To understand how to manufacture product in China, you need more than just finding a factory. It’s a structured process across design, supplier selection, prototyping, production, quality control, and logistics. This guide will help you see why China is a strong manufacturing choice, how to protect your interests, how to identify reliable suppliers, and how to manage quality and delivery efficiently.

Get 20% offf

Your First Order

Why Choose Manufacturing In China

Choosing China for manufacturing goes far beyond low costs. China offers unmatched production capacity, fast turnaround, mature supply chains, and wide material options. However, foreign buyers must also understand challenges such as communication, IP protection, and quality control. This section breaks down what makes China a global manufacturing hub—and what to prepare for when exploring how to manufacture product in China.

The Core Advantages Of Manufacturing In China

Lower Production Cost Efficiency

China’s cost advantage isn’t only labor—it’s the entire ecosystem. Material suppliers, machining workshops, mold makers, packaging factories, testing labs, and logistics hubs operate within tight geographic clusters. This reduces transportation time and cost by 20–40%.

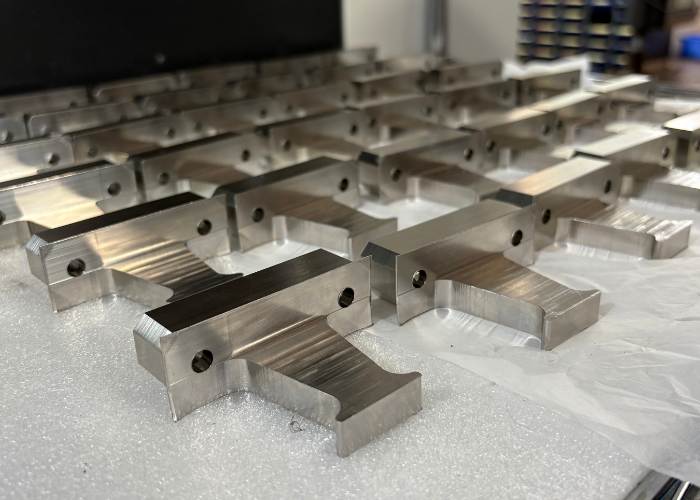

Massive Production Capacity & Scalability

Whether you need 100 units or 1 million units, China’s factories can scale quickly. For example, in CNC machining, a single facility may run 100–300 machines, enabling bulk production while keeping delivery within 7–15 days.

Unmatched Speed-to-Market

Thanks to strong coordination between suppliers, molds, machining, finishing, and assembly, China’s lead times are often 30–50% faster than other countries. This helps startups validate products and launch faster.

Complete Industrial Supply Chain

You can find almost any process: CNC machining, injection molding, die-casting, PCB assembly, textiles, electronics, and more. This “all-in-one” ecosystem significantly reduces project complexity.

Key Challenges In China Manufacturing

Communication & Language Gap

Although many factories have English-speaking staff, misunderstandings still occur. Precise drawings, tolerance charts, and QC checklists are essential.

Quality Variation Across Factories

Two factories may quote the same product at $2 and $6. The difference usually comes from equipment level, material source, and internal QC standards.

Intellectual Property Risks

Without proper NNN agreements, patents, and design control, sensitive information may leak. Splitting suppliers for different components is a common practice to reduce risks.

MOQ Requirements

Some factories require high MOQ to maintain cost efficiency. Negotiation strategies and finding small-batch-friendly suppliers are crucial.

Product Types Suitable For Manufacturing In China & Their Main Cities

| Product Type | Why It Fits China Manufacturing | Main Manufacturing Cities / Industrial Clusters |

| Consumer Electronics | Mature supply chain, fast iteration, strong component ecosystem | Shenzhen, Dongguan |

| CNC Metal & Plastic Parts | Large machining capacity, competitive pricing, advanced 3–5 axis capabilities | Shenzhen, Dongguan, Shanghai, Suzhou |

| Injection Molded Parts | Highly developed mold-making industry, high-volume production efficiency | Dongguan, Ningbo, Zhejiang |

| Apparel & Textiles | Skilled labor, large-scale factories, diverse material sourcing | Guangzhou, Fujian, Zhejiang |

| Toys & Household Goods | Strong plastic supply chain, global export experience | Dongguan, Ningbo, Shenzhen |

| Smart Devices & IoT Products | Complete electronics ecosystem, PCB + assembly + testing in one region | Shenzhen, Suzhou |

| Automotive Aftermarket Parts | Competitive machining, casting, and assembly capabilities | Guangzhou, Ningbo, Shenzhen |

Product Preparation Stage — From Idea To Technical Documentation

Before you manufacture your product in China, you must prepare accurate, production-ready documentation. Clear files reduce misunderstandings, control costs, and ensure manageable quality. Good preparation is the foundation of successful manufacturing.

Product Concept, 3D/2D Drawings, BOM & CTQ

To understand how to manufacture product in China, the first step is to convert ideas into technical files:

3D models (STEP/IGS): Used for CNC machining, mold design, structure evaluation.

2D drawings: Include tolerances, materials, surface finish, datum.

BOM: Defines materials, part list, and manufacturing processes.

CTQ (Critical to Quality): Highlights features that affect assembly or performance.

Example:

A U.S. IoT device project failed twice because the buyer didn’t specify CTQ, causing the factory to apply standard tolerances. Clear CTQs could have avoided $3,000+ in rework.

Packaging Design & Label Requirements

Packaging impacts both compliance and logistics:

Protection level & drop-test requirements

Retail packaging structure (color box, blister, inserts)

Labeling (SKU, barcode, warnings, origin)

Amazon FBA / CE / RoHS compliance details

Example:

Many Amazon sellers face FBA rejection simply because packaging didn’t pass ISTA 3A testing. Early confirmation prevents costly delays.

Regulatory Standards (US/EU Regulations & Testing)

Factories in China do not automatically apply international regulations—you must specify:

Electronics: CE, FCC, RoHS, REACH

Kids products: CPC, ASTM F963

Mechanical: ISO 12100, EN 60204

Materials: Food-grade, medical-grade, UL94-V0

Insight:

Over 60% of failed product launches come from unmet regulatory requirements, not manufacturing issues.

Pricing Strategy, Target Cost & Business Model

Successful manufacturing requires defining cost from the market backward:

Retail Price – Channel Fees – Profit = Target Manufacturing Cost

Example:

Retail: $49

Channel fee: 30%

Profit target: 25%

→ Target cost = $22

How To Implement Intellectual Property & Risk Protection

Whether you are a startup or an established brand, you must establish a clear protection mechanism before launching a project. This includes signing a compliant NNN agreement, registering trademarks in both Chinese and English in advance, ensuring ownership of molds, and reducing the risk of being copied by reasonably splitting the supply chain.

NDA vs. NNN — Which One Truly Protects You In China?

Most foreign companies believe an NDA is enough—but an NDA alone does NOT protect you in China.

You need an NNN Agreement (Non-Disclosure, Non-Use, Non-Circumvention):

Non-Disclosure

The factory cannot share your designs or files.

Non-Use

They cannot use your design to produce competing products—this is the biggest gap in traditional NDAs.

Non-Circumvention

They cannot bypass you and sell directly to your market or customers.

A European client once used only an NDA, the supplier then produced similar items for other brands using the same mold. After switching to NNN, the issue was resolved.

Trademark Registration In China — Apply Early, Register Chinese Name, Conduct Searches

China follows a“first-to-file”trademark system, so filing early is essential.

You must:

Register before sharing your design

Do this before any supplier sees your files.

Register a Chinese version of your brand

Otherwise, someone else may register a Chinese “nickname” and block you.

Conduct conflict checks

Using Class + Subclass comparison is necessary in China.

A U.S. brand once had their goods held at customs for two months because someone else owned the Chinese version of their trademark.

Mold & Tooling Ownership — Spell It Out in the Contract

Mold disputes are extremely common in Chinese manufacturing.

If ownership is unclear, the factory may prevent you from transferring molds.

Your contract must specify:

Mold ownership: 100% belongs to the buyer

Usage limitations

Mold photos + ID number

Storage and transfer rights

Penalties if the factory refuses release

One North American client paid 20% more for years because the factory refused to release the mold due to vague contract terms.

Reduce Copycat Risks By Splitting The Supply Chain

For complex or high-value products, splitting production is an effective defense.

Methods include:

Produce critical components in separate factories

Example: PCBA, battery, and enclosure sourced independently.

Final assembly at a trusted partner

Only the last factory sees the complete product.

Keep key formulas or parameters confidential

Sensitive processes can be controlled internally.

A medical devices client used a three-factory split strategy, which successfully prevented copycat attempts in the domestic market.

How To Find And Evaluate Reliable Manufacturers In China

To truly understand how to manufacture product in China, selecting the right supplier is the most critical step. China’s supply chain is vast, but quality and transparency vary greatly. A structured approach—online sourcing, trade shows, factory audits, and background verification—ensures you find reliable, long-term manufacturing partners.

Online Sourcing Platforms

Online platforms are the easiest entry into China sourcing:

Alibaba: Best for international buyers, with Trade Assurance for safer transactions.

1688: Lowest domestic prices, ideal for identifying real manufacturers.

Made-in-China / Globalsources: Strong for industrial and mechanical suppliers.

Offline Channels

Offline channels offer clearer insight into a supplier’s capabilities:

Trade shows (e.g., Canton Fair, Shenzhen Manufacturing Expo) allow you to meet hundreds of factories in one place.

Factory visits help verify real machinery, workforce, and quality systems.

Pros & Cons of Working With A Sourcing Agent

Pros

Local communication and negotiation power

Knowledge of processes, materials, and supplier networks

Can perform inspections, audits, and follow-up

Cons

Higher service fees

Risk of agents blocking direct factory access

Recommendation: Use agents for initial filtering but build direct relationships later.

How To Build A Supplier Shortlist

A strong supplier shortlist is built through:

Tracking quotes, lead times, MOQs, and communication speed

Reviewing sample quality and technical competence

Eliminating suppliers who refuse documentation or respond slowly

Comparing quotes against industry averages

Good suppliers respond within 24 hours and provide engineering insights, not just prices.

How To Verify A Factory’s Background

Factory verification prevents costly mistakes:

Business license: Confirm the factory is legally allowed to make your product

ISO certificates: Show maturity of quality systems

Client cases & export markets: Suppliers exporting to EU/US typically maintain higher standards

Pro tip: Ask for their latest 3 inspection reports to judge real quality consistency.

How To Choose A Truly Reliable Factory

Selecting the right Chinese factory is one of the most decisive steps when learning how to manufacture product in China. A reliable supplier determines your quality, cost, lead time, and long-term scalability. This section helps you evaluate factories using structured RFQs, critical questions, due-diligence methods, and product-fit assessments—so you can confidently pick a partner you can trust.

Key Elements Of An RFQ

A professional RFQ (Request for Quotation) is more than a price inquiry—it is a tool to filter out unqualified suppliers.

Technical Details Drive Accurate Pricing

Factories base their quotes on 2D/3D drawings, tolerances, materials, surface finish, BOM, and special processes.

Example: When I request CNC machining quotes, tolerances like ±0.01 mm can increase costs 15–40%.

Absence of detail leads to under-quoting, then raising prices later.

Compliance Standards Ensure Manufacturability

Certifications (ISO9001, IATF16949, RoHS, REACH) reflect the factory’s capability and quality mindset.

Products for U.S./EU markets require clear compliance notes in the RFQ.

Quantity Affects Cost Structure

Chinese factories calculate pricing based on material usage, machine time, and amortized overhead.

Low-MOQ orders may be quoted 20–50% higher.

High-volume orders reduce cost significantly.

Lead Time Predicts Capacity & Reliability

A factory that promises unrealistically fast delivery is often overloaded or inexperienced.

Realistic CNC lead time: 7–15 days

Injection molding lead time: 3–5 weeks

QC Requirements Prevent Hidden Costs

Specify IQC/PQC/OQC requirements upfront.

Clear QC points often reduce defect rates by 30% in my past projects.

Critical Questions To Ask Suppliers

Asking the right questions will quickly reveal whether a factory is transparent, capable, and trustworthy.

MOQ Requirements

Factories with very high MOQs may not fit startups.

A typical CNC shop: 1–50 pcs

Injection molding: 500–5,000 pcs

Price-Change Policy

Ask: “What conditions may trigger a price adjustment?”

Common triggers: material cost changes, tolerance changes, mold revision.

Lead-Time Reliability

Ask for their on-time delivery rate.

Good factories maintain ≥ 95% on-time performance.

Hidden Capabilities

Ask whether they outsource any part.

If a supplier outsources 30–60% of the work, quality consistency may drop.

Supplier Due Diligence

Due diligence reduces risk more effectively than negotiation.

Business Legitimacy Check

Verify:

Business license

Legal representative

Registered capital

Factories with < RMB 1 million registered capital often indicate small, unstable workshops.

ISO Certifications

ISO9001 — general manufacturing

IATF16949 — automotive

ISO13485 — medical

A factory certified for your product category is generally 40–60% more reliable.

Testing & Compliance Records

Request past reports (RoHS, REACH, FCC, CE).

If a supplier refuses, that’s a red flag.

Reputation & Customer Portfolio

Factories with export experience in EU/US markets typically have better quality control.

You may ask:

“Which regions do you export to?”

“Do you have long-term repeat customers?”

How To Tell If A Factory Truly Fits Your Product

Not every factory is suitable for your product—even if they claim “yes, we can.”

Match Their Core Competency

A CNC machining shop specializing in aerospace parts may not be suitable for consumer electronics housings.

Look for factories whose existing production closely matches your needs.

Review Real Sample Quality

Request samples from previous projects.

Surface finish

Tolerance consistency

Assembly fit

If samples vary in quality, expect inconsistent mass production.

Evaluate Communication Efficiency

A trustworthy supplier replies within 12–24 hours with detailed answers.

Slow or vague communication often predicts production delays.

Assess Factory Scale & Equipment

For CNC:

Look for 3-axis + 5-axis machines

Consider whether they own CMM inspection machines

Small workshops struggle with tight tolerances and batch stability.

Conduct a Video or On-Site Audit

Ask the factory to show real production lines via video call.

This immediately exposes fake trading companies.

Prototyping Stage — Confirming Manufacturability

In the journey of how to manufacture product in China, prototyping is the most critical step to confirm whether your product can actually be mass-produced. A clear sampling process, solid sample order terms, standardized evaluation, and a pre-production run will help you catch up to 80% of potential issues before mass production—saving time, cost, and unnecessary risks.

Sample Production Process

Submit design files: 3D/2D drawings, BOM, CTQ requirements. Clear inputs = accurate samples.

Factory DFM review: Evaluates manufacturability, tolerances, materials, weak points.

Prototype schedule: Typical CNC / molding samples take 3–10 days.

Supplier self-inspection: Dimensions, appearance, basic functional checks.

Shipping samples: Usually via DHL/UPS/FedEx (3–7 days).

Pro Tip:

For complex precision parts, request machining photos or videos during sampling.

Sample Order Terms

Lead time: Should be clearly written (e.g., CNC samples in 7 days, molded samples in 15 days).

Revision policy: Agree on 1–2 free revisions, extra changes billed at cost.

Sample fees: High-precision or molded parts may cost more, fees can often be deducted in mass production.

Tooling ownership: Clarify mold/tool ownership, maintenance responsibility, and storage location.

Reminder:

Clear tooling terms prevent disputes later — especially for injection molding.

Sample Evaluation

Dimensional inspection: Use calipers, CMM, or projectors to check all CTQs.

Appearance review: Color, texture, bubbles, scratches, mixed materials, etc.

Functional & strength tests: Electronics require power-on tests, mechanical parts may need load or durability tests.

Material verification: ROHS, material certificates, hardness tests, etc.

Pro Tip:

Use a Sample Evaluation Form with OK/NG items for consistency.

Pre-production Run (PPR)

Purpose: Ensures small-batch production can match sample quality.

Batch size: Typically 20–200 units depending on product type.

Checkpoints:

Batch consistency

Fixture/ jig issues

Cycle time verification

Material batch stability

PPR report: Confirms whether mass production is safe to proceed.

Industry Insight:

A pre-production run catches 70% of mass-production issues ahead of time—crucial for electronics, injection molding, and precision CNC parts.

What Preparations Are Needed Before Production

Before moving into mass production, the key is to confirm every technical and commercial detail.By setting clear contract terms, defining a complete BOM, establishing measurable quality standards, and aligning on a realistic production schedule, you greatly reduce manufacturing risks and ensure smoother, more reliable delivery.

Purchase Contract

A well-defined contract is your protection when manufacturing in China.

Key elements include:

Pricing & Payment Terms: Commonly 30% deposit + 70% before shipment, specify whether mold fees, packaging, testing, or certificates are included.

BOM Details: Every material, grade, and process must be listed to prevent unauthorized substitutions.

Warranty Terms: Define defect rate limits, rework/compensation rules, and warranty duration.

Liability Clauses: Include mold ownership, delay penalties, and force majeure rules.

I once handled a project where unclear BOM details led to a supplier swapping materials—causing a full batch failure. Precise documentation prevents such issues.

Quality Control Plan

Manufacturing in China requires stable and consistent quality—not just output.

A strong QC plan includes:

IQC: Inspect incoming materials (especially CNC metal, plastics, electronics).

PQC: Process inspection to catch tolerance drift, deformation, assembly issues.

OQC: Final inspection using AQL standards to prevent large-scale defects.

Define CTQs (Critical to Quality points) to make quality standards measurable and enforceable.

Production Scheduling & Workflow Management

Production delays occur when your project is not prioritized.

Best practices:

Confirm the full production timeline: pre-production, machining, finishing, assembly, testing.

Set milestone deliverables: sample approval, FAI, mid-production inspection, final inspection.

Establish a communication rhythm: Updates every 2–3 days with photos, videos, or reports.

Tools like Gantt charts, ERPs, or Trello greatly improve visibility and avoid last-minute surprises.

Supply Chain Sustainability & Compliance

For global markets, compliance is non-negotiable.

You should verify:

Material compliance: ROHS, REACH, FDA, CA65, UL, etc.

Environmental & social standards: ISO 14001, SA8000 when required by EU or US buyers.

Traceability systems: Material batches, inspection records, and production logs.

Industries like medical, automotive, and aerospace often require complete upstream traceability.

Mass Production Stage: How To Manage Production And Quality Control

During mass production, risks and costs scale rapidly, making quality control and real-time communication essential.With structured communication, mid-production inspections, and final quality checks, you can identify issues early and deliver consistent, reliable products.

Communication Methods And Reporting During Production

The longer the production cycle, the more important stable communication becomes. Reliable Chinese manufacturers provide weekly or milestone-based updates including photos, videos, and progress reports.

For example, many CNC partners I work with send “progress bundles” containing machining status, surface finishing schedules, and packaging preparation.

Effective practices include

Daily or weekly updates through WeChat, WhatsApp, or email

Requiring a clear production schedule such as a Gantt chart

Setting fixed review meetings

This transparency helps you detect delays, material shortages, or quality deviations before they escalate.

During Production Inspection (DPI)

DPI is one of the most critical checkpoints for preventing batch-wide defects. Conducted when 20%–80% of the goods are finished, DPI identifies dimensional issues, injection molding defects, assembly friction, coating inconsistency, and more.

Third-party inspection teams typically perform dimensional sampling, appearance checks, and functional testing. One of my previous customers skipped DPI for anodized aluminum parts and later received an entire batch with color deviation, resulting in a 10-day delay. After implementing DPI, similar issues never occurred again.

DPI helps

Detect early trends

Avoid last-minute rework

Reduce defect rates and shipping delays

Final Inspection

Final inspection is the last safeguard before shipment. It includes AQL sampling, packaging verification, barcode testing, and quantity confirmation.

For EU/US shipments, additional checks include

Drop-test for packaging durability

Compliance marks such as CE or FCC

Batch traceability

FAI ensures your customer receives ready-to-sell products—not defective items waiting for rework.

Common Quality Issues & Corrective Actions

Common mass-production issues in China include

Dimensional drift from machine wear

Warping or shrinkage in plastic injection

Surface inconsistency such as anodizing color variance

Assembly misalignment or functional failures

Effective corrective actions include

Root cause analysis

Adjusting machining parameters or injection settings

Adding jigs and gauges for assembly

Establishing clear rework standards and deadlines

From my experience managing hundreds of production runs, DPI and FAI can typically reduce defect rates by up to 60%.

How To Get Your Product Delivered: Logistics & International Shipping

When learning how to manufacture product in China, logistics is often overlooked, yet it determines your delivery speed, cost, and customer experience. Choosing the wrong method can lead to delays, unexpected duties, or extra charges. This section explains shipping methods, customs, trade terms, insurance, and cost-saving strategies.

Sea Freight vs Air Freight vs Express

Sea Freight

Best for large-volume, low-urgency shipments. Lowest cost but takes 25–45 days.

Example: A 2000-piece metal parts shipment to the US cost only 20% of the air freight price.

Air Freight

Faster (5–10 days) but more expensive. Ideal for urgent or high-value goods.

Real case: Most CNC-machined parts for equipment repairs are sent by air to avoid downtime.

Express (DHL, FedEx, UPS)

Fastest (3–7 days) but highest cost. Best for samples or small batches.

Example: Automotive aftermarket samples usually use FedEx for easy tracking.

Customs Clearance & Trade Terms

EXW

Buyer handles all transportation and customs. Suitable for advanced buyers.

FOB

Seller delivers to the China port, buyer handles shipping onward. Most common option.

CIF

Seller pays freight and insurance to the destination port but not customs clearance.

DDP

Seller handles everything until the goods arrive at your door. Highest cost but minimal effort for the buyer.

Example: Many EU customers prefer DDP to avoid dealing with VAT and customs.

Freight Forwarders & the Role Of Insurance

Freight Forwarders

They handle booking, customs filing, documentation, and tracking.

A good forwarder can save 10–30% shipping costs and reduce delays.

Transportation Insurance

Goods face risks like damage, moisture, and loss during transit.

Basic cargo insurance is strongly recommended, especially for electronics and metal parts.

How to Optimize Your Shipping Costs

Reduce dimensional weight with efficient packaging

Consolidate shipments to reduce per-shipment fees

Plan production early to avoid urgent air freight

Compare multiple forwarders, prices vary 5–15%

Use local warehouses or FBA prep centers to cut final-mile costs

Example: A US client saved 28% shipping cost by consolidating all weekly orders.

Cost Structure & Profit Calculation

When evaluating how to manufacture products in China, understanding the complete cost structure is essential. Costs span pre-production, manufacturing, and post-production phases. By breaking down each cost element clearly, you can determine whether your product is suitable for China manufacturing and ensure healthy profit margins.

Pre-production Costs

Design

Design costs include industrial, structural, and engineering design.

Provide clear 3D and 2D drawings to avoid misunderstandings.

Use DFM/DFX reviews to eliminate manufacturability issues early.

Outsourced design may cost from a few hundred to several thousand USD.

Tooling

Tooling is a major one-time investment for injection molding, die casting, and silicone.

Tool steel choice affects durability and cost.

Multi-cavity molds reduce unit cost but increase initial investment.

Tool modifications can cost up to 30% of the original tool price.

Samples

Samples validate manufacturability.

CNC samples are fast but expensive.

Sample lead time is usually 3–10 days.

Samples require dimensional checks and functional testing.

Manufacturing Costs

Material

Material often accounts for the highest percentage of the total cost.

Commodity price fluctuations affect material cost.

Material waste must be included in the BOM.

Certified materials require additional fees.

Labor

China still holds a labor cost advantage.

Skilled labor influences polishing, assembly, and QC.

Factories often operate 24/7 for fast delivery.

Labor cost increases for manual processes.

Processing

Includes CNC machining, molding, stamping, welding, etc.

Machine depreciation affects pricing.

Subcontracted processes add uncertainty.

Better stability lowers cost over time.

Packaging

Packaging affects shipping safety and branding.

Inner packaging protects the product.

Outer cartons or wooden crates ensure safety during transit.

Custom packaging raises cost but improves brand value.

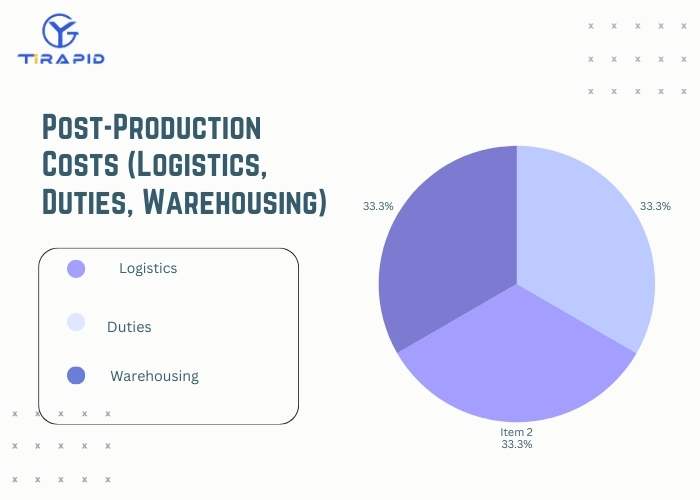

Post-Production Costs (Logistics, Duties, Warehousing)

Logistics

Sea freight: lowest cost but slowest.

Air freight: ideal for high-value or urgent shipments.

Courier: best for samples or small batches.

Duties

Duty rates depend on HS Code.

Additional tariffs may apply (e.g., U.S. 301 tariffs).

Certifications may increase cost.

Warehousing

Domestic consolidation incurs handling fees.

Overseas warehouses (e.g., FBA) have higher costs.

Inventory turnover impacts cash flow.

How To Determine If A Product Fits China Manufacturing

High material content products benefit from China’s raw material cost advantage.

Labor-intensive products achieve lower production cost.

Products requiring complex supply chains fit well in China’s cluster ecosystem.

Technical or custom small-batch products benefit from fast prototyping.

High-volume products reduce per-unit cost significantly when tooling is amortized.

Common Production Mistakes And How To Avoid

When learning how to manufacture product in China, many buyers fall into the same traps: choosing suppliers solely by price, placing orders without design files, failing to define quality requirements, skipping contracts, ignoring inspections, and neglecting IP protection. Avoiding these mistakes will greatly reduce risks, delays, and extra costs.

Relying Too Much On Price

Low price does not equal good value in China manufacturing.

Quotes 30% below market average usually indicate risk

Many buyers who chose the cheapest supplier ended up paying more for rework

Evaluate pricing together with capacity, material sources, and QC systems

Ordering Without Design Files

Factories cannot guess your requirements.

Missing 3D/2D drawings, BOM, and tolerances causes massive variation

After converting a client’s sketch into STEP+2D files, their yield improved by 40%

Technical documentation forms the foundation of consistent manufacturing

Undefined Quality Requirements

Without standards, you cannot enforce quality.

Define tolerances, key dimensions (CTQ), surface finish, and inspection method

If not specified, factories use their own judgement

Clear quality criteria ensure predictable results

No Contract Signed

Verbal promises offer zero protection.

Contracts must include pricing, lead time, warranties, mold ownership, penalties

Attach BOM, drawings, QC criteria

No contract = no accountability when issues occur

Skipping Product Inspections

Most severe quality problems come from no inspections.

Use three checkpoints: IQC, DPI, PSI

Third-party inspection costs only USD 120–300

Inspection should cover measurement, appearance, function tests

No IP Protection

IP issues are real but preventable.

Use an NNN agreement instead of a standard NDA

Register your trademark in China early

Clearly define mold ownership

Use supply-chain separation for sensitive components

FAQs

What Are The Advantages Of Manufacturing Products In China?

When I evaluate how to manufacture product in China, the advantages are clear: highly optimized supply chains, mature industrial clusters, and competitive pricing. China offers labor and production costs that are often 20–40% lower than Western markets. Industrial clusters in cities like Shenzhen, Suzhou, and Ningbo allow 5–20 km sourcing radius, which shortens lead times by up to 30%. With this ecosystem, I can scale from prototype to mass production rapidly and cost-effectively.

Which Products Are Typically Manufactured In China By Multinational Corporations?

When multinational brands plan how to manufacture product in China, they often choose segments that benefit most from China’s mature supply chain. These include consumer electronics (70% of global output), CNC-machined parts, plastic injection parts, apparel, toys, IoT devices, and automotive aftermarket components. I also see Fortune 500 companies produce medical devices, home appliances, and smart hardware in China because suppliers offer certified quality systems such as ISO 9001, ISO 13485, and IATF 16949.

What Difficulties Should Be Considered When Manufacturing Products In China?

When I plan how to manufacture product in China, I must consider several challenges: communication barriers, inconsistent quality control, intellectual property risks, and factory transparency. Up to 45% of production delays I’ve seen are caused by unclear specifications or undocumented revisions. MOQ requirements can be high, and some factories lack strong internal QC systems. Without an NNN agreement, early trademark registration, and strict pre-shipment inspections, the risk of disputes and rework significantly increases.

What Are The Necessary Stages For Manufacturing Products In China?

From my experience, understanding how to manufacture product in China requires following a structured process: product definition, supplier sourcing, RFQ comparison, prototyping, tooling, pre-production runs, mass production, quality inspections, and international logistics. Each stage has measurable impact. For example, First Article Inspection reduces defect rates by 30–60%, and a clear BOM can prevent 80% of common misunderstandings. Following this full workflow ensures predictable costs, stable quality, and on-time delivery.

What Data Should Be Protected When Manufacturing Products In China?

When deciding how to manufacture product in China safely, I must protect core data including CAD files (STEP/IGS), 2D drawings, BOM, CTQ requirements, material specifications, firmware, branding files, and mold ownership documentation. I register trademarks in China early to avoid hijacking and always use an NNN agreement instead of a Western NDA. In my experience, over 60% of IP disputes originate from unclear mold ownership and uncontrolled file sharing—so securing these documents is essential.

Conclusion

Manufacturing a product in China is not simple, but it is a mature and highly proven pathway. With clear documentation, the right factory selection, solid quality control, and proper IP protection, China allows your product to reach the market faster and more competitively. Now it is your turn to take the next step. Where are you in your manufacturing journey? Are you still shaping the idea, preparing prototypes, or already searching for a supplier? Feel free to share your stage with me. I can help assess feasibility, refine your design, or guide you through the full process from concept to mass production.