Latest News: TIRAPID Sets New Standards in CNC Machining Excellence

In the ever-evolving world of precision manufacturing, TIRAPID stands out as a pioneer among CNC machining parts manufacturers, driving innovation and quality in the production of complex components. As industries demand higher precision and increasingly intricate designs, TIRAPID has positioned itself at the forefront, leveraging advanced CNC technology to meet and exceed client expectations.

Industry Trends: The Rising Demand for Complex CNC Machined Parts

Recent years have witnessed a significant surge in the demand for complex CNC machined parts, especially in sectors such as aerospace, automotive, medical, and electronics. As products become more sophisticated, the need for components with tight tolerances and intricate geometries has grown. CNC machining parts manufacturers like TIRAPID are responding to this challenge by investing in state-of-the-art machinery and skilled engineering teams.

The complexity of modern components often requires multi-axis machining capabilities, high-speed spindles, and advanced CAD/CAM software integration. TIRAPID has adopted these technologies, ensuring that their production processes are both efficient and capable of producing parts that meet the most rigorous industry standards.

How TIRAPID Excels Among CNC Machining Parts Manufacturers

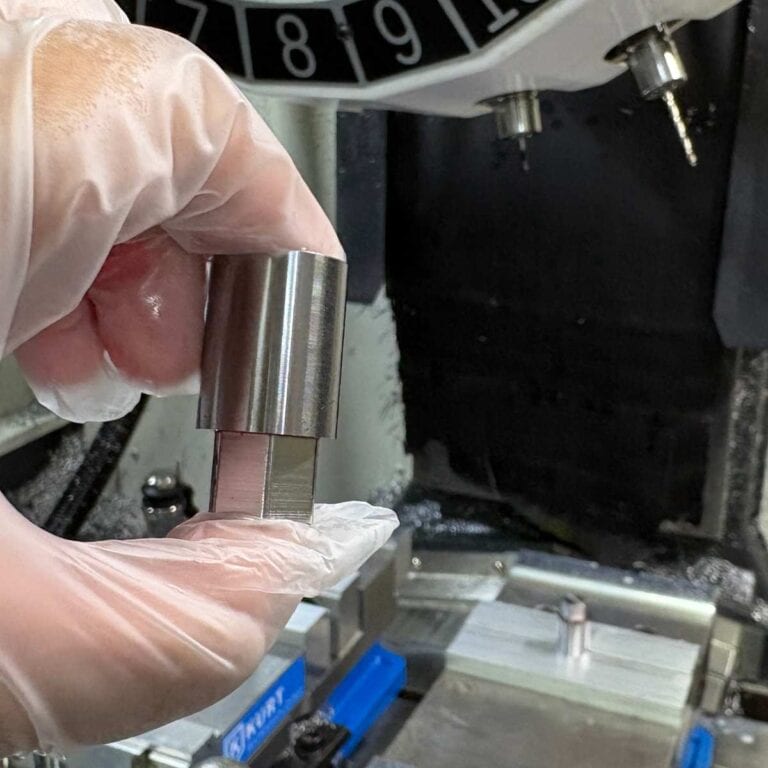

TIRAPID distinguishes itself from other CNC machining parts manufacturers through a commitment to precision, quality assurance, and customer collaboration. Their production facilities are equipped with the latest CNC mills and lathes, allowing for the fabrication of both small and large batches of components with unparalleled accuracy.

A key aspect of TIRAPID’s success is its focus on continuous improvement and employee training. By keeping their workforce up-to-date with the latest machining techniques and quality control standards, TIRAPID ensures that each part leaving their facility meets or exceeds customer expectations. Additionally, the company’s dedication to lean manufacturing principles enhances efficiency, reduces waste, and accelerates lead times.

Key Capabilities of TIRAPID

- 5-axis and multi-axis CNC machining

- High-precision tolerances up to ±0.005mm

- Wide range of materials: metals, plastics, and composites

- Rapid prototyping and low-to-high volume production

- Comprehensive quality assurance processes

Industry Expansion: The Role of CNC Machining in Modern Manufacturing

The global manufacturing landscape is undergoing a transformation, with CNC machining playing a pivotal role in this evolution. CNC machining parts manufacturers are integral to the supply chains of industries that require high reliability and repeatability. For instance, in the aerospace sector, the demand for lightweight, durable, and complex components has never been higher. TIRAPID’s expertise in machining titanium, aluminum, and other advanced materials makes them a preferred partner for leading aerospace companies.

In the medical device industry, precision is non-negotiable. TIRAPID’s ability to produce intricate components for surgical instruments, implants, and diagnostic devices showcases their mastery of both technical and regulatory requirements. Their ISO-certified processes ensure compliance and traceability throughout the production cycle.

Spotlight on Prototype Machining and Custom CNC Parts

Among the many services offered by TIRAPID, prototype machining and custom CNC parts production stand out for their flexibility and speed. Prototype machining allows clients to quickly test and iterate designs, reducing time-to-market for new products. TIRAPID employs rapid prototyping techniques, including CNC milling and turning, to deliver functional prototypes that closely mimic final production parts.

Custom CNC parts are essential for industries with unique requirements. TIRAPID collaborates closely with clients to develop bespoke solutions, from one-off components to full-scale production runs. Their engineering team provides valuable design-for-manufacturability feedback, optimizing parts for both performance and cost.

Quality Assurance and Certification: Building Trust with Clients

Quality assurance is the backbone of TIRAPID’s operations. As one of the leading CNC machining parts manufacturers, the company adheres to international standards such as ISO 9001 and AS9100. Every component undergoes rigorous inspection using advanced metrology equipment, including coordinate measuring machines (CMMs) and optical comparators.

Traceability is maintained throughout the production process, with detailed documentation available for every batch. This commitment to transparency and accountability has earned TIRAPID a reputation for reliability among clients in regulated industries.

Client-Centric Approach: Collaboration from Design to Delivery

One of TIRAPID’s core strengths is its client-centric approach. From the initial consultation to final delivery, the company works closely with customers to ensure that every requirement is met. Their engineering team provides design support, material selection guidance, and process optimization recommendations, resulting in better products and smoother project execution.

| Service | Description |

|---|---|

| Prototype Machining | Rapid production of functional prototypes for testing and validation |

| Custom CNC Parts | Tailored solutions for unique industry requirements |

| Volume Production | Scalable manufacturing for small to large batch sizes |

Looking Ahead: The Future of CNC Machining Parts Manufacturers

As technology continues to advance, CNC machining parts manufacturers like TIRAPID are poised to play an even greater role in shaping the future of manufacturing. With the integration of automation, artificial intelligence, and digital twins, the industry is moving toward smarter, more connected production environments.

TIRAPID remains committed to investing in cutting-edge technology and expanding its capabilities to meet the evolving needs of clients worldwide. By maintaining a focus on quality, innovation, and customer satisfaction, TIRAPID is set to remain a leader in the CNC machining industry for years to come.

For those seeking reliable, high-precision CNC machining solutions, TIRAPID offers the expertise and resources necessary to turn complex designs into reality. Whether for prototype machining, custom CNC parts, or large-scale production, TIRAPID stands ready to deliver excellence at every stage.

Tags:5 Axis CNC Machining,CNC Turning Services,Wire EDM,CNC Machining Services