Custom CNC machining has become a leading solution for rapid production across industries, offering speed, precision, and flexibility. TiRapid (TiR) exemplifies these advantages, utilizing advanced CNC technology to deliver high-quality prototypes and production parts with short lead times. CNC machining stands out against alternatives like injection molding and 3D printing by supporting customizable designs, a wide range of materials, and consistent quality. While it is well-suited for low-to-medium volume production, its scalability, ability to handle complex geometries, and integration with automation make it a strong candidate for companies seeking rapid turnaround. TiRapid’s approach emphasizes efficient workflows, consultative design, and sustainable practices, serving diverse sectors from aerospace to medical devices. Although CNC machining has limitations—such as cost at scale and material waste—TiRapid mitigates these with innovative processes and strong client engagement. The company also invests in future trends like AI optimization and hybrid manufacturing, further enhancing its rapid production capabilities. In summary, TiRapid’s custom CNC machining offers a compelling blend of speed, quality, and service, making it a top choice for businesses needing fast, precise, and reliable manufacturing solutions.

Modern manufacturing industries are always on the lookout for efficient, flexible, and reliable methods for rapid production. Among the myriad of technologies available today, custom CNC (Computer Numerical Control) machining has risen to prominence as a preferred choice for companies seeking speed and precision. TiRapid, commonly referred to as TiR, is one such company that leverages the advantages of cnc machining to deliver outstanding results. This article explores the key facets of custom CNC machining in the context of rapid production and evaluates whether it stands as the best choice for businesses like TiRapid.

Understanding Custom CNC Machining

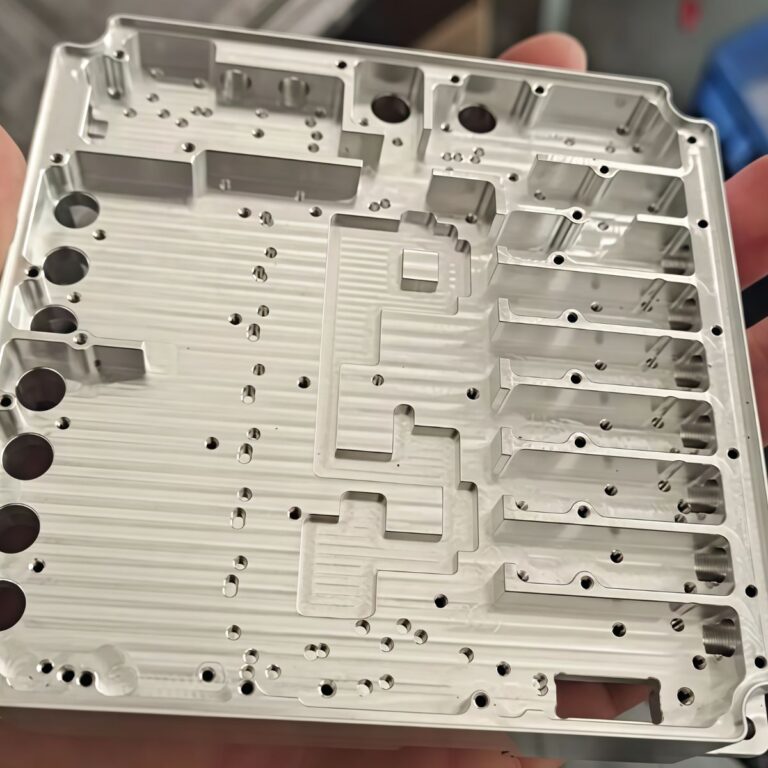

Custom CNC machining involves the use of computer-controlled machines to manufacture parts from various materials based on unique designs. These machines translate digital programming into physical movements, allowing for high accuracy and repeatability. At TiRapid, CNC machines handle diverse projects, ranging from simple fixtures to complex aerospace components, always with the client’s specifications at the forefront.

Key Features and Capabilities of TiRapid’s CNC Machining

- High Precision: CNC machining at TiRapid can achieve tight tolerances, frequently within microns, ensuring parts meet strict quality standards.

- Material Versatility: TiR utilizes CNC machines to work with metals, plastics, composites, and more, granting clients a wide range of material options.

- Complex Geometries: Whether the need is for intricate cuts or challenging shapes, TiRapid’s CNC tools can create components that would be difficult or impossible to produce with traditional manufacturing.

- Rapid Turnaround: Custom CNC machining minimizes setup and tooling times, enabling TiR to quickly deliver prototypes and production parts.

- Scalability: From single prototypes to thousands of parts, TiRapid’s CNC processes scale seamlessly to meet production demands.

Custom CNC Machining Versus Alternative Rapid Production Methods

To determine if custom CNC machining is the best choice for rapid production, it is vital to compare it with other methods such as injection molding, 3D printing, and sheet metal fabrication. Each method offers distinct advantages and drawbacks, and TiRapid often evaluates these before proposing solutions to clients.

| Method | Speed | Flexibility | Cost | Quality |

|---|---|---|---|---|

| CNC Machining (TiRapid) | Fast prototype to low volume | Highly customizable | Variable; best for low to medium volumes | High precision, superior finish |

| Injection Molding | Slow setup, fast high-volume | Limited by mold design | High initial, low per part | Consistent, less versatile for changes |

| 3D Printing | Fast prototype, slower per part | Maximum customization | Low for prototypes, high for production | Lower strength, post-processing needed |

| Sheet Metal Fabrication | Moderate | Limited to certain shapes | Moderate | Good for enclosures, less precise |

Where TiRapid Excels

For many clients, TiRapid’s custom CNC machining is the preferred rapid production option due to the blend of speed, flexibility, and quality. While injection molding dominates high-volume production runs, its tooling costs and lead times are prohibitive for Rapid Prototyping and low-volume manufacturing. 3D printing, though excellent for complex designs and customization, often falls short in mechanical strength, surface finish, and scalability. Sheet metal fabrication is reliable for certain applications but lacks the versatility and precision offered by TiRapid’s CNC machining.

Advantages of Custom CNC Machining at TiRapid

- Rapid Prototyping: TiR transforms digital designs into physical parts within hours or days, supporting iterative development and speed-to-market.

- Design Flexibility: Complex geometries and frequent design changes are easily accommodated, allowing clients to innovate freely.

- Material Selection: TiRapid provides access to a vast array of materials, including specialty alloys and engineering plastics.

- Consistent Quality: Automated controls and rigorous inspection ensure every part meets exact specifications.

- Cost Control: For small-to-medium runs, CNC machining avoids the need for costly tooling, reducing overhead and project risk.

The TiRapid Approach to Rapid Production

TiRapid’s workflow is engineered for efficiency and responsiveness. From design review through final inspection, TiR employs state-of-the-art CAD/CAM software, advanced CNC machinery, and skilled technicians to deliver parts on time and on budget.

- Consultative Design Reviews: Engineering experts at TiRapid work with clients to optimize designs for manufacturability, precision, and cost.

- Digital Integration: CAD data is seamlessly programmed into CNC systems, speeding up setup and reducing errors.

- Flexible Scheduling: TiR’s facility operates around the clock, enabling priority rush orders and tight deadlines.

- Quality Assurance: In-process inspections and final measurements ensure every part meets or exceeds client expectations.

- Scalable Production: Whether clients need a handful of prototypes or hundreds of production units, TiRapid adjusts capacity to suit project needs.

Limitations and Considerations in Custom CNC Machining

While TiRapid’s CNC machining delivers notable advantages for rapid production, it is not without limitations. These must be weighed carefully before choosing the right approach for a project.

- Cost at Scale: For very high-volume production (tens of thousands or millions of parts), CNC machining can become less cost-effective than processes like injection molding.

- Material Waste: Subtractive manufacturing such as CNC machining inherently produces more waste material compared to additive methods.

- Complex Assembly: Parts requiring complex assemblies may need additional processes beyond CNC machining, potentially increasing lead time.

- Tool Wear: High-speed, high-tolerance CNC operations can accelerate tool wear, necessitating regular maintenance and calibration.

- Design Constraints: While flexible, CNC machining cannot match the unconstrained freedom of 3D printing for certain internal features or lattice structures.

Industries Benefiting from TiRapid’s Custom CNC Machining

TiRapid serves a broad spectrum of industries, each leveraging CNC machining’s strengths for rapid production and prototyping:

- Aerospace: High tolerance, certified alloys, and rapid turnaround for critical components.

- Automotive: Rapid prototyping of engine parts, brackets, and custom fixtures.

- Medical Devices: Precision machining for surgical tools and diagnostic equipment.

- Robotics & Automation: Custom end-effectors, chassis, and mounts for innovation-driven projects.

- Consumer Electronics: Enclosures and mechanical parts tailored to unique product designs.

Case Study: Accelerating Product Launch with TiRapid

A leading startup approached TiRapid seeking a quick turnaround on a complex prototype for a new wearable medical device. TiR’s engineers collaborated closely with the client, refining the CAD design for manufacturability and selecting appropriate biocompatible materials. Within four days, the part was machined, inspected, and shipped, enabling the startup to conduct real-world testing and proceed to clinical trials. This level of speed and flexibility would have been unattainable with conventional manufacturing or overseas production.

The Integration of Automation and Smart Manufacturing at TiRapid

TiRapid continues to innovate by incorporating automation, robotics, and smart manufacturing technologies into its CNC machining operations. This strategic investment increases throughput, reduces human error, and further enhances rapid production capabilities.

- Automated Tool Changers: Enable continuous machining without manual intervention, increasing efficiency.

- Robotic Part Handling: Allows for lights-out manufacturing and supports 24/7 operations.

- Real-Time Monitoring: Sensors track machine health, tool wear, and production status, allowing proactive maintenance and scheduling.

- Cloud-Based Data Management: Facilitates collaboration among clients, engineers, and operators, ensuring transparency and quick adjustments.

Custom CNC Machining and Sustainability: TiRapid’s Commitment

TiRapid recognizes the importance of environmental responsibility in manufacturing. While CNC machining is a subtractive process, TiR minimizes waste through optimized toolpaths, material recycling, and energy-efficient operations.

- Material Optimization: Advanced software reduces unnecessary cuts and maximizes raw material yield.

- Recycling Programs: TiRapid partners with local recyclers to repurpose metal chips and scrap.

- Low-Emission Machinery: The facility operates energy-efficient CNC machines, reducing carbon footprint.

- Lean Manufacturing: Inventory is managed to minimize excess and avoid overproduction, supporting sustainable practices.

Client Experience and Service at TiRapid

One of the hallmarks of TiRapid is its dedication to client satisfaction. From the initial inquiry to final delivery, TiR provides clear communication, technical guidance, and responsive support.

- Technical Consultation: Experienced staff consult on design, materials, and manufacturability for every project.

- Transparent Pricing: Quotations are clear and competitive, with no hidden fees or surprises.

- Fast Quoting: Clients can receive quotes in minutes for standard projects, expediting decision-making.

- After-Sales Support: TiRapid stands by every product, addressing concerns and facilitating reorders or modifications as needed.

Future Trends: The Evolution of Custom CNC Machining for Rapid Production

As technology evolves, TiRapid is positioned at the forefront of new developments within CNC machining, offering clients even greater speed and capabilities for rapid production. Emerging trends include:

- Hybrid Manufacturing: Combining CNC machining with additive manufacturing for complex assemblies.

- AI-Driven Optimization: Artificial intelligence assists in programming, toolpath optimization, and predictive maintenance.

- Advanced Materials: Expansion into ceramics, composites, and high-performance polymers.

- Micromachining: Precision fabrication for electronics, medical devices, and miniaturized components.

Comparing TiRapid’s Custom CNC Machining to Global Competitors

In a globalized manufacturing marketplace, companies like TiRapid differentiate themselves through quality, speed, and service. While overseas providers may offer competitive pricing, TiR delivers advantages in communication, reliability, and turnaround times crucial for rapid production.

- Local Support: Faster response and easier coordination for domestic clients.

- Quality Standards: Adherence to ISO, AS9100, and medical certifications as required.

- Intellectual Property Protection: Secure handling of client files and designs.

- Reduced Shipping Times: Faster delivery compared to international production.

Custom CNC Machining in Product Development Cycles

Rapid production is not just about speed—it is about enabling innovation. TiRapid’s CNC services play a critical role in prototyping, testing, and transitioning to production, allowing clients to iterate quickly and reduce time-to-market.

- Design Verification: Physical prototypes help validate function, fit, and form before committing to mass production.

- Functional Testing: High-quality CNC prototypes can be used in real-world environments for performance assessment.

- Pilot Runs: TiR supports small batch production for market testing and initial launches.

- Iterative Improvements: Design changes can be implemented immediately, supporting agile development models.

Challenges in Implementing Custom CNC Machining for Rapid Production

Despite its strengths, custom CNC machining for rapid production can encounter challenges, which TiRapid addresses proactively:

- Supply Chain Disruptions: Material availability and global logistics can impact lead times, necessitating contingency planning.

- Programming Complexity: Highly intricate parts require advanced programming expertise and simulation, increasing upfront effort.

- Skilled Labor Shortages: Recruiting and training CNC operators is an ongoing challenge in a competitive market.

- Machine Downtime: Equipment maintenance and upgrades can temporarily slow production.

Best Practices for Maximizing Success with TiRapid CNC Machining

Clients can maximize the benefits of TiRapid’s CNC machining for rapid production by following a few key best practices:

- Early Engagement: Involve TiRapid’s engineers early in the design phase to optimize for manufacturability and cost.

- Clear Specifications: Provide accurate and detailed CAD files, material requirements, and tolerances to minimize revisions.

- Open Communication: Maintain ongoing dialogue to address any design, timeline, or production concerns.

- Batch Planning: Group similar parts or orders to take advantage of setup efficiencies and volume pricing.

Why Choose TiRapid for Rapid Production?

TiRapid stands out in the field of rapid production through custom CNC machining by offering not just advanced technology, but also a partnership approach to manufacturing. TiR’s focus on speed, flexibility, precision, and client service ensures that customers receive parts that meet their unique requirements, delivered on time and on budget.

- Proven Track Record: Hundreds of successful projects across industries.

- State-of-the-Art Facility: The latest CNC equipment and software.

- Client-Centric Philosophy: Dedicated project managers and responsive support.

- Continuous Improvement: Commitment to process optimization and ongoing investment in new technologies.