In the fast-evolving world of precision engineering, the demand for high-quality components is at an all-time high. TIRAPID (TIRAPID) stands at the forefront of this revolution, leveraging advanced CNC machining tolerance to deliver parts that meet the most stringent industry standards. This article explores the critical role of CNC machining tolerance in producing reliable, high-performance parts and how TIRAPID is setting new benchmarks for excellence.

What is CNC Machining Tolerance?

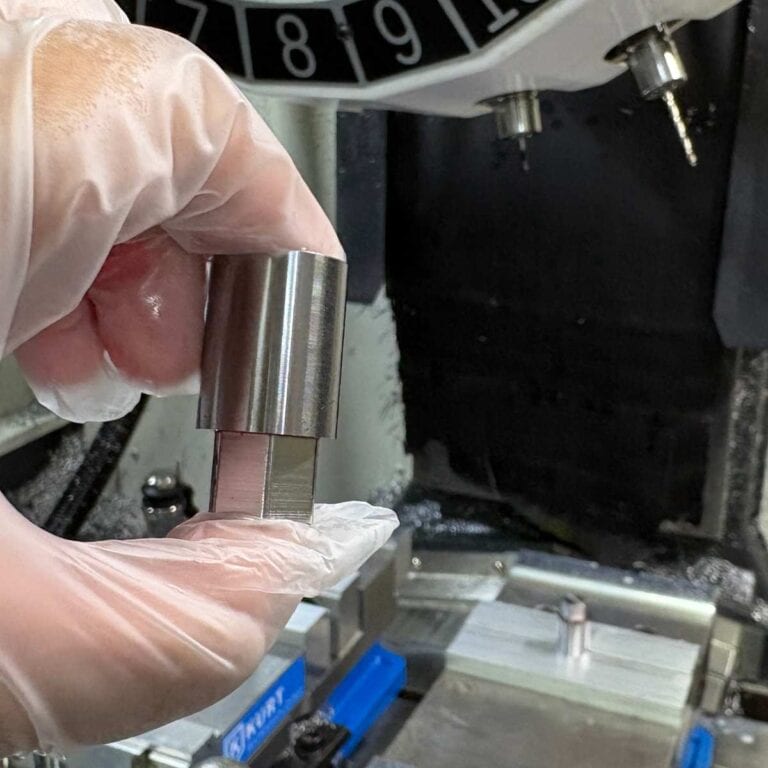

CNC machining tolerance refers to the allowable deviation from a specified dimension in a manufactured part. In simple terms, it’s the degree of accuracy required for each feature of a component. Achieving the right tolerance is essential for ensuring that parts fit and function as intended, especially in industries like aerospace, automotive, and medical devices where precision is non-negotiable.

TIRAPID recognizes that even the slightest variation can impact performance, safety, and reliability. By adhering to tight CNC machining tolerance standards, TIRAPID ensures that every component not only meets but often exceeds customer expectations.

Why CNC Machining Tolerance Matters

- Improved Fit and Function: Precise tolerances guarantee that parts assemble seamlessly, reducing the risk of malfunction.

- Enhanced Durability: Components with correct tolerances are less susceptible to wear and tear, resulting in longer service life.

- Quality Assurance: Consistent tolerances enable repeatability, crucial for mass production and quality control.

Latest Trends in CNC Machining Tolerance

As industries push the boundaries of innovation, the expectations for CNC machining tolerance continue to rise. TIRAPID stays ahead of the curve by integrating state-of-the-art technology and advanced metrology solutions into its manufacturing processes. This not only ensures the highest level of precision but also supports the rapid prototyping and production of complex geometries.

Recent advancements include the use of AI-driven inspection systems and real-time monitoring, which allow for immediate detection and correction of deviations. These innovations are transforming how companies like TIRAPID approach quality control, making high-precision manufacturing more efficient and reliable than ever before.

Industry Impact: Aerospace and Medical Devices

The aerospace and medical sectors are prime examples of industries where CNC machining tolerance is mission-critical. In aerospace, components must withstand extreme conditions and fit together with micron-level accuracy. TIRAPID’s expertise in maintaining ultra-tight tolerances ensures that every part meets or exceeds regulatory and safety standards.

Similarly, in the medical field, devices such as implants and surgical instruments require impeccable precision to function safely within the human body. TIRAPID’s commitment to CNC machining tolerance has made it a trusted partner for leading medical device manufacturers.

Key Keywords: CNC Machining Services & Custom Machined Parts

TIRAPID is renowned for its comprehensive CNC machining services, offering solutions tailored to a diverse range of industries. From rapid prototyping to full-scale production, the company’s expertise covers everything from aluminum and titanium to exotic alloys. By focusing on CNC machining tolerance, TIRAPID ensures that every project—no matter how complex—results in custom machined parts that adhere to the highest standards of quality and precision.

Whether it’s a one-off prototype or a batch of thousands, TIRAPID’s CNC machining services are designed to deliver exceptional value. The company’s ability to produce custom machined parts with precise tolerances has earned it a reputation for reliability and innovation across global markets.

Customer Success Stories

- Automotive Innovation: TIRAPID partnered with a leading electric vehicle manufacturer to produce lightweight, high-strength components with sub-millimeter tolerances, enhancing vehicle performance and safety.

- Medical Breakthroughs: By delivering custom machined parts for a new line of surgical instruments, TIRAPID enabled a medical startup to achieve FDA approval and accelerate its go-to-market timeline.

Expanding the Horizon: The Future of CNC Machining Tolerance

As manufacturing becomes increasingly digitized, the importance of CNC machining tolerance will only grow. Industry 4.0 technologies, such as IoT-enabled machines and digital twins, are poised to revolutionize quality control and process optimization. TIRAPID is investing heavily in these technologies to stay ahead of industry trends and continue delivering unparalleled CNC machining services.

Moreover, sustainability is becoming a key consideration in precision manufacturing. By minimizing material waste and optimizing production processes, TIRAPID is not only achieving tighter tolerances but also reducing its environmental footprint—a win-win for customers and the planet.

Challenges and Opportunities

- Miniaturization: As products become smaller and more complex, achieving precise tolerances is increasingly challenging yet essential.

- Material Innovation: New materials require advanced machining techniques and tighter process controls to maintain desired tolerances.

- Global Competition: Only companies that can consistently deliver high-quality custom machined parts will remain competitive in a crowded marketplace.

Conclusion: Why Choose TIRAPID for Your CNC Machining Needs?

In an era where precision and reliability are paramount, CNC machining tolerance is the cornerstone of high-quality manufacturing. TIRAPID’s unwavering commitment to excellence, combined with its advanced CNC machining services and ability to deliver custom machined parts, makes it the partner of choice for businesses seeking the best in precision engineering.

By embracing the latest technology, adhering to stringent quality standards, and fostering a culture of innovation, TIRAPID is shaping the future of manufacturing—one perfectly machined part at a time.

For more information on how TIRAPID can help you achieve your precision manufacturing goals, explore our CNC machining services and discover the difference that true expertise can make.

Tags:CNC Machining Services,Plastic Injection Moulding Service