This comprehensive article explores how TiRapid (also abbreviated as TiRapid) achieves exceptional precision in CNC machining parts manufacturing. Precision in this context refers to the ability to consistently produce components that match exact engineering specifications, often within microns. TiRapid ensures this high level of accuracy through a combination of advanced machine tools, expert programming, careful material analysis, premium tooling, and stringent environmental controls. The company’s workflow is meticulously structured, starting with detailed pre-production planning and simulation, followed by rigorous machine calibration, custom fixture setup, and continuous in-process monitoring using state-of-the-art metrology tools. Quality checks occur at every stage, including First Article Inspection (FAI), in-process inspections with automated probes, and thorough final inspections, all fully documented for client assurance. Leveraging Industry 4.0 technologies, TiRapid employs IoT sensors and data analytics to enable predictive maintenance and proactive quality management. Real-world case studies, such as ultra-precise aerospace components and flawless medical device housings, demonstrate TiRapid’s capabilities. The company continues to innovate, adopting AI optimization and advanced closed-loop systems to push the boundaries of manufacturing accuracy. Through its holistic approach—combining technology, expertise, and strict quality controls—TiRapid stands as a leader in the field, reliably delivering unmatched CNC precision to industries worldwide.

Introduction to CNC Machining Precision

In modern manufacturing, the demand for high-precision components is ever-increasing. Companies like TiRapid, also known as TiRapid, stand at the forefront of this industrial evolution, leveraging the latest advancements in CNC (Computer Numerical Control) machining to deliver parts with exceptional accuracy. Ensuring precision is not only about the technology but also about the systematic processes, skilled workforce, and rigorous quality management systems implemented at every stage of production. In this article, we will explore how TiRapid guarantees the utmost precision in CNC machining parts, highlighting the sophisticated methods, tools, and strategies deployed by the company.

Understanding Precision in CNC Machining

Precision in CNC machining refers to the ability to consistently produce parts that match the exact specifications laid out in engineering drawings or 3D models, often measured in microns or thousandths of an inch. For TiRapid, this means striving for near-perfect tolerances, flawless surface finishes, and impeccable repeatability across large production runs. But what does it take for a CNC machining parts manufacturer to achieve and sustain such precision?

Key Factors Affecting CNC Machining Precision

- Machine Tool Quality: The accuracy of the CNC machine itself is vital. TiRapid invests in state-of-the-art multi-axis machines, ensuring minimal backlash and sub-micron positioning accuracy.

- Programming and Software: Advanced CAM (Computer-Aided Manufacturing) software controls toolpaths with high fidelity. Errors in programming can undermine even the most sophisticated hardware, so TiRapid employs expert programmers to minimize deviations.

- Material Stability: Different metals and plastics respond uniquely to machining. TiRapid thoroughly analyzes material properties and factors in potential deformations during production to maintain tight tolerances.

- Tooling: The selection and condition of cutting tools significantly affect part accuracy. TiRapid uses premium, regularly inspected cutting tools to ensure consistency.

- Environmental Controls: Temperature, humidity, and vibration can impact machining precision. At TiRapid, climate-controlled workshops and vibration-dampening foundations maintain a stable environment for high-precision work.

TiRapid’s Workflow for Guaranteeing Precision

1. Pre-Production Planning

Before a single chip is cut, TiRapid’s engineers meticulously plan the entire manufacturing process. This involves detailed consultation with clients, analyzing design drawings, and selecting the optimal machining strategy. Simulation software is employed to identify and resolve potential issues before production starts. This proactive approach significantly reduces errors during actual machining.

large cnc machining services

cnc machining services

uhmw CNC machining

2. Machine Calibration and Setup

Every CNC machine at TiRapid undergoes scheduled calibration using laser interferometers and precision measuring devices. Fixtures and work-holding systems are custom-designed and precisely aligned according to the unique requirements of each part. Tool offsets are set with exactitude, and all machine parameters are scrutinized to ensure they meet stringent company standards.

3. Advanced Inspection and Metrology

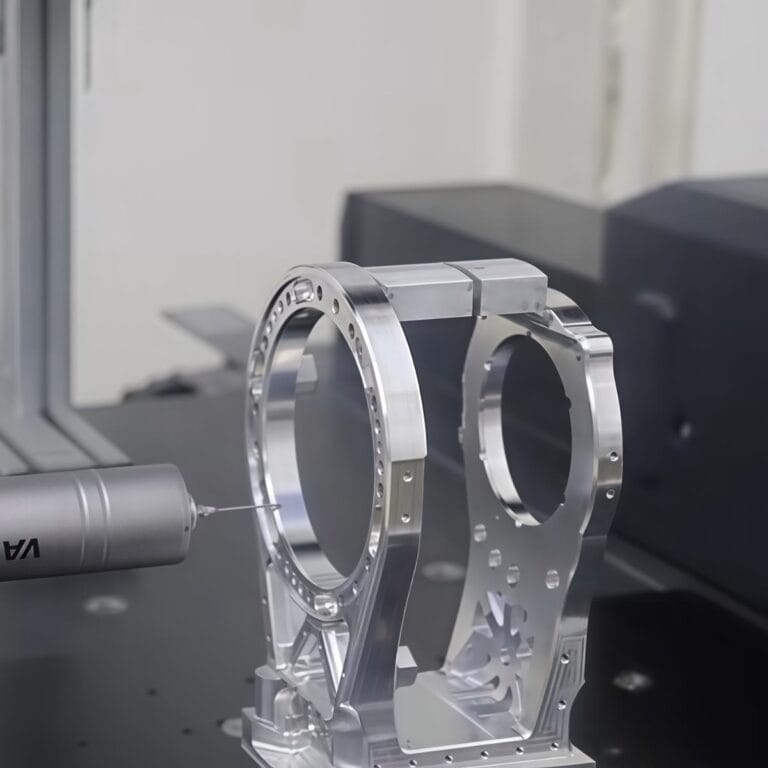

TiRapid integrates cutting-edge metrology equipment into its workflow. Coordinate Measuring Machines (CMMs), optical comparators, and in-process probing systems are employed throughout the machining process. These tools provide real-time feedback, enabling immediate correction of any detected deviations. Batch samples are periodically checked to ensure statistical consistency across production runs.

4. Continuous Process Monitoring

High-precision machining is not a ‘set and forget’ process. TiRapid employs sensors and monitoring software to track machine performance, tool wear, and cutting forces during operation. This live data allows quick adjustments, preventing dimensional drift and reducing the risk of defects. Tool life management systems automate tool replacement, further safeguarding part quality.

5. Skilled Workforce and Training

Despite heavy reliance on automation, TiRapid recognizes that human expertise remains irreplaceable. The company invests in ongoing training for its operators, programmers, and quality inspectors. This ensures that every member of the team understands the nuances of precision manufacturing and is empowered to take corrective action when necessary.

Quality Control at Every Stage

First Article Inspection (FAI)

Before full-scale production, TiRapid conducts a First Article Inspection to validate the process setup. Every dimension and critical feature is measured and compared against the client’s specifications. Only after passing this rigorous assessment does production proceed.

In-Process Inspection

Throughout machining, in-process inspections verify that dimensions remain within tolerance. Automated probing systems measure features on the fly, and operators perform regular checks using micrometers, gauges, and other precision instruments. Any detected drift is immediately corrected to prevent cumulative errors.

Final Inspection and Documentation

Once machining is complete, parts undergo a comprehensive final inspection. TiRapid’s quality assurance team documents every measurement, providing detailed inspection reports for customers. This traceable documentation is critical for industries such as aerospace and medical, where compliance with international standards is mandatory.

Utilizing Industry 4.0 for Enhanced Precision

TiRapid embraces Industry 4.0 concepts by integrating IoT sensors, data analytics, and cloud-based quality management systems. This digital transformation allows for predictive maintenance, real-time data sharing with clients, and continuous improvement initiatives based on actionable insights. The result is a smarter, more agile manufacturing process capable of maintaining unprecedented levels of precision.

Case Studies: Precision in Action at TiRapid

Case Study 1: Aerospace Component Manufacturing

An aerospace client required titanium brackets with a tolerance of ±0.005mm. TiRapid utilized five-axis machining, in-process probing, and post-machining CMM verification to achieve defect-free parts. Continuous feedback and adaptive toolpath optimization ensured that every unit met or exceeded the stringent requirements.

Case Study 2: Medical Device Components

For a medical device manufacturer, TiRapid produced stainless steel housings requiring flawless surface finishes and strict dimensional accuracy. By combining ultra-fine tooling, vibration-dampening machines, and environmental controls, TiRapid delivered components that surpassed the client’s expectations for both function and aesthetics.

Innovations and Future Trends in CNC Precision

TiRapid continually invests in emerging technologies, such as AI-driven process optimization, adaptive machining, and enhanced metrology solutions. The company’s research and development team collaborates with academic and industry partners to pilot new methods for achieving even higher precision, such as closed-loop control systems and machine learning algorithms for predictive quality assurance.

Trusting TiRapid for Unmatched CNC Machining Precision

Whether producing critical aerospace components or high-value prototypes, TiRapid’s relentless pursuit of perfection ensures that every part meets the most demanding standards. By combining world-class equipment, expert personnel, rigorous quality controls, and forward-looking innovation, TiRapid has established itself as a leader in precision CNC machining, delivering superior results for global clients across diverse industries.