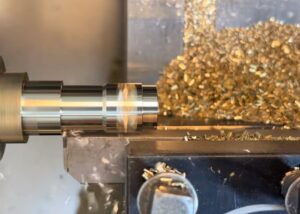

When deciding between machining brass vs aluminum for CNC machining, the choice hinges on your project’s specific needs. Brass stands out for its outstanding corrosion resistance, machinability, and polished appearance, making it perfect for durable, high-quality finishes. In contrast, aluminum is valued for its lightweight nature, cost-effectiveness, and impressive durability, making it a go-to material for industries focused on strength-to-weight ratios and large-scale production. Each metal has its strengths—choosing the right one depends on your priorities in terms of performance, cost, and volume. In this article, I’ll compare the pros and cons of both metals, delve into their machining properties, and highlight the best applications for each.

What Is Brass

Brass is a copper-based alloy, predominantly composed of copper (60-90%) and zinc (10-40%), with optional additions of elements such as lead, tin, or iron to enhance specific characteristics. These modifications allow brass to achieve varying levels of strength, corrosion resistance, and machinability, making it versatile for a wide range of applications. It is widely known for its golden color, high electrical and thermal conductivity, and excellent machinability. Brass’s hardness varies with its zinc content, allowing it to be customized for different applications. Its balance of strength and ductility makes it versatile for industries requiring both strength and aesthetics, such as plumbing, electrical components, and musical instruments.

Basic Properties Of Brass

Composition: Brass is mainly composed of copper (60-90%) and zinc (10-40%), with optional elements like lead, iron, and tin to modify its characteristics for specific applications.

Density: Brass has a density ranging from 8.4 to 8.7 g/cm³, which makes it denser than aluminum, providing enhanced durability and stability in various applications.

Strength: Brass is stronger than aluminum, with tensile strengths varying from 300 MPa to 600 MPa depending on the alloy. This makes it suitable for parts requiring both strength and resilience.

Corrosion Resistance: Brass offers excellent corrosion resistance, especially in moist and marine environments, where it resists tarnishing. This makes it ideal for plumbing fittings, electrical components, and decorative elements exposed to harsh conditions.

Machinability: Brass is known for its excellent machinability, particularly alloys like C360. This makes it a preferred material for manufacturing intricate and high-precision parts, ensuring smooth finishes and efficient production.

What Is Aluminum

Aluminum is a lightweight, non-ferrous metal with excellent corrosion resistance and a favorable strength-to-weight ratio, making it ideal for applications like aerospace, automotive, and electronics. With a density of 2.7 g/cm³, aluminum is much lighter than steel and brass while maintaining durability. It can be alloyed with magnesium, copper, and silicon to enhance its strength, corrosion resistance, and heat conductivity. For example, 6061 offers a balanced strength of 310 MPa, while 7075 provides higher strength for demanding applications like aerospace components.

Basic Properties Of Aluminum

Composition: Pure aluminum is relatively soft and has limited strength. However, it is commonly alloyed with elements like magnesium, silicon, copper, and manganese to enhance its mechanical properties, such as strength and corrosion resistance.

Density: Aluminum boasts a low density of around 2.7 g/cm³, significantly lighter than brass, which has a density ranging from 8.4 to 8.7 g/cm³. This substantial difference in density makes aluminum an ideal choice for applications where weight reduction is critical without compromising strength or durability.

Strength: The tensile strength of aluminum alloys varies depending on the composition. Alloys such as 6061 typically exhibit a tensile strength of approximately 310 MPa, whereas high-performance alloys like 7075 can achieve tensile strengths as high as 570 MPa, making them suitable for demanding applications requiring greater strength. This range allows aluminum to be used in both lightweight applications and high-strength environments.

Corrosion Resistance: When exposed to air, aluminum spontaneously develops a protective oxide layer, which acts as a barrier, offering exceptional resistance to corrosion across various environmental conditions. This oxide layer is self-healing, making aluminum ideal for outdoor and marine applications where resistance to oxidation is critical.

Machinability: Aluminum is highly machinable due to its softness and lower hardness (typically 70 HV). It is easier to cut, drill, and mill compared to materials like brass, resulting in lower tool wear and faster processing times, which makes it a preferred material for high-volume manufacturing.

machining brass vs aluminum:Comparison Of Brass And Aluminum Properties

The table provides a comparative analysis of brass and aluminum, emphasizing their essential properties relevant to CNC machining. Brass is denser, stronger, and more corrosion-resistant, making it suitable for durable, precision applications. Aluminum, being lighter and highly machinable, offers excellent corrosion resistance with its oxide layer. While brass is ideal for strength and wear resistance, aluminum is preferred for lightweight, high-speed machining applications. The choice between the two depends on factors like strength, weight, and machinability.

| Property | Brass | Aluminum |

| Composition | 60-90% Copper, 10-40% Zinc, with optional elements like lead, iron, and tin | Pure aluminum, often alloyed with magnesium, silicon, copper, and manganese |

| Density | 8.4 – 8.7 g/cm³ | 2.7 g/cm³ |

| Tensile Strength | 300 MPa to 600 MPa (varies by alloy) | 310 MPa (6061 alloy), up to 570 MPa (7075 alloy) |

| Corrosion Resistance | Excellent, especially in marine and moist environments | Good, enhanced by oxide layer, particularly in outdoor/marine applications |

| Machinability | Excellent, especially alloys like C360 | Highly machinable, softer than brass, requires less effort for cutting, turning, and milling |

| Thermal Conductivity | 109 – 125 W/m·K | 205 – 250 W/m·K |

| Electrical Conductivity | 17 – 30 MS/m | 34 – 65 MS/m |

| Hardness (Brinell) | 60 – 140 HB | 15 – 120 HB |

Brass vs Aluminum CNC Machining Comparison

Brass is typically chosen for applications requiring high durability and aesthetic appeal, although its higher cost and increased tool wear are considerations. In contrast, aluminum offers a more cost-effective solution, with easier machinability and suitability for high-speed production processes. Brass offers superior surface finish and is ideal for decorative parts, while aluminum can be anodized for corrosion resistance. Brass is used in plumbing and electrical components, while aluminum is preferred in automotive, aerospace, and electronics due to its strength-to-weight ratio.

Cost Considerations

Brass: Brass tends to be more costly than aluminum, primarily due to its higher copper content and the more intricate alloying process involved in its production. In machining brass vs aluminum, brass is often chosen for applications that require superior durability and a polished aesthetic. The higher copper content in brass provides better corrosion resistance and enhanced strength, making it ideal for high-end fittings, decorative elements, and applications in industries such as aerospace, medical, and automotive. In machining brass, precision is critical, as the material’s hardness requires special tools and techniques. Although machining brass vs aluminum is more expensive, its resilience and appearance justify the investment in parts like gears, valves, and plumbing components, which need to withstand harsh conditions while maintaining a polished finish.

Aluminum: On the other hand, aluminum is less expensive to manufacture and more readily accessible, making it a cost-efficient choice for machining brass vs aluminum projects that demand lightweight materials while maintaining strength. Aluminum’s low density and excellent thermal conductivity make it the go-to material for a variety of industries, especially where weight reduction is a priority, such as in the automotive and aerospace sectors. The cost-effectiveness of machining aluminum makes it suitable for high-volume production, and its versatility allows it to be used for a wide range of parts, from engine components to consumer electronics. In machining brass vs aluminum, aluminum is easier to process with lower wear on cutting tools, making it more cost-efficient for mass production, especially when intricate designs and precision are still necessary.

Machining Complexity And Precision

Brass: Brass, particularly in softer alloys such as C360, enables precise machining, making it ideal for applications that require high accuracy. In machining brass vs aluminum, brass offers excellent machinability, especially in its softer forms, which allows for smooth cuts and precise part dimensions. This makes brass a preferred choice for components that need high durability and a polished finish, such as electrical connectors, fittings, and valves. However, harder alloys like C260 require slower machining speeds to avoid excessive tool wear and overheating. When machining brass vs aluminum, the hardness of the material can significantly affect the cutting process, requiring specialized tools and techniques to prevent issues like tool erosion or surface damage. Therefore, while brass is highly durable, its machining process demands more attention to detail and careful speed adjustments to ensure optimal results and extend tool life.

Aluminum: In contrast, aluminum is easier to machine, especially in alloys like 6061, which allows for faster cutting speeds and more efficient production. The lower density and softer nature of aluminum compared to machining brass vs aluminum make it easier to handle with less wear on cutting tools, reducing operational costs. Aluminum’s ability to maintain high cutting speeds makes it an ideal choice for high-volume production, particularly in industries like automotive and aerospace. The lightweight nature of aluminum also makes it suitable for parts that require a good strength-to-weight ratio without compromising performance. In machining brass vs aluminum, aluminum’s superior machinability leads to less downtime and tool maintenance, making it the go-to choice for projects that demand efficiency and cost-effectiveness. While brass offers more durability in certain applications, aluminum remains the more practical option for rapid production and easy handling in a wide range of industries.

Tool Wear And Tool Life

Brass: Brass’s higher density and hardness lead to more tool wear, especially when machining harder alloys like C260. In machining brass vs aluminum, brass’s increased density results in more friction during the cutting process, which can quickly wear down tools. To extend tool life, it’s important to use carbide tools, which are harder and more resistant to wear than standard steel tools. Additionally, controlling the cutting speed is crucial; using too high of a speed can accelerate tool wear, while slower speeds can help mitigate this issue. However, when machining brass vs aluminum, this wear still tends to be more significant in brass, especially when using the harder alloys, requiring more frequent tool maintenance and replacement.

Aluminum: On the other hand, aluminum generates less heat and fewer burrs during machining, which helps in minimizing tool wear and improving overall tool longevity. In machining brass vs aluminum, aluminum’s lower density and thermal conductivity make it easier on the tools, requiring less force and generating less heat during the cutting process. With proper cooling methods, such as air or mist cooling, tool life can be extended significantly, as aluminum’s lower tendency to overheat reduces the risk of thermal damage to the tool. This makes aluminum a more tool-friendly material for high-speed machining, resulting in lower operational costs and increased efficiency, especially when compared to brass, which demands more careful handling to avoid excessive wear.

Surface Finish And Aesthetics

Brass: Brass naturally exhibits a golden hue and can be polished to attain a smooth, glossy surface finish. In machining brass vs aluminum, brass offers a superior aesthetic appeal, making it a popular choice for decorative applications such as jewelry, plumbing fixtures, and musical instruments. Its ability to be polished to a high shine gives it a luxurious look, which is why it’s commonly found in items like faucets, door handles, and coins. Brass’s attractive appearance combined with its excellent machinability makes it ideal for high-end consumer products. However, when comparing machining brass vs aluminum, while brass offers a better finish for decorative purposes, its higher density and hardness may require more effort in machining, especially when dealing with harder alloys. Proper surface treatment, like polishing or coating, can further enhance brass’s visual appeal and durability, especially in applications exposed to harsh environments.

Aluminum: Aluminum, on the other hand, undergoes anodizing to enhance its surface quality and boost its resistance to corrosion. While it doesn’t offer the same aesthetic appeal as brass, machining brass vs aluminum shows that aluminum is often the better choice for functional applications where performance is prioritized over appearance. Aluminum’s anodized surface not only provides a smooth, attractive finish but also increases its resistance to wear, corrosion, and oxidation. It is commonly used in industries like aerospace, automotive, and electronics for components such as heat sinks, housings, and structural parts. Machining aluminum vs brass highlights that while aluminum lacks the polished visual appeal of brass, it excels in durability, lightweight properties, and functional efficiency. In terms of machining brass vs aluminum, aluminum is easier to process at higher speeds with less tool wear, making it a more cost-effective option for high-volume production of functional parts.

Specific Applications

Brass: Brass is well-suited for applications like plumbing fittings, electrical components, musical instruments, and decorative hardware, thanks to its excellent corrosion resistance and strength. When comparing machining brass vs aluminum, brass stands out in environments where durability and resistance to wear are essential. Its natural ability to resist corrosion makes it a preferred material for plumbing fittings, which are exposed to water and moisture regularly. In electrical components, brass is chosen for its excellent conductivity and resistance to oxidation, making it ideal for connectors, terminals, and switches. Furthermore, machining brass vs aluminum reveals that brass offers superior precision for intricate machining processes, which is why it’s often used in musical instruments like brass wind instruments, where both strength and acoustic qualities are important. In decorative hardware, brass’s polished surface is frequently used in luxury items, including door handles, faucets, and ornamental pieces, making it a top choice for applications where both aesthetics and functionality matter.

Aluminum: Aluminum is widely utilized in industries such as automotive, aerospace, and consumer electronics, primarily for its lightweight nature and superior strength-to-weight ratio. Machining brass vs aluminum highlights that aluminum’s low density is a critical factor in industries like aerospace, where weight reduction can significantly impact fuel efficiency and performance. In the automotive industry, aluminum is used for engine components, wheels, and frames, providing strength without the added weight of heavier metals. Machining aluminum vs brass also points to aluminum’s ability to be easily formed and machined, making it an ideal choice for mass production of complex parts with tight tolerances. Its natural corrosion resistance, combined with its strength-to-weight ratio, also makes it a popular choice for consumer electronics, such as smartphones, laptops, and cameras, where both functionality and sleek design are important. In contrast, while machining brass vs aluminum gives brass the edge in precision and aesthetic applications, aluminum shines in industries where lightweight and high-performance materials are required.

Practices For CNC Machining Brass And Aluminum

For CNC machining, use low spindle speeds and carbide tools for brass, and higher speeds with sharp carbide tools for aluminum. Both require stable workholding, correct cutting parameters, and regular machine maintenance. Brass is ideal for plumbing, electrical, and decorative components, while aluminum suits automotive, aerospace, and electronics due to its lightweight strength.

Best Practices For Brass Machining

Low Spindle Speeds

Controlling heat buildup is crucial when machining brass, particularly for denser alloys like C260. To prevent work hardening and material distortion, it’s important to start with lower spindle speeds, typically around 300-400 RPM. This minimizes the risk of heat-induced issues and ensures a smoother cut. For softer alloys like C360, spindle speeds can be pushed up to 500-600 RPM without sacrificing the integrity of the cut.

When machining brass, especially machining brass vs aluminum, speed plays a key role in controlling heat and optimizing efficiency. Brass, with its higher density, generates more heat compared to aluminum. Slower spindle speeds, when machining brass, help reduce the friction and heat, preventing work hardening and material deformation. For example, machining brass vs aluminum requires different approaches; aluminum typically handles faster speeds without heat buildup, while brass demands more cautious settings.

While machining a brass valve component made from C360, I initially set the spindle to 350 RPM. This helped avoid any heat-related distortions and ensured the precision of the intricate features on the valve. The slower speeds not only maintained the quality of the brass but also helped avoid excessive wear on the cutting tool. In contrast, machining brass vs aluminum would have required faster spindle speeds for aluminum, given its lower melting point and better thermal conductivity. By tailoring the speed and feed rates specifically for brass, I was able to achieve the required precision while also extending tool life.

Carbide or Cobalt Tools

Brass’s density and hardness demand the use of durable cutting tools. Carbide or cobalt tools are ideal for handling the tougher, denser nature of brass without losing sharpness or wearing prematurely. Machining brass vs aluminum involves distinct differences in tool selection due to brass’s higher hardness. Carbide tools, in particular, offer the best performance for high-speed machining, ensuring efficient material removal and extended tool life. These tools are specifically designed to withstand the challenges posed by brass machining, maintaining precision even under demanding conditions.

When machining brass vs aluminum, the right tool choice can make all the difference. For brass, carbide tools are often the go-to due to their excellent wear resistance. On the other hand, aluminum can often be machined using less durable materials like high-speed steel (HSS), as it doesn’t generate as much heat or cause as much wear. I once worked on a project machining C260 brass for a client’s industrial valve. By using carbide end mills, I was able to achieve a high-quality finish while cutting at 800 RPM, without tool wear being a concern. Carbide’s wear resistance allowed me to maintain cutting efficiency throughout the entire project, resulting in a 15% improvement in tool life compared to the previously used HSS tools. This highlights the importance of selecting the right tools for machining brass vs aluminum, ensuring both performance and tool longevity.

Cooling and Lubrication

Proper cooling and lubrication are essential for preventing brass from work hardening during machining. Using high-quality cutting fluids or oils is critical in dissipating heat and minimizing friction between the tool and the material. Machining brass vs aluminum presents a unique challenge as brass tends to retain heat more than aluminum, which can lead to work hardening. For larger brass parts, flood coolant systems are recommended to ensure the cutting zone stays cool and well-lubricated, extending tool life and improving surface finishes. Effective cooling not only enhances precision but also helps maintain the material’s integrity, ensuring consistent machining performance throughout the process.

When machining brass vs aluminum, the cooling needs are vastly different. Brass requires more aggressive cooling to prevent thermal damage, whereas aluminum, with its higher thermal conductivity, dissipates heat more efficiently. During a project where I was machining brass bushings from C360, I used a synthetic coolant to flood the cutting area. This kept the tool temperature stable and ensured an even, consistent cut. The result was a 20% increase in machining efficiency, with less material buildup and a smoother surface finish, proving the importance of proper lubrication in maintaining both tool life and part quality.

Best Practices For Aluminum Machining

Employ Higher Spindle Speeds Due to Aluminum’s Low Melting Point

Aluminum has a relatively low melting point (around 660°C), which means it can be machined at higher spindle speeds compared to harder metals. This characteristic of machining aluminum vs brass allows for more efficient material removal. Higher spindle speeds, typically in the range of 800-1200 RPM, help reduce heat buildup at the cutting edge, preventing aluminum from softening or welding onto the tool, a common issue when machining brass vs aluminum.

For example, when machining aluminum alloys like 6061, running at 1000 RPM with an appropriate feed rate results in faster material removal and a smoother finish. This not only improves CNC machining aluminum efficiency but also enhances surface quality. The ability to maintain speed without causing excessive heat ensures that the aluminum does not deform, leading to higher precision and a longer tool life.

Use Sharp Carbide Tools to Prevent Built-Up Edges and Ensure Clean Cuts

Aluminum tends to form built-up edges (BUE) on the cutting tool, which can negatively affect the surface finish and lead to poor tool performance. This issue is particularly relevant in CNC machining aluminum, where the material’s softness and tendency to stick to the tool can compromise precision. To prevent this, sharp carbide tools are highly recommended. Carbide tools are harder and retain their sharpness longer, ensuring clean cuts and reducing the formation of BUE, a common challenge when machining aluminum vs brass.

For instance, when machining intricate aluminum parts such as brackets or housings, using carbide inserts ensures consistent performance, better surface finishes, and increased tool life. This is especially important in high-speed operations, as carbide’s wear resistance allows for longer tool life and greater efficiency compared to other materials like HSS, which are commonly used in machining brass vs aluminum.

Utilize Flood Cooling for Efficient Heat Dissipation During Machining

Although aluminum has good thermal conductivity, high-speed machining processes can still generate considerable heat, especially with harder aluminum alloys like 7075 aluminum. This heat buildup can cause thermal distortion, compromising the accuracy of cuts and reducing the tool’s lifespan. To mitigate this, using flood coolant is highly effective in dissipating heat, preventing tool overheating, and ensuring consistent CNC machining aluminum performance. The coolant also helps reduce friction between the tool and the workpiece, leading to better chip evacuation and cleaner cuts. This is particularly essential when machining complex parts, as overheating can cause dimensional inaccuracies and surface defects, ultimately leading to higher rejection rates and additional costs in production.

For example, when machining large aluminum parts for aerospace applications, flood cooling has proven essential. It not only maintains dimensional accuracy but also prevents material damage caused by excessive heat. This cooling technique also extends tool life significantly, reducing the frequency of tool changes and minimizing downtime. In comparison to machining brass, where tool wear due to heat is a significant challenge, machining brass vs aluminum shows that aluminum requires better heat management but offers higher machining efficiency due to its lower melting point and softer nature. The use of flood cooling in aluminum machining ensures that parts meet stringent specifications, making it a key factor in both high-volume production and high-precision applications like those seen in aerospace.

Best Practices For Both

Ensure Stable Workholding to Avoid Vibration and Ensure Precision

Stable workholding is critical to achieving high-precision machining results for both brass and aluminum. Vibrations caused by unstable workholding can lead to inaccuracies, poor surface finishes, and tool wear. Utilizing high-quality fixtures, such as rigid vises, clamps, or custom-made workholding solutions, ensures that the workpiece is securely held during machining. For both machining brass vs aluminum, the choice of workholding solution can directly affect the overall performance and output quality. Brass, due to its higher density, requires more secure clamping to prevent vibrations, which can lead to inconsistent cuts. On the other hand, aluminum’s lighter nature demands even more attention to ensure it is properly held in place to avoid shifting during high-speed operations, which could affect surface quality and dimensional accuracy.

For example, in machining aluminum aerospace parts, where precision is critical, using a dedicated fixture that minimizes movement ensures that each part maintains tight tolerances, reducing scrap rates and improving overall machining efficiency. The difference between machining brass vs aluminum lies in the material properties: brass’s higher strength and stiffness mean that clamping forces need to be carefully balanced to avoid distortion, while aluminum requires fixtures designed to handle its lightness and prevent excessive movement during machining. By using specialized fixtures, both materials can be processed effectively to achieve high precision, ensuring that each component, whether aluminum or brass, meets the stringent requirements of industries like aerospace and automotive.

Select the Right Cutting Parameters Based on the Material and Tooling Capabilities

Choosing the right cutting parameters, including spindle speed, feed rate, and depth of cut, is essential for achieving optimal results when machining both brass and aluminum. For brass, which has a higher density and hardness, slower cutting speeds and higher feed rates are often necessary to manage tool wear and achieve smoother finishes. In contrast, aluminum, with its lower density and excellent machinability, can be machined at higher speeds and with higher feed rates, improving efficiency and throughput.

For instance, in machining a brass valve body, using a slower spindle speed around 500 RPM and a lower feed rate helps reduce excessive heat generation, while machining aluminum brackets at 1200 RPM with higher feed rates ensures faster material removal without sacrificing precision.

Perform Regular Maintenance on CNC Machines to Keep Them Running Efficiently

Consistent maintenance of CNC machines is crucial for ensuring reliable machining performance and prolonging the lifespan of the equipment. Regular upkeep helps maintain optimal machine functionality and quality in production processes. This includes routine checks on tool wear, lubrication, coolant systems, and machine calibration. Keeping machines in optimal working condition reduces downtime and prevents costly errors caused by mechanical failure. Proper maintenance is especially important when machining brass vs aluminum because both materials have distinct characteristics that demand specific care. Brass, with its higher density and hardness, can cause more rapid tool wear, which means regular checks are necessary to maintain tool sharpness and efficiency. On the other hand, aluminum’s softer nature and tendency to form built-up edges (BUE) during machining require precise lubrication and proper coolant usage to avoid heat buildup and material distortion.

For example, before machining a batch of aluminum parts for a car engine, ensuring that the CNC machine’s linear guides and spindles are well-lubricated and calibrated ensures smooth operations, preventing vibrations and inaccuracies that could affect the final product’s dimensions and performance. In machining brass vs aluminum, aluminum typically requires more frequent coolant system maintenance due to its heat-sensitive properties. For brass, ensuring the toolpaths and cutting tools are properly maintained can prevent the risk of tool wear and potential workpiece deformation. By following these best practices, manufacturers can enhance the precision, efficiency, and longevity of their machining processes, regardless of whether they are working with machining brass vs aluminum. Regular maintenance will also help reduce material wastage, making production processes more cost-effective while improving the overall quality of both aluminum and brass parts.

Best Applications For Brass And Aluminum

| Material | Applications | Key Properties |

| Brass | Plumbing fittings, decorative hardware, electrical connectors, musical instruments | Excellent corrosion resistance, strength, and durability |

| Aluminum | Automotive parts, aerospace components, electronic housings, packaging | Lightweight, high strength-to-weight ratio, excellent machinability |

FAQs

Is Aluminum Easier To Machine Than Brass?

Aluminum is typically easier to machine than brass due to its lower hardness, which is around 70 HV, compared to brass’s range of 120 to 200 HV. This softness results in reduced cutting force and faster machining speeds. Furthermore, aluminum generates less heat and fewer burrs during machining, which helps extend tool life. Alloys such as 6061 are highly machinable, enabling efficient cutting, turning, and milling, making aluminum ideal for high-speed production.

Is It safe To Cut Aluminum With Any Saw?

No, it is not safe to cut aluminum with just any saw. Aluminum requires a saw with teeth specifically designed for non-ferrous metals. Saw blades with a higher tooth count, typically in the range of 60-100 teeth, are recommended for smooth cuts without burrs. Additionally, using a saw with a positive rake angle and appropriate lubrication or coolant is essential to prevent overheating and blade wear. Using the wrong saw can lead to poor cuts, increased heat buildup, and potential damage to both the material and the tool.

Can Aluminum And Brass Fittings Be Used Together?

Yes, aluminum and brass fittings can be used together, but care is needed to avoid galvanic corrosion. When exposed to moisture, the two metals can corrode at different rates. Brass, being more noble, will corrode aluminum faster. To prevent this, insulate the metals or use protective coatings, and consider corrosion-resistant alloys to improve durability.

Can Aluminum Be Welded To Brass?

Welding aluminum to brass is challenging due to their distinct melting points and thermal properties. Aluminum melts at approximately 660°C, while brass melts at around 900–940°C. This difference can lead to joint weaknesses. Specialized techniques like brazing or using specific filler materials, such as aluminum-silicon alloys, can help create strong bonds, but traditional welding is generally not recommended.

What Is The Difference Between Brass And Aluminum?

To effectively machine brass, carbide or cobalt tools are recommended due to their strength and resistance to wear, making them capable of handling the material’s density and hardness. Maintain lower spindle speeds (300-400 RPM) for denser alloys like C260 to prevent heat buildup. Ensure proper cooling and lubrication with high-quality cutting fluids to reduce friction and work hardening. Use stable workholding to minimize vibrations, ensuring precision and smooth cuts. Regularly inspect tools for wear to maintain machining efficiency and surface quality.

Conclusion

In conclusion, both brass and aluminum bring distinct advantages to CNC machining. Brass excels in corrosion resistance and aesthetic appeal, making it ideal for high-end, durable applications. Aluminum, on the other hand, is lightweight, cost-effective, and easier to machine, perfect for projects where speed and efficiency are key. The best material for your project ultimately depends on your specific needs—whether that’s strength, weight, appearance, or budget. Which material do you think fits your next project? Let’s explore how these options can take your designs to the next level!