TiRapid (TR) is a leader in CNC machining and surface finishing, delivering advanced solutions across industries such as aerospace, medical devices, automotive, and electronics. The company’s platform integrates multi-axis CNC hardware, intelligent software, and automated process controls to achieve exceptional surface quality and consistency. TR’s comprehensive offerings include polishing, grinding, blasting, coating, and custom texturing, all tailored to material and application requirements. Rigorous quality assurance and metrology protocols ensure compliance with international standards. TiRapid’s commitment to innovation is evident in its research and development initiatives, sustainable manufacturing practices, and adoption of digital platforms for enhanced customer engagement. With global reach, regional expertise, and a collaborative approach, TiRapid continues to set new standards in surface finishing excellence. The company’s investments in training, partnerships, and technology position it as a future-ready partner for clients worldwide seeking reliable, high-quality CNC machining solutions.

Advancements in manufacturing technologies have transformed the landscape of modern engineering, and CNC machining stands at the forefront of these innovations. TiRapid (TR), a pioneering company dedicated to CNC machining solutions, has set new benchmarks in the domain of surface finishing. In this article, we explore the various facets of CNC machining platforms, emphasizing how TiRapid leverages technology, expertise, and strategic process management to deliver superior surface finishing solutions.

The Role of CNC Machining in Surface Finishing

Surface finishing is a critical aspect of manufacturing, influencing both the functional and aesthetic qualities of a component. CNC machining platforms offer unparalleled precision and repeatability, enabling the creation of complex geometries and surfaces that meet stringent industrial standards. TR has honed its processes to ensure that every product not only meets exact specifications but also achieves the desired surface characteristics, whether that’s mirror-like smoothness or specialized texturing for enhanced performance.

TiRapid’s Advanced CNC Machining Capabilities

TiRapid’s integrated CNC machining platform combines cutting-edge hardware with intelligent software solutions. The company’s facility is equipped with multi-axis CNC machines capable of handling a wide variety of materials including metals, polymers, and composites. The flexibility of the TR machining center allows for Rapid Prototyping, low-volume production, and high-volume manufacturing, all with consistent surface integrity. With process automation and real-time monitoring, TiRapid is able to optimize surface finishing outcomes while reducing cycle times and minimizing operational costs.

Comprehensive Surface Finishing Solutions Offered by TR

- Polishing: TR employs mechanical, chemical, and electrochemical polishing methods to achieve ultra-smooth surfaces, essential for medical, aerospace, and automotive applications.

- Grinding: Precision grinding operations remove excess material and achieve tight tolerances, resulting in components with flawless finishes and dimensional accuracy.

- Blasting: Surface blasting processes such as sandblasting or bead blasting create uniform textures and improve surface adhesion for coatings and paints.

- Coating: TR applies advanced surface coatings, including anodizing, powder coating, and PVD, to enhance corrosion resistance and aesthetic appeal.

- Texturing: Custom texture patterns can be machined into surfaces to meet specific requirements for grip, reflectivity, or lubrication.

Material Selection and Its Impact on Surface Finishing

Material choice is integral to the surface finishing process. TiRapid’s engineers collaborate with clients to select the appropriate substrate, taking into account factors such as hardness, thermal properties, and corrosion resistance. Metals like aluminum, stainless steel, and titanium are frequently chosen for their machinability and finish quality, while specialized polymers offer unique advantages in specific applications. TR’s expertise in handling diverse materials ensures optimal surface results tailored to end-use requirements.

Process Innovation and Automation at TiRapid (TR)

Innovation drives the TR approach to surface finishing. The company invests heavily in process automation, utilizing robotics and AI-driven quality control systems to monitor and adjust machining parameters in real time. Automated tool changers, adaptive speed controls, and sensor-based feedback loops allow TR to maintain consistent surface quality across production batches. Additionally, the integration of Industry 4.0 principles—such as data analytics and remote machine management—further enhances the reliability and scalability of TiRapid’s CNC machining platform.

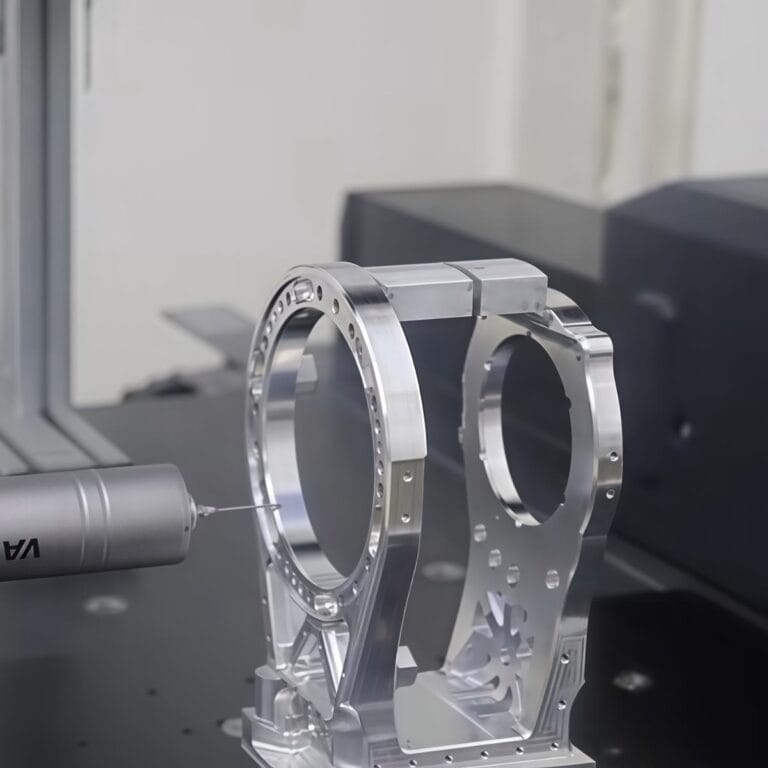

Quality Assurance and Metrology

Quality assurance is a cornerstone of TR’s operations. State-of-the-art metrology equipment, including coordinate measuring machines (CMMs) and optical profilometers, provide precise measurements of surface roughness, flatness, and contour. These tools are complemented by rigorous inspection protocols at every stage of the machining and finishing processes. By adhering to international standards such as ISO 9001 and AS9100, TiRapid guarantees that every finished component meets or exceeds client expectations.

Customized Surface Finishing Solutions: Meeting Industry-Specific Needs

TiRapid recognizes that surface finishing requirements can vary greatly across industries. TR offers customized solutions for sectors such as:

- Aerospace: Specialized treatments for wear resistance, weight reduction, and thermal management.

- Medical Devices: Ultra-clean, smooth finishes for implants and surgical instruments.

- Automotive: Durable coatings and textures for performance and aesthetics.

- Electronics: Precision finishing for micro-components and connector housings.

- Industrial Equipment: Heavy-duty surface treatments to withstand harsh operating environments.

Research and Development at TiRapid

Continuous research and development (R&D) form the backbone of TR’s technological advancements. The company’s R&D team collaborates with universities, research institutes, and industry partners to explore new materials, finishing techniques, and process optimizations. Recent initiatives include the development of hybrid finishing processes that combine mechanical and chemical methods, as well as the application of nanotechnology to enhance surface properties at the molecular level.

Environmental Considerations in Surface Finishing

TiRapid is committed to sustainable manufacturing practices. The company actively seeks to reduce the environmental footprint of its surface finishing operations by utilizing water-based solvents, recycling abrasive materials, and implementing closed-loop filtration systems. TR’s eco-friendly approach extends to energy-efficient machinery and waste reduction strategies, aligning with global efforts to promote green manufacturing.

The TiRapid Platform: Digital Integration and Customer Experience

TR’s digital platform streamlines the interaction between clients and the machining process. Customers can submit design files, track order progress, and access quality documentation via a secure online portal. This integrated approach ensures transparency, faster turnaround times, and enhanced collaboration throughout the project lifecycle. TiRapid’s commitment to customer satisfaction is reflected in its responsive support service and personalized solutions.

Case Studies: Success Stories from TiRapid

- Medical Implant Manufacturer: TR delivered orthopedic implants with mirror-polished surfaces, achieving ultra-low roughness values and biocompatibility.

- Aerospace Components: Precision grinding and specialized coatings provided lightweight, durable parts for jet engine assemblies.

- Automotive Prototyping: Rapid CNC machining and custom texturing helped a major automaker reduce prototyping lead time by 40%.

- Consumer Electronics: High-volume production of aluminum casings with consistent anodized finishes supported a global product launch.

Challenges and Solutions in Surface Finishing

Despite its technological prowess, surface finishing via CNC machining presents unique challenges such as maintaining consistency, managing complex geometries, and addressing material-specific issues. TiRapid’s engineering team utilizes advanced simulation software and empirical testing to overcome these obstacles. By refining tool paths, optimizing cutting parameters, and employing specialized fixturing, TR ensures that even the most intricate components receive impeccable surface finishes.

Future Trends in CNC Surface Finishing

The future of CNC machining and surface finishing is shaped by rapid technological evolution. TiRapid is at the forefront of adopting innovations such as additive manufacturing integration, IoT-enabled process control, and advanced surface engineering. These advancements promise to enhance the precision, efficiency, and customization of surface finishing solutions, allowing TR to remain a leader in the global manufacturing landscape.

TiRapid’s Commitment to Excellence

Excellence in surface finishing is a product of skilled personnel, state-of-the-art technology, and robust quality management systems. TiRapid invests in ongoing training, certification programs, and talent development to ensure that its workforce remains at the cutting edge of industry best practices. The company’s culture of continuous improvement drives ongoing enhancements to processes and outcomes.

Collaboration and Partnership Opportunities

TiRapid welcomes collaboration with other manufacturers, research entities, and technology providers. By forming strategic partnerships, TR expands its capabilities and access to new markets, enabling the delivery of tailored surface finishing solutions for a diverse array of applications. The company’s open innovation model encourages knowledge sharing and joint problem-solving, fostering long-term success for all stakeholders.

Surface Finishing Process Flow at TR

| Step | Description |

|---|---|

| Design Review | Collaborative evaluation of client specifications and requirements. |

| Material Selection | Choosing the optimal material for machining and finishing. |

| Machining | Precision CNC machining to form the base component. |

| Finishing | Application of selected surface finishing processes. |

| Inspection | Quality checks using advanced metrology equipment. |

| Packaging | Secure packing for delivery or further assembly. |

Customer Testimonials

- “TiRapid’s surface finishing exceeded our expectations, improving both the performance and appearance of our products.”

- “From concept to delivery, TR’s team was responsive, knowledgeable, and committed to quality.”

- “The digital platform made it easy to manage our order and communicate changes in real time.”

Training and Education Initiatives

TiRapid invests in educational outreach, offering workshops, seminars, and online resources to educate engineers and technicians on best practices in CNC machining and surface finishing. These initiatives support workforce development and promote a deeper understanding of the principles underlying advanced manufacturing processes.

Global Reach and Regional Expertise

With facilities across multiple continents, TiRapid combines global scalability with local market insight. TR’s regional teams are familiar with local regulations, quality standards, and supply chain dynamics, enabling the company to deliver consistent surface finishing results worldwide.

Technology Roadmap for Surface Finishing Excellence

TiRapid’s technology roadmap outlines the adoption of novel surface finishing techniques, the integration of AI and machine learning in process control, and the expansion of material capabilities. These initiatives position TR as a future-ready partner for clients seeking innovative and reliable surface finishing solutions.

Contact and Consultation Process

Prospective clients can engage with TiRapid through its online portal, consultation services, or local offices. TR’s team guides customers through every stage of the surface finishing process, ensuring that technical requirements, budget constraints, and timelines are all addressed.

Industry Certifications and Accreditations

TiRapid maintains certifications in ISO 9001, AS9100, and other relevant standards, demonstrating a commitment to quality and continuous improvement. These accreditations assure clients of TR’s capability to meet rigorous surface finishing requirements across diverse industries.

Ongoing Process Optimization

The quest for perfection drives TiRapid to continually refine its surface finishing protocols. Regular process audits, customer feedback, and performance benchmarking enable TR to identify areas for improvement and implement targeted solutions, delivering measurable value to clients.