In today’s manufacturing industry, CNC machining technology plays a vital role, and the selection of metal materials often determines the success of a project. When it comes to hard metal vs soft metal, each category has distinct properties that bring unique advantages and limitations in different application scenarios. Understanding their characteristics, differences, and selection strategies is essential for achieving the best results in CNC machining. In this article, I’ll guide you through an in-depth look at these two types of metals, helping you make informed and practical decisions for your projects.

What Is Metal

Metals are among the earliest materials discovered and used by humans, dating back over 7,000 years to the Bronze Age and Iron Age. Early civilizations learned to extract metals like copper, tin, and iron from ores through smelting—a process that transformed human technology, leading to stronger tools, weapons, and machines.

From a microscopic point of view, the metallic bond gives metals their unique combination of strength, ductility, and conductivity. Depending on composition and atomic arrangement, metals can be divided into hard metals—such as tungsten steel, tool steel, and titanium alloys—and soft metals, including aluminum, copper, and brass.

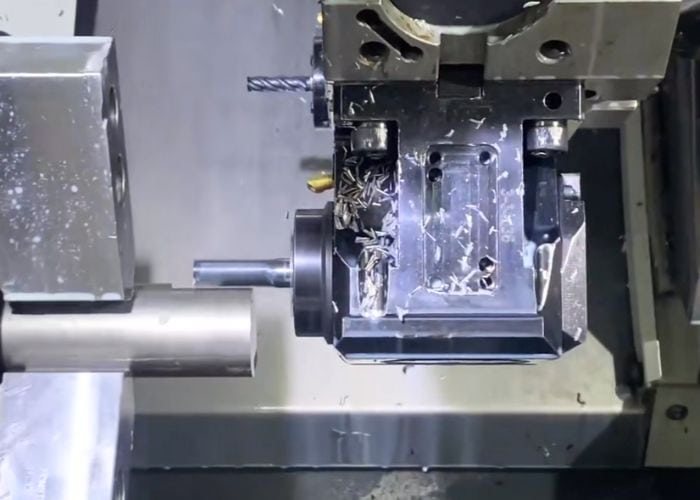

In modern manufacturing, metals play an irreplaceable role. Hard metals are used for high-strength, wear-resistant components like cutting tools, molds, and aerospace parts, while soft metals are favored for their ductility and ease of machining, ideal for electronic housings, automotive heat exchangers, and decorative products.

In short, metal is the foundation of engineering materials, combining mechanical strength, electrical performance, and formability, making it indispensable across industries from aerospace to everyday consumer goods.

What Is Hard Metal

Hard metal, also known as cemented carbide, originated in Germany in the 1920s when researchers developed a method to combine tungsten carbide (WC) particles with a metallic binder such as cobalt. This innovation—initially designed to replace diamond tools—revolutionized modern machining by providing a material nearly as hard as diamond but far more affordable and machinable.

Essentially, hard metal is a composite material formed by sintering fine carbide powders with a binder metal under high temperature and pressure. The carbide gives it extreme hardness (up to 94 HRA), while the metal binder provides toughness and prevents brittleness. This unique microstructure ensures excellent wear resistance, high strength, and thermal stability, even in harsh conditions.

Today, hard metals are indispensable in manufacturing industries. They are widely used for cutting tools, molds, aerospace components, and high-pressure mechanical parts. For instance, tungsten carbide inserts in stamping dies extend mold life from hundreds of thousands to millions of cycles, while titanium alloys in jet engines maintain strength above 1,600 °C.

In summary, hard metals represent the perfect balance between hardness and toughness, making them the backbone of precision machining and advanced industrial production worldwide.

What Is Soft Metal

Soft metals have accompanied human civilization since its earliest days. The discovery and use of copper and gold in the Neolithic and Bronze Ages (around 5000–3000 BC) marked the beginning of metalworking history. These easily malleable and ductile materials could be shaped by hammering or casting without breaking—unlike hard, brittle stones. Over time, humans refined smelting and alloying techniques, producing materials such as bronze (copper-tin) and later aluminum and magnesium alloys, which revolutionized modern industry.

Scientifically, soft metals refer to metals with low hardness but high ductility and plasticity. Their atoms are arranged in relatively loose metallic bonds, allowing layers of atoms to slide over one another easily under stress. This gives soft metals their excellent machinability, electrical and thermal conductivity, and formability, making them essential in industries like electronics, transportation, architecture, and consumer goods.

Today, soft metals such as aluminum, copper, and brass are indispensable in manufacturing. They enable lightweight designs, efficient heat transfer, and precision forming, providing both performance and cost efficiency. In CNC machining, their low hardness allows for higher cutting speeds and smoother finishes—ideal for modern precision manufacturing.

In short, soft metals are the foundation of lightweight and high-efficiency design, combining flexibility with functionality to support everything from smartphones to spacecraft.

Difference Between Hard Metal and Soft Metal

The difference between hard metal and soft metal lies not only in hardness, but also in atomic structure, mechanical behavior, and processing characteristics. Hard metals are designed for strength and durability under extreme stress, while soft metals focus on ductility, conductivity, and cost-efficiency. Understanding these distinctions helps engineers choose the right material for each specific manufacturing or design requirement.

1. Hardness and Strength

Hard metals, such as tungsten carbide, tool steel, and titanium alloys, exhibit extremely high hardness and compressive strength. For instance, the hardness of tungsten carbide can reach 80–94 HRA, far exceeding that of aluminum alloys (30–100 HB). This makes them ideal for cutting tools, molds, and aerospace components that must endure high pressure, friction, and wear.

Soft metals like aluminum, copper, and brass, on the other hand, have lower hardness but excellent toughness and ductility. Aluminum’s elongation of 20–40% allows it to absorb impact energy without cracking, which is why it’s widely used in automotive bumpers and vibration-resistant components. In other words, hard metals resist deformation, while soft metals deform safely to absorb energy.

2. Processing and Machinability

Hard metals are more difficult to process. Their high hardness leads to increased cutting forces, tool wear, and heat generation, requiring specialized coatings (like TiN or AlTiN), low cutting speeds, and efficient coolant systems. For example, when machining titanium alloys, cutting speeds are often 50–80% lower than when machining aluminum, and tool life depends heavily on cooling strategy.

Soft metals, by contrast, are easier to machine. Their lower hardness means higher cutting speeds and feed rates can be used, significantly improving productivity. However, issues like chip entanglement and surface roughness must be managed carefully. In CNC machining of aluminum alloys, engineers often use tools with large rake angles and chip breakers to prevent sticking and ensure a clean surface finish.

3. Cost and Application Scenarios

In terms of cost, hard metals are more expensive due to complex production and processing requirements. They are irreplaceable in high-end and critical industries, such as aerospace, defense, and precision mold manufacturing, where performance is more important than price.

Soft metals, meanwhile, offer excellent cost efficiency and are ideal for large-scale production where weight reduction and manufacturability are key. In automotive manufacturing, for example, hard metals are used in engine pistons and crankshafts, while soft metals like aluminum alloys are used for frames, housings, and brackets, reducing overall weight and cutting production costs by 20–30%.

In short, hard metals prioritize strength and durability, making them ideal for high-stress environments, while soft metals excel in machinability, conductivity, and cost-effectiveness, supporting mass production. A smart combination of both—like using titanium for high-load parts and aluminum for lightweight structures—helps achieve the perfect balance between performance, efficiency, and cost.

How To Choose The Right Metal For CNC Machining

Choosing metals suitable for CNC machining requires comprehensive consideration of application scenario requirements, cost and efficiency, processing equipment and technical requirements, etc. Hard metals are suitable for high-performance fields due to their excellent wear resistance and strength, while soft metals are suitable for mass production applications due to their good machinability and cost advantages.

The following is a table I made to help you analyze how to scientifically select metal materials from multiple aspects :

| Factor | Hard Metal | Soft Metal |

| Application scenario requirements | – Suitable for high temperature, high pressure and high wear environment. – Examples: aircraft engine blades (titanium alloy), industrial cutting tools (cemented carbide). | – Suitable for scenes with complex shapes, light weight but low strength requirements. – Examples: electronic housing (aluminum alloy), automotive interior parts (magnesium alloy). |

| Material Cost | 5-10 times that of ordinary aluminum alloy . | 50%-70% cheaper than hard metals . |

| Processing Cost | – High tool cost: Carbide tools are 2-3 times more expensive than high-speed steel tools. – Long processing time: The processing time is 2-3 times that of soft metals . | – High processing speed: cutting speed up to 1000-3000 m/min . – Reduce production cost by about 15%-25% and shorten production cycle. |

| Mechanical Properties | – High hardness and strength: The hardness of cemented carbide reaches 80-94HRA , suitable for high loads and harsh conditions. | – Better toughness: For example, the elongation of aluminum alloy can reach 20%-40% , which is suitable for scenarios with high requirements for impact toughness. |

| Wear Resistance And Fatigue Performance | – Excellent wear resistance, suitable for long-term use in high friction conditions, such as engine crankshafts and gear parts. | – Less wear resistance, but performs well in scenarios where stress is not frequent. |

| Processing Difficulty | – Difficult cutting: low cutting speed and efficient cooling system are required (coolant pressure can reach 10-20 MPa ). | – Excellent processing performance in CNC milling and CNC turning — achievable with standard CNC machines by optimizing tool design to reduce chip entanglement. |

| Equipment Requirements | – High-end equipment: high-speed cutting machine tools (spindle speed 20,000 rpm ), and high-performance tools such as diamond-coated tools are required. | – Ordinary CNC machine tools can meet the processing requirements, and the equipment cost is relatively low. |

| Typical Application Scenarios | – Aerospace: such as titanium alloys for turbine blades and fuselage structures. – High-end molds: such as cemented carbide molds. | – Consumer electronics: such as aluminum alloy housings. – Automobiles: such as aluminum alloy brackets and magnesium alloy parts to reduce weight and costs. |

| Processing Efficiency | – Long processing time, suitable for high value-added, small batch production. | – Fast processing speed, suitable for large-scale batch production, improving efficiency and reducing costs. |

| Economical | – Long-term economical: high-performance applications in high-end fields can offset high costs and are suitable for critical components and high-precision requirements. | – Short-term economic efficiency: low cost, high efficiency, suitable for scenarios with low performance requirements, and widely used in the production of general mechanical parts. |

FAQs

Is Gold A hard Or Soft Metal?

Gold is a soft metal. I remember that its Brinell hardness is only about 25 HB , which is softer than most metals. The gold jewelry we often see is easily scratched because the hardness of pure gold is very low. However, gold has very good ductility. For example, 1 gram of gold can be stretched into a 3,000-meter-long gold wire or hammered into a 1-square-meter gold foil.

Is Silver A Hard Or Soft Metal?

Silver is a soft metal with a Brinell hardness of about 24 HB , which is similar to gold, but slightly harder. Pure silver is also easily scratched and may wear out over time. However, silver is also very ductile. For example, 1 gram of silver can be stretched into more than 2,000 meters of silver wire .

What Is The Hardest Metal In The World?

The hardest metal in the world is chromium. Its Mohs hardness is as high as 8.5 and its Brinell hardness is 700 HB , which is much higher than ordinary metals. I once read that chromium can still maintain extremely high hardness under high temperature conditions, so it is widely used in the manufacture of cutting tools and wear-resistant coatings .

Is Titanium A Hard Or Soft Metal?

Titanium is a hard metal, but it has a good balance between hardness and toughness. The Brinell hardness of titanium is usually between 200-400 HB , and the tensile strength of titanium alloys, such as the commonly used Ti-6Al-4V, can reach 950 MPa .

What Is The Softest Metal In The World?

The softest metal in the world is cesium. Its Brinell hardness is only 0.2 HB , and it can be scratched with a fingernail. The melting point of cesium is also very low, about 28.5°C , and it will become liquid at a slightly higher room temperature in the summer. I remember that cesium is very chemically active and will react violently immediately when it comes into contact with water. Although this metal is soft, its application is irreplaceable in some high-tech fields, such as atomic clocks.

What Is The Difference Between Hard Copper And Soft Copper?

The difference between hard copper and soft copper lies in their processing methods and usage scenarios. Hard copper has not been annealed, has high strength, and its tensile strength can reach more than 200 MPa , which is suitable for use in places where high strength is required. After annealing, the ductility of soft copper is significantly improved, and the elongation can reach 40%-50% , which is more suitable for use in places that require bending and forming. I personally prefer to use soft copper to make parts with complex shapes, which is easier to process.

If The Hardness Of A Metal Increases, What Happens To Its Brittleness?

Increased hardness usually means increased brittleness. I remember once processing high carbon steel. After hardening, the hardness was as high as 60 HRC , but it broke easily when impacted. The reason is simple. The hardening process restricts the movement of crystal dislocations inside the material, and the plastic deformation capacity is greatly reduced.

Conclusion

Hard metal and soft metal have their own characteristics in CNC processing. Hard metal is suitable for high precision and extreme environments due to its high strength, wear resistance and high temperature resistance, while soft metal is more suitable for large-scale production and lightweight design due to its good machinability and low cost. In actual selection, we need to choose according to comprehensive factors such as specific application scenarios, processing efficiency and economy to help our projects be successfully completed.