Machining polycarbonate (PC) is a key CNC process for plastic parts requiring high impact resistance, optical clarity, and dimensional stability. CNC machining polycarbonate is widely used for machine guards, transparent panels, enclosures, and precision industrial components where strength and visibility must coexist.

This guide outlines proven methods for reliable, cost-effective machining polycarbonate in both prototype and production applications.

Get 20% offf

Your First Order

What Is Polycarbonate (PC)?

widely used in CNC machining for applications requiring impact resistance, transparency, and dimensional stability. Unlike brittle plastics such as acrylic, polycarbonate is highly tough and can absorb significant mechanical energy without cracking, making it well suited for safety-related and load-bearing components.

From a machining standpoint, polycarbonate provides predictable cutting behavior when thermal effects are properly controlled. It maintains dimensional stability during machining, supports tight tolerances, and can be post-processed to achieve optical clarity when required. These traits make it suitable for both functional and transparent CNC machined parts.

Key engineering characteristics of polycarbonate include:

- High impact resistance and toughness

- Good dimensional stability under load

- Moderate heat resistance among thermoplastics

- Optical clarity for protective components

- Better machinability than brittle plastics such as acrylic

Polycarbonate is commonly available in sheet, rod, tube, and block forms,allowing flexibility across CNC milling, routing, drilling, and turning for a wide range of industrial geometries.

Polycarbonate Machinability Explained

When engineers ask whether a plastic is “easy to machine,” they are usually referring to how predictable the material behaves under cutting forces and heat. Polycarbonate is generally considered highly machinable, but for very different reasons than metals.

Unlike brittle plastics that fracture or chip, polycarbonate softens when exposed to heat. This allows clean cutting and smooth surfaces when parameters are correct, but it also means excessive heat can cause melting, smearing, or fused edges.

From a machinability standpoint:

Polycarbonate is more forgiving than acrylic in terms of cracking

It is less heat-tolerant than many engineering plastics

Tool sharpness and chip evacuation are more critical than cutting force

This combination makes polycarbonate well suited for CNC machining—but only when thermal control and stress management are part of the process strategy.

Machining Acrylic vs Polycarbonate

From a CNC machining perspective, acrylic and polycarbonate differ mainly in brittleness, heat response, and machining risk. Acrylic is harder and more brittle, which allows clean cutting and good surface finish, but it is prone to chipping or cracking under vibration, poor fixturing, or sharp internal corners. Polycarbonate is significantly tougher and impact-resistant, making it less likely to fracture during machining.

However, polycarbonate is more sensitive to heat buildup. Excessive spindle speed or poor chip evacuation can cause melting, edge fusion, or surface smearing. Compared to acrylic, machining polycarbonate typically requires lower cutting speeds, higher feed rates, and stricter thermal control. In CNC applications, acrylic is commonly used for display or optical parts with low mechanical load, while polycarbonate is preferred for machine guards, enclosures, and safety-related components where toughness and durability are critical.

CNC Machining Methods for Polycarbonate

CNC Milling

CNC milling is widely used for polycarbonate sheets and blocks. Sharp, polished tools combined with moderate spindle speeds and aggressive chip evacuation help prevent melting and surface smearing.

CNC Turning

Polycarbonate rod is commonly machined on CNC lathes. Consistent feed rates and smooth cutting edges are key to achieving stable diameters and uniform surface finish.

CNC Drilling

Drilling requires careful heat control. Peck drilling, reduced spindle speeds, and adequate chip clearance help prevent hole deformation and stress cracking.

CNC Routing

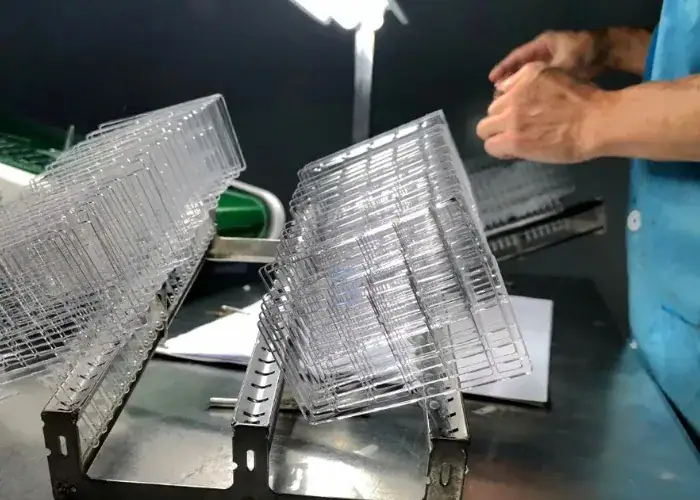

CNC routing is common for large polycarbonate sheets, particularly for machine guards and panels. Vacuum fixturing is often used to maintain stability without inducing stress.

Bending and Forming (Post-Machining)

After machining, polycarbonate parts can be thermally bent or formed to create curved shapes. This method is frequently used for curved safety guards and transparent enclosures.

Machining Polycarbonate: Speeds and Feeds

Exact cutting parameters depend on tooling geometry, machine rigidity, and part design. However, experienced CNC engineers generally follow these principles:

- Use sharp, polished cutting tools

- Run lower spindle speeds than aluminum

- Apply higher feed ratesto carry heat away

- Avoid dwelling in one location

- Use air blast or light mist coolingrather than flood coolant

Compared with aluminum, polycarbonate typically runs at lower RPM and higher feed rates to reduce heat accumulation. Proper speeds and feeds reduce internal stress and significantly improve edge quality.

Polycarbonate Forms Used in CNC Machining

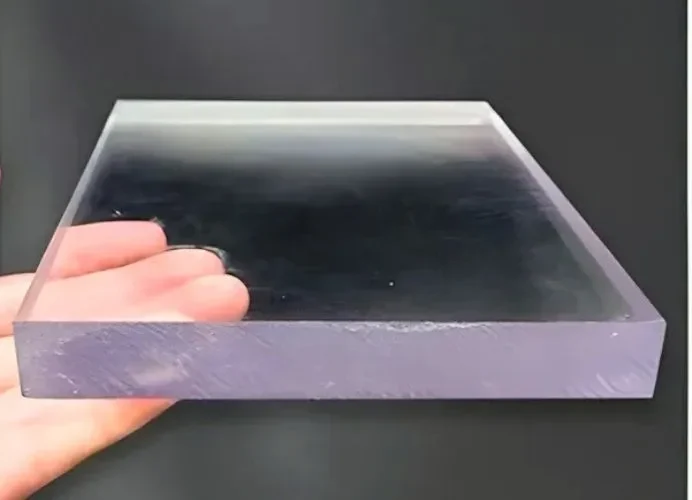

Polycarbonate Sheet for CNC Machining

Polycarbonate sheets are commonly machined into flat panels, machine guards, and protective covers. During CNC machining, proper backing support and rigid fixturing are essential to prevent vibration, chatter, and surface distortion—especially on large or thin sheets.

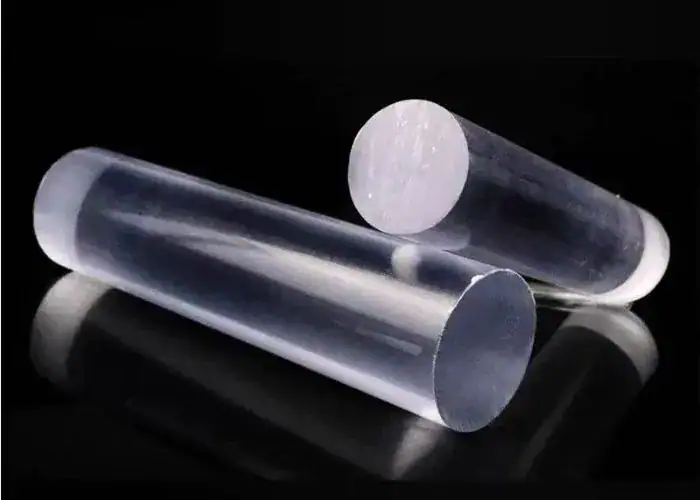

Polycarbonate Rod for CNC Machining

Polycarbonate rods are well suited for turned components such as bushings, spacers, and cylindrical parts. For tight-tolerance machining, stress-relieved rod stock is recommended to improve dimensional stability and reduce the risk of distortion during turning.

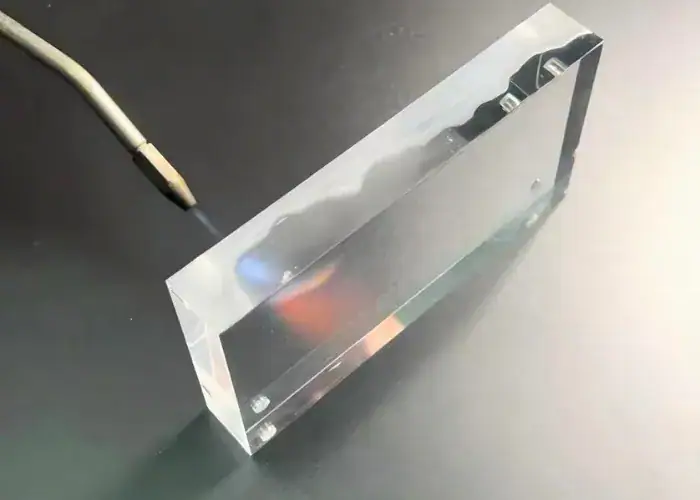

Polycarbonate Block for CNC Machining

Polycarbonate blocks are used for thicker parts or complex 3D geometries requiring extensive material removal. Deep cuts generate more heat, so careful control of cutting parameters and step-down strategies is critical to minimize internal stress buildup.

Applications of CNC Machined Polycarbonate

Polycarbonate machining is widely used across industries, including:

- Machine guards and safety enclosures

- Industrial housings and covers

- Optical and transparent components

- Medical device parts

- Electrical insulation components

- Structural plastic parts requiring impact resistance

Its balance of strength, clarity, and machinability makes polycarbonate a preferred engineering plastic.

Finishing Options for Machined Polycarbonate

Mechanical Polishing

Mechanical polishing removes visible tool marks and improves surface smoothness using sanding, buffing, or abrasive compounds. It works well for cosmetic surfaces, covers, and housings where you want a cleaner look and better touch feel, but it typically does not restore true optical transparency like vapor polishing.

For PC, the key is controlling pressure and temperature—too much heat can create haze, smearing, or local stress. It’s best applied to non-optical areas and edges, and should be paired with stress-management practices if the part will see load or impact.

Flame Polishing

Flame polishing uses controlled heat to briefly reflow the surface layer and restore edge clarity quickly, making it useful for transparent panels and cut edges that need a cleaner appearance.

However, it is highly operator-dependent: overheating can cause edge rounding, distortion, bubbles, yellowing, or micro-cracks, and it may also increase internal stress near the surface. For functional parts, flame polishing is usually best limited to edges rather than critical sealing faces or tight-tolerance features. If the part will be loaded or assembled with fasteners, stress relief annealing is often recommended afterward.

Vapor Polishing

Vapor polishing (often solvent vapor polishing) provides the highest optical clarity and gloss by smoothing micro-scratches and tool marks at a near-molecular level, making it ideal for transparent windows, lenses, and display components.

It can dramatically improve light transmission and visual quality compared with sanding or flame polishing. The trade-off is process sensitivity: it must be tightly controlled to avoid dimensional change, surface waviness, or stress cracking, especially near sharp corners or thin walls. Engineers should treat vapor polishing as an optical finishing step and design with proper radii, consistent wall thickness, and realistic tolerances.

Stress Relief Annealing

Stress relief annealing reduces internal stresses introduced during machining, drilling, and finishing—especially important for high-precision parts, thin walls, press-fit features, or parts exposed to chemicals, vibration, or mechanical load. It improves dimensional stability, reduces the risk of cracking or crazing, and helps maintain transparency over time.

Annealing is commonly recommended after aggressive machining, tight-tolerance finishing, flame polishing, or vapor polishing. The exact temperature/time cycle depends on part thickness and geometry, so it should be planned as part of the overall manufacturing route, not an afterthought.

Design Tips for Machining Polycarbonate

- Avoid sharp internal corners

- Use generous fillets and radii

- Allow for thermal expansion

- Avoid thin walls near fasteners

- Consider stress relief for tight tolerances

Good design-for-manufacturing decisions significantly affect part quality and long-term performance.

FAQs

How Do You Machine Polycarbonate Rod on a CNC Lathe?

Polycarbonate rod is typically machined using sharp, polished cutting tools and controlled spindle speeds. Consistent feed rates help minimize heat buildup and prevent surface smearing. For tight-tolerance parts, stress-relieved rod stock is strongly recommended to improve dimensional stability.

How Do You Machine Polycarbonate Sheet?

Polycarbonate sheets are commonly CNC routed or milled. Proper fixturing, such as vacuum tables, helps prevent vibration and chatter. Lower spindle speeds combined with steady feed rates reduce melting, edge fusion, and surface haze during machining.

How Do You Make Polycarbonate Clear After Machining?

Optical clarity can be restored through vapor polishing, flame polishing, or fine mechanical polishing. Stress relief annealing before polishing is often recommended to reduce internal stress and improve long-term transparency.

Can You Machine Polycarbonate?

Yes. Polycarbonate machines well when cutting heat and chip evacuation are properly controlled. CNC machining polycarbonate is widely used for parts that require both mechanical strength and optical transparency.

How Do You Machine Polycarbonate Correctly?

Use sharp tools, optimized speeds and feeds, effective chip evacuation, and stress-aware part design. Avoid excessive heat, dwelling cuts, and sharp internal corners to maintain surface quality and dimensional accuracy.

Can Polycarbonate Be Machined to Create Curved Windows?

Yes. Polycarbonate can be CNC machined and then thermally formed to create curved windows. This process is commonly used for safety guards, transparent enclosures, and protective panels.

Best Way to Machine Polycarbonate (PC)

The best way to machine polycarbonate is to use sharp carbide tools, moderate cutting speeds, and effective heat control. Polycarbonate softens easily under heat, so proper chip evacuation, air blast or light coolant, and stable fixturing are essential to prevent melting, stress, or surface damage during CNC machining.

Conclusion

Machining polycarbonate requires an understanding of both material behavior and CNC process control. When properly machined, polycarbonate delivers excellent impact resistance, dimensional stability, and optical performance for demanding engineering applications.

At TiRapid, we support engineers and buyers in machining polycarbonate parts with consistent quality—from prototypes to production. If you’re evaluating polycarbonate for CNC machining, feel free to send us your drawings for a fast feasibility review.