 mm is common. Stress relief before finishing can cut this by 60%.

Example: TiRapid pre-stress-relieves 4140 shafts before grinding, reducing warpage to less than 0.02 mm.

Tolerance Ranges (Typical CNC Steel Machining)

| Feature | Standard Tolerance | High-Precision Capability |

| Linear dimensions | ±0.05 mm | ±0.01 mm |

| Hole diameters | H7–H9 | H6 achievable |

| Flatness | 0.05 mm / 100 mm | ≤0.015 mm |

| Angularity | ±0.5° | ±0.2° |

| Thread pitch accuracy | ±0.02 mm | ±0.01 mm |

Surface Finishes and Post-Processing for Steel Parts

Surface finishes and post-processing are vital steps in Steel CNC Machining, directly influencing corrosion resistance, wear durability, and visual appeal. Choosing the right finish ensures both functional reliability and a refined appearance, making your steel parts truly production-ready.

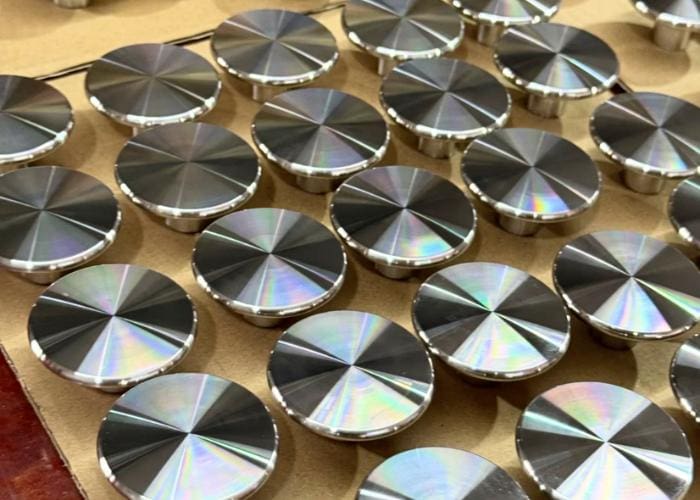

1. As-Machined Finish

The as-machined surface represents the natural texture after CNC cutting without additional treatment. Tool marks and slight irregularities are visible, but it maintains tight dimensional accuracy.

Characteristics: Slightly rough (Ra 3.2–6.3 µm), precise geometry.

Applications: Internal mechanical parts, prototypes, or tight-fit assemblies where appearance is secondary.

Example: TiRapid often ships as-machined 1045 shafts used in testing fixtures, ensuring ±0.01 mm concentricity.

2. Bead Blasting

Bead blasting propels fine glass or ceramic beads to achieve a uniform matte finish. It removes small burrs and scratches, improving both texture and coating adhesion.

Characteristics: Satin-like matte, smooth touch, Ra 0.8–3.2 µm.

Applications: Automotive housings, robotics casings, visible industrial panels.

Example: TiRapid uses bead blasting for stainless steel brackets before anodizing to ensure even coating density.

3. Powder Coating

This process applies dry powder electrostatically, then heat-cures it into a tough, colored layer. It provides long-term durability and weather resistance.

Characteristics: Highly durable, customizable colors, corrosion resistance > 1,000 hrs salt spray.

Applications: Outdoor machinery, equipment frames, automotive covers.

Example: TiRapid coats 4140 structural frames for agricultural machinery with black matte powder for improved wear life.

4. Electroplating

Electroplating covers the steel surface with metals such as zinc, nickel, or chrome to enhance corrosion protection and aesthetics.

Characteristics: Smooth and reflective, hardness up to 900 HV (chrome), strong chemical resistance.

Applications: Automotive fasteners, marine parts, decorative components.

Example: TiRapid applies zinc-nickel plating on precision bolts, achieving over 720-hour corrosion resistance.

5. Black Oxide & QPQ Treatment

Black oxide and QPQ (Quench-Polish-Quench) processes form a dense oxide film, providing wear and rust resistance while preserving dimensional accuracy.

Characteristics: Uniform black finish, no dimensional growth, good oil retention.

Applications: Tool steel components, gears, defense and robotics hardware.

Example: TiRapid delivers QPQ-treated 4140 shafts with 20% longer fatigue life than untreated equivalents.

6. Polishing and Grinding

Mechanical polishing and fine grinding enhance surface smoothness and aesthetics, especially for stainless steel parts.

Characteristics: Mirror-like Ra ≤ 0.2 µm, eliminates tool marks.

Applications: Medical devices, decorative panels, precision shafts.

Example: TiRapid polished 316L parts for laboratory devices, achieving mirror reflection with zero surface waviness.

7. Heat Treatment + Passivation

After machining, heat treatment strengthens the structure; passivation chemically stabilizes stainless steel by removing free iron.

Applications: Aerospace, chemical, and medical-grade assemblies requiring ultimate corrosion resistance.

Example: TiRapid performs passivation on 17-4PH fittings for marine sensors, increasing corrosion resistance by 40%.

Advantages of Steel CNC Machining

Steel CNC machining offers high precision, durability, and flexibility, making it suitable for demanding industries like automotive, aerospace, and robotics. The process ensures reliable quality, smooth finishes, and strong mechanical performance for both prototypes and mass production.

Precision and Accuracy

CNC machines achieve tolerances up to ±0.01 mm, ensuring perfect fits for complex assemblies.

Strength and Durability

Steel provides high tensile strength and excellent wear resistance, ideal for heavy-load components.

Wide Material Adaptability

Applicable to carbon, alloy, and stainless steels, meeting diverse industry needs.

Smooth Surface Finishes

Machining and post-treatment produce finishes from Ra 3.2 to Ra 0.2 µm for better sealing and appearance.

High Efficiency

Automated systems allow 24-hour production, reducing lead time and improving productivity.

Cost Efficiency

For medium and large batches, CNC machining reduces waste and lowers per-part cost.

Flexibility

Design changes and prototypes can be quickly implemented without new tooling.

Challenges and Limitations in Machining Steel

Steel CNC machining offers precision and strength, but it also faces challenges that affect cost, quality, and efficiency. Understanding these limitations helps manufacturers improve productivity and maintain stable accuracy.

Tool Wear

High-strength steels like 4140 and 17-4PH quickly wear cutting tools, increasing tool cost and downtime.

Heat Distortion

Steel retains cutting heat, which may cause warping or dimensional errors without proper cooling.

Programming Complexity

Complex parts require advanced CNC programming and setup, adding time and skill demand.

Equipment Cost

High-end CNC machines and software require large investment, raising project cost.

Skilled Labor

Machining steel needs experienced operators to balance feed, speed, and cooling control.

Post-Processing Effects

Processes like heat treatment or coating can slightly change dimensions, requiring re-finishing.

Applications of Steel CNC Machining

Steel CNC machining is widely used in industries that demand strength, precision, and durability. From aerospace structures to medical tools, it transforms raw steel into high-performance components that endure stress, wear, and time — ensuring reliability in every field.

Automotive and Transportation

Steel’s high tensile strength and heat resistance make it ideal for gears, shafts, and engine components.

Example: TiRapid machined 4140 steel drive shafts with ±0.02 mm tolerance for racing applications, improving fatigue life by 25%.

Aerospace and Defense

CNC steel parts, such as brackets and engine mounts, must withstand extreme temperatures and vibration.

Using 17-4PH stainless steel ensures superior corrosion and fatigue resistance for aircraft frames.

Robotics and Automation

Precision-milled steel joints and housings provide structural rigidity and motion accuracy in robotic arms.

Data: Carbon steel linkages hold tolerance within ±0.01 mm for consistent robotic alignment.

Medical Equipment

316L and 17-4PH steels are used for surgical instruments and imaging device frames due to biocompatibility and strength.

TiRapid supplied polished 316L parts for CT scanner frames, achieving Ra ≤ 0.4 µm surface finish.

Heavy Machinery and Construction

Steel CNC components like couplings, pistons, and hydraulic housings endure high pressure and impact loads.

Example: CNC-turned 1045 steel gears improved equipment uptime by 30%.

Energy and Industrial Equipment

Steel’s toughness and wear resistance suit turbines, oilfield tools, and heat exchangers, ensuring long-term reliability.

FQAs

What Is Steel CNC Machining?

Steel CNC Machining is a precision manufacturing process where computer-controlled tools remove material from steel blocks to create accurate components. I use advanced CNC milling and turning to achieve tolerances within ±0.01 mm. This process ensures consistent quality, high strength, and repeatability for industrial-grade steel parts.

What Types Of Steel Are Best For CNC Machining?

The best steels for CNC machining include 1018 mild steel, 1045 medium carbon steel, 4140 alloy steel, and 17-4PH stainless steel. I typically recommend 1018 for cost efficiency, 4140 for strength, and 17-4PH for corrosion resistance. Each grade balances machinability, hardness, and mechanical performance.

How Does CNC Machining Work With Stainless Steel?

When machining stainless steel, I use high-speed CNC tools and carbide cutters with optimized cooling to control heat and tool wear. Stainless grades like 304, 316, and 17-4PH are machined using low feed rates and high cutting forces, ensuring surface roughness under Ra 1.6 μm and precise geometric accuracy.

What Are The Advantages Of CNC Machining Steel Parts?

Steel CNC Machining offers superior strength, dimensional accuracy, and durability. I achieve part tolerances as tight as ±0.005 mm, ideal for aerospace and automotive applications. The process minimizes waste by up to 30%, reduces production lead time, and enables both rapid prototyping and mass manufacturing.

What Are The Challenges Of Machining Hardened Steel?

Machining hardened steel is difficult due to high tool wear and thermal stress. I overcome this by using coated carbide or CBN tools, controlled coolant flow, and reduced cutting speeds. Precision CNC settings ensure stable machining of steels above 45 HRC, maintaining dimensional accuracy and surface finish integrity.

How Much Does Steel CNC Machining Cost?

The cost of Steel CNC Machining typically ranges from $50 to $150 per hour depending on material grade, part complexity, and quantity. I optimize programming and tooling to reduce setup time, cutting total project costs by 15–25% while maintaining precision and consistent production quality.

What Tolerances Can Be Achieved In Steel CNC Machining?

With modern 5-axis CNC equipment, I routinely achieve dimensional tolerances between ±0.005 mm and ±0.02 mm for steel parts. Surface finishes reach Ra 0.8 μm when fine-milled or ground. Such precision ensures compatibility in aerospace assemblies, high-performance engines, and robotics applications requiring tight fits.

Which Industries Use CNC Steel Parts The Most?

Steel CNC Machining is widely used in aerospace, automotive, robotics, and heavy machinery industries. I produce components like shafts, gears, brackets, and engine mounts. Over 60% of CNC-machined steel parts are used in mechanical and structural assemblies requiring strength, wear resistance, and durability.

Conclusion

Steel CNC machining continues to be a cornerstone of modern manufacturing, combining strength, precision, and efficiency in one process. With proper material selection, optimized tooling, and expert engineering, it delivers durable, high-accuracy components for demanding industries such as aerospace, automotive, and robotics. Though machining steel can be challenging due to its hardness, the results—stronger, longer-lasting parts—make it worth the effort. Partnering with an experienced CNC manufacturer like TiRapid ensures reliable quality, fast delivery, and cost-effective solutions for every project.