Milling and drilling may look similar, but choosing the wrong CNC process can increase cost, extend lead time, and compromise accuracy. This guide breaks down the real differences between CNC milling and drilling—helping you select the right method based on part design, tolerance, and production goals.

Get 20% offf

Your First Order

What Is the Difference Between Milling and Drilling?

The difference between milling and drilling lies in how material is removed and what features can be created. Understanding these two CNC processes helps engineers and buyers choose the most efficient, accurate, and cost-effective machining method.

The core difference between milling and drilling is tool motion and cutting capability.

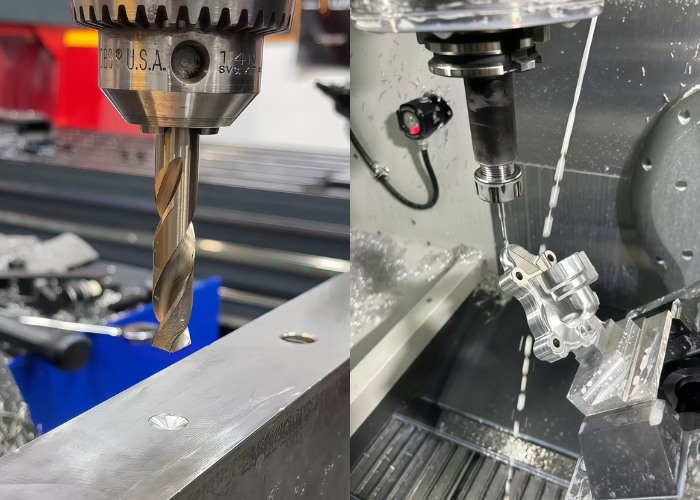

In CNC drilling, the cutting tool rotates and moves only along its axis (usually the Z-axis) to create round holes. The tool path is simple and linear, making drilling highly efficient for producing holes with consistent diameters and depths. In most production environments, drilling is the fastest and lowest-cost method for hole creation.

CNC milling, by contrast, uses a rotating multi-point cutting tool that moves along multiple axes (X, Y, and Z). This allows milling to remove material laterally as well as vertically. As a result, milling can create slots, pockets, contours, flat surfaces, and complex 3D geometries—not just holes.

From my experience in CNC projects, drilling is usually selected when holes are the primary feature and tolerances are moderate. Milling becomes essential when holes require precise positioning, custom shapes, tight tolerances, or when multiple features must be machined in one setup. In many real-world parts, drilling is used first for rough hole creation, followed by milling for finishing or feature integration.

How Milling and Drilling Work: Core Process Comparison

Milling and drilling follow very different cutting motions, even though both are CNC machining processes. Understanding how each process works at a core level helps you select the right method for accuracy, efficiency, and cost control.

CNC drilling works by rotating a drill bit and feeding it vertically along the Z-axis into the workpiece. The cutting action is axial, meaning material is removed straight down to form cylindrical holes. Because the tool path is simple and highly controlled, drilling delivers fast cycle times and consistent hole geometry, making it ideal for high-volume hole production.

CNC milling operates differently. A rotating milling cutter removes material not only vertically but also laterally by moving across the X, Y, and Z axes. This multi-directional cutting allows milling to shape flat surfaces, slots, pockets, contours, and complex 3D features. In my experience, milling is often used when a part requires precise feature placement or multiple geometries in a single setup.

In practice, drilling focuses on efficient hole creation, while milling provides broader shaping capability. Many CNC projects combine both processes to balance speed and design flexibility.

Technical Differences Between CNC Milling and CNC Drilling

Although CNC milling and CNC drilling are often used together, their technical differences in tool motion, axis control, and cutting mechanics directly affect accuracy, cost, and achievable part features.

The core technical difference lies in cutting motion and axis engagement. CNC drilling uses a rotating drill bit that feeds strictly along the Z-axis. Material removal occurs axially, producing round, straight holes with high efficiency and stable chip evacuation.

CNC milling, by contrast, relies on a rotating multi-edge cutter that moves along multiple axes—typically X, Y, and Z. This allows both axial and radial cutting, enabling complex geometries such as slots, pockets, contours, and interpolated holes.

From my experience, drilling delivers faster cycle times and lower programming complexity, while milling provides tighter positional accuracy and greater design freedom. These technical differences determine which process delivers the best balance between speed, precision, and flexibility.

Cost, Efficiency, and Production Impact

Cost, efficiency, and production impact are often the deciding factors when choosing between CNC milling and drilling. While both processes are cost-effective in the right context, their impact on unit cost, lead time, and throughput can differ significantly.

Cost Comparison

From my experience, CNC drilling is generally more economical for simple, repetitive hole-making. Machine investment, tooling, and setup costs are lower, making drilling ideal for high-volume production. Cost drivers mainly include hole diameter, depth, quantity, and tool life.

CNC milling, by contrast, involves higher costs due to multi-axis motion, complex fixturing, longer setup times, and more expensive cutting tools. Milling cost increases with part complexity, material hardness, number of features, and required tolerances.

Efficiency and Production Speed

Drilling typically operates at higher spindle speeds and follows a direct cutting path, which makes cycle times short and predictable. For parts dominated by holes, drilling

offers superior throughput.

Milling is inherently slower because it relies on complex toolpaths and controlled material removal across multiple axes. However, milling can combine multiple features—faces, slots, pockets, and holes—into a single setup, which often improves overall process efficiency for complex parts.

Lead Time and Production Impact

Drilling projects usually have shorter lead times due to simple programming and minimal setup. Milling lead time tends to be longer, especially for custom or aerospace-grade components, but it reduces secondary operations and re-fixturing.

In real production, I often see milling reduce total project time despite longer machining cycles, because it eliminates downstream processes. Choosing the right process directly affects delivery speed, cost stability, and production scalability.

Advantages and Limitations of Milling vs Drilling

Both milling and drilling play critical roles in CNC machining, but their advantages and limitations differ significantly. Understanding these trade-offs helps engineers and buyers select the most efficient process for accuracy, cost control, and production speed.

Advantages of CNC Milling

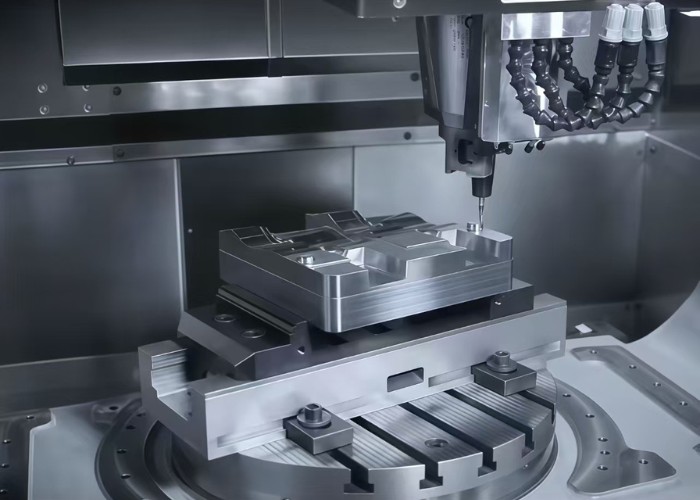

From my experience, CNC milling stands out for its versatility. By using multi-point cutting tools across 3 to 5 axes, milling can create complex geometries, flat surfaces, pockets, slots, and contours in a single setup. Typical milling tolerances reach ±0.005–0.01mm, making it ideal for aerospace, medical, and precision industrial parts.

Milling also supports a broad material range, including aluminum, stainless steel, titanium, engineering plastics, and composites. With CNC automation, milling delivers repeatable accuracy and consistent quality from prototyping to batch production. In many projects, milling reduces assembly issues by machining multiple features in one operation.

Limitations of CNC Milling

However, milling comes with higher capital and operating costs. CNC milling machines require more complex fixturing, longer setup times, and advanced programming—especially for 4-axis and 5-axis machining. Tooling costs and energy consumption are also higher compared to drilling. For simple hole-making tasks, milling is often inefficient and unnecessarily expensive.

Advantages of CNC Drilling

CNC drilling excels in speed and cost-efficiency for hole-making. Using a fixed-diameter rotating drill bit, it produces precise cylindrical holes quickly and consistently. In high-volume production, drilling offers lower machine costs, simpler setups, and reduced energy usage. Hole depths of several hundred millimeters are achievable with proper tooling and cooling.

Limitations of CNC Drilling

The main limitation of drilling is its lack of versatility. Drilling is restricted to hole creation and cannot produce slots, pockets, or complex profiles. Surface finish and positional accuracy are also limited compared to milling. In my experience, drilling alone is rarely sufficient for parts that require tight tolerances or multi-feature integration.

Applications and Industry Use Cases

Applications are one of the most decisive factors when comparing milling vs drilling. Each process serves distinct industry needs, and choosing the right one directly impacts part functionality, cost efficiency, and manufacturing scalability.

Applications of CNC Milling

From my experience, CNC milling is widely used in industries where part geometry is complex and precision across multiple surfaces is critical. It enables machining of flat faces, slots, pockets, angled features, and undercuts in a single setup.

Typical milling applications include automotive components such as engine blocks, cylinder heads, and gearbox housings. In aerospace and medical manufacturing, milling is essential for producing high-precision structural parts, implants, and surgical components. It is also the core process for mold making, tooling, and rapid prototyping, where tight tolerances and complex contours are required.

Applications of CNC Drilling

CNC drilling plays a focused but indispensable role wherever precise cylindrical holes are required. It is commonly used for fastener holes, deep or small-diameter holes, and high-repeatability hole patterns.

In aerospace, drilling is critical for airframe assemblies and engine components. Automotive manufacturers rely on drilling for consistent hole placement during assembly, while electronics production depends on drilling for accurate PCB hole layouts. When hole quality, depth consistency, and production speed are priorities, drilling remains the most efficient solution.

Milling vs Drilling: How to Choose the Right CNC Process for Your Part

Choosing between CNC milling and CNC drilling isn’t about which process is better—it’s about which one fits your part design. Understanding their differences in capability, cost, and precision helps you select the right CNC process faster and avoid unnecessary machining time.

| Selection Factor | CNC Milling | CNC Drilling |

| Primary Function | Removes material across surfaces to create slots, pockets, contours, and complex geometries | Creates straight, cylindrical holes |

| Tool Motion | Rotating multi-point cutter moves along X/Y/Z (and multi-axis if needed) | Rotating drill bit feeds mainly along the Z-axis |

| Best-Suited Part Geometry | Complex, prismatic parts with multiple features | Simple parts requiring holes only |

| Feature Capability | Slots, pockets, contours, angled holes, profiles, 3D shapes | Through holes and blind holes only |

| Typical Tolerances | ±0.01mm or tighter with proper setup | ±0.05mm typically (tighter with reaming or milling) |

| Surface Finish Control | Excellent surface finish and edge definition | Limited surface control inside holes |

| Design Flexibility | Very high — supports frequent design changes | Low — limited to hole geometry |

| Programming Complexity | Higher (multi-axis toolpaths, feature sequencing) | Low (simple plunge operations) |

| Cycle Time | Longer for simple holes, efficient for complex features | Very fast for hole-only operations |

| Tooling Cost | Higher (multiple cutters, tool changes) | Lower (standard drill bits) |

| Production Cost | Cost-effective for complex parts or multi-feature designs | Most economical for high-volume hole drilling |

| Typical Applications | Housings, brackets, molds, medical and aerospace components | Fastener holes, mounting holes, basic assemblies |

| When to Choose | When precision, complexity, or multiple features are required | When speed and cost efficiency for holes are the priority |

| Best Practice | Often used to finish or refine drilled features | Often used for rough hole creation before milling |

FAQs

What Is The Difference Between A Mill And A Drill Press?

From my experience, the core difference lies in capability and motion control. A drill press is designed mainly for vertical (Z-axis) movement to create round holes quickly and consistently. A milling machine, by contrast, controls motion along X, Y, and Z axes, enabling lateral cutting, slotting, and contouring. In practice, milling machines achieve tighter tolerances (often ±0.01 mm) and handle complex geometries, while drill presses prioritize speed, simplicity, and low-cost hole production.

Can A Milling Machine Be Used For Drilling?

Yes, in my experience, a CNC milling machine can absolutely perform drilling operations. Modern CNC mills support drilling, tapping, and reaming using standard drill bits with high positional accuracy. While drilling on a mill may have slightly longer cycle times than a dedicated drill press, it offers superior hole location accuracy (often within ±0.01 mm). This makes milling ideal when holes must align precisely with other machined features in the same setup.

Is Drilling A Type Of Milling?

No, drilling is not a type of milling, although both are subtractive machining processes. From my perspective, drilling is a dedicated operation focused solely on axial hole creation using a rotating drill bit. Milling, however, uses a rotating multi-point cutter that moves laterally and vertically to shape surfaces and features. Drilling may be performed on a milling machine, but functionally and mechanically, it remains a distinct machining process.

What Are The Two Common Types Of Drilling Methods?

Based on my experience, the two most common drilling methods are conventional drilling and CNC drilling. Conventional drilling uses manual or semi-automatic drill presses for basic hole creation, suitable for low precision needs. CNC drilling, by contrast, relies on programmed toolpaths, enabling repeatable hole placement, consistent depth control, and higher productivity. CNC drilling is widely used in automotive, aerospace, and electronics manufacturing for high-volume, precision hole-making.

What Is The Purpose Of Milling?

The primary purpose of milling, from my experience, is to machine complex geometries with high accuracy across multiple surfaces. Milling removes material laterally and vertically to create slots, pockets, contours, and flat faces that drilling cannot achieve. With CNC milling, tolerances commonly reach ±0.005–0.01 mm, making it essential for aerospace, medical, and precision industrial parts. Milling also reduces assembly errors by machining multiple features in a single, controlled setup.

Conclusion

CNC drilling is best suited for fast, low-cost creation of straight, cylindrical holes, while CNC milling provides greater flexibility for machining complex geometries, multiple surfaces, and tight tolerances. In real production, drilling is often used for initial hole making, followed by milling to refine features or add complexity. Choosing the right process based on part design, accuracy requirements, and production volume is key to controlling cost, reducing lead time, and ensuring reliable part quality.