TIRAPID, a renowned CNC machining manufacturer, continues to revolutionize the rapid tooling production industry. With a relentless commitment to precision, speed, and innovation, TIRAPID stands out as a leader in providing high-quality, cost-effective solutions for clients across multiple sectors. As rapid tooling becomes increasingly vital in today’s fast-paced manufacturing environment, TIRAPID’s expertise and advanced technology ensure that businesses can accelerate their product development cycles without compromising on quality.

What Is Rapid Tooling and Why Is It Essential?

Rapid tooling is a process that involves the quick fabrication of molds and tools using advanced manufacturing techniques, primarily CNC machining. This approach significantly reduces lead times and costs compared to traditional tooling methods. For industries such as automotive, aerospace, medical devices, and consumer electronics, rapid tooling enables faster prototyping, testing, and market entry.

- Speed: Rapid tooling allows manufacturers to produce parts and prototypes within days instead of weeks or months.

- Flexibility: Design changes can be quickly implemented, supporting iterative development.

- Cost Efficiency: Lower upfront costs and reduced material waste make rapid tooling ideal for short-run production.

How TIRAPID Excels in CNC Machining Manufacturer Services

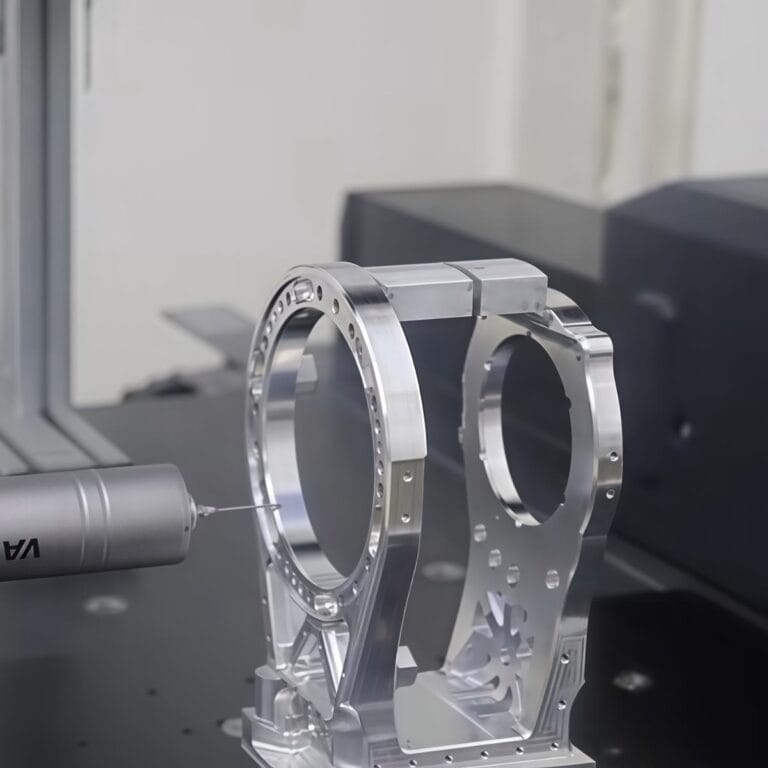

As a trusted CNC machining manufacturer, TIRAPID leverages state-of-the-art CNC equipment and a team of skilled engineers to deliver unmatched accuracy and repeatability. Their rapid tooling production capabilities are supported by advanced software, automated processes, and rigorous quality control measures. This ensures that every tool and prototype meets stringent industry standards.

Clients benefit from TIRAPID’s comprehensive service portfolio, which includes:

- 3-axis, 4-axis, and 5-axis CNC machining

- Custom rapid tooling for injection molding, die casting, and stamping

- Material selection guidance (metals, plastics, composites)

- Prototyping and low-volume production

- Post-processing and finishing services

Industry Trends: The Growing Importance of Rapid Tooling and CNC Machining

In recent years, the demand for rapid tooling has surged due to the rise of agile manufacturing and the need for accelerated product development. Industries are increasingly relying on CNC machining manufacturers like TIRAPID to deliver precision parts and tools at unprecedented speeds. The integration of digital design, automation, and real-time data analytics is further enhancing the efficiency and quality of rapid tooling production.

Global market research indicates that the rapid tooling sector is expected to grow at a compound annual rate of over 8% through 2028. This growth is driven by technological advancements, increased adoption of additive manufacturing, and the expansion of end-use industries. Companies that invest in advanced CNC machining capabilities, like TIRAPID, are well-positioned to capitalize on these trends and support their clients’ evolving needs.

Key Benefits of Partnering with TIRAPID

Choosing TIRAPID as your CNC machining manufacturer for rapid tooling production offers several unique advantages:

- Expertise: Decades of experience in precision engineering and toolmaking

- Innovation: Adoption of the latest CNC technologies and digital manufacturing platforms

- Customer Support: Dedicated project managers and technical advisors

- Global Reach: Serving clients in North America, Europe, Asia, and beyond

- Sustainability: Eco-friendly processes and materials to minimize environmental impact

Spotlight on Advanced CNC Machining Techniques

TIRAPID’s commitment to excellence is evident in its use of cutting-edge CNC machining techniques. High-speed milling, multi-axis turning, and precision grinding allow for the creation of complex geometries with tight tolerances. This is particularly important in rapid tooling, where dimensional accuracy and surface finish are critical for mold performance and part quality.

The company also invests in continuous training for its workforce, ensuring that engineers and machinists are up-to-date with the latest industry standards and best practices. This culture of learning and innovation enables TIRAPID to offer solutions that address even the most challenging tooling requirements.

Integrating Industry 4.0 in Rapid Tooling Production

TIRAPID is at the forefront of Industry 4.0 adoption, integrating smart manufacturing technologies such as IoT-enabled machines, automated inspection systems, and cloud-based project management. These advancements streamline the rapid tooling process, reduce human error, and provide clients with real-time updates on project status.

By harnessing the power of data analytics and machine learning, TIRAPID can optimize production schedules, predict maintenance needs, and enhance overall efficiency. This proactive approach not only improves lead times but also ensures consistent quality across all tooling projects.

Case Study: Rapid Tooling Success in Automotive Prototyping

Recently, TIRAPID partnered with a leading automotive manufacturer to deliver rapid tooling solutions for prototype engine components. The project required high-precision CNC machining of complex aluminum parts, with strict deadlines to support the client’s accelerated product launch schedule. TIRAPID’s team utilized advanced CAD/CAM software and multi-axis CNC machines to produce the required tools in record time, enabling the client to conduct thorough testing and validation before full-scale production.

This successful collaboration highlights the value of working with a CNC machining manufacturer that understands the intricacies of rapid tooling production and can adapt to the specific needs of each industry.

Conclusion: TIRAPID’s Vision for the Future of Rapid Tooling and CNC Machining

As rapid tooling continues to shape the future of manufacturing, TIRAPID remains committed to delivering excellence, innovation, and reliability. By combining advanced CNC machining capabilities with a customer-centric approach, TIRAPID empowers businesses to stay ahead of the competition and bring their products to market faster.

For companies seeking a CNC machining manufacturer that excels in rapid tooling production, TIRAPID offers the perfect blend of technology, expertise, and service. Discover how TIRAPID can transform your product development process and help you achieve your manufacturing goals.